Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Ithaca Epic 950

- Page 1 Epic 950 OEM Integration Manual P/N 95-05245 Rev G Feb. 2007...

- Page 3 This page intentionally left blank...

-

Page 5: Change History

Change History Rev A Initial release July 2004 Rev B Add index, table of page numbers, new commands March 2005 Rev C Add additional communications interface descriptions March 2006 Rev D Added internal/external bezels to bezel mounting section May 2006 Rev E Pg 22 –... -

Page 6: Disclaimer

BANKjet, 50Plus, Insta-Load, Ithaca, "Made to Order. Built to Last", Magnetec, PcOS, POSjet, PowerPocket and TransAct are registered trademarks and Epic 950, Flex -Zone, imPort, ithaColor, iTherm, KITCHENjet, Momentum, QDT and TicketBurst are trademarks of TransAct Technologies, Inc. -

Page 7: Table Of Contents

Trademarks....................ii Table of Contents..................iii Figures ....................vi Tables ....................vi Introducing Your Epic 950 Printer ......1 About Your Epic 950 Printer................. 3 Who Should Read This Guide?..............4 What Is Included in This Guide?..............4 Warranty Options ..................4 Technical and Sales Support................ - Page 8 Loading Tickets into Feeding Mechanism............47 Removing Loaded Tickets ................49 Cleaning the Print Head ................51 Purchasing Cleaning Cards ..............52 Printing a Self-test Ticket................53 Programming for the Epic 950 ......55 Programming for the Epic 950 ..............57 Resetting the Printer ................57 Command Parameters ................57 Character Evaluation................57 16-bit Character Parameters ..............58...

- Page 9 HT – Horizontal Tab................77 LF – Line Feed ..................78 FF – Form Feed..................79 CR – Carriage Return................80 SO – Set Font to Double-wide..............81 DC4 – Cancel Double-wide Mode .............82 ENQ – Request Combined Printer Status............83 20h – FFh – Printable Characters..............84 ESC ENQ 1 –...

- Page 10 Figure 8. Outer Chassis to Final Product ............21 Figure 9. Custom Bezel Mounting and Hardware Requirements......22 Figure 10. Epic 950 Shown with Optional Internal Bezel Assembly......23 Figure 11. Epic 950 Shown with Optional External Bezel Assembly......23 Figure 12. Sensor Breakdown and Locations .............27 Figure 13.

- Page 11 Table 5. Dual Port NELTPLEX Communication PCB Pin-Outs.......38 Table 6. Dual Port RS232 Communication PCB Pin-Outs........39 Table 7. Bezel Power Connector Pin-Outs ............40 Table 8. Conversion from Dots to Inches............58 Table 9. Font Statistics..................59 95-05245 Page vii Rev G...

-

Page 13: Introducing Your Epic 950 Printer

Introducing Your Epic 950 Printer 95-05245 Page 1 Rev G... - Page 14 This page intentionally left blank Page 2 95-05245 Rev G...

-

Page 15: About Your Epic 950 Printer

Above all, the Epic 950 is designed for ease of programming and ease of use in your gaming operations. While supporting the full command language and macro features of the Series 800 printer, the Epic 950 introduces a new higher-level command interface which lets you quickly and easily integrate more layout and printing options than ever –... -

Page 16: Who Should Read This Guide

Sales Department at TransAct’s Ithaca facility. You are responsible for insuring any product returned for service, and you assume the risk of loss during shipment to Ithaca C.O.D. packages are not accepted and warranty repairs are subject to the terms and conditions as stated on the Ithaca warranty policy. -

Page 17: Technical And Sales Support

Our web site at www.transact-tech.com is your on-line portal to obtaining technical assistance with your Ithaca printer. Click on the Technical Support link to find documentation for your Epic 950 printer, including a current copy of this OEM Integration Manual featuring: o Command codes and descriptions. -

Page 18: Return Materials Authorization And Return Policies

TransAct Technologies Incorporated has a full service organization to meet your printer service and repair requirements. If your printer needs service, please contact your service provider first. If any problems still persist, you can directly contact the Ithaca facility’s Technical Support Department at (607) 257-8901 or (877) 7ithaca for a return authorization. -

Page 19: Contact Information

Introducing Your Epic 950 Printer Epic 950 OEM Integration Manual Contact Information TransAct Technologies Incorporated Ithaca Facility 20 Bomax Drive Ithaca, NY 14850 USA Telephone (877) 7ithaca or (607) 257-8901 Main fax (607) 257-8922 Sales fax (607) 257-3868 Technical Support fax... -

Page 21: Epic 950 Specifications And Requirements

Epic 950 Specifications and Requirements 95-05245 Page 9 Rev G... - Page 22 This page intentionally left blank Page 10 95-05245 Rev G...

