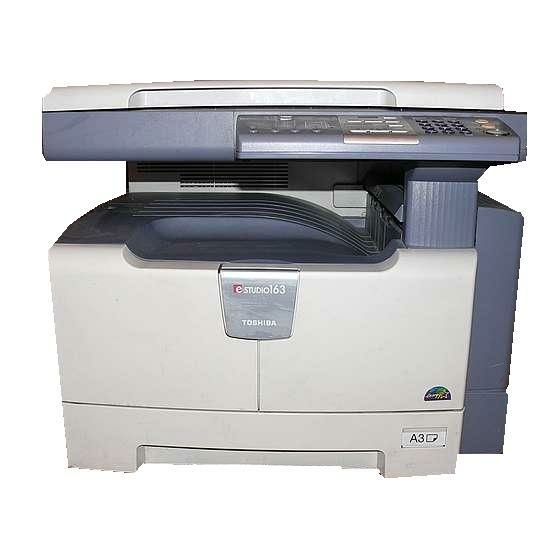

Toshiba e-STUDIO163 Service Manual

Multifunctional digital systems

Hide thumbs

Also See for e-STUDIO163:

- Service manual (236 pages) ,

- Service handbook (235 pages) ,

- Operator's manual (162 pages)

Summary of Contents for Toshiba e-STUDIO163

-

Page 1: Service Manual

SERVICE MANUAL MULTIFUNCTIONAL DIGITAL SYSTEMS e-STUDIO163/203 File No. SME05002400 R05092196100-TTEC VerB_2005-11... - Page 2 © 2005 TOSHIBA TEC CORPORATION All rights reserved...

-

Page 3: E-Studio163/203

GENERAL PRECAUTIONS REGARDING THE SERVICE FOR e-STUDIO163/203 The installation and service should be done by a qualified service technician. 1) Transportation/Installation When transporting/installing the equipment, employ two persons and be sure to hold the posi- tions as shown in the figure. - Page 4 Do not allow a short-circuit or do not use the parts not recommended by Toshiba TEC Corporation. 4) Cautionary Labels During servicing, be sure to check the rating plate and cautionary labels such as “Unplug the power cable during service”, “CAUTION.

- Page 5 5) Disposal of the Equipment, Supplies, Packing Materials, Used Batteries and IC-RAMs Regarding the recovery and disposal of the equipment, supplies, packing materials, used batter- ies and IC-RAMs including lithium batteries, follow the relevant local regulations or rules. Caution: Dispose of used batteries and IC-RAMs including lithium batteries according to this manual. Attention: Se débarrasser de batteries et IC-RAMs usés y compris les batteries en lithium selon ce manuel.

-

Page 7: Table Of Contents

6. SCANNER ........................6-1 6.1 General Description ......................6-1 6.2 Construction......................... 6-2 6.3 Functions ..........................6-3 6.4 Description of Operation ...................... 6-4 6.4.1 Scanning operation ....................6-4 6.4.2 Scan motor drive circuit .................... 6-4 December 2005 © TOSHIBA TEC e-STUDIO163/203 CONTENTS... - Page 8 12.1 General Description ......................12-1 12.2 Construction........................12-2 12.3 Functions ........................... 12-3 12.3.1 Function of each unit ....................12-3 12.3.2 Functions of the toner cartridge PC board (CTRG) ..........12-4 12.3.3 Recovered toner supply mechanism ..............12-5 e-STUDIO163/203 CONTENTS December 2005 © TOSHIBA TEC...

- Page 9 14.2 Operation of DC Output Circuit..................14-2 14.3 Output Channel ......................... 14-3 14.4 Fuse........................... 14-4 14.5 Configuration of Power Supply Unit................... 14-5 14.6 Power Supply Sequence ....................14-6 14.7 AC Wire Harness ....................... 14-7 15. PC BOARDS ....................... 15-1 December 2005 © TOSHIBA TEC e-STUDIO163/203 CONTENTS...

- Page 10 CONTENTS December 2005 © TOSHIBA TEC...

-

Page 11: Specifications / Accessories / Options / Supplies

SPECIFICATIONS / ACCESSORIES / OPTIONS / SUPPLIES Specifications Values in [ ] are for e- STUDIO203 in case that the specification is different among e-STUDIO163 and e-STUDIO203. Copy process Indirect electrophotographic process (dry) Type Desktop type Original table Fixed type (the left rear corner used as guide to place originals) Accepted originals Sheet, book and 3-dimensional object. - Page 12 - [-] B4, LG, FOLIO, COMPUTER - [-] 12 [12] 10.5 [10.5] - [-] A3, LD - [-] 10.5 [10.5] 10.5 [10.5] - [-] e-STUDIO163/203 SPECIFICATIONS / ACCESSORIES / OPTIONS / SUPPLIES December 2005 © TOSHIBA TEC 1 - 2...

- Page 13 (17 to 22 lb. Bond)) Bypass feeding: Stack height TBD mm: equivalent to 100 sheets; 64 to 80 g/m (17 to 22 lb. Bond) December 2005 © TOSHIBA TEC e-STUDIO163/203 SPECIFICATIONS / ACCESSORIES / OPTIONS / SUPPLIES 1 - 3...

- Page 14 * The electric power is supplied to the ADF through the equipment. Total counter ......Electronical counter Dimensions of the equipment ....See the figure below (TBD) T.B.D. Fig. 1-1 e-STUDIO163/203 SPECIFICATIONS / ACCESSORIES / OPTIONS / SUPPLIES December 2005 © TOSHIBA TEC 1 - 4...

-

Page 15: Accessories

Central and South America / Hong Kong AUD: Australia MJD: Europe ASU: Asia SAD: Saudi Arabia IRD: Iran CND: China TWD: Taiwan JPD: Japan December 2005 © TOSHIBA TEC e-STUDIO163/203 SPECIFICATIONS / ACCESSORIES / OPTIONS / SUPPLIES 1 - 5... -

Page 16: Options

Options Platen Cover KA-1640 PC Automatic Document Feeder (ADF) MR-2017 Paper Feed Unit (PFU) MY-1027 Expansion Memory GC-1240 e-STUDIO163/203 SPECIFICATIONS / ACCESSORIES / OPTIONS / SUPPLIES December 2005 © TOSHIBA TEC 1 - 6... -

Page 17: Supplies

Supplies Drum Toner cartridge Developer December 2005 © TOSHIBA TEC e-STUDIO163/203 SPECIFICATIONS / ACCESSORIES / OPTIONS / SUPPLIES 1 - 7... -

Page 18: System List

System List T.B.D. Fig. 1-2 e-STUDIO163/203 SPECIFICATIONS / ACCESSORIES / OPTIONS / SUPPLIES December 2005 © TOSHIBA TEC 1 - 8... -

Page 19: Outline Of The Machine

Scanner damp heater thermostat THMO2 Laser optical unit Polygonal motor Pickup roller Separation finger Paper empty sensor Registration sensor Registration roller Bypass pickup roller Bypass feed roller Bypass separation pad December 2005 © TOSHIBA TEC e-STUDIO163/203 OUTLINE OF THE MACHINE 2 - 1... - Page 20 Center/Side/Edge thermistor THMS1/2/3 Fuser thermostat THMO1 Exit roller Exit sensor Front cover opening/closing switch Front cover opening/closing interlock switch Temperature/humidity sensor Switching regulator ADU cover opening/closing interlock switch e-STUDIO163/203 OUTLINE OF THE MACHINE December 2005 © TOSHIBA TEC 2 - 2...

- Page 21 Toner motor Main motor Switching regulator cooling fan CIS home position sensor Platen sensor Drawer detection switch CLT1 Registration clutch SOL1 Pickup solenoid SOL2 Bypass pickup solenoid December 2005 © TOSHIBA TEC e-STUDIO163/203 OUTLINE OF THE MACHINE 2 - 3...

-

Page 22: Electric Parts Layout

Electric Parts Layout [A] Scanner, control panel THMO2 LPNL Fig. 2-3 e-STUDIO163/203 OUTLINE OF THE MACHINE December 2005 © TOSHIBA TEC 2 - 4... - Page 23 [B] Power supply section, switches Fig. 2-4 December 2005 © TOSHIBA TEC e-STUDIO163/203 OUTLINE OF THE MACHINE 2 - 5...

- Page 24 [C] Laser unit, fuser unit, toner cartridge section CTIF CTRG LAMP1 LAMP2 THMO1 THMS1 THMS2 THMS3 Fig. 2-5 e-STUDIO163/203 OUTLINE OF THE MACHINE December 2005 © TOSHIBA TEC 2 - 6...

