KMC Controls FlexStat Application Manual

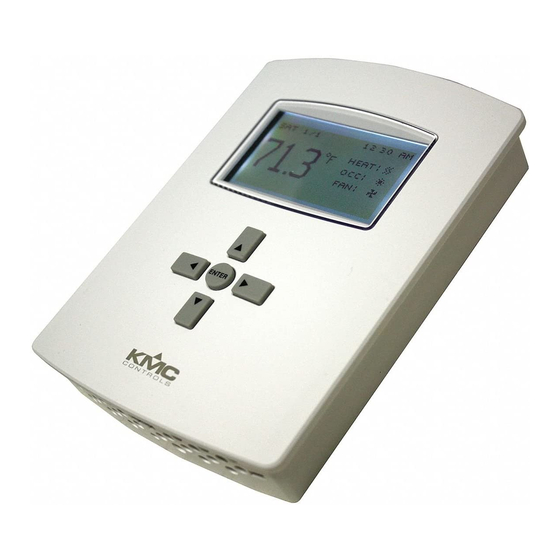

Bacnet programmable thermostats

Hide thumbs

Also See for FlexStat:

- Operation manual (46 pages) ,

- Quick reference manual (2 pages) ,

- Operation manual (46 pages)

Table of Contents

Advertisement

Quick Links

Download this manual

See also:

Operating Manual

Application Guide

Contents

General Information (All Output Configurations) .................. 3

Overview and General Installation ...................................................................4

Mounting Considerations .................................................................................4

Wiring Considerations ......................................................................................4

Inputs and Outputs ..........................................................................................5

Connecting Standard Inputs .........................................................................5

4-20 mA Current Input ................................................................................6

Connecting Outputs .....................................................................................7

Configuration Screens ......................................................................................7

Custom Programming .......................................................................................8

General ........................................................................................................8

Viewing the Control Basic Programs ............................................................8

Modifying the Standard Control Basic Programs ..........................................9

Custom Objects Restrictions/Recommendations ........................................10

Programs During Upgrades and Factory Restores .......................................10

Sample Custom Applications ..........................................................................11

Adding a Remote Temperature Sensor to an Input ......................................11

Calibrating a (Temperature) Sensor ............................................................12

Displaying the Current Setpoint .................................................................13

FlexStat (General)

Displaying Outside Air Temperature ...........................................................14

Displaying Other Objects ...........................................................................14

Mapping Analog Inputs or Outputs as Binary .............................................15

Motion Sensor Applications ........................................................................15

Using Sensors Connected to Other Controllers ..........................................15

2

Custom Web Graphics ....................................................................................17

Hospitality and Locked User Interface Modes ................................................18

Selecting UI Modes ....................................................................................18

Reverting UI Modes ...................................................................................19

Resetting Hospitality Mode Setpoints to Defaults ......................................20

Programming Custom Text for Hospitality Mode ........................................21

Motion/Occupancy Sensor .............................................................................22

Performance and Applications ....................................................................22

Enabling/Disabling the Sensor and Override Time ......................................23

Customizing the Motion Sensor and Override ...........................................23

Adding a Door Contact for Additional Control...........................................24

Adding Remote Motion Sensors .................................................................25

Troubleshooting Motion Sensor Operation .................................................26

Support ..........................................................................................................26

Important Notices ..........................................................................................26

Specifications, design, and operation are subject to change without notice.

1

BACnet Programmable Thermostats

Sensors and DCV ....................................................................................16

FlexStat

™

Application Guide, Rev L

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for KMC Controls FlexStat

-

Page 1: Table Of Contents

Adding a Remote Temperature Sensor to an Input ........11 Support ......................26 Calibrating a (Temperature) Sensor ............12 Displaying the Current Setpoint ..............13 Important Notices ..................26 FlexStat (General) Specifications, design, and operation are subject to change without notice. Application Guide, Rev L... - Page 2 FCU (Fan Coil Unit)—2 or 4 Pipe, Modulating or 2 Position ......30 BAC-1xx36/1xxx36 Common Features ............50 Sequence of Operation (BAC-1xx63/1xxx63) ..........31 BAC-1xx36/1xxx36 Series Applications ............50 FlexStat (All Models) Common Features .............31 AHU (Air Handling Unit) ...............50 Space Temperature Setpoints and Modes ..........31 Staged Heating and Cooling Parameters ..........51 Occupancy Modes ..................32...