-

Page 23: Epic 950 Specifications And Requirements

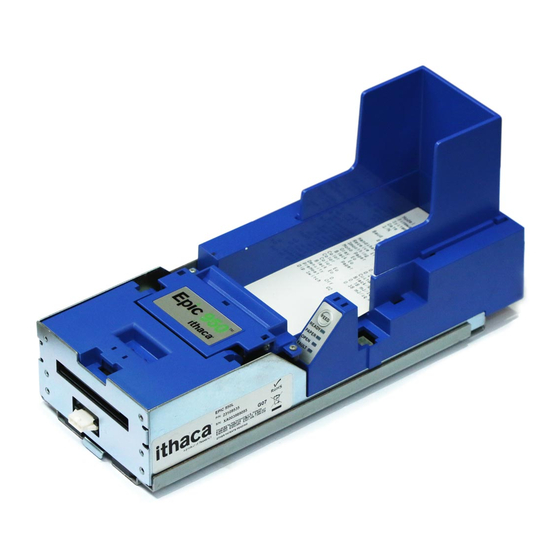

2. Inner Chassis Assembly 3. Printer Ticket Bucket Assembly 4. Outer Chassis Assembly Standard Features The following features are common to the Epic 950 Printers: Key features: • Perforated fan folded tickets in a stack of 200, 300 or 400 tickets. -

Page 24: Optional Features

Epic 950 Specifications and Requirements Epic 950 OEM Integration Manual Other standard features: • Selections of 7.5, 10, 12, 16.5 and 20 characters per inch printing. • Selectable printing of Normal, Double-high, Double-wide and Double- high/Double-wide. • Sensors for Burst Ticket, Ticket Low, Top-of-Form/Ticket Out, Chassis Open, and Ticket Taken. -

Page 25: Dimensions

W: 4.66" (112.5 mm) D: 11.25" (284.2 mm) The Epic 950 is a stationery module, and is designed to work with any of the three interchangeable ticket capacities using extender walls. Please be sure to specify the desired box size when making your selections. -

Page 26: Test Standards

Epic 950 Specifications and Requirements Epic 950 OEM Integration Manual Test Standards EN50081-1-1992 EN55022-1998, Class A FCC CFR-47, Part 15, Class A EM55082-1-1998 EN55024-1998 EN61000-4-2, Level 3 EN6100-4-3, Level 2 EN61000-4-4, Level 2 EN61000-4-5, Level 2 EN61000-4-6, Level 2 ESD IEC 1000-4-2, 6kv direct discharge and 8kv air discharge. -

Page 27: Printing Specifications

Epic 950 Specifications and Requirements Epic 950 OEM Integration Manual Printing Specifications Print Method: Thermal Sensitive Line Dot System. Ticket Handling: TicketBurst ticket buffering with burst. Print Speed: 125 mm/sec. (5" per sec.) max. (monochrome) (in text mode). Presentation Speed: 125 mm/sec. -

Page 28: Design Envelope: Ticket Clearance

Epic 950 Specifications and Requirements Epic 950 OEM Integration Manual # of Characters: 6 min./18 max. Symbol Contrast Value: 70% min. Applicable Standards: ANSI X3.182 gsa-p0038.001.01 Design Envelope: Ticket Clearance A minimum paper clearance distance of .75" is required above the printer’s ticket buckets. -

Page 29: Black Dot Position And Presentation Scheme

Epic 950 Specifications and Requirements Epic 950 OEM Integration Manual Black Dot Position and Presentation Scheme All graphics preprinted on the ticket must be in thermal paper compatible ink. Black Dot Position The back of the ticket is used for the Black Dot/Top of Form indicator. For the printer to sense when a ticket has been indexed to the printing position, a Black Dot/Top of Form sensor is needed. -

Page 30: Ticket Stack Orientation

Epic 950 Specifications and Requirements Epic 950 OEM Integration Manual Ticket Stack Orientation To ensure the ticket is loaded correctly into the printer, the ticket stack must be properly loaded in the ticket box. The stack must be oriented so that the Black Dot/Top of Form mark of the tickets is on the leading edge of the ticket, not near the perforation of the next ticket. -

Page 31: Mounting Requirements

chapter Mounting Requirements 95-05245 Page 19 Rev G... - Page 32 This page intentionally left blank Page 20 95-05245 Rev G...

-

Page 33: Mounting Requirements

Mounting Requirements Epic 950 OEM Integration Manual Mounting Requirements Outer Chassis to Final Product Bottom: 4x M4x 0.7 press nuts. 4x ? .180" thru holes. 2.024 1.904 M4x0.7 PEM NUTS 4PLS .180 4PLS 4.500 7.875 4.430 3.500 1.250 Figure 8. Outer Chassis to Final Product... -

Page 34: Custom Bezel Specifications And Recommendations

Epic 950 printers are designed to accommodate a TransAct or customer-supplied bezel assembly that is mounted following the hardware and mounting dimensions as listed. The following drawing shows the positioning and dimensions of the Epic 950 printer’s mounting points. Bezel assemblies available from TransAct include internal bezels (part nos. 95-06003L (yellow) and 95-06005 (blue), with other colors available) and an external bezel (part no. -

Page 35: Figure 10. Epic 950 Shown With Optional Internal Bezel Assembly

Mounting Requirements Epic 950 OEM Integration Manual Figure 10. Epic 950 Shown with Optional Internal Bezel Assembly. Figure 11. Epic 950 Shown with Optional External Bezel Assembly. 95-05245 Page 23 Rev G... -

Page 37: Epic 950 Printer Sensors

Mounting Requirements Epic 950 OEM Integration Manual chapter Epic 950 Printer Sensors 95-05245 Page 25 Rev G... - Page 38 This page intentionally left blank Page 26 95-05245 Rev G...

-

Page 39: Printer Sensors

Epic 950 Printer Sensors Epic 950 OEM Integration Manual Printer Sensors The Epic 950 printers use several sensors to provide feedback to the host system. The Communications PCB handles all power and interface communications. (Covers not shown for clarity) Figure 12. Sensor Breakdown and Locations... -

Page 40: Top-Of-Form/Ticket Out Sensor

Epic 950 Printer Sensors Epic 950 OEM Integration Manual Top-of-Form/Ticket Out Sensor A Top of Form/Ticket Out Sensor is used to control ticket loading and printing. Ticket Taken Sensor A Ticket Taken Sensor is used to determine when customers have actually taken the printed ticket. - Page 41 Epic 950 Printer Sensors Epic 950 OEM Integration Manual Condition Ready LED Paper LED Open LED Fault LED Unit Ready Cover Open Chassis Open Blink Ticket Out Ticket Low Blink Temperature Error Blink Blink Paper Jam Blink Ram Error 2-Blink...

