KMC Controls FlexStat Operation Manual

Bacnet programmable thermostats

Hide thumbs

Also See for FlexStat:

- Application manual (60 pages) ,

- Operation manual (46 pages) ,

- Quick reference manual (2 pages)

Table of Contents

Advertisement

Quick Links

Operation Guide

Contents

Overview ................................................................ 3

Applications and Installation ................................... 3

Operation (Basic) .................................................... 4

Navigation .......................................................... 4

Room Temp. Setpoint Adjustment ....................... 4

H/C, Fan, Occupancy, and Override ................... 4

Main Menu and Settings ...................................... 4

Display Options .................................................. 5

Configuration (Setup) .............................................. 6

Main Menu Overview ......................................... 6

About the FlexStat ............................................... 6

Advanced Menu .................................................. 7

Damper Setup ............................................. 7

Fan Setup..................................................... 8

Humidity Setup ........................................... 8

Motion Sensor Setup ................................... 8

Optimum Start Setup .................................. 9

Sensor Setup ................................................ 9

Setback (OAT) Lockout Setup .................... 10

Staging Setup ............................................. 10

Valve Setup ............................................... 10

(Advanced) CB (Control Basic) Programs ....... 10

2

Sensor Setup and Information ........... 11

2

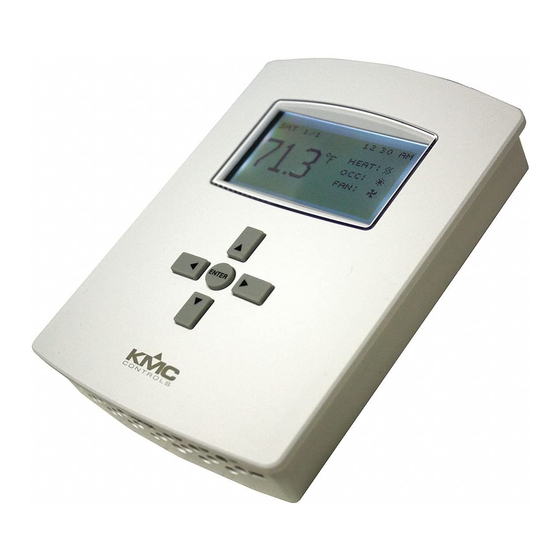

FlexStat

BACnet Programmable Thermostats

Specifications, design, and operation are subject to change without notice.

1

(Advanced) Communications (BACnet) .......... 14

(Advanced) Date/Time ................................... 16

(Advanced) BACnet Device Properties ........... 17

(Advanced) Inputs .......................................... 17

(Advanced) Temp. Setpoint Limits .................. 17

(Advanced) PID Loop Configuration .............. 18

(Advanced) Restart/Restore ........................... 18

(Advanced) Test .............................................. 19

(Advanced) Trend Logs ................................... 20

(Advanced) User Interface (UI) ...................... 21

Contrast .................................................... 21

Display Blanking ....................................... 21

Inactivity ................................................... 21

Rotation Values .......................................... 21

Show Temperature Tenths (Decimals) ........ 21

Show Time and Date .................................. 21

Mode ......................................................... 21

Alarms ............................................................... 23

Date/Time ......................................................... 23

DCV (Demand Control Ventilation) .................. 24

Schedules .......................................................... 24

Setpoints ........................................................... 25

System Modes ................................................... 25

Trend Viewer ..................................................... 26

FlexStat

™

Operation Guide, Rev. R

Advertisement

Table of Contents

Troubleshooting

Summary of Contents for KMC Controls FlexStat

-

Page 1: Table Of Contents

Configuration (Setup) ..........6 (Advanced) Trend Logs ........20 Main Menu Overview ......... 6 (Advanced) User Interface (UI) ...... 21 About the FlexStat ..........6 Contrast ............ 21 Advanced Menu ..........7 Display Blanking ........21 (Advanced) Application and Additional Setup .. 7 Inactivity ........... - Page 2 Upgrading Firmware Issues ....... 37 Alarm, (False) Space Temp. or Humidity ..30 Firmware Upgrade Failures ......37 Back-Up Issues ..........30 FlexStat Malfunctions After Upgrade ..... 38 Communication Issues ........30 Wiring Issues ............. 39 Ethernet/IP Network Communication Issues .. 30 Installation Wiring Considerations ....