-

Page 3: General Information (All Output Configurations)

General Information (All Output Configurations) This document gives wiring details, schematics of sample applications (including bills of material with KMC Controls products), and other related information for the award-winning FlexStat. This document is BAC-1xxxx or BAC-13xxxx divided into: BAC-12xxxx and BAC-14xxxx... -

Page 4: Overview And General Installation

Overview • To prevent excessive voltage drop, use a conductor size that is Wire the FlexStat to the desired equipment (see below for general pur- adequate for the wiring length! Allow plenty of “cushion” to allow pose wiring and switch configuration) and select the relevant program for transient peaks during startup. -

Page 5: Inputs And Outputs

1/4 the proper value. NOTE: ALL the input pull-up resistor switches must be fully latched in the correct positions. See the Connections and Wiring section of the relevant FlexStat Installation Guide. A single incorrect IN3 = IN2 = Ω... -

Page 6: 4-20 Ma Current Input

4–20 mA source. 1. Connect an external 250 ohm resistor from input to ground. (Do not install the resistor inside the FlexStat’s case since the heat generated by the resistor may skew the temperature readings.) The resistor converts the 4–20 mA current input to a 1–5 VDC voltage that can be read by the thermostat’s analog-to-digital converter. -

Page 7: Connecting Outputs

Switched (relay) Common connection (in place of the GND terminal used DATE/TIME with analog outputs). SCHEDULE Do not attach a device that draws current exceeding the FlexStat’s SETPOINTS SYSTEM output capacity: • Maximum output current for individual ANALOG outputs is 20 Navigate the menus and change settings by pressing a combination of mA @ 12 VDC (each). -

Page 8: Custom Programming

FlexStat using BACstage (ver. 2.4.0.26 or later) or To examine the code in a particular FlexStat, copy the code and paste it TotalControl (ver. -

Page 9: Modifying The Standard Control Basic Programs

9. Then programs 2 through 5 are set to NOT autorun, pro- REM PERFORM APPROPRIATE SECTION OF CODE BASED ON grams 6 through 9 are set to autorun, and the FlexStat is restarted. FLEXSTAT CONFIGURATION Program 1 IF APP_MAIN_TYPE = AHU THEN Program 1 interacts with the user interface (display and menus). -

Page 10: Custom Objects Restrictions/Recommendations

BAC-1xxxx Point Definitions file. EDIT CB PROGRAMS DONE NOTE: See also Viewing the Control Basic Programs on page 8. NOTE: Customized programs are the responsibility of the user. KMC Controls does not provide support for such programs. FlexStat (General) Application Guide, Rev L... -

Page 11: Sample Custom Applications

Sample Custom Applications Adding a Remote Temperature Sensor to an Input For space temperature, the FlexStat uses an internal sensor tied to Ana- In BAC-1xxxx FlexStats with only three external inputs, to have the re- log Input #1. However, a thermistor can also be connected to one of the mote sensor’s value shown on the FlexStat display instead of the internal... -

Page 12: Calibrating A (Temperature) Sensor

4. Press the Left button until the home screen appears. NOTE: Body heat can affect the temperature of the FlexStat and/or a To calibrate the space sensor using BACstage or TotalControl, navigate thermometer. -

Page 13: Displaying The Current Setpoint

Displaying the Current Setpoint setpoint present value (AV27) to AV25 and configure it to auto-run: AV25 = AV27 Method 1 3. Restart the FlexStat. WED 11/19 3:20 PM NOTE: If several readings (objects) are configured to show in the field, the field will sequentially show each one. For models with COOL: humidity sensors (which display HUM: xx%), changing AV22’s... -

Page 14: Displaying Outside Air Temperature

OAT to OUTSIDE). Temperature sensor (AI3) present value to AV25 and configure it to auto-run: 3. Restart the FlexStat. AV25 = AI3 NOTE: If several readings (objects) are configured to show in the field, 3. Restart the FlexStat. -