- Page 25 [D] Developer unit section THMS4 THMO3 Fig. 2-6 December 2005 © TOSHIBA TEC e-STUDIO163/203 OUTLINE OF THE MACHINE 2 - 7...

- Page 26 [E] Driving section CLT1 SRAM MAIN SOL1 Fig. 2-7 e-STUDIO163/203 OUTLINE OF THE MACHINE December 2005 © TOSHIBA TEC 2 - 8...

- Page 27 [F] Drawer section Fig. 2-8 December 2005 © TOSHIBA TEC e-STUDIO163/203 OUTLINE OF THE MACHINE 2 - 9...

- Page 28 [G] Bypass unit SOL2 Fig. 2-9 e-STUDIO163/203 OUTLINE OF THE MACHINE December 2005 © TOSHIBA TEC 2 - 10...

-

Page 29: Symbols And Functions Of Various Components

Polygonal motor EXT-FAN-MOT Exhausting ozone and cooling down Fig. 2-6 Exhaust fan the equipment inside PS-FAN-MOT Cooling down the switching regulator Fig. 2-4 Switching regulator cooling fan December 2005 © TOSHIBA TEC e-STUDIO163/203 OUTLINE OF THE MACHINE 2 - 11... - Page 30 Controlling the power transmission of Fig. 2-7 Pickup solenoid the feed roller SOL2 SFB-SOL Controlling the power transmission of Fig. 2-9 Bypass pickup solenoid the bypass pickup roller e-STUDIO163/203 OUTLINE OF THE MACHINE December 2005 © TOSHIBA TEC 2 - 12...

- Page 31 SCN-DH-R Preventing condensation in the scan- Fig. 2-3 Scanner damp heater (Right) ner unit DRM-DH Preventing condensation of the drum Fig. 2-6 Drum damp heater December 2005 © TOSHIBA TEC e-STUDIO163/203 OUTLINE OF THE MACHINE 2 - 13...

- Page 32 • Generating high voltage and supply- ing it to the main charger, developer, transfer and separation units • Supplying AC power to the heater lamp e-STUDIO163/203 OUTLINE OF THE MACHINE December 2005 © TOSHIBA TEC 2 - 14...

-

Page 33: General Description

General Description 2.4.1 System block diagram Fig. 2-10 December 2005 © TOSHIBA TEC e-STUDIO163/203 OUTLINE OF THE MACHINE 2 - 15... -

Page 34: Construction Of Boards

This is the interface board with the CTRG board in the toner cartridge. Information written in the IC chip on the CTRG board is read into the SoC on the MAIN board through this board. e-STUDIO163/203 OUTLINE OF THE MACHINE December 2005 © TOSHIBA TEC... - Page 35 AC electric power input. This is then provided to each electric part. • FUS board: This is the board to provide AC electric power for driving the damp heater. December 2005 © TOSHIBA TEC e-STUDIO163/203 OUTLINE OF THE MACHINE 2 - 17...

-

Page 36: Disassembly And Replacement Of Covers

Take off the front cover while lifting it up. Fig. 2-12 [B] Inner tray Remove 2 screws and take off the Inner tray. Inner tray Fig. 2-13 e-STUDIO163/203 OUTLINE OF THE MACHINE December 2005 © TOSHIBA TEC 2 - 18... - Page 37 Left cover Fig. 2-14 [D] Tray rear cover Take off the left cover. P.2-19 "[C] Left cover" Take off the tray rear cover. Tray rear cover Fig. 2-15 December 2005 © TOSHIBA TEC e-STUDIO163/203 OUTLINE OF THE MACHINE 2 - 19...

- Page 38 Remove 2 screws and take off the front right cover. Fig. 2-16 [F] Front upper cover Remove 1 screw and take off the front upper cover. Front upper cover Fig. 2-17 e-STUDIO163/203 OUTLINE OF THE MACHINE December 2005 © TOSHIBA TEC 2 - 20...

- Page 39 P.2-18 "[A] Front cover" Open the ADU cover. Pull out the drawer. Remove 2 screws and take off the right front cover. Right front cover Fig. 2-20 December 2005 © TOSHIBA TEC e-STUDIO163/203 OUTLINE OF THE MACHINE 2 - 21...

- Page 40 Take off the 2 screw and take off the right rear cover. Right rear cover Fig. 2-21 Rear cover Remove 6 screws and take off the rear cover. Rear cover Fig. 2-22 e-STUDIO163/203 OUTLINE OF THE MACHINE December 2005 © TOSHIBA TEC 2 - 22...

-

Page 41: Disassembly And Replacement Of Pc Boards

Take off the rear cover. P.2-22 "[J] Rear cover" Disconnect 14 connectors. Fig. 2-23 Remove 5 screws and take off the MAIN board. MAIN board Fig. 2-24 December 2005 © TOSHIBA TEC e-STUDIO163/203 OUTLINE OF THE MACHINE 2 - 23... - Page 42 Ground wire off. Switching regulator unit Fig. 2-27 e-STUDIO163/203 OUTLINE OF THE MACHINE December 2005 © TOSHIBA TEC 2 - 24...

- Page 43 Disconnect 2 connectors. Connector Fig. 2-28 Remove 8 screws and take off the switching regulator board. Switching regulator board Fig. 2-29 December 2005 © TOSHIBA TEC e-STUDIO163/203 OUTLINE OF THE MACHINE 2 - 25...

-

Page 44: Removal And Installation Of Options

Turn the power OFF and unplug the power cable. Take off the connector cover. Fig. 2-30 Disconnect the connector. Fig. 2-31 Remove 1 screw on the rear right side. Fig. 2-32 e-STUDIO163/203 OUTLINE OF THE MACHINE December 2005 © TOSHIBA TEC 2 - 26... - Page 45 Remove 1 screw and 1 washer on the rear left side. Fig. 2-33 Open the ADF. Fig. 2-34 Remove 2 screws on the front side. Fig. 2-35 December 2005 © TOSHIBA TEC e-STUDIO163/203 OUTLINE OF THE MACHINE 2 - 27...

- Page 46 Turn the power OFF and unplug the power cable. Take off the Rear cover. P.2-22 "[J] Rear cover" Remove the ground wire. Fig. 2-37 Disconnect the connector. Fig. 2-38 e-STUDIO163/203 OUTLINE OF THE MACHINE December 2005 © TOSHIBA TEC 2 - 28...

- Page 47 Remove 1 screw and take off 1 fixing brack- ets on the front left side. Fig. 2-40 Remove 1 screw and take off 1 fixing brack- ets on the front right side. Fig. 2-41 December 2005 © TOSHIBA TEC e-STUDIO163/203 OUTLINE OF THE MACHINE 2 - 29...

- Page 48 Remove 1 screw and take off 1 fixing brack- ets on the rear right side. Fig. 2-43 (10) Lift up the equipment and take off the PFU. Fig. 2-44 e-STUDIO163/203 OUTLINE OF THE MACHINE December 2005 © TOSHIBA TEC 2 - 30...

-

Page 49: Copy Process

Transfer bias: Improves transfer efficiency. Transfer: Transfers the visible toner image on the photoconductive drum onto paper. December 2005 © TOSHIBA TEC e-STUDIO163/203 COPY PROCESS 3 - 1... -

Page 50: Details Of Copying Process

As this image on the drum formed by the negative potential is not visible, it is called an “electrostatic latent image.” Time ( t ) Black area of original -500 White area of original Discharge Charging process process Electric potential of the photoconductive drum Fig. 3-3 e-STUDIO163/203 COPY PROCESS December 2005 © TOSHIBA TEC 3 - 2... - Page 51 (Example) Light Value of image receiving signals to be amount output T.B.D. Light Difference between "light " and "dark" is divided into 256 steps. Dark Fig. 3-5 Fig. 3-6 December 2005 © TOSHIBA TEC e-STUDIO163/203 COPY PROCESS 3 - 3...

- Page 52 (laser emission) to expose the drum surface and form an electrostatic latent image on it. Image LDR board processing section Polygonal mirror Semiconductive laser element Photo- conductive drum Fig. 3-7 e-STUDIO163/203 COPY PROCESS December 2005 © TOSHIBA TEC 3 - 4...

- Page 53 Switching of developer bias polarity With the area which has no negative charge, background fogging is decreased by switching the bias to the positive polarity (approx. +150 V). Charging AC bias December 2005 © TOSHIBA TEC e-STUDIO163/203 COPY PROCESS 3 - 5...