-

Page 3: Overview

Network Devices and Remote Monitoring mounted, thermostat/controllers are native BACnet Advanced Application Controllers (B-AAC) for use in a BACnet system. The FlexStat simplifies net- worked zone control for common packaged HVAC Optional equipment, such as packaged rooftop units, fan coil... -

Page 4: Operation (Basic)

Setpoints section under the Main Menu. (In the Setpoints menu, heating/cooling set- points/setbacks and deadband can be changed with, if required, the correct password access. See Set- points on page 25.) FlexStat Operation Guide, Rev. R... -

Page 5: Display Options

(Pressing Enter for less time will turn on the back- COOL: light if it is off.) The desired scale will persist on the OCC: display until this process is repeated or the FlexStat FAN: is restarted. HUM: 36% RH After a restart, the temperature scale will revert to When Display Blanking is enabled, the display whatever scale is set in the Application menu. -

Page 6: Configuration (Setup)

Configuration (Setup) NOTE: Menus shown in this document reflect About the FlexStat FIRMWARE VERSION R2.1.0.9 or later. Actual context-sensitive screens are ABOUT FLEXSTAT dependent on firmware version, FlexStat MODEL: BAC–141136CE MORE ABOUT model, and options selected. FW: FLEXSTAT R1.3.0.0 COMMUNICATION APP: AIR HANDLER FIRMWARE NOTE: If appear at the top of the screen OPT: MOD H / MOD C HARDWARE MORE (such as in the Main Menu), scroll up or UPTIME: 28D 00:32:57 down to see the rest of the menu’s off-... -

Page 7: Advanced Menu

Auxiliary/Emergency Heat section scrolling up or down to see all the options. under Sequence of Operation (BAC-1xx63/1xxx63) in the FlexStat Application Guide.) (Advanced) Application and Additional Setup Comp OAT Low (AV17) is the outside air tempera- ture value, below which the compressor is locked out APPLICATION (when lockout is enabled). -

Page 8: Fan Setup

15 minutes—to further conserve energy according to the guidelines by Portland Energy Conservation, Inc. (PECI). In Basic or Standard DCV mode or no DCV is selected, the setpoint value is restored by the full amount immediately when FlexStat Operation Guide, Rev. R... -

Page 9: Optimum Start Setup

In BAC-12xxxx/13xxxx/14xxxx models, Input 9 (AI9) When Optimum Start is enabled, the FlexStat soon can be configured for an external KMC SAE-10xx “learns” the amount of time required to reach sensor. -

Page 10: Setback (Oat) Lockout Setup

See About the FlexStat on Proportional valves have a 0–10 VDC default for page 0–100% open. Change as needed (e.g., 10–2 VDC). NOTE: Customized programs are the responsibility of the user. KMC Controls does not provide support for such programs. FlexStat Operation Guide, Rev. R... -

Page 11: (Advanced) Co 2 Sensor (And Dcv)

DCV (Demand Control Ventilation sequences to provide optimal ventila- After power is first applied or the FlexStat is restart- tion and energy savings for a space. When BAC- ed, the sensor goes through a warm-up for approxi- 12xxxx/13xxxx/14xxxx models have an application mately half a minute. - Page 12 Although Advanced DCV is the most complex to other pollutants become excessive during unoc- configure, it is more energy efficient than Stan- cupied times (with no ventilation), the FlexStat’s dard while still optimizing IAQ. Standard or Advanced DCV configuration is recommended.

- Page 13 (20° F default) for which the VENT MODE = Displays (only) in which ventilation building’s heating system is designed. mode the FlexStat is functioning (see OA AREA = The outside air damper position (2% illustration): default) required to provide the outdoor •...

-

Page 14: (Advanced) Communications (Bacnet)

“E” models), plug an Ethernet cable directly into the • Override—Ventilation override has RJ-45 modular jack on the back of the FlexStat. been manually selected from the DCV To set protocol and parameters for BACnet menu, and the space is temporarily... - Page 15 To avoid possible communication of internal MS/TP communication status and error issues with the network or a computer connected counters from that FlexStat’s perspective. The MS/TP through a KMD-5576 USB Communicator, the Max Diagnostics menu has two selections: Master number should be the lowest number •...

-

Page 16: (Advanced) Date/Time

If the FlexStat is used in a BACnet network with UTC (Advanced) Date/Time (Coordinated Universal Time) synchronization (via DATE/TIME broadcasting or addressing a single thermostat) set the DATE: APRIL 11 2009 UTC Offset value. The UTC Offset value is in minutes... -

Page 17: (Advanced) Bacnet Device Properties

“Out-of-Service: False” means the input is active (not 2. Enter to select. out of service). If it is “true,” the input is inactive. NOTE: In firmware versions R1.3.0.4 and earlier, The FlexStat menu only shows the status. The status the FlexStat could also be restarted or can only be changed through BACstage or TotalCon- restored to factory defaults from this trol. -

Page 18: (Advanced) Pid Loop Configuration

System/Occupancy/Fan settings have a default Proportional Band were called Deadband password level of User. This level can be changed for in FlexStat firmware versions earlier than each function to None, Operator, or Administrator R2.0.0.6 (see the diagram). through the Access Levels menu. Passwords are set in the Passwords menu. -

