Table of Contents

Troubleshooting

Summary of Contents for Sensia INSTRUCT P30 INTELLIGENT VSD

- Page 1 LIFT CONTROL SYSTEMS INSTRUCT LIFT CONTROL SYSTEMS P30 and S30 Low Voltage Installation, Operation & Maintenance Manual MODEL: INSTRUCT P30 INTELLIGENT VSD INSTRUCT S30 INTELLIGENT VSD Manual No: LCS-ENG-M0014, Rev. 01...

- Page 2 Sensia and may not be copied, imitated, or used, in whole or in part, without the express prior written permission of Sensia. An asterisk (*) is used throughout this document to designate marks of Sensia. Other company, product, and...

- Page 3 P30 and S30 Low Voltage VSD REVISION HISTORY REVISION: DESCRIPTION OF CHANGE: SENSIA ISSUER: DATE: Initial Release Lift Control Systems 30 Apr 2022...

-

Page 4: Table Of Contents

P30 and S30 Low Voltage VSD Table of Contents Section 1: Product Description ....................11 Motor Controller ............................. 11 Section 2: QHSE ..........................12 2.1 Operating Safety Precautions ........................12 2.2 Installation and Maintenance Safety......................13 Section 3: Inspection/Storage/Disposal ..................14 3.1 Inspection of New Unit .......................... - Page 5 P30 and S30 Low Voltage VSD 6.1.2 Navigation and Number Keys ......................42 6.1.3 Single-Function Keys........................43 6.1.4 LCD Display Elements........................43 6.1.5 Main Screens ............................ 46 6.1.6 HIM Start-up menu ........................... 51 Section 7: Installation ........................53 7.1 Installation Safety Precautions ........................53 7.2 Input and Output Power Wiring .........................

- Page 6 P30 and S30 Low Voltage VSD Section 12: Appendixes ....................... 76 Appendix A: Menu Maps ......................77 Appendix B: Reference Material ....................78 Harmonics worksheet ..........................78 Application Data and Issue identification Table ..................81 Appendix C: VSD Module Catalogue Number Explanation ............84 Appendix D: VSD Modbus/TCP Adapter Status Indicator ............

- Page 7 P30 and S30 Low Voltage VSD List of Figures Figure 5-1:Typical Drive - PCP Controller Interconnection/ Communication Wirings ........22 Figure 5-2: Typical Drive - SRP Controller Interconnection/ Communication Wirings ........23 Figure 5-3 Load Cell Wiring Connections to Molex Terminal ................29 Figure 5-4: Inclinometer Wiring Connections to Molex Terminal..............

- Page 8 P30 and S30 Low Voltage VSD List of Tables Table 4-1: Operating Specifications ........................ 16 Table 4-2: Instruct PCP Controller Specifications ................... 17 Table 4-3: Instruct SRP Controller Specifications ................... 18 Table 5-1: Analog Sensors Connection ......................25 Table 5-2: Accumulator/Counter Connection ....................26 Table 5-3: Modbus Sensor Connection ......................

- Page 9 P30 and S30 Low Voltage VSD WARNING! To avoid the risk of electric shock and fire, the following safety instructions must be observed and the guidelines followed. The specifications must not be exceeded, and the device must only be applied as described in the following.

- Page 10 P30 and S30 Low Voltage VSD...

-

Page 11: Section 1: Product Description

Section 1:Product Description Section 1: Product Description The INSTRUCT* P30 Intelligent VSD and INSTRUCT S30 Intelligent VSD are Sensia’s low voltage variable speed drive system that provides high performance and sophisticated power and motor control at the surface. While the P30 drive is equipped with an INSTRUCT PCP Controller and customised for Progressive Cavity Pump (PCP) applications, the S30 drive is equipped with an INSTRUCT SRP Controller and customised for Sucker Rod Pump (SRP) applications. -

Page 12: Section 2: Qhse

P30 and S30 Low Voltage VSD Section 2:QHSE Section 2: QHSE The following safety precautions should be followed when installing, operating, or maintaining a Sensia VSD 2.1 OPERATING SAFETY PRECAUTIONS 1. Do not power up the VSD until this entire operation manual is reviewed. -

