KMC Controls FlexStat Operation Manual

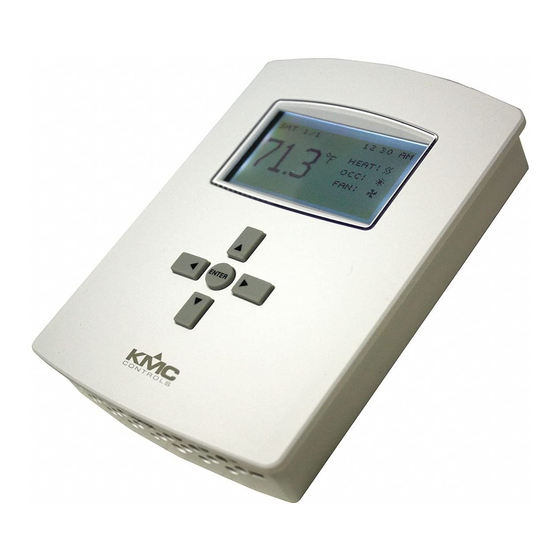

Bacnet programmable thermostats

Hide thumbs

Also See for FlexStat:

- Application manual (60 pages) ,

- Operation manual (46 pages) ,

- Quick reference manual (2 pages)

Table of Contents

Advertisement

Operation Guide

Contents

Overview ................................................................ 3

Applications and Installation ................................... 3

Operation (Basic) .................................................... 4

Home, Main Menu, and Override Screens .......... 4

Navigation .......................................................... 4

Main Menu and Settings ...................................... 4

Room Temp. Setpoint Adjustment ....................... 4

H/C, Fan, Occupancy, and Override ................... 4

Configuration (Initial Setup) ................................... 5

Main Menu Overview ......................................... 5

About the FlexStat ............................................... 5

Advanced Menu .................................................. 6

(Advanced) Application Options ...................... 6

(Advanced) CB (Control Basic) Programs ......... 7

(Advanced) BACnet Communications .............. 8

(Advanced) Date/Time ..................................... 8

(Advanced) BACnet Device Properties ............. 9

(Advanced) Inputs ............................................ 9

(Advanced) Temp. Setpoint Limits .................... 9

(Advanced) Motion Sensor ............................... 9

FlexStat

BACnet Programmable Thermostats

Specifications, design, and operation are subject to change without notice.

(Advanced) Trend Logs ................................... 11

(Advanced) Test .............................................. 11

(Advanced) User Interface (UI) Modes .......... 12

Alarms ............................................................... 13

Date/Time ......................................................... 13

Schedules .......................................................... 14

Setpoints ........................................................... 15

System Setup ..................................................... 15

Trend Viewer ..................................................... 15

Resetting the FlexStat ............................................ 16

Types of Reset .................................................... 16

Warm and Cold Starts ....................................... 16

Restore Factory ................................................. 17

Network Connection ............................................. 18

BACnet MS/TP Network Communication ...... 18

PC Data Port Connection ............................... 18

Maintenance ......................................................... 19

Firmware Upgrade ................................................ 19

Programming (Custom) ......................................... 19

1

FlexStat

™

Operation Guide, Rev. K

Advertisement

Table of Contents

Troubleshooting

Subscribe to Our Youtube Channel

Summary of Contents for KMC Controls FlexStat

-

Page 1: Table Of Contents

System Setup ............. 15 Configuration (Initial Setup) ........5 Trend Viewer ............. 15 Main Menu Overview ......... 5 About the FlexStat ..........5 Resetting the FlexStat ..........16 Advanced Menu ..........6 Types of Reset ............ 16 (Advanced) Application Options ...... 6 Warm and Cold Starts ........ - Page 2 Upgrading Firmware Issues ....... 25 KMD-5576 Communication Issues ....20 Firmware Upgrade Failures ......25 MS/TP Network Communication Issues ..20 FlexStat Malfunctions After Upgrade ..... 25 Cover, Display, and Reset Issues ......21 Wiring Issues ............. 26 Cover Binds on Backplate ......21 Installation Wiring Considerations ....