Page 15: Mapping Analog Inputs Or Outputs As Binary

Remote Motion Sensors on page 25. This program will work with a built- in motion sensor enabled or disabled. It will also work with FlexStat models that have no built-in motion sensor. NOTE: Customized programs are the responsibility of the user. KMC Controls does not provide support for such programs. -

Page 16: Co 2 Sensors And Dcv

SAE-10xx must also be configured to match the FlexStat’s typical occupation levels at any given time are usually lower than these input, and the FlexStat’s IN9 pull-up resistor must be set for 0–12 VDC! “worst case” design levels. Hence, such building spaces receive more BAC-13xxxx/14xxxx FlexStats also have the external sensor option, and ventilation than necessary and energy is wasted. -

Page 17: Custom Web Graphics

See the *(8) and *(9) notes in the illustration below. If locking NOTE: See also the Alarms out the FlexStat’s user interface is desired, write to a higher and (Advanced) priority level (i.e., 7/8) from the web interface. If, on the other Trend Logs sections hand, the FlexStat’s user interface should always have priority,... -

Page 18: Hospitality And Locked User Interface Modes

NOTE: As additional security against unauthorized bypass of Pushing Left Button Goes to Field A Screen (Pushing Right Hospitality or Locked UI mode from the FlexStat, set at least Button Goes to an Operator level password. (See the FlexStat Operation... -

Page 19: Reverting Ui Modes

Reverting UI Modes Via the User Interface Via BACstage or TotalControl Reverting to Standard mode can be done through the FlexStat’s user To revert to Standard mode through BACstage or TotalControl: interface with a combination of button presses or by changing MSV9’s 1. -

Page 20: Resetting Hospitality Mode Setpoints To Defaults

Control Basic REM AV27 = UI Setpoint; BV7 = Heat/Cool Mode program section below to determine values to control. • Custom programming can be put into the FlexStat. See the Control RESET_SETPOINT : Basic program section below and... -

Page 21: Programming Custom Text For Hospitality Mode

After custom text and icons have been configured, restart (cold start) • F = Fan (four blades, rotating when animated) the FlexStat to complete the process! NOTE: Firmware earlier than R1.3.0.11 did not support Hospitality • V = Vent (horizontal lines, waving when animated) mode at all, and R1.3.0.11 natively supported only FCU or HPU... -

Page 22: Motion/Occupancy Sensor

Top View Side View (10 m) (10 m) For any FlexStat model with a (passive infrared) motion/occupancy sen- ° 46.5 sor option, be sure to install it where it will have unobstructed view of the most typical traffic area. Do not install it behind curtains or other obstructions. -

Page 23: Enabling/Disabling The Sensor And Override Time

1 hour after motion was FIRST detected. (This functions similarly to REM MOTION SENSOR OCCUPANCY CONTROL OPERATION CODE the override when a setpoint change is detected at the FlexStat’s user ONLY interface.) The timer length of occupancy override is configurable in the LOCALS MOTION_SENSOR System menu. -

Page 24: Adding A Door Contact For Additional Control

(wired to an available input on the FlexStat) allows the room to remain identified as occupied even though no motion is sensed for some time. To use a door contact, copy FlexStat Program 1 into Program 6 and put Additional Code... -

Page 25: Adding Remote Motion Sensors

Situations that would need remote sensors to be connected to the Flex- Menu Configuration Stat include: SCHEDULE NOTE: All Schedules must • Areas too large for adequate coverage by the FlexStat’s built-in sensor. ENTIRE WEEK [MON–SUN] be deleted or set to • Areas with obstructions that block sensor coverage. WEEKDAYS [MON–FRI] ENTIRE WEEK OFF. -

Page 26: Troubleshooting Motion Sensor Operation

Performance and Applications on page 22 about effective range, false detections, and other detection issues. • The FlexStat must be installed where there is a clear view of typical Important Notices occupancy movement (reliable range is out to about 33 feet). Remove or move obstacles. -

Page 27: Bac-1Xx63/1Xxx63 Series (6 Relays And 3 Analog Outputs)