- Page 54 2. Toner scattering occurs. 3. Background fogging occurs. Solution: Replace the developer material. No frictional electrification occurs on the area where the toner is caked. Fig. 3-12 Magnetic roller Magnetic brush development e-STUDIO163/203 COPY PROCESS December 2005 © TOSHIBA TEC 3 - 6...

- Page 55 This is caused by the magnetic force lines between the south and north poles. Photoconductive drum Magnetic force Magnetic roller line Fig. 3-13 Additional Explanation The life of the toner cartridge (number of output pages) varies depending on the following condi- December 2005 © TOSHIBA TEC e-STUDIO163/203 COPY PROCESS 3 - 7...

- Page 56 As indicated in the figure below, the life of the toner cartridge varies depending on the copy mode and coverage of originals. A full block in the figure below denotes approx. 5,000 output pages. T.B.D. Fig. 3-14 e-STUDIO163/203 COPY PROCESS December 2005 © TOSHIBA TEC 3 - 8...

- Page 57 From 11 mm from leading edge to 5 mm from trailing edge (C) 445 µADC From 5 mm from trailing edge to trailing edge (L) 310 µADC Direction of transportation Drum rotation Transfer charger Toner Fig. 3-16 December 2005 © TOSHIBA TEC e-STUDIO163/203 COPY PROCESS 3 - 9...

- Page 58 To prevent this, a separation finger is used to forcibly separate the paper which was left around the drum. Separation finger Paper movement Separation charger Drum rotation Fig. 3-18 e-STUDIO163/203 COPY PROCESS December 2005 © TOSHIBA TEC 3 - 10...

- Page 59 The edge of the urethane rubber cleaning blade is pressed against the photoconductive drum sur- face to scrape off the residual toner on it. The toner is then caught by the recovery blade. Recovery blade Cleaning blade Drum rotation Fig. 3-21 December 2005 © TOSHIBA TEC e-STUDIO163/203 COPY PROCESS 3 - 11...

- Page 60 The photoconductive drum becomes electri- cally conductive. All of the negative charge remaining on the pho- toconductive drum is conducted to the ground. Preparation for the next printing is completed. e-STUDIO163/203 COPY PROCESS December 2005 © TOSHIBA TEC 3 - 12...

-

Page 61: Comparison With E-Studio230/280

Thin roller coated with fluoroplastic (ø30) Pressure roller: PFA tube roller (ø30) • Cleaning Cleaning roller for pressure roller (ø16) None • Heater Heater lamp Turned ON/OFF by thermistor December 2005 © TOSHIBA TEC e-STUDIO163/203 COPY PROCESS 3 - 13... - Page 62 COPY PROCESS December 2005 © TOSHIBA TEC 3 - 14...

-

Page 63: General Operation

GENERAL OPERATION Overview of Operation Operation of equipment Operation during initializing, pre-running and ready Drawer feed copying by [START] button Bypass feed copying Copying operation Interrupt copying December 2005 © TOSHIBA TEC e-STUDIO163/203 GENERAL OPERATION 4 - 1... -

Page 64: Description Of Operation

Buttons on the control panel enabled → When no button is pressed for a certain period of time, - Set number “1” is displayed. Equipment returns to the normal ready state. e-STUDIO163/203 GENERAL OPERATION December 2005 © TOSHIBA TEC 4 - 2... -

Page 65: Drawer Feed Copying

→ Polygonal motor, main motor and exit motor OFF → Drum, fuser unit and developer unit stop → Fans return to the ready rotation → LED “START” ON and the equipment enters the ready state December 2005 © TOSHIBA TEC e-STUDIO163/203 GENERAL OPERATION 4 - 3... - Page 66 Timing chart for copying one A4 size sheet fed from the drawer T. B . D . e-STUDIO163/203 GENERAL OPERATION December 2005 © TOSHIBA TEC 4 - 4...

-

Page 67: Bypass Feed Copying

→ LED “INTERRUPT” OFF by pressing the [INTERRUPT] button → Equipment returns to the status before the interruption 4) Press the [START] button → The copying operation before the interruption is resumed. December 2005 © TOSHIBA TEC e-STUDIO163/203 GENERAL OPERATION 4 - 5... -

Page 68: Detection Of Abnormality

(C) Misfeed in equipment (D) Replace the toner cartridge (E) Developer unit not installed properly 3) Abnormality not cleared without turning OFF the main switch (F) Call for service e-STUDIO163/203 GENERAL OPERATION December 2005 © TOSHIBA TEC 4 - 6... -

Page 69: Description Of Abnormality

Registration sensor is not turned ON in a fixed period of time Clear paper symbol is displayed : E12 Copying operation is disabled Solution: The bypass paper sensor is turned OFF by removing the paper from the bypass tray. December 2005 © TOSHIBA TEC e-STUDIO163/203 GENERAL OPERATION 4 - 7... - Page 70 Registration sensor detects jamming of the leading edge of paper: Registration sensor is not turned ON in a fixed period of time after the pickup solenoid is turned Paper jam (E21 and E09) e-STUDIO163/203 GENERAL OPERATION December 2005 © TOSHIBA TEC 4 - 8...

- Page 71 Error code is displayed instead of the set number by pressing the [CLEAR] button and [8] button simultaneously when the “Call for service” is blinking. Refer to the error code table in the Service Handbook. December 2005 © TOSHIBA TEC e-STUDIO163/203 GENERAL OPERATION 4 - 9...

-

Page 72: Flow Chart

Flow Chart 4.4.1 Immediately after the power is turned ON T.B.D. Fig. 4-3 e-STUDIO163/203 GENERAL OPERATION December 2005 © TOSHIBA TEC 4 - 10... - Page 73 T.B.D. Fig. 4-4 December 2005 © TOSHIBA TEC e-STUDIO163/203 GENERAL OPERATION 4 - 11...

- Page 74 GENERAL OPERATION December 2005 © TOSHIBA TEC 4 - 12...

-

Page 75: Automatic Paper Feed Copying

4.4.2 Automatic paper feed copying T.B.D. Fig. 4-5 December 2005 © TOSHIBA TEC e-STUDIO163/203 GENERAL OPERATION 4 - 13... - Page 76 T.B.D. Fig. 4-6 e-STUDIO163/203 GENERAL OPERATION December 2005 © TOSHIBA TEC 4 - 14...

-

Page 77: Control Panel

LEDs to display codes, values and the states (including each mode) of the equipment. The button switches and the LEDs are mounted on the control panel PC board-L (LPNL board) and are installed the inside of the control panel. T.B.D. December 2005 © TOSHIBA TEC e-STUDIO163/203 CONTROL PANEL 5 - 1... -

Page 78: Items Displayed On Control Panel

5) Error code When a paper jam or a service call has occurred, its error code is displayed in 3 digits by pressing the [CLEAR/STOP] button and the [8] key simultaneously. e-STUDIO163/203 CONTROL PANEL December 2005 © TOSHIBA TEC 5 - 2... - Page 79 [START] button to perform the setting. When the set- ting needs to be canceled halfway, press the [FUNCTION CLEAR] button. December 2005 © TOSHIBA TEC e-STUDIO163/203 CONTROL PANEL 5 - 3...

-

Page 80: Relation Between Equipment State And Operation

Operation copy job rupting copy quantity rupting copy rupting copy acceptable Cover open Clears copy Clears each Operation quantity setting acceptable Toner empty Operation acceptable Paper jam Service call e-STUDIO163/203 CONTROL PANEL December 2005 © TOSHIBA TEC 5 - 4... -

Page 81: Operation

The LED is turned ON only when the two conditions below are met. 1) The FET connected to the LED anode is ON. 2) The cathode side of the LED is “L” level. December 2005 © TOSHIBA TEC e-STUDIO163/203 CONTROL PANEL 5 - 5... -

Page 82: Disassembly And Replacement

Note: When installing the control panel unit, be sure not to have the harness being caught by the front right cover and the unit. Control panel unit Fig. 5-4 e-STUDIO163/203 CONTROL PANEL December 2005 © TOSHIBA TEC 5 - 6... - Page 83 Take off 2 brackets by removing 2 screws each. Bracket Fig. 5-6 Remove 12 screws and take off the control panel PC board. Control panel PC board Fig. 5-7 December 2005 © TOSHIBA TEC e-STUDIO163/203 CONTROL PANEL 5 - 7...

- Page 84 CONTROL PANEL December 2005 © TOSHIBA TEC 5 - 8...