Page 19: (Advanced) Test

To lock the buttons after configuration is complete (and disable further changes), select Locked UI mode. See (Advanced) User Interface (UI) on page For additional physical security and protection from vandalism, install the FlexStat inside a third- party locking thermostat guard/cover (but proper airflow must be maintained). FlexStat Operation Guide, Rev. R... -

Page 20: (Advanced) Trend Logs

APR17 6:27PM, 81.2 be more practical to use as a trend log. APR17 7:27PM, 82.3 See the FlexStat Application Guide and relevant The FlexStat generates one or more default trend FlexStat Installation Guide for other desired input logs that are dependent on options and applications: and output objects in an application. • Space temperature is always the default trend To set the desired object to track, press: log #1. -

Page 21: (Advanced) User Interface (Ui)

2: OAT: HIDE at least an Operator level password. See 3: CO2: SHOW 4: UI4: HIDE (Advanced) Security Levels and Passwords on page NOTE: To further configure the FlexStat or revert to Standard mode, see the FlexStat The Rotation Values menu allows easy setting of Application Guide. what applicable optional values (e.g., humidity, outside air temperature, and/or CO... - Page 22 Motion Sensor Setup on page again. The same is true for the unoccupied 8). The FlexStat will stay On (in occupied mode), setpoint. To automatically reset setpoints and the schedule will be ignored. to default values at particular times, a building automation system can overwrite •...

-

Page 23: Alarms

AI7.) • Space Humidity Alarm—humidity above 65% for over 300 seconds. This is available only in FlexStat models with a humidity sensor and a This menu allows changes to the date and time dehumidification option selected in the Humid- information (only). More options (such as UTC offset and daylight saving time options) are available in the ity setup. -

Page 24: Dcv (Demand Control Ventilation)

4. Up/Down to increment/decrement value. 4. Up/Down to increment/decrement value. 5. Enter to exit value editing. Mode displays whether the FlexStat is functioning in Normal, Pre-purge, Startup, Standby, Recovery, 6. Left to move back to days or back one page. -

Page 25: Setpoints

Setpoint Differential, was moved to the Limits menu. See (Advanced) Temp. Setpoint Limits on page 17. Also, “Deadband” was separated into Heating and Cooling Proportional Bands and moved to the Loops menu. See (Advanced) PID Loop Configuration on page FlexStat Operation Guide, Rev. R... -

Page 26: Trend Viewer

Resetting the FlexStat Types of Reset TREND VIEWER SPACE TEMP 2: SPACE HUMIDITY If the FlexStat is not operating correctly or if a low 3: FAN limit alarm has occurred, the FlexStat should be 4: COOL 1 reset (reinitialized). Any reset interrupts normal op- 5: COOL 2... -

Page 27: Restore Factory

To perform a WARM start, do one of the following: 2. When prompted for the required restart, press Enter. (To Cancel, press the right button and then • From the FlexStat menu, select Advanced > Re- Enter or just let the display time-out). start/Restore > Warm Start. 3. After the FlexStat has restarted, review the set- •... -

Page 28: Network Connection

MS/TP Network Communication PC Data Port Connection Connect the EIA-485 MS/TP network wiring and set The FlexStat is equipped with a PC data port located the EOL switches accordingly. (See the Installation at the bottom of the thermostat housing. This port... -

Page 29: Maintenance

About the Flex- Programming (Custom) Stat on page Firmware in the FlexStat can be upgraded using a PC The FlexStat has a library of built-in applications and and an HTO-1103 Firmware Flash Upgrade Kit avail- options that are configured through the FlexStat’s able from KMC Controls. -

Page 30: Troubleshooting

(mixed air temp.) is not configured as “Out Of Communications (BACnet) on page 14 Service.” KMD-5576 (Data Port) Communication Issues NOTE: After a low limit alarm is generated, the fan will not run until after the FlexStat is • For Ethernet-enabled models, a FlexStat in one of restarted. (See Resetting the FlexStat on the Ethernet or IP modes must (temporarily) be page 26.) -

Page 31: Ms/Tp Network Communication Issues

• Ensure wiring is correct. See Wiring Issues on connectors. page CAUTION • If a new BAC-12xxxx FlexStat is installed on an old BAC-10000 series backplate, the input/power/ The 6-external-input BAC-12xxxx/13xxxx/14xxxx series are NOT COMPATIBLE WITH THE communications terminals are misaligned. MS/ BACKPLATES OF OLDER (3-external-input) BAC- TP communications may be damaged. -

Page 32: Display Is Blank (Or Erratic)

FlexStat functions properly, runs! Allow plenty of “cushion” in replace the first FlexStat. measurements A meter may be too slow to register transient dips or peaks during • If the FlexStat has been damaged, check the phas- startup. See Wiring Issues on page ing of the power and network lines.See Wiring Issues on page •... -