-

Page 43: Electrical Connections

chapter Electrical Connections 95-05245 Page 31 Rev G... - Page 44 This page intentionally left blank Page 32 95-05245 Rev G...

-

Page 45: Interface Connections

Epic 950 OEM Integration Manual Interface Connections The Epic 950 printer is equipped with one of several communication interface options. In all cases power and communication connections are made to a connector or connectors located at the rear of the printer. -

Page 46: Rs232 Serial Communications Interface Pcb

Electrical Connections Epic 950 OEM Integration Manual RS232 Serial Communications Interface PCB The RS232 Serial interface connector is a 14 position Molex Minifit Jr®., part number 39- 30-1140, which mates with Molex part number 39-01-2140 or equivalent. Serial Communication PCB Pin-Outs... -

Page 47: Usb Communications Interface Pcb

Electrical Connections Epic 950 OEM Integration Manual USB Communications Interface PCB The USB Communications PCB contains two connectors. § Power - 4 position Molex Minifit Jr®., part number 39-30-1040, which mates with Molex part number 39-01-2040 or equivalent. § USB Communications - Type B USB connector... -

Page 48: Netplex Communications Interface Pcb

Electrical Connections Epic 950 OEM Integration Manual NETPLEX Communications Interface PCB The NETPLEX Communications interface connector is a 10 position Molex Minifit Jr®., part number 39-30-1100, which mates with Molex part number 39-01-2100 or equivalent. NETPLEX Communication PCB Pin-Outs PIN #... -

Page 49: Universal Usb/Netplex Communications Interface Pcb

Electrical Connections Epic 950 OEM Integration Manual Universal USB/NETPLEX Communications Interface The Universal USB/NETPLEX interface supports both USB and NETPLEX communications. This interface contains three connectors: § Power - 4 position Molex Minifit Jr®., part number 39-30-1040, which mates with Molex part number 39-01-2040 or equivalent. -

Page 50: Dual Port Netplex Communications Interface Pcb

Electrical Connections Epic 950 OEM Integration Manual Dual Port NETPLEX Communications Interface PCB The Dual Port NETPLEX Communications interface contains three connectors § NETPLEX Communications. - 10 position Molex Minifit Jr®., part number 39-30- 1100 for NETPLEX connections which mates with Molex part number 39-01- 2100 or equivalent. -

Page 51: Dual Port Rs232 Communications Interface Pcb

Electrical Connections Epic 950 OEM Integration Manual Dual Port RS232 Communications Interface PCB The Dual Port RS232 Communications interface contains three connectors § RS232 Communications 14 position Molex Minifit Jr®., part number 39-30-1140 which mates with Molex part number 39-01-2040 or equivalent. -

Page 52: Bezel Lamp Connector

Electrical Connections Epic 950 OEM Integration Manual Bezel Lamp Connector The bezel connector is a Molex Minifit Jr®, part number 39-01-4032 and will mate with a Molex part number 39-01-4030 or equivalent. Figure 11. Bezel Lamp Connector Location and Connector Information... -

Page 53: Firmware Download Port

Electrical Connections Epic 950 OEM Integration Manual Firmware Download Port The Epic 950 printer features an imPort firmware and graphics download port, as shown in the figure below. This port uses a 4-pin Molex connector with an RS-232 interface. For further details on this use of this proprietary download port, please contact TransAct Technical Support. -

Page 54: Printer Block Diagram

Electrical Connections Epic 950 OEM Integration Manual Printer Block Diagram Figure 16. Epic 950 Electrical Operations Diagram Page 42 95-05245 Rev G... -

Page 55: Operational Procedures

chapter Operational Procedures 95-05245 Page 43 Rev G... - Page 56 This page intentionally left blank Page 44 95-05245 Rev G...

-

Page 57: Racking/Unracking The Inner Chassis

Epic 950 OEM Integration Manual Racking/Unracking the Inner Chassis All Epic 950 printers use a slider/detent/latch system with latch arms to retain the Inner Chassis from accidentally being separated from the Outer Chassis. The Epic 950 is opened for service by simply pulling on the ticket cover, pulling the Inner Chassis forward from the Outer Chassis as you would a filing cabinet. - Page 58 Operational Procedures Epic 950 OEM Integration Manual • Align the base of the Inner Chassis with the outer walls of the Outer Chassis, seating it within side walls A and B as shown in Figure 17. • While pulling outwards on the Release Lever, slide the Inner Chassis towards the rear of the Outer Chassis until it latches at the rear of the Outer Chassis.

-

Page 59: Loading Tickets Into Feeding Mechanism

When loading new ticket stacks, be sure that there is power to the printer. The first ticket of the stack must be inserted into the printer by hand. The Epic 950 printers’ ticket tray is integrated with a guide to direct the ticket into the printer mechanism. Once the leading ticket enters the Top of Form sensor, the ticket will be automatically fed into the Printer Mechanism. - Page 60 Operational Procedures Epic 950 OEM Integration Manual Loading tickets into the ticket supply box: (Refer to the label on printer) • Load tickets into the ticket supply tray, making sure that the Black Dot is positioned as shown in Figure 18.