Page 13: Installation And Maintenance Safety

P30 and S30 Low Voltage VSD Section 2:QHSE 2.2 INSTALLATION AND MAINTENANCE SAFETY Potential Severity: Serious Potential Loss: Assets, Personnel Hazard Category: Electrical, Machinery equipment hand tools Ignoring the following instructions can cause physical injury or death, or damage to the equipment 1. -

Page 14: Section 3: Inspection/Storage/Disposal

The circuit boards and display module of the drive and motor controller used in this equipment may contain lead solder and solder paste. The boards should be disposed of according to local regulations. Please contact your local environmental agency or Sensia HSE advisor for details on proper disposal of electrical components and packaging in your particular area. - Page 15 P30 and S30 Low Voltage VSD Section 3:Inspection/Storage/Disposal Potential Severity: Major Potential Loss: Personnel Hazard Category: Electrical, Explosives, Fire flammable, Toxic corrosive hazardous substances Never dispose of electrical components by incineration.

-

Page 16: Section 4: Specifications

P30 and S30 Low Voltage VSD Section 4:Specifications Section 4: Specifications 4.1 OPERATING SPECIFICATIONS The following table lists operating specifications and ranges for the P30 and S30 drives. Table 4-1: Operating Specifications Item Standard Specifications Principal Control Control System Pulse-Width Modulation (PWM) with Flux Open- Parameters Loop Vector Control Input Voltage Supply... -

Page 17: Table 4-2: Instruct Pcp Controller Specifications

P30 and S30 Low Voltage VSD Section 4:Specifications Item Standard Specifications Color White Ambient Temperature -15 to +50°C (5 to 122°F) Relative Humidity 5 - 95% maximum (non-condensing) Vibrations 1.000 mm (0.040 in.) displacement, 1 g peak Altitude 1000 m (3280 ft) Service Environment Consult factory for harsh environment applications such as offshore, cold climate, or desert... -

Page 18: Table 4-3: Instruct Srp Controller Specifications

P30 and S30 Low Voltage VSD Section 4:Specifications Table 4-2: Instruct PCP Controller Specifications (continued) Touchscreen Interface Display type Thin-film-transistor (TFT) color LCD Display size 5.7 in Resolution 320 × 240 pixels (QVGA) Touch panel service 1 million taps or more life USB interface USB 2.0 (Type A) -

Page 19: Section 5: Wiring

P30 and S30 Low Voltage VSD Section 5:Wiring Section 5: Wiring This section contains intra- and interconnection information for the VSDs: to incoming (customer-supplied) power • • from the main power bus through the drive and other components inside the drive enclosures •... -

Page 20: Grounding

P30 and S30 Low Voltage VSD Section 5:Wiring Note 1. Contactors who are used to connect drive terminals should be capable of switching low-current signals (i.e., 5 mA). 2. When wiring with parallel conductors, keep the conductors together in phase sets with U1, V1, W1 in one conduit and parallel conductors U2, V2, W2 in another conduit. -

Page 21: Interconnection Wiring

P30 and S30 Low Voltage VSD Section 5:Wiring Potential Severity: Light Potential Loss: Assets Hazard Category: Machinery equipment hand tools, Temperature Surface motors operating from adjustable-speed drive power sources tend to operate at higher temperatures which may increase the need for more frequent lubrication cycles. Failure to lubricate motors driven by adjustable-speed drives could cause premature failure of the motor. -

Page 22: Figure 5-1:Typical Drive - Pcp Controller Interconnection/ Communication Wirings

P30 and S30 Low Voltage VSD Section 5:Wiring Figure 5-1:Typical Drive - PCP Controller Interconnection/ Communication Wirings... -

Page 23: Figure 5-2: Typical Drive - Srp Controller Interconnection/ Communication Wirings

P30 and S30 Low Voltage VSD Section 5:Wiring Figure 5-2: Typical Drive - SRP Controller Interconnection/ Communication Wirings... -

Page 24: Motor Controller Wiring

For the purpose of discussion in this manual, VSD wiring is confined to interconnection or communication wiring to or from the drive, or to the motor controller or other external devices in the Sensia VSD systems. Wiring internal to the drives is not within the scope of this manual. -