-

Page 3: Overview

(141) resistor switch settings, see the relevant model’s Installation Guide. For extended information about wiring and sequences for specific applications, see the FlexStat Application Guide. 1.125 (28.6) CAUTION To avoid damage from ground loops and other... -

Page 4: Operation (Basic)

HEAT or COOL will show (and be animated when From the Home (temperature display) screen, press there is an active command), depending on the cur- the Right arrow button to enter the Main Menu. You rent mode. This can also be turned OFF. may need to enter a password to change any settings. To override these modes from the Home (tempera- ture display) screen, press the Left arrow button. Press Up or Down to get to the desired line and then Enter (twice) to edit the mode setting. Press Left to exit to Home. FlexStat Operation Guide, Rev. K... -

Page 5: Configuration (Initial Setup)

NOTE: Menus shown in this document reflect firmware version R1.3.0.4 or later. Actual ABOUT FLEXSTAT context-sensitive screens are dependent FW: FLEXSTAT on firmware version, FlexStat model, and VERSION: R1.3.0.0 BUILT: DEC 11 2009 @13:55:07 options selected. ASV: BAC_1xx63 R1.3.0.0 +6... -

Page 6: Advanced Menu

Advanced Menu The type of application (as well as the model of ADVANCED FlexStat) affects the context-sensitive options under APPLICATION CB PROGRAMS Additional Setup. COMMUNICATION DATE/TIME Auxiliary Heat (Heat Pump Only) DEVICE INPUTS AUX HEAT SETUP LIMITS AUX HEAT: COMP LOCKOUT DELAY (MINS): 60 The Advanced Menu displays various submenus. -

Page 7: (Advanced) Cb (Control Basic) Programs

Valve Setup Programs menu (or BACstage). VALVE SETUP UPDATE MANAGER TYPE: 2–POSITION PROGRAM CONFIG ERROR ACTION: NRM OPEN ENABLE FACTORY: ENABLE CUSTOM: NO EDIT CB PROGRAMS DONE NOTE: Customized programs are the responsibility See also (Advanced) Motion Sensor on page of the user. KMC Controls does not provide support for such programs. FlexStat Operation Guide, Rev. K... -

Page 8: (Advanced) Bacnet Communications

UTC OFFSET: 300 and those to the east shall be negative DST ENABLE: TRUE values.” The value is in minutes, not hours. DST AUTO: TRUE DST START: >2ND SUN MAR 2:00 AM To enter date and time information, press: 1. Up/Down to move among entries. 2. Enter to select. 3. Right/Left to move among value fields. 4. Up/Down to increment/decrement value. For areas that observe Daylight Saving Time, select True/On for DST ENABLE. If the FlexStat is used in a BACnet network with UTC (Coordinated Universal Time) synchronization (via broadcasting or addressing a single thermostat) set the UTC Offset value. The UTC Offset value is in minutes and corresponds to the distance of the local time zone to the zero degree meridian. In stand-alone operation or networks that do not have UTC broad- casts, setting this value is not necessary. FlexStat Operation Guide, Rev. K... -

Page 9: (Advanced) Bacnet Device Properties

RESTORE FACTORY: NO To set the BACnet device instance, name, and To set the minimum and maximum allowed user/ location, press: operator setpoint values, press: 1. Up/Down to move among entries. 1. Up/Down to move among entries. 2. Enter to select. 2. Enter to select. The FlexStat can also be restarted or restored to 3. Right/Left to move among value fields. factory defaults from this menu. See Resetting the 4. Up/Down to increment/decrement value. FlexStat on page 16 for more information about that function. (Advanced) Motion Sensor... -