-

Page 85: Scanner

MAIN board, the data are transmitted to the writing section. After that, an arithmetic operation is performed on the digital signal, which is then transmitted to the data writing section. T.B.D. Fig. 6-1 December 2005 © TOSHIBA TEC e-STUDIO163/203 SCANNER 6 - 1... -

Page 86: Construction

Scanning section Original glass Original glass ADF Original glass CIS unit (CIS) Y-G LED array RGB LED array Rod-lens array Drive section Scan motor (M1) CIS home position sensor (S1) e-STUDIO163/203 SCANNER December 2005 © TOSHIBA TEC 6 - 2... -

Page 87: Functions

CIS unit through the timing belt to move the unit form side to side. 4) CIS home position sensor (S1) This sensor detects if the CIS unit is at its home position. December 2005 © TOSHIBA TEC e-STUDIO163/203 SCANNER 6 - 3... -

Page 88: Description Of Operation

The CIS unit (CIS) stops and stays at the shading position during the shading correction, and at the scanning position during the scanning operation. 6.4.2 Scan motor drive circuit T.B.D e-STUDIO163/203 SCANNER December 2005 © TOSHIBA TEC 6 - 4... -

Page 89: Contact Image Sensor Unit Control Circuit

MAIN board Contact image sensor unit +24V Green Blue Yellow-Green SCNLEDVR3-1 Serial data SCNLEDVR1-1 converter SCNLEDVR2-1 SCNLEDROFF-1 SCNLEDGOFF-1 ASIC SCNLEDBOFF-1 SCNLEDASTOFF-1 Fig. 6-2 December 2005 © TOSHIBA TEC e-STUDIO163/203 SCANNER 6 - 5... -

Page 90: Ccd Control Circuit

Contact image sensor unit TRCLCK CK2B MCLCK RSCLCK IMGDTA[0] SCNIMGA[0] IMGDTA[1] SCNIMGA[1] CDIN1 IMGDTA[2] SCNIMGA[2] CDIN2 IMGDTA[3] SCNIMGA[3] CDIN3 IMGDTA[4] SCNIMGA[4] CDIN4 IMGDTA[5] SCNIMGA[5] IMGDTA[6] SCNIMGA[6] IMGDTA[7] SCNIMGA[7] Fig. 6-3 e-STUDIO163/203 SCANNER December 2005 © TOSHIBA TEC 6 - 6... - Page 91 ( S-K) I = k ( W- K) Coefficient Image data before correction Black data (stored in "Black" memory) White data (stored in "White" memory) Fig. 6-5 December 2005 © TOSHIBA TEC e-STUDIO163/203 SCANNER 6 - 7...

-

Page 92: Disassembly And Replacement

3. When installing the original glass, fit 2 guides of the original glass in the groove of the scanner top cover. Fig. 6-7 Take off the ADF original glass. ADF Original glass Fig. 6-8 e-STUDIO163/203 SCANNER December 2005 © TOSHIBA TEC 6 - 8... - Page 93 Remove 6 screws and take off the scanner top cover. Fig. 6-10 [C] Scan motor (M1) Take off the scanner top cover. P.6-9 "[B] Scanner top cover" Disconnect 1 connector. Connector Fig. 6-11 December 2005 © TOSHIBA TEC e-STUDIO163/203 SCANNER 6 - 9...

- Page 94 3. The scan motor is pulled by the belt tension jig. Fix the screw A and then B at the stopped position. 4. Remove the belt tension jig. Belt tension jig Fig. 6-14 e-STUDIO163/203 SCANNER December 2005 © TOSHIBA TEC 6 - 10...

- Page 95 Fig. 6-16 [E] CIS unit (CIS) Take off the original glass. P.6-8 "[A] Original glass" Move the CIS unit to the right most position. CIS unit Fig. 6-17 December 2005 © TOSHIBA TEC e-STUDIO163/203 SCANNER 6 - 11...

- Page 96 When installing the belt stopper, install it so that the protrusion of the stopper fits in the V- groove on the inside of the CIS unit drive belt-1. CIS unit drive belt-1 Fig. 6-20 e-STUDIO163/203 SCANNER December 2005 © TOSHIBA TEC 6 - 12...

- Page 97 CIS case comes under the CIS unit drive belt-1. Shaft Shaft guide Fig. 6-22 [G] CIS unit drive belt-1 Take off the CIS case. P.6-12 "[F] CIS case" Tension spring Remove the tension spring. Fig. 6-23 December 2005 © TOSHIBA TEC e-STUDIO163/203 SCANNER 6 - 13...

- Page 98 Take off the right rear cover. P.2-22 "[I] Right rear cover" Take off the CIS unit drive belt-1. P.6-13 "[G] CIS unit drive belt-1" Loosen 2 fixing screws of the scan motor. Fig. 6-26 e-STUDIO163/203 SCANNER December 2005 © TOSHIBA TEC 6 - 14...

- Page 99 CIS unit drive belt-2 Pulley Note: When assembling the CIS unit drive belt-2, be sure to perform the tension adjustment for the scan motor. P.6-9 "[C] Scan motor (M1)" Fig. 6-27 December 2005 © TOSHIBA TEC e-STUDIO163/203 SCANNER 6 - 15...

- Page 100 SCANNER December 2005 © TOSHIBA TEC 6 - 16...

-

Page 101: Image Processing

Smoothing processing, external input system interface, image area control, laser related control and printer high quality image processing December 2005 © TOSHIBA TEC e-STUDIO163/203 IMAGE PROCESSING 7 - 1... -

Page 102: Configuration

Configuration The following diagram shows the image processing section of this equipment. T.B.D. Fig. 7-2 e-STUDIO163/203 IMAGE PROCESSING December 2005 © TOSHIBA TEC 7 - 2... -

Page 103: Main Board

External input system interface Image area control Laser related control Printer high quality processing 7.3.2 Functions of image processing circuit The image processing section mounted on the SLG board realizes the followings: December 2005 © TOSHIBA TEC e-STUDIO163/203 IMAGE PROCESSING 7 - 3... - Page 104 The above averaging operation is performed for all the pixels to accomplish the high reproducibil- ity of original. (The following is the case that the low pass filtering is applied on the primary scanning pixel.) e-STUDIO163/203 IMAGE PROCESSING December 2005 © TOSHIBA TEC 7 - 4...

- Page 105 Solid black area Low contrast area Original Image signal After correction Fig. 7-5 December 2005 © TOSHIBA TEC e-STUDIO163/203 IMAGE PROCESSING 7 - 5...

- Page 106 6) External output system interface This function controls the output of the output interface. e-STUDIO163/203 IMAGE PROCESSING December 2005 © TOSHIBA TEC 7 - 6...

- Page 107 This function sets the effective image area in horizontal and vertical directions to be output. 11)Laser related control This function performs the APC (Auto Power Control). 12)Printer high quality processing This function reproduces the image signals output from the printer controller sharper. December 2005 © TOSHIBA TEC e-STUDIO163/203 IMAGE PROCESSING 7 - 7...

- Page 108 IMAGE PROCESSING December 2005 © TOSHIBA TEC 7 - 8...

-

Page 109: Laser Optical Unit

The unit must not be disassembled in the field as they are very sensitive to dust and finely adjusted at the factory. T.B.D. Fig. 8-1 T.B.D. Fig. 8-2 December 2005 © TOSHIBA TEC e-STUDIO163/203 LASER OPTICAL UNIT 8 - 1... -

Page 110: Structure

Polygonal motor unit Polygonal motor (M4) Polygonal mirror 6 planes Polygonal mirror cover fθ lens 1 fθ lens 2 H-Sync returning mirror Slit glass H-sync signal detection PC board (SNS) e-STUDIO163/203 LASER OPTICAL UNIT December 2005 © TOSHIBA TEC 8 - 2... - Page 111 "CAUTION. HOT", "CAUTION. HIGH VOLTAGE", "CAUTION. LASER BEAM", etc. to see if there is any dirt on their surface and if they are properly stuck to the equipment. December 2005 © TOSHIBA TEC e-STUDIO163/203 LASER OPTICAL UNIT 8 - 3...

- Page 112 One scan is completed by completion of steps (A) to (C). One scan is performed on one plane of the polygonalmirror. Six scans can be made with one rotation of the polygonal mirror. e-STUDIO163/203 LASER OPTICAL UNIT December 2005 © TOSHIBA TEC 8 - 4...

- Page 113 PC board (SNS). The primary scanning synchronizing signal is generated based on this reflection. 5) Slit glass Slit glass is located where the laser beams are output from the laser optical unit, and it protects the unit from dust. December 2005 © TOSHIBA TEC e-STUDIO163/203 LASER OPTICAL UNIT 8 - 5...