Page 25: Installing The Analog Sensors On The Terminal Block

P30 and S30 Low Voltage VSD Section 5:Wiring Sensor Connection Types Vibration X Modbus Vibration Y Modbus Flow Rate Modbus, 4...20 mA input (Generic), 4...20 mA input (Wedge) VFD, 4...20 mA input, Accumulator, Modbus Analog Input 6 4...20 mA input Analog Input 7 4...20 mA input Torque... -

Page 26: Confirming Sensor Readings

P30 and S30 Low Voltage VSD Section 5:Wiring Table 5-2: Accumulator/Counter Connection Termination Point at Termination Point at Signal Signal Type Standalone PCP Embedded PCP Terminal Connection Controller Controller Rod Speed CNT: 0 CNT: 0 TB-ACC: + Sensor Signal Accumulator/ Counter Rod Speed CNT: COM... -

Page 27: Other Sensors

P30 and S30 Low Voltage VSD Section 5:Wiring b. Select Read a configuration from an RTU. c. Click Next. d. From the drop-down menu, select a Communication Type. Use USB if you have a direct connection from your RTU to a laptop. e. -

Page 28: Table 5-4: Digital Input Connection

P30 and S30 Low Voltage VSD Section 5:Wiring Table 5-4: Digital Input Connection Termination Point at Termination Point at Signal Standalone PCP Embedded PCP Signal Type Terminal Description Controller Controller Signal Return Signal Return P5: DI0 Spare P5: DI0 TB-DI: +24 TB-DI0: SIG TB-DI: +24 Generic Drive... -

Page 29: External Sensors Connections To Srp Controller

P30 and S30 Low Voltage VSD Section 5:Wiring Connection Point at Connection Point at Standalone PCP Embedded PCP Signal Type Signal Connection Terminal Controller Controller Signal Return Signal Return P7: DO3 Common P7: DO3 P7: DO3 P7: DO4 Spare P7: DO4 P7: DO4 P6: DO5 P6: DO5... -

Page 30: Power Jumper Configuration

P30 and S30 Low Voltage VSD Section 5:Wiring Figure 5-4: Inclinometer Wiring Connections to Molex Terminal 5.8 POWER JUMPER CONFIGURATION The drives contain protective MOVs and common mode capacitors that are referenced to ground. To guard against drive damage and/or operation problems, these devices must be properly configured. Figure 5-5: MOV and AC EMI Capacitor Phase to Ground (Frames 1…7) Figure 5-6: MOV and AC EMI Capacitor Phase to Ground (Frames 8…10) AC Input Only... -

Page 31: Figure 5-7: Common Mode Capacitors To Ground (All Frames)

P30 and S30 Low Voltage VSD Section 5:Wiring Figure 5-7: Common Mode Capacitors to Ground (All Frames) Note A properly configured drive has either all jumpers connected or all jumpers disconnected, depending on whether the power source is solid grounded or non-solid grounded. If jumpers are neither all connected or all disconnected, the power jumpers are not properly configured. -

Page 32: Frames 2

P30 and S30 Low Voltage VSD Section 5:Wiring Table 5-7: Recommended Power Jumper Configurations for Frames 8…10 Power Source Type Jumper PE-A1 Jumper PE-A2 Jumper PE-B Benefits Of Correct (MOV) (Input filter (DC bus Configuration on Power caps) common Source Type mode caps) Non-Solid Ground •... -

Page 33: Frames 6, And 7 Power Jumper Wire Removal And Storage

P30 and S30 Low Voltage VSD Section 5:Wiring When screws are installed, use this torque and tool: • Recommended torque = 1.36 N•m (12.0 lb•in) ±0.14 N•m (1.2 lb•in) • Recommended screwdriver = 6.4 mm (0.25 in.) flat or T15 Hexalobular Figure 5-9: Typical Frames 2…5 Jumper Screw Installation Locations (Frame 4 shown) 5.8.2 FRAMES 6, AND 7 POWER JUMPER WIRE REMOVAL AND STORAGE Frames 6 and 7 use jumper wires to complete an electrical connection when installed. -