-

Page 61: Removing Loaded Tickets

Operational Procedures Epic 950 OEM Integration Manual Removing Loaded Tickets The Epic 950 printers have two ways to remove unused tickets from the printer mechanism: • The first way is to release the Ticket Cover by lifting and rotating backward, this will relieve pressure to the platen and tickets can be removed. - Page 62 Operational Procedures Epic 950 OEM Integration Manual 6. Proceed with ticket loading procedure. Page 50 95-05245 Rev G...

-

Page 63: Cleaning The Print Head

Operational Procedures Epic 950 OEM Integration Manual Cleaning the Print Head Two kinds of periodic cleaning operations will ensure continued high print quality from your Epic 950 printer: 1. Paper dust removal. Use a soft brush to clean the paper dust from inside the printer and chassis area. -

Page 64: Purchasing Cleaning Cards

Operational Procedures Epic 950 OEM Integration Manual 6. Open the cover and then remove the cleaning card by gently pulling it back. 7. Repeat process if necessary. 8. Properly dispose of used cleaning card. Purchasing Cleaning Cards Cleaning cards are available through TransAct – consult Chapter 1 for contact information by telephone or the Internet. -

Page 65: Printing A Self-Test Ticket

Epic 950 OEM Integration Manual Printing a Self -test Ticket The Epic 950 printer has the ability to print a pre-defined self-test ticket, to test the normal printing functionality of the unit, and create a printout of the current printer configuration. -

Page 66: Figure 21. Sample Self-Test Ticket

Operational Procedures Epic 950 OEM Integration Manual Figure 21. Sample self-test ticket. Page 54 95-05245 Rev G... -

Page 67: Programming For The Epic 950

Programming for the Epic 950 95-05245 Page 55 Rev G... - Page 68 This page intentionally left blank Page 56 95-05245 Rev G...

-

Page 69: Programming For The Epic 950

Character Evaluation Most of the parameters that are sent to the Epic 950 Printer are evaluated based on their decimal value. Some commands accept parameters by either their decimal value or the representative character. -

Page 70: 16-Bit Character Parameters

16-bit character. Though the calculations are all done within the Epic 950 Printer, it is important to understand how the characters are handled. For two specified 8-bit parameter values n1 and n2, the resulting 16-bit value is... -

Page 71: Font Statistics

Table 9. Font Statistics Objects Objects are the basic units that the Epic 950 prints. An object can be either a line of text characters, a bar code, a landscape graphic, a landscape line, or a bitmap dot line. Each of these objects has different rules relating to them, as discussed below. -

Page 72: Portrait Printing Mode

In landscape printing, text characters exit the printer from the left side of the character to the right. Before the Epic 950 Printer can be switched to landscape printing mode, the set characters per line command (GS t) must be set. -

Page 73: General Notes

In any mode, the set feed length command (GS L) is used to determine how far the Epic 950 will feed in search of a Black Dot/Top of Form indicator. If the Epic 950 finds a Black Dot/Top of Form indicator before the maximum feed distance is reached, it will stop at that point, rather than continuing. -

Page 74: Text Objects

Once it is created, a text object will remain active until it is terminated. While a text object is active, any printable characters sent to the Epic 950 will be added to that text object. The only exceptions are printable characters that are sent as part of a command. -

Page 75: Bar Code Objects

If an incorrect number of characters or delimiters are sent, the Epic 950 will not print correctly. Bar codes that are too long to fit within the printable area of a ticket are truncated. This usually results in an unreadable bar code being printed. -

Page 76: Graphic Objects

No landscape graphic may be wider than 256 dots, though they may be as tall as the width of the Epic 950’ print head. If a graphic needs to be printed wider than 256 dots, either subdivide it into narrower sections or print it using bitmap graphics commands. -

Page 77: The Por.ini File

Programming for the Epic 950 Epic 950 OEM Integration Manual The POR.INI File The POR.INI file contains system/printer initialization parameters. This file follows the standard INI file format of sections defined in brackets (ie. [POR]) followed by single-line parameter settings. -

Page 78: Por.ini File Parameter Definitions

Programming for the Epic 950 Epic 950 OEM Integration Manual POR.INI File Parameter Definitions [Dipswitch n] The parameter after the [Dipswitchn] will be set if the corresponding dip switch is active. The list on the previous page is the default settings for dip switches. The dip switch definitions may be changed as required. - Page 79 Programming for the Epic 950 Epic 950 OEM Integration Manual ErrorLog This parameter sets the printer in a mode to collect information on any errors that occur. This is used to help diagnose problems in the field. This should remain off for normal operation.

-

Page 80: Dip Switch Settings

Series 800 emulation. It should not be activated when replacing a Series 800 printer. To see what features are available in the Smart Suite enhancements, refer to the Epic 950 Smart Suite Supplement. To activate the progress status features in the Demo program, you must turn this feature on. - Page 81 Programming for the Epic 950 Epic 950 OEM Integration Manual Switch 8 activates 2-color operation. 95-05245 Page 69 Rev G...

-

Page 82: Flash Memory And Firmware Download Port

The format of the firmware is TransAct propriet ary. This format can only be understood by the Epic 950 printer. It is compressed and encoded in such a way that any modification to it will be detected and cause a printer fault. -

Page 83: Non-Firmware Memory Features

(provided by TransAct) with the actual firmware in the Epic 950 printer. This tool verifies that the cyclical redundancy check (CRC) performed on the firmware memory is identical to the firmware file provided by TransAct. -

Page 84: Smart Suite Features

Programming for the Epic 950 Epic 950 OEM Integration Manual Smart Suite Features The Epic 950 includes a suite of smart features and tools to facilitate and enhance the printer’s integration and performance. This list includes: • Programmable automatic periodic status reporting (128 bytes of information, or more) •... -

Page 85: Command Reference

chapter Command Reference 95-05245 Page 73 Rev G... - Page 86 This page intentionally left blank Page 74 95-05245 Rev G...

