Renishaw ATOM Installation Manual

Rotary encoder systems

Hide thumbs

Also See for ATOM:

- Installation manual (42 pages) ,

- Installation manual (75 pages) ,

- Installation manual (63 pages)

Table of Contents

Advertisement

Quick Links

Download this manual

See also:

Installation Manual

Advertisement

Table of Contents

Summary of Contents for Renishaw ATOM

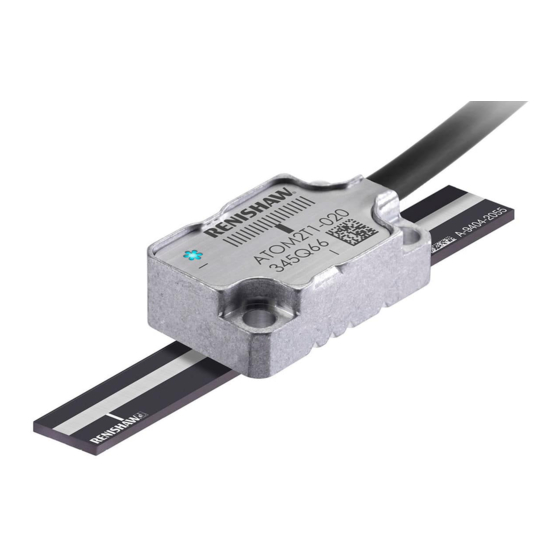

- Page 1 Installation guide M-9693-9717-03-C ATOM rotary encoder systems RSLM high accuracy linear encoder ™...

-

Page 2: Table Of Contents

Contents Product compliance ACi interface: FPC variant Storage and handling Installation drawing ATOM system installation overview Input signals RCDM rotary disc installation drawing Output signals Cable variant Mounting the disc Installation drawing Aligning the disc Readhead cable input connector Input signals... -

Page 3: Product Compliance

ATOM cabled readhead and accessories Further information Further information relating to the ATOM encoder range can be found in the ATOM system Data sheet (L-9517-9563). This can be downloaded from our website www.renishaw.com/encoder and is also available from your local representative. This document may not be copied or reproduced in whole or in part, Renishaw plc declares that ATOM complies with the applicable standards and regulations. -

Page 4: Storage And Handling

Storage and handling Scale and readhead N-heptane Propan-2-ol CHOHCH Storage Operating Humidity +70 °C +70 °C -20 °C 0 °C 95% relative humidity (non-condensing) to EN 60068-2-78 ATOM rotary installation guide... -

Page 5: Atom System Installation Overview

ATOM system installation overview This section gives an overview of the steps involved in installing, setting-up and calibrating an ATOM system. More detailed information is contained within the rest of the document. For information on designing the readhead and disc into the system refer to the detailed installation drawings and 3D models on www.renishaw.com or contact your local Renishaw representative. -

Page 6: Rcdm Rotary Disc Installation Drawing

FPC cable Alignment band for (Roll tol. ±1°) aligning the disc on the hub /shaft 0.22 For detailed installation drawings, including tolerances, refer to www.renishaw.com (Pitch tol. ±1°) Radial tolerance 0.36 Longitudinal tolerance Line count E (mm) -

Page 7: Mounting The Disc

Disc contact surface Adhesive overspill areas Align the disc so it is concentric with the hub/shaft. Cure the adhesive. Contact your local Renishaw representative for more information on designing the mounting surface, suggested materials and adjustment methods. ATOM rotary installation guide... -

Page 8: Aligning The Disc

Rotate the assembly and repeat steps 3-5 until the total alignment band movement is within the design specifications. Cure the adhesive. Recheck the run-out. Contact your local Renishaw representative for more information on aligning the disc. ATOM rotary installation guide... - Page 9 This method involves monitoring the output signals of two readheads mounted 180 degrees apart Restore factory defaults on both ATOM systems by pressing and holding the CAL button on both and adjusting the disc to minimise the difference in count between the two heads.