BAC-1xx63/1xxx63 Series (6 Relays and 3 Analog Outputs) This section is specific to the BAC-1xx63/1xxx63 series (with 6 relays and 3 analog outputs). Model numbers with the additional digit (BAC- 12xxxx, 13xxxx, and BAC-14xxxx) have three additional inputs and op- tions for CO sensing (BAC-13xxxx and BAC-14xxxx) and IP network connections (BAC-1xxxxxE). -

Page 28: Bills Of Materials (Bac-1Xx63/1Xxx63)

(internal vs. external) will be used to control DCV sequences. See the NOTE: See also the RTU section for 2-stage options. FlexStat Operation Guide for more details. NOTE: See also... -

Page 29: Rtu (Roof Top Unit)-1 Or 2 Heat And 1 Or 2 Cool

Installation Guide section for detailed drawings and input/ DCV is enabled, IN9 is assumed to be connected to an external SAE-10xx CO sensor. See the FlexStat Operation Guide output connections as well as other important installation information. more details. BAC-1xx63/1xxx63 Series (6 Relays and 3 Analog Outputs) Section... -

Page 30: Fcu (Fan Coil Unit)-2 Or 4 Pipe, Modulating Or 2 Position

NOTE: Humidity and motion/occupancy sensor options are dependent NOTE: See also Sequence of Operation (BAC-1xx63/1xxx63) on page on FlexStat model. Demand Control Ventilation is not available NOTE: See the corresponding BAC-1xx63 or BAC-1xxx63 with FCU applications. Installation Guide section for detailed drawings and input/... -

Page 31: Sequence Of Operation (Bac-1Xx63/1Xxx63)

Occupancy Mode section and when the unit is The first step in setting up an unconfigured FlexStat is to select the units in Standby Mode as described in the Standby Mode section. -

Page 32: Occupancy Modes

The complimentary active setpoint (i.e., cooling, if the to temporarily override the space temperature setpoints for a prede- FlexStat is presently in the heating mode) is then set to the minimum termined period of time. As such, occupancy override may be activated setpoint differential away from the present mode active setpoint (limits during either occupied mode or unoccupied mode. -

Page 33: Optimum Start

Econ Minimum Position is held to zero as ventilation is not needed until Optimum Start scheduled occupancy begins. NOTE: Optimum Start was added in firmware ver. R2.0.0.9. Optimum Stop calculates the time before the scheduled off time that Optimum Start uses historical performance data, outside temperature, the space temperature (without heating or cooling) may be allowed to and length of the unoccupied period to calculate a pre-start time needed “drift”... -

Page 34: Fan Control

• If the unit is configured to have fan status, and if the fan is com- setting (adjustable, for ventilation) or the mixed air temperature PI loop. manded to run and the FlexStat does not see a response on the The mixed air temp loop will modulate from 0 to 100% as the mixed air fan status input within 5 seconds, a fan alarm is generated. -

Page 35: Dcv (Demand Controlled Ventilation)-General Information

(with no venti- mode is set to “heating” during unoccupied mode or is set to “off” in lation), the FlexStat’s Standard or Advanced DCV configuration is any occupancy mode, the outside damper will close. If at any time there recommended. -

Page 36: Dcv-Basic Configuration

Standard while OA Full still optimizing IAQ. DCV Signal Outside Air Component Damper NOTE: See the FlexStat Operation Guide for more information about to OAD “Standard” Position Signal Component configuring DCV. - Page 37 When Space CO2 is between CO2 Base and CO2 Max, the damper shall Ventilation Startup modulate proportionally between OA Area and OA Full. If OA Purge is set to zero (default) and motion/occupancy is sensed during the first 20 minutes immediately following scheduled Occupied When Space CO2 exceeds CO2 Max, the damper shall increase propor- mode, Ventilation mode is set to STARTUP and the fan is called for to tionally above OA Full limited by OA Max (40% default) using the same...

- Page 38 2. If OA is between OA Low Vent (65° F default) and OA High Vent (80° exceeds CO2 Max – 100 ppm, in which case the fan operates with the F default), the OA damper shall be set to 100% open. OA damper at OC Recov Pos as determined above until Space CO2 <= CO2 Max.

