Table of Contents

Advertisement

Quick Links

Service Manual

EN

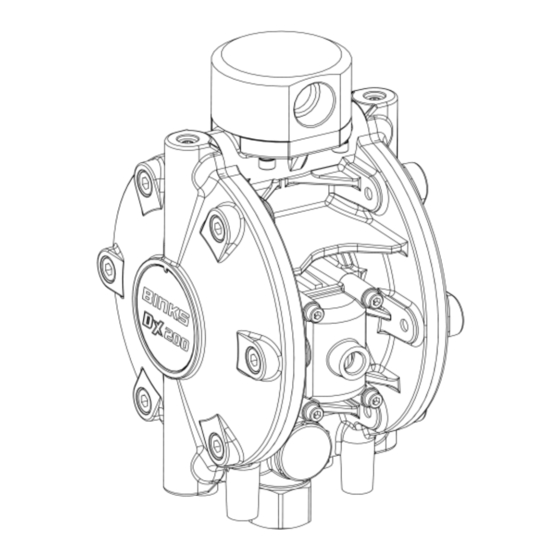

DX200 Stainless Steel

Diaphragm Pump

DX200SR

DX200SN

Patent US 9447780

DX200SM

DX200SP

IMPORTANT! DO NOT DESTROY

It is the Customer's responsibility to have all operators and service personnel read and understand this

manual.

Contact your local Carlisle Fluid Technologies representative for additional copies of this manual.

READ ALL INSTRUCTIONS BEFORE OPERATING THIS PRODUCT

77-3211 R2 (04/2024)

www.carlisleft.com

Advertisement

Table of Contents

Summary of Contents for Carlisle Binks DX200SR

- Page 1 It is the Customer's responsibility to have all operators and service personnel read and understand this manual. Contact your local Carlisle Fluid Technologies representative for additional copies of this manual. READ ALL INSTRUCTIONS BEFORE OPERATING THIS PRODUCT 77-3211 R2 (04/2024)

-

Page 2: Eu Declaration Of Conformity

Notified body details and role: Element Materials Technology (2812) Lodging of Technical file This Declaration of conformity / incorporation is issued Carlisle Fluid Technologies UK Ltd, under the sole responsibility of the manufacturer: Ringwood Road, Bournemouth, BH11 9LH. UK Representative authorised to compile the technical file Sales and Marketing Director. - Page 3 Approved body details and role: Element Materials Technology (0891) Lodging of Technical file This Declaration of conformity/incorporation is issued Carlisle Fluid Technologies UK Ltd, under the sole responsibility of the manufacturer: Ringwood Road, Bournemouth, BH11 9LH. UK UKCA Declaration of Conformity...

- Page 4 In this part sheet, the words WARNING, CAUTION and NOTE are used to emphasize important safety information as follows: WARNING CAUTION NOTE Hazards or unsafe practices which could result in Hazards or unsafe practices which could result in Important installation, operation or maintenance minor personal injury, product or property severe personal injury, death or substantial property information.

-

Page 5: Specification

Specification Ratio: Maximum air inlet pressure: 7 bar [100 psi] Maximum fluid pressure: 7 bar [100 psi] Displacement per cycle: 0.20 Litres [0.05 US gall] Output @ 60 cycles / min: 12 Litres/min [3.17 US gall/min] Maximum Recommended Continous Cycle Rate [cycles/min]: Maximum Recommended Intermittent Cycle Rate [cycles / min]:... -

Page 6: Installation

Installation Dimension DX200SN 249mm DX200SR 270mm SECTION Z-Z DX200SM 379mm DX200SP 339mm 6/20 77-3211 R2 (04/2024) www.carlisleft.com... -

Page 7: Prior To Use

Prior To Use This product should be flushed with a suitable compatible solvent prior to use. Mount the pump securely and position the pump at a convenient height to allow for maintenance. Attach flexible hoses to all connections. Connect a regulated air supply to the air connection. Set the pump speed to a slow cycle rate and prime the pump to remove any air before increasing pressure. -