Page 34: Figure 5-10: Frame 6 Jumper Wire Locations

P30 and S30 Low Voltage VSD Section 5:Wiring Figure 5-10: Frame 6 Jumper Wire Locations Figure 5-11: Frame 7 Jumper Wire Locations... -

Page 35: Drive Control Board And Option Modules Terminal Designations

P30 and S30 Low Voltage VSD Section 5:Wiring 5.9 DRIVE CONTROL BOARD AND OPTION MODULES TERMINAL DESIGNATIONS 5.9.1 VSD MAIN CONTROL BOARD Name Description HIM connector DPI port 1 (HIM Cradle) connection Fan connector Power supply for internal cooling fan (Frames 2 and 3) Battery receptacle User installed CR1220 lithium coin cell battery provides power to the real-time clock (optional, not supplied). -

Page 36: Vsd I/O Option Module (20-750-2262C-2R)

P30 and S30 Low Voltage VSD Section 5:Wiring Name Description I/O terminal block TB1 I/O Terminal Designations Fixed I/O Terminal Name Description Digital input 0 Connections for AC power supply. Di 0ac 120V AC (132V AC High state: 100…132V AC max) Low state: 0…30V AC Di C... - Page 37 P30 and S30 Low Voltage VSD Section 5:Wiring TB1 Terminal Designations Related Terminal Name Description Parameter Terminating point for wire shields when an Shield EMC plate or conduit box is not installed Ptc– Motor PTC (–) Motor protection device (Positive Temperature Coefficient) On port X Ptc+...

-

Page 38: Vsd Modbus/Tcp Adapter Option Module (20-Comm-M)

P30 and S30 Low Voltage VSD Section 5:Wiring TB2 Terminal Designations (Two Relay Outputs: 2R) Relay Out Terminal Name Description Related Parameter R0NO Relay 0 N.O. Relay normally open contact output: 10, 100, 101, 240V AC, 24V DC, 2 A max 105, 106 Relay 0 Common On port X... -

Page 39: Vsd Dual-Port Ethernet/Ip Option Module (20-750-Enetr)

P30 and S30 Low Voltage VSD Section 5:Wiring The VSD Modbus/TCP adapter is attached to 20-750-20COMM Carrier kit. This carrier kit enables the use of the adapter with the drives. The carrier kit shall be installed to Port 6 of the drive. Installing it at Port 4 or Port 5 makes the adjacent left port inaccessible to other option modules and can interfere with network cable connections. - Page 40 P30 and S30 Low Voltage VSD Section 5:Wiring Refer to Appendix E:VSD Dual-port Ethernet/IP Option Module Status Indicator for the interpretation of the indications. Ethernet/IP Option Module Rotary Switches Switch Name Description HUNDREDS Switch TENS Sets the node address of the option module Switch ONES Switch...

-

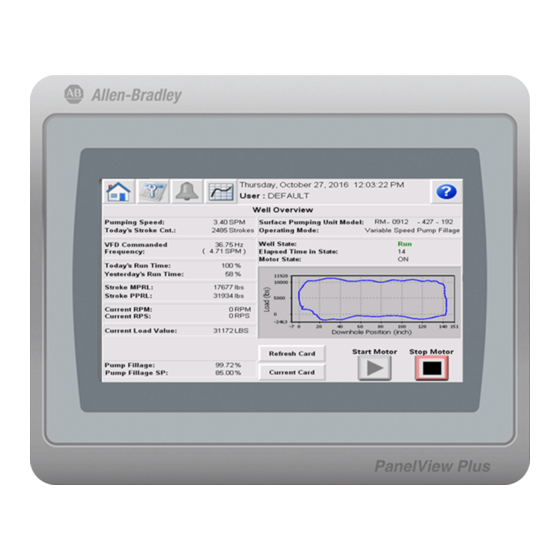

Page 41: Section 6: Operator Interface

P30 and S30 Low Voltage VSD Section 6:Operator Interface Section 6: Operator Interface For the operator interface of the motor controller, refer to the respective controller manual: INSTRUCT PCP Intelligent Controller Hardware Installation Manual (LCS-ENG-M0017) • • INSTRUCT PCP Intelligent Controller Configuration Manual (LCS-ENG-M0018) •... -