Page 10: (Advanced) Security Levels And Passwords

FAN OCC/UNOCC: OPER To lock the buttons after configuration is complete (and disable further changes), select Locked UI Access to the Main Menu, Setpoint Adjust, and mode. See (Advanced) User Interface (UI) Modes on System/Occupancy/Fan settings have a default page password level of User. This level can be changed for each function to None, Operator, or Administrator For additional physical security and protection through the Access Levels menu. Passwords are set from vandalism, install the FlexStat inside a third- in the Passwords menu. party locking thermostat guard/cover (but proper airflow must be maintained). Any person can view the display but might not be able to change any settings without logging in with one of the three levels of passwords: Menu Items Access Levels Menus User Operator Administrator • None (Level “0”): No password is required (everyone has access). (For example, anyone can... -

Page 11: (Advanced) Trend Logs

APR17 7:27PM, 82.3 NOTE: Space temperature (AI1) is the default trend log #1. If AI2 is configured for discharge air temperature, that will become the default trend log #2. See Sensor Setup on page To set the desired object to track, press: 1. Up/Down to move among entries. 2. Enter to select. The trend log buffer may be viewed by scrolling down and selecting View Log Buffer. The buffer may also be viewed from the Main Menu by scrolling down to the Trend Viewer (see page 15). NOTE: The BACnet standard for log intervals is hundredths of seconds. The simplified display on the FlexStat converts the value to minutes. However, BACstage and ™ TotalControl do display hundredths of ® seconds but in different ways. For a “10” (minute) interval on a FlexStat display, TotalControl would show “00:10:00.00” (hours:minutes:seconds.hundredths of seconds) and BACstage would show “60000” (hundredths of seconds) instead. NOTE: If applicable to the model, the humidity sensor is AI5 and the motion sensor is BI6, which can also be configured for trend logs. -

Page 12: (Advanced) User Interface (Ui) Modes

Standard mode! Field B NOTE: As additional security against Screen) unauthorized bypass of Hospitality or Locked UI mode from the FlexStat, set (No Field C Screen Exists) at least an Operator level password. See Custom Hospitality mode programming is required (Advanced) Security Levels and Passwords... -

Page 13: Alarms

• Low Limit Alarm (freeze stat)—space temperature is below the adjustable (under Damper Setup) low limit alarm temp for one second (when configured for the economizer option). After a low limit alarm is generated, the fan will not run until after the FlexStat is restarted. See Restart under Resetting the FlexStat on page 16. See also Damper Setup on... -

Page 14: Schedules

Menu.) WEEKDAYS 7:30:00 AM ON To enter upcoming holidays, press: 2: 5:15:00 PM OFF 1. Up/Down to move among entries. 2. Enter to select. 3. Right/Left to move among value fields. [—>] DELETES ENTRY 4. Up/Down to increment/decrement value. To enter weekly schedules for occupied (ON) and unoccupied (OFF) times, press: 1. Right/Left to move among days and Enter to select. 2. Up/Down to move among entries and Enter to select and edit. 3. Right/Left to move among value fields. 4. Up/Down to increment/decrement value. 5. Enter to exit value editing. 6. Left to move back to days or back one page. FlexStat Operation Guide, Rev. K... -

Page 15: Setpoints

3. Up/Down to increment/decrement value. Occupancy Override on this menu is the amount of time (in hours) a manual change in the setpoint (via the Up and Down buttons) will be allowed to over- ride the scheduled setpoint. When the time is set to 0, the override state will last until the next schedule change. NOTE: Occupancy override can also be removed while on the Home screen by pushing the left button, navigating to OCC, hitting Enter twice, and changing ON to OFF. See H/C, Fan, Occupancy, and Override on page FlexStat Operation Guide, Rev. K... -

Page 16: Resetting The Flexstat

Before resetting the FlexStat, manually CB PROGRAMS INSTANCE: 1 COMMUNICATION override equipment as needed. If a large fan DATE/TIME is controlled by the FlexStat, for example, set NAME: FlexStat_101 DEVICE LOCATION: KMC Controls a minimum off time. See Fan Setup on page 6... -