-

Page 10: System Connection

None of these readhead variants has an integral calibration (CAL) button. Provision should be made Contact your local Renishaw representative for more information of the FPC design requirements. in the customers’ electronics for momentarily connecting the CAL line to 0 V to initiate the calibration routine, switch AGC on/off or restore factory defaults. - Page 11 Do not pull upwards or sideways as disengage the locking mechanism. this may damage the readhead. Do not use tools such as screwdrivers or tweezers to open the locking lever as this may cause damage to the connector or PCB. ATOM rotary installation guide...

-

Page 12: Aci Interface

Minimum exposed conductor strip length 1.5 mm Shielding Maximum exposed conductor strip length 2.5 mm (to ensure isolation from the body) For optimum performance: Contact your local Renishaw representative for more information of the FPC design requirements. Ensure 100% shielding Ground the mounting brackets Shielding... - Page 13 Maximum exposed conductor strip length 2.5 mm (to ensure isolation from the body) Ground the mounting brackets Use a metal clamp around the cable ferrule to ground the readhead cable Contact your local Renishaw representative for more information of the FPC design requirements. Ensure continuity of all shields Shielding...

-

Page 14: Ri Interface

NOTE: Care is required to hold the assembly together as the PCB is fixed only to the 15 way connector and the Readhead jack screws are loose. connection socket ATOM rotary installation guide... -

Page 15: Ti Interface

Refit the cover plate ensuring the cable ferrule is located in the recess on the inside and no wires are trapped under the cover plate. When the system has been connected proceed with ‘Readhead mounting and alignment’ and ’System calibration’ sections. ATOM rotary installation guide... -

Page 16: Readhead Mounting And Alignment: Methods

Care must be taken to ensure the disc surface is not scratched. upon the system design, these are detailed below. Renishaw offer a DTI adapter (A-9401-0105) that can be used For more details on designing the mounting bracket and selecting the appropriate to assist with this process. -

Page 17: Dummy Head (A-9401-0072)

10 Adjust longitudinal and radial offset of the readhead to obtain a Green readhead set-up LED around the full axis of rotation. An oscilloscope or Renishaw USB set-up tool kit and software can be used to help maximise the signal size. For more information on the Renishaw USB set-up tool kit contact your local Renishaw representative. -

Page 18: Calibration Overview

Calibration is an essential operation that completes readhead set-up, with the optimum incremental and reference mark signal settings stored in the readhead’s non-volatile memory. This section is an overview of the calibration procedure for an ATOM system. More detailed information on calibrating the system is on page 17. -

Page 19: System Calibration (Cal)

>3 seconds >3 seconds then disconnect then release then release The readhead set-up LED will be Green with the addition of Blue when AGC is active. NOTE: The system must be calibrated before switching AGC on. ATOM rotary installation guide... -

Page 20: Led Diagnostics

Alarm output will take the form of 3-state or line driven E- signal depending on interface configuration. Also, some configurations do not output overspeed alarm. See product nomenclature for details. -Momentary status only, while fault condition remains. -Alarm may result in axis position error, re-datum to continue. ATOM rotary installation guide... -

Page 21: Troubleshooting

Check the disc and readhead orientation Check that the readhead variant is the correct type for the chosen scale (see the ATOM data sheet (L-9517- 9563) for details of readhead configuration) Unable to get a Green LED around a System run-out is not... - Page 22 Check the readhead optical window and disc are clean and free from contamination Check that the readhead variant is the correct type for the chosen scale (see the ATOM data sheet (L-9517- 9563) for details of readhead configuration) Ensure you are not over-speeding the readhead during calibration mode (maximum speed <100 mm/sec)

-

Page 23: Atom Readhead

Ø2.5 min through 16.5 20.5 R>20 Dynamic bend radius R>10 Static bend radius 5 min Identification marks for readhead manufacture only. Notches will vary depending on readhead type. Not optical centreline For detailed installation drawings refer to www.renishaw.com ATOM rotary installation guide... -