-

Page 39: Dehumidification

If “allow clg hum” is set to “no,” then the humidifier valve is automati- cally closed any time the FlexStat is operating in the cooling mode and 3. Night Flush Mode stops when any of the following conditions are... -

Page 40: Staged Heating And Cooling Parameters

The user interface display backlight will illuminate any time any button The method of controlling the heating and cooling valves is based on the is pushed on the FlexStat. It will remain illuminated for 60 seconds (ad- fan configuration: justable). The display is also controllable from Control Basic program- ming. -

Page 41: Hpu (Heat Pump Unit)

FlexStat is presently cooling. If the “allow htg dehum” setpoint, the compressor is de-energized. If the space temp drops option is set to “no” and the FlexStat is presently heating, then the dehu- below the active heating setpoint minus the deadband AND the midification mode is automatically stopped. - Page 42 active cooling setpoint plus one half the deadband AND the first temperature drops 1.0° F (0.56° C) below the Compressor OAT Low Limit. stage of compressor has been off for at least the minimum off The compressor lockout mode is disabled if the outside air temperature time, the first stage of compressor will be energized.

-

Page 43: Fcu (Fan Coil Unit), 2-Pipe

The application is capable of determining whether heating or cooling fully in either heating or cooling mode, all water available flags water is available even in a stand-alone configuration. If the FlexStat are turned off. has a call for heating or cooling greater than 10% and the unit does •... -

Page 44: Fcu (Fan Coil Unit), 4-Pipe

“On,” the valves function in a modulating fashion. Actual re- FCU (Fan Coil Unit), 4-Pipe sponse may vary slightly due to PI action of the control loops, but generally, the heating valve will start to open as the space Fan Control temperature drops below the active heating setpoint and modu- The fan follows the base sequence for fan operation as listed in the Flex-... -

Page 45: Rtu (Roof Top Unit)

setpoint plus the deadband AND the first stage of cooling has been en- RTU (Roof Top Unit) ergized for at least the stage delay AND the second stage of cooling has been off for at least the minimum off time, the second stage of cooling Fan Control will be energized. -

Page 46: Bac-1Xx36/1Xxx36 Series (3 Relays And 6 Analog Outputs)

BAC-1xx36/1xxx36 Series (3 Relays and 6 Analog Outputs) This section is specific to the BAC-1xx36/1xxx36 series (with 6 relays and tions for CO sensing (BAC-13xxxx and BAC-14xxxx) and IP network 3 analog outputs). Model numbers with the additional digit (BAC- connections (BAC-1xxxxxE). -

Page 47: Bills Of Materials (Bac-1Xx36/1Xxx36)

STE-1451 OUTSIDE TEMPERATURE SENSOR vs. external) will be used to control DCV sequences. See the STE-6011 REMOTE TEMPERATURE SENSOR, TYPE II FlexStat Operation Guide for more details. SAE-10xx REMOTE CO SENSOR, SPACE OR DUCT NOTE: Humidity and motion/occupancy sensor options are dependent... - Page 48 REFERENCE KMC PART # PART DESCRIPTION REFERENCE KMC PART # PART DESCRIPTION BAC-1xx36/ BAC-1xx36/ FLEXSTAT BACNET THERMOSTAT, 6 RELAY & 3 ANALOG OUTPUTS FLEXSTAT BACNET THERMOSTAT, 6 RELAY & 3 ANALOG OUTPUTS 1xxx36 1xxx36 REE-3211 MULTI-VOLTAGE CONTROL RELAY, 1.2 VA REE-3211 MULTI-VOLTAGE CONTROL RELAY, 1.2 VA...

-

Page 49: Fcu (Fan Coil Unit)-2 Or 4 Pipe, Modulating

FCU (Fan Coil Unit)—2 or 4 Pipe, Modulating BILL OF MATERIALS: AHU, Modulating Heat and Modulating Cool REFERENCE KMC PART # PART DESCRIPTION BILL OF MATERIALS: FCU, 2-Pipe, Modulating BAC-1xx36/ FLEXSTAT BACNET THERMOSTAT, 6 RELAY & 3 ANALOG OUTPUTS 1xxx36 REFERENCE KMC PART # PART DESCRIPTION REE-3211 MULTI-VOLTAGE CONTROL RELAY, 1.2 VA... -