Page 17: Restore Factory

Restore Factory Restore Factory (restoring the FlexStat to the factory CAUTION settings) does the following: After a return to factory defaults, applications are • Clears present values. unconfigured. You must select the desired appli- cation and appropriate settings before connected • Restores the object database/configuration to the equipment will operate properly. (See (Advanced) defaults. -

Page 18: Network Connection

From the FlexStat menus, adjust the device instance or troubleshooting. number, the MAC address, and baud rate from the defaults as necessary. Set the Max Master to the To connect a computer to the port, a means of minimum necessary for the network. See (Advanced) converting the EIA-485 signal to a USB or EIA-232 BACnet Device Properties on page 9 and (Advanced) (formerly RS-232) signal will be needed. For USB, BACnet Communications on page use a KMC KMD-5576 USB Communicator. For EIA-232, use a third-party interface. (See the instruc- NOTE: The current FlexStat MAC address and tions included with those devices and software.) To device instance numbers can be viewed in connect to the PC data port: the About menu. Each BACnet device on a 1. Connect the keyed, flat end of the KMD-5624 network must have a unique MAC address interface cable (included with the KMD-5576) to and device instance. the port on the bottom of the FlexStat. 2. Connect the modular plug of the cable to the interface device that converts the EIA-485 signal from the FlexStat into a USB or EIA-232 signal. 3. Connect the suitable cable from the interface... -

Page 19: Maintenance

To maintain maximum sensitivity of optional built-in light almond motion sensors, occasionally wipe dust or dirt off the HMO-10000W HMO-10000 in lens—but do not use any fluid on the sensor. white HPO-0044 Replacement cover hex screw Firmware Upgrade HTO-1103 FlexStat firmware The existing version of firmware can be viewed from flash upgrade kit (formerly the About the FlexStat screen. (See About the Flex- KMD-5699)* Stat on page Firmware in the FlexStat can be upgraded using a KMD-5567 Network surge PC and an HTO-1103 Firmware Flash Upgrade Kit suppressor available from KMC Controls. (For full upgrade instructions, see the HTO-1103 Installation Guide, KMD-5575 Network repeater/ P/N 913-019-04.) (The old KMD-5699 part number isolator was changed to HTO-1103 in Aug. 2010 to better reflect its “tool” identity.) KMD-5576 EIA-485 to USB... -

Page 20: Troubleshooting

BACnet Communications on page (mixed air temp.) is not configured as “Out Of • See Wiring Issues on page Service.” NOTE: After a low limit alarm is generated, the fan will not run until after the FlexStat is restarted. (See Resetting the FlexStat on page 16.) Alarm, (False) Space Temp. or Humidity •... -

Page 21: Cover, Display, And Reset Issues

• If the display is functioning (e.g. time is updat- ing correctly), but the buttons have no effect NOTE: When installing the cover on the except to turn on the backlight, the FlexStat is in backplate, be sure to not pinch or dislodge Locked UI mode. See (Advanced) User Interface any wiring. -

Page 22: Custom Programming And Web Issues

• Using BACstage or TotalControl, check that the of the user. KMC Controls does not provide input is not configured as “Out Of Service.” support for such programs. • Restore the FlexStat to factory settings (see Reset- • In the FlexStat Application Guide (P/N 913-019- ting the FlexStat on page 16) and reconfigure. 03), carefully REVIEW ALL the information in the Custom Programming section! Motion/Occupancy Sensor Does Not Work • Set programs to autorun and/or check if they • The initial firmware (R.1.0.0.0 and earlier) did not have halted. Review (Advanced) CB (Control... -