Page 33: Custom Programming And Web Issues

Input, Sensor, and Value Issues Control Basic Programs Do Not Work Level Value Is Frozen or Is 0 • After power is first applied or the FlexStat is NOTE: The FlexStat has a library of built- restarted, the sensor goes through a warm-up for in applications and options that are approximately half a minute. -

Page 34: Co Level Is "Too High

(occ status) is not configured as “Out Of Service.” See the Connections and Wiring section of the • The FlexStat must be installed where there is a relevant FlexStat Installation Guide. A single clear view of typical traffic area (reliable range is incorrect switch position may affect multiple out to about 33 feet). -

Page 35: Temperature Setpoint Is Not Maintained

(e.g., concrete block wall), blocked from normal air circulation by obstructions, exposed NOTE: An issue can occur if a FlexStat has been un- to heat sources (e.g., lights, computers, copiers, powered long enough for it to lose its RTC... -

Page 36: Output, Fan, And Relay Issues

• Check the fan configuration—see Fan Setup on page required power exceeds the FlexStat’s capacity. (REE-3211/3221/3213 relays could, • Restart the FlexStat. After a low limit alarm is however, be used with the FlexStat relays generated, the fan will not run until after the and a separate power source.) FlexStat is restarted. (See Resetting the FlexStat on page 26.) •... -

Page 37: Relay (Internal) Does Not Work

Relays are NO, SPST (Form “A”). To prevent damage, never plug the programming pod into a FlexStat that is powered. Always attach • Check current draw of load. Substitute an output the power cable last. -

Page 38: Flexstat Malfunctions After Upgrade

• If the USB port does not appear in the drop- FlexStat Malfunctions After Upgrade down list, close the tool, remove power to the • After the update process is over, if the FlexStat FlexStat, disconnect the FlexStat from the USB display remains blank but the backlight is on or port, reconnect the FlexStat to the USB port, the display locks up at a later time, check that restore power to the FlexStat, and restart the tool. -

Page 39: Wiring Issues

O Ohms (Closed Contact) Dependent on 24 VAC Application) SC 1–3 (Jumper to Common/–/C Relay 2 Turn Device 24 VAC 24 VAC On Manually) Phase/ /R Relay 1 Terminal Voltages and Resistances with FlexStat REMOVED from Backplate FlexStat Operation Guide, Rev. R... -

Page 40: Support

KMC Controls, Inc. makes no representations or warran- ties with respect to this document. In no event shall KMC Controls, Inc. be liable for any damages, direct or incidental, arising out of or related to the use of this document. -

Page 41: Reference

Reference NOTE: See also the Definitions of Terms on page Acronyms and Abbreviations Common acronyms and abbreviations in FlexStat HVAC = heating ventilating and air conditioning and related documents include: Hz = hertz amp = amperes IP = Internet protocol A = amperes... -

Page 42: Definitions Of Terms

Green Building and Con- slave devices cannot (since slaves can only reply trols Glossary (SB-046). A hyperlinked to messages from other devices). KMC advanced online version can be downloaded from application controllers are all MS/TP master the Brochures section of KMC Controls devices. -

Page 43: Index

Index BV35 (Motion Sensor Standby): Abbreviations: About the FlexStat: Calibration Access Levels, Password: Analog Input Offset: Accessories: CO2 Sensor (Gas): Acronyms: Temperature Offset: Adapter Backplate, HTO-1103: CA Title 24: Adjustment. See Configuration; Override; Setpoint CO2 Sensor: 11, 21, Administrator Password:... - Page 44 Heat Pump Unit (HPU): Display Home (Temperature Display) Screen: Blanking: 5, 21, Hospitality Mode: Contrast: HPU (Heat Pump Unit): Decimal Values (Tenths): 5, HTO-1103 FlexStat Firmware Flash Upgrade Kit: Hospitality Mode: 5, Humidity Locked: 5, Alarm: Options: Dehumidification Option: Rotation Values: 5,...

- Page 45 Rotation Values (Display): Configuring (Setup): Route Status: Operator Password: RS-485. See EIA-485 Optimum Start: Outage, Power: Out-of-Service: SAE-10xx CO2 sensors: Outputs: 26, SAT (Supply Air Temperature). See Discharge Air Tem- Override: 4, 14, perature (DAT) Schedules: Security: FlexStat Operation Guide, Rev. R...

- Page 46 Increments, Decimal: 5, Limits: Remote Sensor: 9, KMC Controls Scale, Selecting: 19476 Industrial Drive Setpoint: 4, 17, New Paris, IN 46553 Tenths (Decimals): 574.831.5250; Fax 574.831.5252 Trend Log: www.kmccontrols.com; info@kmccontrols.com Troubleshooting: FlexStat © 2014 KMC Controls, Inc. Operation Guide, Rev. R 913-019-02R...

Need help?

Do you have a question about the FlexStat and is the answer not in the manual?

Questions and answers