Page 50: Sequence Of Operation (Bac-1Xx36/1Xxx36)

“fixed,” then any time the fan is called for, it will run at the speed designated by the Fixed Speed setting. This allows for the fan For common features, see FlexStat (All Models) Common Features on speed to be manually set by a balancer. page If the Output Speed is set to “Auto,”... -

Page 51: Staged Heating And Cooling Parameters

• With the fan mode set to “Auto,” the heating valve will open Upon further rise in temperature above the active heating setpoint, the 100% if the space temperature falls below active heating setpoint first stage of heating will be deenergized. minus deadband and fully close when space temp rises above active heating setpoint. -

Page 52: Economizer Control

shall modulate to maintain 53.0° F (11.7° C) until the space temp reaches Economizer Control the cooling setback setpoint at which point it shall close. If at any time If the economizer option is enabled, the economizer mode is determined during unoccupied mode the economizer mode is disabled based on by comparing outside air temperature (OAT) to the economizer enable OAT, the outside air damper will close. -

Page 53: Fcu (Fan Coil Unit), 2-Pipe

The application is capable of determining whether heating or cooling water available flags are turned off. water is available even in a stand-alone configuration. If the FlexStat has • With the fan mode set to “Auto,” the valve operates in a “two- a call for heating or cooling greater than 10% and the unit does not know position”... -

Page 54: Fcu (Fan Coil Unit), 4-Pipe

occupancy mode is set to constant or “On,” the valves func- FCU (Fan Coil Unit), 4-Pipe tion in a modulating fashion. Actual response may vary slightly due to PI action of the control loops, but generally, the heating Fan Control valve will start to open as the space temperature drops below the The fan follows the base sequence for fan operation as listed in the Flex-... -

Page 55: Bac-1Xx30 Series (3 Relays And 0 Analog Outputs)

BAC-1xx30 Series (3 Relays and 0 Analog Outputs) This section is specific to the BAC-1xx30 series (with 3 relays and 0 ana- log outputs). NOTE: IN1 is the room temp. Outputs sensor AI1 NOTE: SC = Switched (Relay) Common BACnet MS/TP –A Network... -

Page 56: Bills Of Materials (Bac-1Xx30)

DUCT TEMPERATURE SENSOR NOTE: Humidity and motion/occupancy sensor options are dependent CSE-1102 AIR DIFFERENTIAL PRESSURE SWITCH, 0.05-12" WC on the FlexStat model. In BAC-10130/11130, dehumidification or economizer options can be selected but not both. XEE-6311-075 TRANSFORMER, 120/240/277/480:24 VAC, 75 VA... -

Page 57: Sequence Of Operation (Bac-1Xx30)

Sequence of Operation (BAC-1xx30) For common features, see FlexStat (All Models) Common Features on page 31 For HPU applications, see relevant sections in HPU (Heat Pump Unit) on page 41 For AHU, Heating Unit, and Cooling Unit applications, see relevant... -

Page 58: Bac-1Xxx53 Series (5 Relays, 1 Triac, & 3 Analog Outputs)

–A the Scroll Digital compressor over 10–100% of the rated capacity. Below Relay 5 (W | W1) 10% cooling demand, the FlexStat controls at 10% to meet low levels Inputs of demand. In multiple compressor (tandem) applications, the FlexStat Relay 4 (Y2 | Y2) -

Page 59: Index

Humidification: Dehumidification: 39, 41, 42, 44, 45, 52, BACstage: 8, 13, 17, Discharge Air Temp: Binary Inputs: Display: 13, Images, FlexStat and System: Door Contact with Motion Sensor: IN7 (Remote Temp. Sensor): Calibration: Inputs: 5, CA Title 24: 35, Installation:... - Page 60 Setpoints: 13, 17, Outside Air Temperature (OAT): 14, 34, Space Temp. and Humidity: Overrides: 23, KMC Controls, Inc., 19476 Industrial Drive, New Paris, IN 46553; 574.831.5250; www.kmccontrols.com; info@kmccontrols.com FlexStat (General) Application Guide, Rev L © 2012 KMC Controls, Inc. 913-019-03L...

Need help?

Do you have a question about the FlexStat and is the answer not in the manual?

Questions and answers