-

Page 114: Laser Diode Control Circuit

Power source Laser power Semiconductive laser Laser driver comparison circuit circuit Constant optical output Monitor efficiency Monitor output regulation circuit Fig. 8-8 e-STUDIO163/203 LASER OPTICAL UNIT December 2005 © TOSHIBA TEC 8 - 6... -

Page 115: Polygonal Motor Control Circuit

Low level High level PMTR-0 Polygonal motor ON signal PMTRCLK Polygonal motor reference clock PMTRSTS-0 Polygonal motor PLL control signal Rotating at a constant Stopping or error speed December 2005 © TOSHIBA TEC e-STUDIO163/203 LASER OPTICAL UNIT 8 - 7... -

Page 116: Disassembly And Replacement

Take off the left cover. P.2-19 "[C] Left cover" Disconnect 1 connector and take off the switching regulator cooling fan while sliding it upward. Connector Switching regulator cooling fan Fig. 8-12 e-STUDIO163/203 LASER OPTICAL UNIT December 2005 © TOSHIBA TEC 8 - 8... -

Page 117: Drive Unit

The toner motor which drives the toner cartridge is also installed in the drive unit. T.B.D. Fig. 9-1 December 2005 © TOSHIBA TEC e-STUDIO163/203 DRIVE UNIT 9 - 1... -

Page 118: Configuration

Unit to be driven Drive transmission Main motor Drum Gears Developer unit Gears Cleaner unit Timing belt, gears Fuser unit Timing belt, gears Rollers Timing belt, gears Toner motor Toner cartridge Gears e-STUDIO163/203 DRIVE UNIT December 2005 © TOSHIBA TEC 9 - 2... -

Page 119: Functions

The main motor is a DC motor which is controlled by control signals output from the MAIN board. The driving force of the toner motor is transmitted to the toner cartridge via gears. December 2005 © TOSHIBA TEC e-STUDIO163/203 DRIVE UNIT... -

Page 120: Main Motor Control Circuit

"L" level to the ASIC. 9) When MMTRBK-0 signal from the ASIC becomes "L" level, the motor is braked. When the MMTR-0 signal becomes "H" level, the motor is stopped. e-STUDIO163/203 DRIVE UNIT December 2005 © TOSHIBA TEC 9 - 4... - Page 121 • MMTRBK-0 signal: This signal applies a brake on the main motor. When this signal becomes "L" level, a brake is applied to the rotation of the motor. December 2005 © TOSHIBA TEC e-STUDIO163/203 DRIVE UNIT 9 - 5...

-

Page 122: Disassembly And Replacement

Tonner motor Connector Disconnect 1 connector, remove 2 screws, take off the toner motor with the bracket, and then remove 1 bushing and 1 gear. Bracket Bushing Gear Fig. 9-4 e-STUDIO163/203 DRIVE UNIT December 2005 © TOSHIBA TEC 9 - 6... - Page 123 Registration roller holder Fig. 9-6 Remove 1 clip and take off the bushing. Clip Bushing Fig. 9-7 December 2005 © TOSHIBA TEC e-STUDIO163/203 DRIVE UNIT 9 - 7...

- Page 124 Remove 3 screws and take off the main motor drive unit. Connector Main motor drive unit Fig. 9-8 Loosen 1 tensioner fixing screw and remove the tension spring. Tensioner spring Fig. 9-9 e-STUDIO163/203 DRIVE UNIT December 2005 © TOSHIBA TEC 9 - 8...

- Page 125 Main motor drive unit Fig. 9-10 Note: Assemble the main motor drive unit with the tensioner fixing screw loosened. And then, tighten it after hooking the tension spring. Tensioner spring Fig. 9-11 December 2005 © TOSHIBA TEC e-STUDIO163/203 DRIVE UNIT 9 - 9...

- Page 126 DRIVE UNIT December 2005 © TOSHIBA TEC 9 - 10...

-

Page 127: Paper Feeding System

Fig. 10-1 Item Pickup roller Separation pad Registration roller (Rubber) Registration roller (Metal) Bypass pickup roller Bypass feed roller Bypass separation pad Paper empty sensor Registration sensor Bypass sensor December 2005 © TOSHIBA TEC e-STUDIO163/203 PAPER FEEDING SYSTEM 10 - 1... -

Page 128: Configuration

Periodic replacement part Bypass sensor (S8) Bypass pickup solenoid (SOL2) Bypass pickup clutch Bypass feed clutch Registration roller Registration roller clutch (CLT1) Registration sensor (S4) Drawer detection switch (SW5) e-STUDIO163/203 PAPER FEEDING SYSTEM December 2005 © TOSHIBA TEC 10 - 2... -

Page 129: Functions

When the bypass pickup solenoid (SOL2) is turned OFF, the spring ten- sion of the one-way clutch decreases to cut off the drive. December 2005 © TOSHIBA TEC e-STUDIO163/203 PAPER FEEDING SYSTEM 10 - 3... - Page 130 This sensor detects that the leading edge of the paper has reached the registration roller and the trailing edge of the paper has passed the registration roller. 15)Drawer detection sensor (SW5) The switch to detect whether the drawer is closed or not. e-STUDIO163/203 PAPER FEEDING SYSTEM December 2005 © TOSHIBA TEC 10 - 4...

-

Page 131: Operation

When the picking up force of the roller increases, one sheet of paper is finally released from the claws. The sheet released from the separation claws is directly transported to the registration roller by the pickup roller. T.B.D. Fig. 10-3 December 2005 © TOSHIBA TEC e-STUDIO163/203 PAPER FEEDING SYSTEM 10 - 5... -

Page 132: Bypass Tray

(SOL2) is turned OFF to stop the bypass pickup roller and bypass feed roller, and the bypass pickup roller returns to its original position. T.B.D. Fig. 10-5 e-STUDIO163/203 PAPER FEEDING SYSTEM December 2005 © TOSHIBA TEC 10 - 6... -

Page 133: General Operation

The paper stops at the registration roller and the leading edge of the paper turns ON the registration sensor (S4). • The registration clutch (CLT1) is turned ON and the paper aligned with the registration roller is trans- ported to the transfer unit. December 2005 © TOSHIBA TEC e-STUDIO163/203 PAPER FEEDING SYSTEM 10 - 7... -

Page 134: Disassembly And Replacement

Remove 2 screws, and take off the bypass unit by lifting it up. Note: When installing the bypass unit, place the guide behind the transfer unit. Bypass unit Fig. 10-7 e-STUDIO163/203 PAPER FEEDING SYSTEM December 2005 © TOSHIBA TEC 10 - 8... - Page 135 Hold the tray straight up, slide its front and rear arms to the cutout portion of the tray to Bypass tray release them, and then take off the bypass tray. Fig. 10-10 December 2005 © TOSHIBA TEC e-STUDIO163/203 PAPER FEEDING SYSTEM 10 - 9...

- Page 136 Remove 1 screw on the bottom of the bypass separation pad unit, and take off the cover. Cover Fig. 10-12 Release 2 latches and take off the bypass separation pad. Bypass separation pad Fig. 10-13 e-STUDIO163/203 PAPER FEEDING SYSTEM December 2005 © TOSHIBA TEC 10 - 10...

- Page 137 Clip Bypass roller unit Note: When installing the bypass roller unit, insert Coupling the shaft into the bushing and the coupling on the rear side. Shaft Fig. 10-16 December 2005 © TOSHIBA TEC e-STUDIO163/203 PAPER FEEDING SYSTEM 10 - 11...

- Page 138 P.10-11 "[D] Bypass roller unit" Bypass feed roller Remove 1 clip. Then pull out the shaft and remove 1 pin. Take off the bypass feed roller. Shaft Clip Fig. 10-18 e-STUDIO163/203 PAPER FEEDING SYSTEM December 2005 © TOSHIBA TEC 10 - 12...

- Page 139 Release 2 latches and take off the bypass sensor. Bracket Bypass sensor Fig. 10-20 [H] Bypass pickup solenoid (SOL2) Take off the bypass unit. P.10-8 "[A] Bypass unit" Remove 1 screw. Bypass unit Fig. 10-21 December 2005 © TOSHIBA TEC e-STUDIO163/203 PAPER FEEDING SYSTEM 10 - 13...