- Page 87 Command Reference Epic 950 OEM Integration Manual This section describes the commands for programming the Epic 950 Printer. Each section contains a description of each command, listed by name in alphabetical order. The ASCII, hexadecimal, and decimal values for each command are also provided. See Appendix A for a list of ASCII, hexadecimal, and binary codes.

-

Page 88: Bel - Audio Alert

Command Reference Epic 950 OEM Integration Manual BEL – Audio Alert Description Generates an audio alert. The default is a single sound, lasting the period of time defined by the audio alert setting defined by the ESC BEL command. If the audio alert is turned off by setting the number of alert cycles in ESC BEL to zero, this command does not function. -

Page 89: Ht - Horizontal Tab

Command Reference Epic 950 OEM Integration Manual HT – Horizontal Tab Description Moves the cursor position to the next multiple of eight single-width characters. If the HT command causes the cursor to move beyond the printable area, the text will wrap to the next line. -

Page 90: Lf - Line Feed

Command Reference Epic 950 OEM Integration Manual LF – Line Feed Description Prints the current line of text, and advances the text position to the beginning of the next line. Note that the line feed, line feed/carriage return, carriage return, and carriage return/line feed instructions all behave as a single line feed. -

Page 91: Ff - Form Feed

Command Reference Epic 950 OEM Integration Manual FF – Form Feed Description This command prints the contents of the text buffer, and then advances the print media. The form is advanced until either of the following two conditions occurs: •... -

Page 92: Cr - Carriage Return

Command Reference Epic 950 OEM Integration Manual CR – Carriage Return Description Prints the current line of text, and advances the text position to the beginning of the next line. Note that the line feed, line feed/carriage return, carriage return, and carriage return/line feed instructions all behave as a single line feed. -

Page 93: So - Set Font To Double-Wide

Command Reference Epic 950 OEM Integration Manual SO – Set Font to Double-wide Description Causes all the text that follows the command on the same line to be printed as double- wide characters. Double-wide characters are canceled by a line feed (CR or LF) or the DC4 command. -

Page 94: Dc4 - Cancel Double-Wide Mode

Command Reference Epic 950 OEM Integration Manual DC4 – Cancel Double-wide Mode Description Cancels double-wide text printing and returns the text to normal. See also: SO – Set Font to Double-wide ESC W – Wrap Data Expression ASCII [DC4] Hexadecimal Decimal <20>... -

Page 95: Enq - Request Combined Printer Status

Command Reference Epic 950 OEM Integration Manual ENQ – Request Combined Printer Status Description Returns four status bytes: GS y (so that the status string can be recognized/parsed by the host), followed by the response byte for the GS S Return Printer Status command and then by the response byte for the GS z Request Printer Status command. -

Page 96: 20H - Ffh - Printable Characters

Command Reference Epic 950 OEM Integration Manual 20h – FFh – Printable Characters Description These characters, while not part of an escape (command) sequence, will be printed using the currently selected font. The standard, printable ASCII characters are associated with their normal values, which range from decimal value 32 to decimal value 255. -

Page 97: Esc Enq 1 - Return Version Information

Command Reference Epic 950 OEM Integration Manual ESC ENQ 1 – Return Version Information Description Returns version information for your Epic 950 printer, in the format: [ENQ]1<length byte><Name/version string> Example output: [ENQ]1< 20>TransAct M950 S00114 Expression ASCII [ESC] ENQ 1... -

Page 98: Esc Bel - Configure Audio Alert

Command Reference Epic 950 OEM Integration Manual ESC BEL – Configure Audio Alert Description The ESC BEL command alters the way the audio alert sounds when the BEL command is issued. The default is a single sound lasting the period of time defined by the audio alert setting parameters below. -

Page 99: Esc Sp - Set Right-Side Character Spacing

Command Reference Epic 950 OEM Integration Manual ESC SP – Set Right-Side Character Spacing Description This command sets the character spacing for the right side of the character. The spacing value <n> is specified in dots, where 1 dot = 1/203 inch. -

Page 100: Esc ! - Select Print Mode(S)

Command Reference Epic 950 OEM Integration Manual ESC ! – Select Print Mode(s) Description Selects the font and right -side character spacing, using the convention shown below. Expression ASCII [ESC] ! <n> Hexadecimal 1BH 21H <n> Decimal <27> <33> <n>... -

Page 101: Esc $ - Set Absolute Horizontal Position In

Command Reference Epic 950 OEM Integration Manual ESC $ – Set Absolute Horizontal Position in page mode Description Sets the horizontal print position measured from the left edge of the page, for the currently selected print direction. Distance is specified in dots, where 1 dot = 1/203 inch. -

Page 102: Esc * - Reset To Defaults

Command Reference Epic 950 OEM Integration Manual ESC * – Reset to Defaults Description Returns the printer to its power-up condition, clears all buffers, and resets all character attributes. The ESC * command is the same as the ESC @ command. -

Page 103: Esc @ - Reset To Power-Up Condition

Command Reference Epic 950 OEM Integration Manual ESC @ – Reset to Power-up Condition Description Returns the printer to its power-up condition, clears all buffers, and resets all character attributes. The ESC @ command is the same as the ESC * command. -