Page 23: Temperature Reading Is Incorrect

• Using BACstage or TotalControl, check that • Check that the output is on. AI1 (space temp.) is not configured as “Out Of • See Wiring Issues on page Service.” • See also Fan Does Not Run on page • Check that the FlexStat is NOT mounted on an exterior wall, mounted on or near a large thermal • If Restore Factory has just been performed, see mass (e.g., concrete block wall), blocked from the Note and Cautions in Restore Factory on normal air circulation by obstructions, exposed page to heat sources (e.g., lights, computers, copiers, • If the firmware has just been upgraded, firm- coffee makers) or to sunlight (at any time of the ware for the wrong model type may have been day), exposed to drafts from windows or air installed (e.g., BAC-1xx63 firmware accidentally vents, or exposed to air flow through the conduit installed in a model BAC-1xx36). In the About... -

Page 24: Fan Does Not Run

• Check that the output is on. • Check the fan configuration—see Fan Setup on page • See Wiring Issues on page • Restart the FlexStat. After a low limit alarm is • Restart the FlexStat. generated, the fan will not run until after the • If Restore Factory has just been performed, see FlexStat is restarted. (See Resetting the FlexStat the Note and Cautions in Restore Factory on on page 16.) -

Page 25: Upgrading Firmware Issues

Upgrading Firmware Issues Firmware Upgrade Failures FlexStat Malfunctions After Upgrade • If a message appears that the operation has • Check application configuration. failed, ensure the WD (watch dog) jumper is NOTE: Restoring to the factory defaults and TEMPORARILY removed during the upgrade reconfiguring might be needed if how the process! Reinstall the pin on the left and center FlexStat operates changes. Read all notes... -

Page 26: Wiring Issues

Relay 3 O Ohms (Closed Contact) Dependent on 24 VAC Application) SC 1–3 (Jumper to Common/–/C Relay 2 Turn Device 24 VAC 24 VAC On Manually) Relay 1 Phase/ /R Terminal Voltages and Resistances with FlexStat REMOVED from Backplate FlexStat Operation Guide, Rev. K... -

Page 27: Support

Controls, Inc. All rights reserved. No part of this resources for configuration, publication may be reproduced, transmitted, tran- application, operation, scribed, stored in a retrieval system, or translated programming, upgrading into any language in any form by any means without and much more is avail- the written permission of KMC Controls, Inc. able on the award-winning The material in this document is for information KMC Controls web site purposes only. The contents and the product it (www.kmccontrols.com). describes are subject to change without notice. The collection of FlexStat KMC Controls, Inc. makes no representations or documents won a prestigous warranties with respect to this document. In no event publications award for techni- shall KMC Controls, Inc. be liable for any damages, cal marketing support from direct or incidental, arising out of or related to the the Chicago chapter of the use of this document. Society for Technical Commu- nication in March 2010. FlexStat Operation Guide, Rev. K... -

Page 28: Reference

Reference Acronyms and Abbreviations Common acronyms and abbreviations in FlexStat LCD = liquid crystal display and related documents include: mA = milliamperes amp = amperes MAC = media access control A = amperes max. = maximum AAC = Advanced Application Controller min. = minimum A/C = air conditioning mm = millimeters AC = alternating current MS/TP = master-slave/token-passing AHU = air handling unit NC = normally closed avg. = average NO = normally open AWG = American Wire Gauge pF = picofarad BACnet = Building Automation Control network RA = reverse acting BTL = BACnet Testing Laboratories RH = relative humidity C = Celsius RS = Recommended Standard cfh = cubic feet per hour RTC = real time clock cfm = cubic feet per minute RTU = roof top unit cm = centimeters SPDT = single pole double throw DA = direct acting... -

Page 29: Definitions Of Terms

Roof Top Unit (RTU)—An HVAC unit that is supplied as a package and installed outside of a building. a call for heat, the heat pump pulls heat from a source such as outside air or the ground and puts Router—A device that connects two or more networks it into a space. On a call for cooling, the process is and chooses the best path for data packets. reversed. Unit Ventilator—A type of fan coil unit installed in a Max Master—The highest MAC address a device will window or outside wall that supplies outside air attempt to locate when polling for master devices ventilation in addition to heating and cooling. on the local network. USB (Universal Serial Bus)—A popular, plug-and- MS/TP (Master Slave/Token Passing)—A protocol play, high-speed, serial computer interface. (using the EIA-485 signaling standard) in which master devices can initiate requests for data but UTC (Coordinated Universal Time)—An international slave devices cannot (since slaves can only reply standard for determining time zones. to messages from other devices). KMC advanced application controllers are all MS/TP master devices. FlexStat Operation Guide, Rev. K... -