- Page 140 Then take off the 2 gears and the bracket. Gear Gear Bracket Bushing E-ring Fig. 10-23 Remove 1 E-ring, and take off the bypass pickup clutch with its shaft. E-ring Bypass pickup clutch Fig. 10-24 e-STUDIO163/203 PAPER FEEDING SYSTEM December 2005 © TOSHIBA TEC 10 - 14...

- Page 141 Remove 1 E-ring, and take off the bypass feed clutch. E-ring Bypass feed clutch Fig. 10-26 Remove the gear, spring, cover and cap. Cover Spring Gear Fig. 10-27 December 2005 © TOSHIBA TEC e-STUDIO163/203 PAPER FEEDING SYSTEM 10 - 15...

- Page 142 Bracket bracket. Connector Fig. 10-29 Release 2 latches and take off the paper empty sensor. Bracket Paper empty sensor Fig. 10-30 e-STUDIO163/203 PAPER FEEDING SYSTEM December 2005 © TOSHIBA TEC 10 - 16...

- Page 143 3. Remove 1 screw and take off the dump heater cover. Dump heater cover Fig. 10-32 4. Take off 2 pickup rollers by releasing 2 latches each. Pickup roller Fig. 10-33 December 2005 © TOSHIBA TEC e-STUDIO163/203 PAPER FEEDING SYSTEM 10 - 17...

- Page 144 Take off the registration roller clutch. P.10-18 "[L] Registration roller clutch (CLT1)" Disconnect 1 connector, remove 1 screw, and then take off the pickup solenoid. Connector Pickup solenoid Fig. 10-36 e-STUDIO163/203 PAPER FEEDING SYSTEM December 2005 © TOSHIBA TEC 10 - 18...

- Page 145 Remove 1 E-ring, 1 clip, and take off 1 gear and the registration roller (rubber) while slid- ing them to the front side. Registration roller (rubber) Fig. 10-39 December 2005 © TOSHIBA TEC e-STUDIO163/203 PAPER FEEDING SYSTEM 10 - 19...

- Page 146 Registration roller (metal) Fig. 10-41 Remove 1 E-ring, 1 bushing and then take off 1 pin and 1 gear. E-ring Gear Bushing Registration roller (metal) Fig. 10-42 e-STUDIO163/203 PAPER FEEDING SYSTEM December 2005 © TOSHIBA TEC 10 - 20...

- Page 147 Feed gear unit Connector Gear-A Fig. 10-43 Remove 1 screw and take off the pickup solenoid from the feed gear unit. Pickup solenoid Feed gear unit Fig. 10-44 December 2005 © TOSHIBA TEC e-STUDIO163/203 PAPER FEEDING SYSTEM 10 - 21...

- Page 148 PAPER FEEDING SYSTEM December 2005 © TOSHIBA TEC 10 - 22...

-

Page 149: Drum Related Section

Main charger Recovery blade Drum thermistor Post-Transfer guide Exhaust fan Separation charger Transfer charger Transfer guide roller Pre-Transfer guide Toner cartridge installation switch Ozone filter Drum Fig. 11-1 December 2005 © TOSHIBA TEC e-STUDIO163/203 DRUM RELATED SECTION 11 - 1... -

Page 150: Configuration

Transfer unit Transfer/Separation charger Transfer charger wire PM parts Separation charger wire PM parts Exhaust fan (M6) Ozone filter PM parts Transport guide Temperature/humidity sensor (S3) Switching regulator (PS) e-STUDIO163/203 DRUM RELATED SECTION December 2005 © TOSHIBA TEC 11 - 2... -

Page 151: Functions

Therefore, the needle electrode enables to reduce the ozone amount. Main charger Needle electrode Charge Fig. 11-2 December 2005 © TOSHIBA TEC e-STUDIO163/203 DRUM RELATED SECTION 11 - 3... - Page 152 Thus the main charger grid, transfer/separation charger, transfer guide bias, developer bias, laser output and auto-toner output are controlled to be at their optimum states. e-STUDIO163/203 DRUM RELATED SECTION December 2005 © TOSHIBA TEC 11 - 4...

-

Page 153: High-Voltage Output Control Circuit

Developer Magnetic roller Developer HVTM-0 Transfer HVTAC-0 Transfer charger bias HVTT-0 ASIC Separation HVTSP-0 Separation charger bias HVTGB-0 Transfer guide Transfer guide HVSDWN-0 bias Leakage detection Fig. 11-3 December 2005 © TOSHIBA TEC e-STUDIO163/203 DRUM RELATED SECTION 11 - 5... -

Page 154: Description Of Operation

High-voltage generation circuit leakage detection signal (HVSDWN-0): This signal is for leakage detection of the high-voltage generation circuit. This signal becomes "L" level at the occurrence of such an abnormality. e-STUDIO163/203 DRUM RELATED SECTION December 2005 © TOSHIBA TEC 11 - 6... -

Page 155: Drum Temperature Detection Circuit

The drum thermistor is a device whose resistance decreases as the temperature rises; thus, the volt- age input to the A/D converter becomes smaller along with the rise of the temperature. MAIN board Digital data DRTH-1A converter Drum thermistor Fig. 11-4 December 2005 © TOSHIBA TEC e-STUDIO163/203 DRUM RELATED SECTION 11 - 7... -

Page 156: Temperature/Humidity Detection Circuit

SoC. The higher the temperature or the humidity is, the higher the output voltage of this sensor becomes. MAIN board Temperature/ humidity sensor TEM-1A (Temp) Digital data converter HMS-1A (Hum) Fig. 11-5 e-STUDIO163/203 DRUM RELATED SECTION December 2005 © TOSHIBA TEC 11 - 8... -

Page 157: Disassembly And Replacement

Note: When installing the process unit, make sure that the connector (harness) is not caught under the developer unit. Process unit Fig. 11-6 December 2005 © TOSHIBA TEC e-STUDIO163/203 DRUM RELATED SECTION 11 - 9... - Page 158 Harness tact the gears and harness of the process unit front cover each other. Process unit front cover Fig. 11-8 e-STUDIO163/203 DRUM RELATED SECTION December 2005 © TOSHIBA TEC 11 - 10...

- Page 159 Release 1 latch and take off the discharge LED unit. Note: Be careful not to touch or scratch the drum surface at this time. Discharge LED unit Latch Fig. 11-11 December 2005 © TOSHIBA TEC e-STUDIO163/203 DRUM RELATED SECTION 11 - 11...

- Page 160 P.11-12 "[D] Main charger" Remove the spring and take off the main Main charger grid charger grid. Note: Do not touch the mesh area of the grid. Spring Fig. 11-14 e-STUDIO163/203 DRUM RELATED SECTION December 2005 © TOSHIBA TEC 11 - 12...

- Page 161 Needle electrode Notes: 1. Do not touch the needle electrode directly with bare hands. 2. Make sure not to hold or bend the needle Terminal electrode. Spring Fig. 11-17 December 2005 © TOSHIBA TEC e-STUDIO163/203 DRUM RELATED SECTION 11 - 13...

- Page 162 Remove 2 screws and take off the drum Drum cleaning blade cleaning blade. Note: Be careful not to touch or scratch the edge of the drum cleaning blade. Fig. 11-19 e-STUDIO163/203 DRUM RELATED SECTION December 2005 © TOSHIBA TEC 11 - 14...

- Page 163 Take off 2 drum separation finger units. P.11-15 "[J] Drum separation finger" Recovery blade Remove 2 screws, and take off the whole recovery blade with the bracket. Fig. 11-22 December 2005 © TOSHIBA TEC e-STUDIO163/203 DRUM RELATED SECTION 11 - 15...

- Page 164 Release 2 latches and take off the terminal cover on the front side. Release 1 latch and take off the terminal Terminal cover cover on the rear side. Fig. 11-25 e-STUDIO163/203 DRUM RELATED SECTION December 2005 © TOSHIBA TEC 11 - 16...

- Page 165 When taking off the transfer unit, take off the process unit first to prevent the drum from light. Open off the ADU cover. Take off the transfer unit while pulling the Transfer unit lever. Fig. 11-27 Disconnect 1 connector. Connector Fig. 11-28 December 2005 © TOSHIBA TEC e-STUDIO163/203 DRUM RELATED SECTION 11 - 17...

- Page 166 Release 1 latch and take off the rear side guide. Guide Fig. 11-30 Remove 1 screw and take off the ozone filter cover. Ozone filter Take off the ozone filter. Ozone filter cover Fig. 11-31 e-STUDIO163/203 DRUM RELATED SECTION December 2005 © TOSHIBA TEC 11 - 18...