Page 104: Esc B - Print Bitmap (Bmp) Image

Note that the first character of a bitmap file is always “B”, therefore ESC B is recognized by the Epic 950 as the code to print a bitmap file. The printer decodes the BMP file header and will print the image data after checking important parameters, such as width, height and number of colors. -

Page 105: Esc E - Form Feed

Command Reference Epic 950 OEM Integration Manual ESC E – Form Feed This command prints the cont ents of the text buffer, and then advances the print media. The form is advanced until either of the following two conditions occurs: •... -

Page 106: Esc F - Select Fonts

Command Reference Epic 950 OEM Integration Manual ESC F – Select Fonts Description The ESC F command selects a font based on the specified point size, width ratio and attributes. Expression ASCII [ESC] F <n1><n2><n3> Hexadecimal 1BH 46H <n1><n2><n3> Decimal <27>... -

Page 107: Esc G - Turn Double-Strike Mode On/Off

Command Reference Epic 950 OEM Integration Manual ESC G – Turn Double-strike Mode On/Off This command turns double-strike mode on or off. When the least significant bit (LSB) of the parameter n is 0, double-strike mode is turned off. When the LSB is 1, double-strike mode is turned on. -

Page 108: Esc J - Feed N Sublines

Command Reference Epic 950 OEM Integration Manual ESC J – Feed n Sublines Description Feeds n number of sublines (n/203 inch). This command causes the printer to print data stored in the buffer and then feed n number of dot lines. This command is similar in functionality to the GS d command. -

Page 109: Esc M - Set Font To 12 Cpi

Command Reference Epic 950 OEM Integration Manual ESC M – Set Font to 12 cpi Description Changes the character size for subsequent characters to the 12 cpi normal font. This is the default font. Fonts may only be changed at the beginning of a line, prior to any printable characters. -

Page 110: Esc P - Set Font To 16 Cpi

Command Reference Epic 950 OEM Integration Manual ESC P – Set Font to 16 cpi Description Changes the character size for subsequent characters to the 16 cpi mini font. Fonts may only be changed at the beginning of a line, prior to any printable characters. -

Page 111: Esc S - Set Font To 20 Cpi

Command Reference Epic 950 OEM Integration Manual ESC S – Set Font to 20 cpi Description Changes the character size for subsequent characters to the 20 cpi font. Fonts may only be changed at the beginning of a line, prior to any printable characters. -

Page 112: Esc T - Set Font To 7 Cpi

Command Reference Epic 950 OEM Integration Manual ESC T – Set Font to 7 cpi Description Changes the character size for subsequent characters to the 7 cpi headline font. Fonts may only be changed at the beginning of a line, prior to any printable characters. -

Page 113: Esc U - Set Font To 10 Cpi

Command Reference Epic 950 OEM Integration Manual ESC U – Set Font to 10 cpi Description Changes the character size for subsequent characters to the 10 cpi headline font. Fonts may only be changed at the beginning of a line, prior to any printable characters. -

Page 114: Esc V - Return Firmware Revision

Command Reference Epic 950 OEM Integration Manual ESC V – Return Firmware Revision Description This command returns two ASCII characters that represent the firmware revision. Expression ASCII [ESC] V Hexadecimal 1BH 56 Decimal <27> <86> Parameters None Page 102 95-05245... -

Page 115: Esc W - Wrap Data

If you do not wait, you may lose If n1 and n2 are received successfully by the host, you can be reasonably assured that there is an Epic 950 attached to the serial port, and that your program can communicate with the printer. -

Page 116: Esc X - Set Horizontal Starting Position

Command Reference Epic 950 OEM Integration Manual ESC X – Set Horizontal Starting Position Description This command is used in landscape printing to set a new offset from the left margin from which to begin printing text and bar code objects. Distance is specified in dots (1 dot = 1/203 inch). -

Page 117: Esc Y - Set Vertical Starting Position

Command Reference Epic 950 OEM Integration Manual ESC Y – Set Vertical Starting Position Description This command is used in landscape printing to set a new offset from the top margin from which to begin printing text and bar code objects. Distance is specified in millimeters, with a maximum allowable value of 53 millimeters. -

Page 118: Esc C - Select Color

Command Reference Epic 950 OEM Integration Manual ESC c – Select Color Description The ESC c command selects the current print color. Note that this command is only effective when using 2-color ticket stock. Expression ASCII [ESC] c n Hexadecimal... -

Page 119: Esc T - Set Print Direction In Page Mode

Command Reference Epic 950 OEM Integration Manual ESC t – Set Print Direction in Page Mode Description ESC t sets the print direction and starting position in page mode specified by the parameter n, as shown below. The default setting is n = 0. This command is enabled only in page mode. -

Page 120: Gs Dc2 - Set Font To Double-High

Command Reference Epic 950 OEM Integration Manual GS DC2 – Set Font to Double-high Description Causes the current font to be printed at twice its normal height. The double-high setting will remain in effect until the current line attributes are cleared. -

Page 121: Gs Dc3 - Cancel Double-High Font

Command Reference Epic 950 OEM Integration Manual GS DC3 – Cancel Double-high Font Description Cancels the double-high characters and returns to normal size font. This command must be sent at the beginning of a line, in front of any printable characters. -

Page 122: Gs Rs - Set Inverse Print Mode

Command Reference Epic 950 OEM Integration Manual GS RS – Set Inverse Print Mode Description Causes all the data that follows the command and appears on the current line to be printed as inverse characters (white on black). Inverse characters are canceled when character attributes are canceled. -