Page 8: Important Notes

Paint section materials of construction DX200S# Pumps Item Material Pump body inserts Stainless Steel End cap Stainless Steel Diaphragms PTFE Seals FKM/PE Valve ball & spring Stainless Steel End cap plugs Stainless Steel Ball Cage (Acetal) POM Fluid regulator & pulsation chamber Stainless Steel DX200SE# Pumps Item... -

Page 9: Spare Parts

Spare Parts Item Part No. Description DXK-222 Check valve seal kit x 4 DXK-260 Enamel check valve seal kit x 4 DXK-223 Check valve kit x 4 DXK-262 Enamel check valve kit x 4 DXK-224 Diaphragm kit x 2 DXK-225 Shaft &... - Page 10 Spare Parts 10/20 77-3211 R2 (04/2024) www.carlisleft.com...

- Page 11 Spare Parts Item Part No. Description DXK-213 Diaphragm assembly DXK-214 Regulator Insert DXK-228 Fluid regulator assembly DXK-229 Inlet/outlet seal x 4 DXK-230 Insert seal x 4 DXK-231 Non regulated assembly DXK-18 Cover, seal & screws DXK-25 Gasket x 4 DXK-216 Air valve kit 0114-011798 Grounding cable 4m...

- Page 12 Spare Parts Note: Refer to manual 77-3216 for pulsation chamber spare parts 12/20 77-3211 R2 (04/2024) www.carlisleft.com...

- Page 13 Spare Parts Item Part No. Description DXK-232 1/2'' Female inlet connector kit, with seals DXK-233 1/2'' Male inlet connector kit, with seals DXK-234 3/4'' Female inlet connector kit, with seals DXK-235 1/2'' - 3/8'' Male inlet connector kit, with seals DXK-230 Seal x 4 DXK-229...

-

Page 14: Maintenance

Maintenance Key - Maintenance symbols Order for dis-assembly (reverse for assembly) Grease (AGMD-010) refer to figure Spanner or socket size Torque required 14/20 77-3211 R2 (04/2024) www.carlisleft.com... - Page 15 Maintenance Figure 1 Figure 2 15/20 77-3211 R2 (04/2024) www.carlisleft.com...

- Page 16 Maintenance Figure 3 Rotate insert 90° Line up to the inlet port that you require 16/20 77-3211 R2 (04/2024) www.carlisleft.com...

-

Page 17: Maintenance Schedule

Maintenance schedule Typical period Recommended operation - Check for fluid or air leaks - Inspect Pump for Correct operation Monthly - Check for any excessive mechanical noise - Check for excessive fluid pressure pulsation - Perform a pump stop test to ensure correct operation, by ensuring pump stops when the spraygun trigger is closed and there is no fluid flow. - Page 18 Bare pump selection DX200 For use with Pump body Air regulators Stainless Steel No regulator DX200## 1 Regulator DX200#N & P Stainless Steel - Enamel 2 Regulators DX200#R 2 Regulators DX200#N 3 Regulators DX200#R Fluid regulator Note Fluid regulator versions DX200SER & Regulator DX200SEM are not suitable for use with enamel No regulator...

- Page 19 Air regulators DXA-AC1-200 1 Regulator - Pump 2 Regulators DXA-AC2-200 - Pump - Fluid regulator DXA-AC22-200 2 Regulators - Pump - Spraygun DXA-AC3-200 3 Regulators - Pump - Spraygun - Fluid regulator Item Part No. Description GA-382-P Gauge S-1817 Ø4mm Hose MPV-10 QD stem 1\4"...

- Page 20 WARRANTY POLICY This product is covered by Carlisle Fluid Technologies’ materials and workmanship limited warranty. The use of any parts or accessories, from a source other than Carlisle Fluid Technologies, will void all warranties. Failure to reasonably follow any maintenance guidance provided, may invalidate any warranty.

Need help?

Do you have a question about the Binks DX200SR and is the answer not in the manual?

Questions and answers