- Page 167 Take off the transfer/separation charger. P.11-16 "[L] Transfer/Separation charger" Post transfer guide Remove 1 screw and take off the post trans- fer guide. Fig. 11-33 Remove 4 screws. Fig. 11-34 December 2005 © TOSHIBA TEC e-STUDIO163/203 DRUM RELATED SECTION 11 - 19...

- Page 168 [Q] Temperature/humidity sensor (S3) Take off the left cover. P.2-19 "[C] Left cover" Disconnect 1 connector, remove 1 screw, and then take off the temperature/humidity Temperature/ sensor. Humidity sensor Fig. 11-37 e-STUDIO163/203 DRUM RELATED SECTION December 2005 © TOSHIBA TEC 11 - 20...

-

Page 169: Development System

The developer unit is driven by the main motor (M3) to rotate the mixers and the developer sleeve. T.B.D. Fig. 12-1 December 2005 © TOSHIBA TEC e-STUDIO163/203 DEVELOPMENT SYSTEM 12 - 1... -

Page 170: Construction

Auto-toner sensor Drum thermistor THMS4 Recovered toner supply mechanism (Toner recycling auger) Toner cartridge Toner cartridge PC board CTRG Toner cartridge interface PC board CTIF Toner motor M2 (Ch. 9) e-STUDIO163/203 DEVELOPMENT SYSTEM December 2005 © TOSHIBA TEC 12 - 2... -

Page 171: Functions

(M2). The toner cartridge in this equipment mounts the toner cartridge PC board (CTRG), and the data identifying genuine TOSHIBA toner cartridges and the counter values determining that the car- tridge is nearly empty are written in this board. These data are read out by the toner cartridge interface PC board (CTIF) in this equipment, and data related to toner supply are also written in the toner car- tridge PC board (CTRG). -

Page 172: Functions Of The Toner Cartridge Pc Board (Ctrg)

The toner cartridge in this equipment mounts the toner cartridge PC board (CTRG). An IC chip is embedded in this board, and the data identifying genuine TOSHIBA toner cartridge and thresholds determining that the cartridge is nearly empty are written in this chip. -

Page 173: Recovered Toner Supply Mechanism

When the value of the toner near-empty status threshold setting (08-****) is set at “3”, neither of the car- tridge detecting function (including detection of the use of a genuine TOSHIBA cartridge) and the toner remaining check function is enabled. -

Page 174: Toner Motor Control Circuit

The toner motor is driven when the ON/OFF signal (TNRMTON-0) output from the ASIC becomes “L” level. MAIN board +24VD Toner motor ASIC TNRMTON-0 Fig. 12-3 e-STUDIO163/203 DEVELOPMENT SYSTEM December 2005 © TOSHIBA TEC 12 - 6... -

Page 175: Auto-Toner Circuit

ASIC Toner cartridge Recovered toner supply mechanism Toner Toner motor Main Recovered motor toner converter Toner density signal Auto-toner sensor Control voltage signal Developer material converter Fig. 12-4 December 2005 © TOSHIBA TEC e-STUDIO163/203 DEVELOPMENT SYSTEM 12 - 7... -

Page 176: Function Of Auto-Toner Sensor

The toner motor is driven. → Toner is supplied from toner cartridge. → The auto-toner sensor output changes. → The toner density returns to normal value. → The toner-empty state is cleared. e-STUDIO163/203 DEVELOPMENT SYSTEM December 2005 © TOSHIBA TEC 12 - 8... - Page 177 The ratio of the toner against the carrier in the developer material increases. → The magnetic resistance increases. → The detection output decreases. → The auto-toner output V decreases. December 2005 © TOSHIBA TEC e-STUDIO163/203 DEVELOPMENT SYSTEM 12 - 9...

-

Page 178: Disassembly And Replacement

1. Be careful not to touch or scratch the drum surface at this time. Developer unit Fig. 12-6 2. Do not deform the Guide Mylar by touch- ing this. Guide mylar Fig. 12-7 e-STUDIO163/203 DEVELOPMENT SYSTEM December 2005 © TOSHIBA TEC 12 - 10... - Page 179 Remove the developer material from rear side. Note: When removing the developer material, be careful not to drop the developer material on the gears of the developer unit. Fig. 12-10 December 2005 © TOSHIBA TEC e-STUDIO163/203 DEVELOPMENT SYSTEM 12 - 11...

- Page 180 Auto toner sensor rial" Place the developer unit upside down. Disconnect 1 connector, release 1 latch, and then rotate the auto toner sensor counter- clockwise to take it off. Fig. 12-12 e-STUDIO163/203 DEVELOPMENT SYSTEM December 2005 © TOSHIBA TEC 12 - 12...

- Page 181 Fig. 12-14 Remove 1 screw. Disconnect 1 connector while taking off the recovered toner drive unit. Remove 1 gear. Connector Gear Recovered toner drive unit Fig. 12-15 December 2005 © TOSHIBA TEC e-STUDIO163/203 DEVELOPMENT SYSTEM 12 - 13...

- Page 182 (Mark the position if needed.) When reassembling, match the polarity adjustment lever with the previously marked position on the scale. Polarity adjustment lever Fig. 12-18 e-STUDIO163/203 DEVELOPMENT SYSTEM December 2005 © TOSHIBA TEC 12 - 14...

- Page 183 Fig. 12-19 Remove 1 E-ring and take off the guide roller on the front side. E-ring Guide roller Fig. 12-20 Remove 1 screw and the gear. Gear Fig. 12-21 December 2005 © TOSHIBA TEC e-STUDIO163/203 DEVELOPMENT SYSTEM 12 - 15...

- Page 184 Gear Gear Fig. 12-23 (12) Remove 1 E-ring, 1 pin and 1 pulley. (13) Take off the guide roller on the rear side. Guide roller Pulley E-ring Fig. 12-24 e-STUDIO163/203 DEVELOPMENT SYSTEM December 2005 © TOSHIBA TEC 12 - 16...

- Page 185 (15) Take off the developer sleeve. Developer sleeve Fig. 12-26 [G] Mixer Take off the developer sleeve. P.12-13 "[F] Guide roller / Developer sleeve" Doctor sleeve Take off the doctor sleeve. Fig. 12-27 December 2005 © TOSHIBA TEC e-STUDIO163/203 DEVELOPMENT SYSTEM 12 - 17...

- Page 186 Remove 2 bushings and 2 oil seals from the holder. (Replacement of Oil seal: P.12-20 "[H] Oil seal Replacement of Oil Seal") Bushing Fig. 12-29 Take off the mixers-2 and -3. Mixer-3 Mixer-2 Fig. 12-30 e-STUDIO163/203 DEVELOPMENT SYSTEM December 2005 © TOSHIBA TEC 12 - 18...

- Page 187 Remove the bushing and oil seal. End section of mixer-1 (Replacement of Oil seal: P.12-20 "[H] Replacement of Oil Seal") Bushing Oil seal Fig. 12-32 (10) Take off the mixer-1. Mixer-1 Fig. 12-33 December 2005 © TOSHIBA TEC e-STUDIO163/203 DEVELOPMENT SYSTEM 12 - 19...

- Page 188 Apply the grease (Alvania No.2; amount of 2 rice grains) on entire surface of the oil seal evenly. Grease Note: Wipe off the excessive grease. Oil seal Fig. 12-35 e-STUDIO163/203 DEVELOPMENT SYSTEM December 2005 © TOSHIBA TEC 12 - 20...