Page 123: Gs Us - Cancel Inverse Print Mode

Command Reference Epic 950 OEM Integration Manual GS US – Cancel Inverse Print Mode Description Cancels the inverse print mode (white on black) and returns text back to its normal attributes for the remainder of the current line. See also GS RS –... -

Page 124: Gs ! - Select Character Size

Command Reference Epic 950 OEM Integration Manual GS ! – Select Character Size Description This command selects the character height using bits 0 to 2 of parameter n, and selects the character width using bits 4 to 7 of this parameter, as shown below. -

Page 125: Gs $ - Set Absolute Vertical Position In

Command Reference Epic 950 OEM Integration Manual GS $ – Set Absolute Vertical Position in Page Mode Description Sets the vertical print position measured from the top of the page, for the currently selected print direction. Distance is specified in dots, where 1 dot = 1/203 inch. -

Page 126: Gs * - Landscape Mode Graphics

Command Reference Epic 950 OEM Integration Manual GS * – Landscape Mode Graphics Description Prints a graphic image (in landscape mode only). Expression ASCII [GS] * n1 n2 t h w d1…dm Hexadecimal 1DH 2AH n1 n2 t h w d1…dm Decimal <29>... -

Page 127: Gs ? - Crc Verification

Command Reference Epic 950 OEM Integration Manual GS ? – CRC Verification Description Returns the 16-bit cyclical redundancy check (CRC) value for the printer’s memory. Value is returned in the form: [gs]?<hi gh byte of CRC value><low byte of CRC value>... -

Page 128: Gs 0 - Print User Defined Image

Command Reference Epic 950 OEM Integration Manual GS 0 – Print User Defined Image Description Prints an image from the EEPROM memory, if found in the directory. Note: An image must be downloaded to the printer before it can be printed using this command. -

Page 129: Gs 1 - Enter Download Image Mode

Command Reference Epic 950 OEM Integration Manual GS 1 – Enter Download Image Mode Description Enters Download Image mode. Sends an [ACK] when download is complete. Expression ASCII [GS] 1 Hexadecimal 1DH 31 Decimal <29> <49> Parameters None Notes •... -

Page 130: Gs 3 - Image Status Handler

Command Reference Epic 950 OEM Integration Manual GS 3 – Image Status Handler Description Returns status information specified by the value of the parameter n. Expression ASCII [GS] 3 <n> Hexadecimal 1DH 33 <n> Decimal <29> <51> <n> Parameters n = parameter value specified as follows: n = 0: Printer responds with [ACK] if valid firmware, or [NAK] if not expanded memory board. -

Page 131: Gs A - Starting Position Of Bar Code

Command Reference Epic 950 OEM Integration Manual GS A – Starting Position of Bar Code Description This command is used to center a bar code on a text line, and defines the distance from the left where the first bar code will print. The distance is represented in dots, where each dot represents increments of 1/203 of an inch. -

Page 132: Gs E - Set Validation Number Field

Command Reference Epic 950 OEM Integration Manual GS E – Set Validation Number Field Description Sets the Validation Number field flag. Expression ASCII [GS] E Hexadecimal 1DH 45 Decimal <29> <69> Parameters None Notes • This command tells the printer that the next text sent to the printer will be a validation number. -

Page 133: Gs F - Set Field In Page Mode

Command Reference Epic 950 OEM Integration Manual GS F – Set Field in Page Mode Description Sets a text field in page mode, between the horizontal start position (n2 * 256 + n3) and the horizontal end position (n4 * 256 + n5). Positions are specified in dots, where 1 dot = 1/203 inch, relative to the left edge of the page for the currently selected print direction. - Page 134 Command Reference Epic 950 OEM Integration Manual simplify specifying a full width field, by setting <n2><n3><n4><n5> = <0><0><0><0>. • Commands for setting the font and other character attributes to apply to this field should be transmitted before this command. Only printable text characters with a single [CR] or [LF] terminator should follow as data for this command.

-

Page 135: Gs G - Print Custom Graphic

Command Reference Epic 950 OEM Integration Manual GS G – Print Custom Graphic Description Prints a custom graphic. These graphics are predefined by the OEM. Note: This command only functions in landscape mode. Expression ASCII [GS] G n1 n2 t d... -

Page 136: Gs L - Set Feed Length

Command Reference Epic 950 OEM Integration Manual GS L – Set Feed Length Description Sets the distance the print media will advance upon receipt of a form feed (FF or ESC E) command. The distance is represented in dots, where each dot represents increments of 1/203 of an inch. -

Page 137: Gs S - Return Printer Status

Command Reference Epic 950 OEM Integration Manual GS S – Return Printer Status Description Returns a single status byte, from which the printer status is determined by testing the individual bits within this returned status byte. Only bits that have defined values should be tested –... -

Page 138: Gs T - Select Line Wrap/Truncate Modes

Command Reference Epic 950 OEM Integration Manual GS T – Select Line Wrap/Truncate Modes Description Determines how to handle a text wrap condition. A text wrap condition occurs when text extends beyond the end of a line or a page. The default is to wrap at the end of a line and a page. -

Page 139: Gs V - Set Print Orientation

Command Reference Epic 950 OEM Integration Manual GS V – Set Print Orientation Description Causes the printer to print the data stored in the print buffer and then change to the selected orientation. See also GS t – Set Characters per Line in Landscape... -

Page 140: Gs W - Set Bar Code Element Width

Command Reference Epic 950 OEM Integration Manual GS W – Set Bar Code Element Width Description Selects the horizontal size of a bar code element. The Thin parameter represents the thickness of the thin bars (in dots). The Thick parameter represents the thickness of the thick bars (in dots). -