Page 24: Fpc Readhead Dimensions

Identification marks for readhead manufacture only. Notches will vary depending on readhead type. Not optical centreline NOTE: Readhead is supplied with lid separate. FPC cable must be inserted before fitting the lid. For detailed installation drawings refer to www.renishaw.com ATOM rotary installation guide... -

Page 25: Output Signals

ATOM readhead: Output signals Interboard connector 15 way D-type (on interboard) Function Signal Colour Power* 9, 10 4, 5 Brown White 3, 6, 11, 14 12, 13 Incremental Cosine Blue Yellow Sine Green Reference mark Violet Grey Set-up Clear Remote CAL Orange –... -

Page 26: Aci Interface

A-9412-1001 cable (15 way D type) Power 7, 8 2, 9 FPC connector Incremental FPC cable Reference mark NOTE: Care must be taken not to damage the FPC connector when fitting/removing the cable. Set-up Remote CAL ATOM rotary installation guide... -

Page 27: Cable Variant

7, 8 21 ±1 2, 9 Incremental Pin 1 Pin 12 Cable ferrule nominal diameter 5.9 ±0.2 mm JST connector Reference mark Set-up 6.25 Remote CAL Interboard connector for connection to Ri, Ti and cabled ACi interfaces ATOM rotary installation guide... -

Page 28: Pcb Variant

Pin 9 Pin 1 ACi PCB output (Samtec FTS-105-01-L-DV-P-TR) connector Pin 10 Pin 2 Pin 10 Recommended mating connector - Samtec CLP-105-02-F-D-P-TR PCB footprint Pin 9 Clearance holes ∅ 0.74 1.27 1.27 (typ) 0.74 (typ) ATOM rotary installation guide... -

Page 29: Speed

Angular speed depends on disc optical diameter – use the following equation to convert to rev/min. V x 1000 x 60 Angular speed (rev/min) = Where V = maximum linear speed (m/s) and D = Optical diameter (mm) ATOM rotary installation guide... -

Page 30: Ri Interface: Interface Drawing

All power connections should be used either to minimise voltage drop down the cable or incorporate voltage sensing. Push and hold during power ‘Off/On’ cycle - Restore factory defaults … The alarm signal can be output as a line driver signal or 3-state. Please select the preferred option at time of ordering. ATOM rotary installation guide... -

Page 31: Speed

Angular speed depends on disc optical diameter – use the following equation to convert to rev/min. V x 1000 x 60 Angular speed (rev/min) = Where V = maximum linear speed (m/s) and D = Optical diameter (mm) ATOM rotary installation guide... -

Page 32: Ti Interface: Interface Drawing

Alarm output will take the form of 3-state or line driven E signal depending on interface configuration. Push and hold during power ‘Off/On’ cycle - Restore factory defaults Please select the preferred option at time of ordering. Refer to ‘Readhead LED diagnostics’ and ‘Ti LED diagnostics’ for LED indications ATOM rotary installation guide... -

Page 33: Speed

20 µm system – 10 m/s (-3dB) V x 1000 x 60 40 µm system – 20 m/s (-3dB) Angular speed (rev/min) = Where V = maximum linear speed (m/s) and D = Optical diameter (mm) ATOM rotary installation guide... -

Page 34: Electrical Connections

Output specifications Grounding and shielding Analogue output signals Digital output signals All ATOM readheads and Form – Square wave differential line driver to EIA RS422A ACi/customer All ACi interfaces and Ri and Ti digital interfaces Ri and Ti analogue interfaces... -

Page 35: General Specifications

40 µm version <±120 nm 20 µm version < ±75 nm Renishaw encoder systems have been designed to the relevant EMC standards, but must be correctly integrated to achieve EMC compliance. In particular, attention to shielding arrangements is essential. ATOM... - Page 36 RENISHAW ® and the probe symbol used in the RENISHAW logo are registered trade marks of Renishaw plc in the United Kingdom and other countries. *M-9693-9717-03* apply innovation and names and designations of other Renishaw products and technologies are trade marks of Renishaw plc or its subsidiaries.