Page 30: Index

Index Symbols 4 x 4 Handy Box Mounting Plate: 19 Damper Set-Up: 6 Data Port: 18 Date: 8, 13 Abbreviations: 28 Deadband: 15 About the FlexStat: 5 Definitions of Terms: 29 Access Levels, Password: 10 Degrees F or C: 6 Accessories: 19 Delay, Fan: 6, 16 Acronyms: 28 Detector. Motion Sensor Adjustment. Configuration; Override; Setpoint Device Instance: 5, 9, 17, 18 Administrator Password: 10 Device Properties: 9 Advanced Menu: 6 Discharge Air Temperature: 7 Alarms: 6, 7, 13, 20 Display Analog Outputs: 16, 23 Blanking: 15, 21 Application Options: 3, 6, 17 Overview: 4 Application Software Version (ASV): 5 Time-Out: 15 ASV (Application Software Version): 5 Troubleshooting: 21 Auto, Off, Heat, or Cool (System Enable): 15 Auxiliary Heat, Heat Pump: 6 Economizer (Damper): 6 EIA-485: 18 Backlight: 15 EOL (End Of Line) Switches: 20... - Page 31 Sensor. Motion Sensor Off, Auto, Heat, or Cool (System Enable): 15 Offset, Calibration: 9 Jumper, WD: 21 Operation Junction Boxes: 26 Basic: 4 Configuring (Set-Up): 5 Operator Password: 10 KMC Controls: 27 Outage, Power: 16 KMD-5567 Surge Suppressor: 19 Outputs: 16, 23 KMD-5575 Repeater/Isolator: 19 Override: 4, 15 KMD-5576 USB Communicator: 18, 19, 20 KMD-5624 PC Data Port Cable: 19 KMD-5699. HTO-1103 Passwords: 10, 15 PC Data Port: 18 Phasing, Network and Power: 26 Limits: 9, 13 Power Outage/Removal: 16 Locked UI Mode: 12 Programming, Custom: 7, 19, 22 Low Limit Alarm: 6, 13, 20 Pull-Up Resistor Switches: 20, 22 Reference: 28 Reinitialize: 9, 16 Relays: 24 Reset: 9, 16, 21 Resetting/Flashing Display: 21 Restart: 9, 16, 21 Restore: 9, 17 RS-485. EIA-485 FlexStat Operation Guide, Rev. K...

- Page 32 Start (Reset), Cold or Warm: 16 XEE-6000 Series Transformers: 19 Support, Technical: 27 Switches EOL (End of Line): 20 Pull-Up Resistors: 22 System Enable: 15 Setup: 15 Temperature Alarm: 13 Limits: 9 Scale, Selecting: 6 Setpoint: 4, 9, 15 Trend Log: 11 Troubleshooting: 23 Terminals: 3, 21 Terms: 29 Test Menu: 11 Time: 8, 11, 13 KMC Controls Time-Out (Inactivity): 15 19476 Industrial Drive Transformer: 19 Trend Logs PO Box 497 Inputs: 7, 11 New Paris, IN 46553 Intervals: 11 574.831.5250; Fax 574.831.5252 Setup: 11 www.kmccontrols.com Viewer: 15 info@kmccontrols.com Troubleshooting: 20 FlexStat © 2010 KMC Controls, Inc. Operation Guide, Rev. K 913-019-02K...

Need help?

Do you have a question about the FlexStat and is the answer not in the manual?

Questions and answers