-

Page 189: Fuser / Exit Unit

Other than the above rollers, the fuser/exit unit consists of the heater lamps, separation fingers, ther- mistors (THMS1/THMS2/THMS3), fuser thermostat (THMO1), paper transport guide and the exit sen- sor which detects the status of the paper transport, etc. T.B.D. Fig. 13-1 December 2005 © TOSHIBA TEC e-STUDIO163/203 FUSER / EXIT UNIT 13 - 1... -

Page 190: Configurations

Fluoro-plastic coated roller (φ30) Periodic replacement part Heater lamp (LAMP1, LAMP2) 564W+564W Thermistor (THM1, 2, 3) Thermostat (THMO1) Non-contact type (190ºC) Separation finger Periodic replacement part Exit roller e-STUDIO163/203 FUSER / EXIT UNIT December 2005 © TOSHIBA TEC 13 - 2... -

Page 191: Functions

Five separation fingers are installed above the fuser roller, in order to separate paper adhereing to each roller. 9) Exit roller The exit roller, which transports the paper to the inner tray, is driven by the main motor (M3). December 2005 © TOSHIBA TEC e-STUDIO163/203 FUSER / EXIT UNIT 13 - 3... -

Page 192: Operation

And if printing is not performed within another specified period of time after the equipment has entered the Auto Power Save Mode, the equipment then enters the Auto Shut Off mode to turn OFF the 2 heater lamps. e-STUDIO163/203 FUSER / EXIT UNIT December 2005 © TOSHIBA TEC 13 - 4... -

Page 193: Fuser Unit Control Circuit

Main switch Center heater lamp control signal converter Side heater lamp control signal AC line DC line Reset signal Forcible power-off circuit MAIN board Fig. 13-2 December 2005 © TOSHIBA TEC e-STUDIO163/203 FUSER / EXIT UNIT 13 - 5... -

Page 194: Temperature Detection Section

For this reason, the edge thermistor detects the temperature of the end of the fuser roller. When this thermistor detects the abnormal temperature (225ºC), the heater lamp is turned OFF regardless of the temperature of the area where the paper passes on. e-STUDIO163/203 FUSER / EXIT UNIT December 2005 © TOSHIBA TEC 13 - 6... - Page 195 ( Heater lamp OFF ) Warming-up Ready During printing Auto °C Shut Off Mode Fixed time ( 08-XXX ) Temperature of fuser roller Heater lamp Fig. 13-4 December 2005 © TOSHIBA TEC e-STUDIO163/203 FUSER / EXIT UNIT 13 - 7...

- Page 196 OFF again. After confirming that it is the fuser unit abnormality, correct the abnormality and reset the counter value (08-400) to “0” to start up the equipment normally. e-STUDIO163/203 FUSER / EXIT UNIT December 2005 © TOSHIBA TEC 13 - 8...

- Page 197 MAIN circuit abnormality or thermistor abnormality. The thermistors automatically turn OFF the power when the temperature of heater lamp exceeds the specified temperature. Center thermistor MTH-1A Side thermistor STH-1A ADCD0 converter ETH-1A Edge thermistor Fig. 13-5 December 2005 © TOSHIBA TEC e-STUDIO163/203 FUSER / EXIT UNIT 13 - 9...

- Page 198 T.B.D°C or above In Self-diagnosis T.B.D°C or above On usual T.B.D Mode T.B.D°C or above The figures in the “priority” section denote the priority of error checking. e-STUDIO163/203 FUSER / EXIT UNIT December 2005 © TOSHIBA TEC 13 - 10...

-

Page 199: Disassembly And Replacement

P.13-11 "[A] Fuser/Paper exit unit" Spring Remove 1 spring and 2 screws. Separate the pressure roller unit from the Pressure roller unit fuser roller unit. Fuser roller unit Fig. 13-7 December 2005 © TOSHIBA TEC e-STUDIO163/203 FUSER / EXIT UNIT 13 - 11... - Page 200 P.13-11 "[B] Pressure roller unit / Fuser roller unit" Release the latch and take off the gear-A. Gear-A Fig. 13-8 Take off the gear-B. Gear-B Fig. 13-9 Remove the bracket. Bracket Fig. 13-10 e-STUDIO163/203 FUSER / EXIT UNIT December 2005 © TOSHIBA TEC 13 - 12...

- Page 201 Open the guide and slide it to the front side. Then slide its rear hinge downward. Note: Keep the guide being slid to the front side during the steps (3) and (4). Guide Fig. 13-13 December 2005 © TOSHIBA TEC e-STUDIO163/203 FUSER / EXIT UNIT 13 - 13...

- Page 202 Guide Spring Fig. 13-15 Disconnect 1 connector, release 2 latches, and then take off the exit sensor. Exit sensor Connector Fig. 13-16 e-STUDIO163/203 FUSER / EXIT UNIT December 2005 © TOSHIBA TEC 13 - 14...

- Page 203 Take off the fuser roller unit. P.13-11 "[B] Pressure roller unit / Fuser roller unit" Remove 2 screws on each terminal of both center heater lamp and side heater lamp. Fig. 13-19 December 2005 © TOSHIBA TEC e-STUDIO163/203 FUSER / EXIT UNIT 13 - 15...

- Page 204 • Do not apply force onto the roller because Fig. 13-22 it may be deformed. e-STUDIO163/203 FUSER / EXIT UNIT December 2005 © TOSHIBA TEC 13 - 16...

- Page 205 Fuser unit entrance guide Fig. 13-24 Remove 2 springs. Note: When installing the spring, be sure to hang the spring on the upper hook. Spring Fig. 13-25 December 2005 © TOSHIBA TEC e-STUDIO163/203 FUSER / EXIT UNIT 13 - 17...

- Page 206 Take off 2 bushings and then take off the pressure roller. Note: Pressure roller Do not drop the pressure roller when you lift Bushing it up because it is quite heavy. Bushing Fig. 13-27 e-STUDIO163/203 FUSER / EXIT UNIT December 2005 © TOSHIBA TEC 13 - 18...

- Page 207 Fig. 13-29 Fuser thermostat (THMO1) Take off the fuser roller. P.13-16 "[G] Fuser roller" Remove 2 screws and take off the fuser ther- mostat. Fuser thermostat Fig. 13-30 December 2005 © TOSHIBA TEC e-STUDIO163/203 FUSER / EXIT UNIT 13 - 19...

- Page 208 FUSER / EXIT UNIT December 2005 © TOSHIBA TEC 13 - 20...

-

Page 209: Power Supply Unit

+24V voltage which is generated by the DC output circuit. For details of the high-volt- age output circuit, see the following. P.11-5 "11.4 High-Voltage Output Control Circuit" December 2005 © TOSHIBA TEC e-STUDIO163/203 POWER SUPPLY UNIT 14 - 1... -

Page 210: Operation Of Dc Output Circuit

If the protection circuit is activated (except when the fuse is blown), repair the causes such as short-circuiting. Turn ON the power again 1 minute later to clear the overcurrent protection. e-STUDIO163/203 POWER SUPPLY UNIT December 2005 © TOSHIBA TEC 14 - 2... -

Page 211: Output Channel

The following is an output channel for the cover switch line. 1) +24V +24VD: CN104 Pins 21 and 22 Output to the MAIN board, PFU (via MAIN board) December 2005 © TOSHIBA TEC e-STUDIO163/203 POWER SUPPLY UNIT 14 - 3... -

Page 212: Fuse

Bypass pickup solenoid SOL2 Contact image sensor unit +24VDF F202: T.B.D +24VD MAIN board Toner motor F201: T.B.D Main motor Exhaust fan Auto-toner sensor Discharge LED Coin controller e-STUDIO163/203 POWER SUPPLY UNIT December 2005 © TOSHIBA TEC 14 - 4... -

Page 213: Configuration Of Power Supply Unit

14.5 Configuration of Power Supply Unit CN104 CN113 CN105 Regulator F102 CN101 CN106 Fig. 14-1 December 2005 © TOSHIBA TEC e-STUDIO163/203 POWER SUPPLY UNIT 14 - 5... -

Page 214: Power Supply Sequence

0 ms or higher +24V, +24VDF ( Linked with main switch ) OPEN Cover opening/closing CLOSE interlock switch 200 ms or lower +24VD ( Linked with cover switch ) Fig. 14-2 e-STUDIO163/203 POWER SUPPLY UNIT December 2005 © TOSHIBA TEC 14 - 6... -

Page 215: Ac Wire Harness

14.7 AC Wire Harness Fig. 14-3 December 2005 © TOSHIBA TEC e-STUDIO163/203 POWER SUPPLY UNIT 14 - 7... - Page 216 POWER SUPPLY UNIT December 2005 © TOSHIBA TEC 14 - 8...

-

Page 217: Pc Boards

15. PC BOARDS 1) PWA-F-MAIN Fig. 15-1 2) PWA-F-SRAM Fig. 15-2 December 2005 © TOSHIBA TEC e-STUDIO163/203 PC BOARDS 15 - 1... - Page 218 3) PWA-F-LDR Fig. 15-3 4) PWA-F-SNS Fig. 15-4 5) PWA-F-LPNL Fig. 15-5 e-STUDIO163/203 PC BOARDS December 2005 © TOSHIBA TEC 15 - 2...

- Page 219 6) PWA-F-FUS Fig. 15-6 December 2005 © TOSHIBA TEC e-STUDIO163/203 PC BOARDS 15 - 3...

- Page 220 PC BOARDS December 2005 © TOSHIBA TEC 15 - 4...

Need help?

Do you have a question about the e-STUDIO163 and is the answer not in the manual?

Questions and answers