Page 141: Gs D - Feed N Text Lines

Command Reference Epic 950 OEM Integration Manual GS d – Feed n Text Lines Description Prints the contents of the buffer and feeds n number of text lines. This command has the same effect as line feeds. See also ESC J – Feed n Sublines... -

Page 142: Gs H - Set Bar Code Height

Command Reference Epic 950 OEM Integration Manual GS h – Set Bar Code Height Description Defines the height of the bars (in dots) for bar codes. The height is defined in n/203 inch increments, corresponding to the height of a single dot. For example, specify 203 as the value for n to print a 1-inch high bar code. -

Page 143: Gs K - Print Bar Code

Command Reference Epic 950 OEM Integration Manual GS k – Print Bar Code Description Prints a bar code at the current position in the current orientation. The n parameter selects the symbology to be printed. The m parameter specifies how many characters are to be encoded as part of the bar code, except in cases where n=2, where m represents the EAN/UPC symbology to be used. -

Page 144: Gs L - Draw Line In Landscape Mode

Command Reference Epic 950 OEM Integration Manual GS l – Draw Line in Landscape Mode Description The GS l (lower-case “L”) command draws a line in landscape mode. The thickness of the line is determined by the bit set by the parameter m. -

Page 145: Gs T - Set Characters Per Line In Landscape

Command Reference Epic 950 OEM Integration Manual GS t – Set Characters per Line in Landscape Description Creates an internal memory buffer to store landscape text and bar codes until a form feed is received. The size of the buffer is determined by n, the number of characters per line. -

Page 146: Gs U - Set Characters Per Line In Portrait

Command Reference Epic 950 OEM Integration Manual GS u – Set Characters per Line in Portrait Description Creates an internal memory buffer to store portrait text and bar codes. The size of the buffer is determined by n, the number of characters per line. -

Page 147: Gs W - Set Bar Code Module Width

Command Reference Epic 950 OEM Integration Manual GS w – Set Bar Code Module Width Description Selects the horizontal size of a bar code module. The parameter n represents the thickness of the thin bars in dots, where each dot measures 0.0049 inches in 203 dpi and 0.0073 inches in 138 dpi. -

Page 148: Gs Y - Request Combined Printer Status

Command Reference Epic 950 OEM Integration Manual GS y – Request Combined Printer Status Description Returns four status bytes: GS y (so that the status string can be recognized/parsed by the host), followed by the response byte for the GS S Return Printer Status command and then by the response byte for the GS z Request Printer Status command. -

Page 149: Gs Z - Request Printer Status

For firmware compatibility with previous versions of your printer, including Series 800 printers, an earlier status bit convention may be selected at device initialization time via the POR.INI file described in the chapter Programming for the Epic 950, with status bits interpreted as documented below. Expression... - Page 150 Command Reference Epic 950 OEM Integration Manual Ticket not in printer Ticket in printer Not Top of Form State Top of Form State (logical) Ticket loaded Ticket not loaded Bar Code not Completed Bar Code Completed Ticket not Completed Ticket Completed...

-

Page 151: Available Commands

Command Reference Epic 950 OEM Integration Manual Available Commands Name Description Page Audio alert Horizontal Tab Line Feed Form Feed Carriage Return Set Font to Double-w ide Cancel Double-w ide Mode Request Combined Printer Status 20h - FFh Printable Characters... - Page 152 Command Reference Epic 950 OEM Integration Manual GS W Thin Thick Set Bar Code Element Width GS d <n> Feed n Text Lines GS h <n> Set Bar Code Height GS k n m d1…dk Print Bar Code GS l n1 n2 l1 l2 m Draw Line in Landscape Mode GS t <n>...

-

Page 153: Appendix A: Character Codes

Epic 950 OEM Integration Manual Appendix A: Character Codes This appendix contains a list showing the ASCII characters supported by the Epic 950 printer, including a table of supported non-printable control characters, and a chart featuring supported printable characters and their hexadecimal ASCII equivalents. These character values may be up to two bytes in length. -

Page 154: Supported Non-Printable Control Characters

Appendix A: Character Codes Epic 950 OEM Integration Manual Supported Non-Printable Control Characters Note: In the table below, the ^ symbol represents the control key on your keyboard. Character Name Decimal Hexadecimal Binary None 0000 0000 0000 0001 0000 0010... -

Page 155: Supported Printable Characters

Appendix A: Character Codes Epic 950 OEM Integration Manual Supported Printable Characters The following tables contain printable characters supported by the Epic 950 printer, with hexadecimal character codes listed above each character. A. One-byte character codes (Hexadecimal values 20-FF). 95-05245... - Page 156 Appendix A: Character Codes Epic 950 OEM Integration Manual B. T w o-byte character codes (Hexadecimal values 010C-2122). Page 144 95-05245 Rev G...

-

Page 157: Index

Appendix A: Character Codes Epic 950 OEM Integration Manual Index 16-bit Character Parameters, 56 (ESC T) Set Font to 7 cpi, 98 Audio Alert, Configuring, 84 (ESC t) Set Print Direction in Page Available Commands, 137 Mode, 105 Bar Code Objects, 61... - Page 158 Index Epic 950 OEM Integration Manual (GS V) Set Print Orientation, 125 POR.INI File (GS W) Set Bar Code Element Width, Parameter Definitions, 64 Portrait Printing Mode, 58 (GS w) Set Bar Code Module Width, Print Area and Presentation Scheme, 17...

Need help?

Do you have a question about the Epic 950 and is the answer not in the manual?

Questions and answers