Page 42: Navigation And Number Keys

P30 and S30 Low Voltage VSD Section 6:Operator Interface 6.1.2 NAVIGATION AND NUMBER KEYS The five blue multi-function keys (2, 4, 5, 6, and 8) shown below are used to do the following: • Enter their respective numeric value. • Scroll menus/screens. -

Page 43: Single-Function Keys

P30 and S30 Low Voltage VSD Section 6:Operator Interface 6.1.3 SINGLE-FUNCTION KEYS There are four single-function keys, which are highlighted below and listed in the table below. Each single- function key always performs only its dedicated function. 6.1.4 LCD DISPLAY ELEMENTS The basic HIM screen is divided into three display zones, which are shown below and described in their respective subsections that follow. - Page 44 P30 and S30 Low Voltage VSD Section 6:Operator Interface 6.1.4.1 Status Bar The Status Bar provides operating status information for the host drive. 6.1.4.2 Data Area The Data Area displays the data or function presently being acted upon.

- Page 45 P30 and S30 Low Voltage VSD Section 6:Operator Interface 6.1.4.3 Soft Key Labels The Soft Key Labels identify the present function of a corresponding soft key on the keypad. Different screens may show different Soft Key Labels.

-

Page 46: Main Screens

P30 and S30 Low Voltage VSD Section 6:Operator Interface 6.1.5 MAIN SCREENS The HIM main screens include the Status screen, Process screen, Control screen, Folder screens, and Fault Display screens, all of which are described in their respective subsections that follow. 6.1.5.1 Status Screen On power up, the Status screen (below) is shown by default. - Page 47 P30 and S30 Low Voltage VSD Section 6:Operator Interface If you would rather see the Process screen (shown below) as the initial power-up screen, change the HIM Parameter 03 - [Initial Screen] value to ‘1’ (Process Scrn). By default, when the HIM keys are not used for the time period set in Parameter 07 - [User Dspy Time], the screen being displayed at that time will revert back to the initial screen.

- Page 48 P30 and S30 Low Voltage VSD Section 6:Operator Interface 6.1.5.3 Control Screen The Control screen (shown below) is used to directly control the drive. It displays vertical bar graphs of the drive’s speed Reference and Feedback values, and a Key Function Map that corresponds to the navigation/number keys for drive control.

- Page 49 P30 and S30 Low Voltage VSD Section 6:Operator Interface...

- Page 50 P30 and S30 Low Voltage VSD Section 6:Operator Interface 6.1.5.4 Folder Screens The drive and each connected peripheral have its own set of Folder screens: To display the last-viewed Folder screen, press the (Folders) key. The Folder screen Data Area displays: •...

-

Page 51: Him Start-Up Menu

P30 and S30 Low Voltage VSD Section 6:Operator Interface 6.1.5.5 Fault Display Screen The popup Fault Display screen automatically appears when a fault condition is detected for the host drive or any connected peripheral. The popup Fault Display screen flashes to alert that a fault condition exists. The Fault Display screen (example shown below) provides the following information: fault code number •... - Page 52 P30 and S30 Low Voltage VSD Section 6:Operator Interface Note If a start-up routine is initiated, but must be terminated before the routine is completed, be sure to press the Abort soft key to exit the routine.

-

Page 53: Section 7: Installation

P30 and S30 Low Voltage VSD Section 7:Installation Section 7: Installation This section describes how to install the VSD on location. Installation procedures for optional and combinable equipment for the drive are discussed in Section 9: Optional and Combinable Equipment of this manual. -

Page 54: Input And Output Power Wiring

P30 and S30 Low Voltage VSD Section 7:Installation 8. Use lockout/tag out procedures (SEN-HSE-S027) before connecting three-phase power of the correct voltage to input terminals (L1, L2, L3 [R, S, T]) and connect three-phase power from output terminals (T1, T2, T3 [U, V, W]) to a motor of the correct voltage and type for the application. Size the conductors in accordance with section 5.2 Selection of Wiring Equipment and Standard Cable Sizes. - Page 55 P30 and S30 Low Voltage VSD Section 7:Installation For Frames 6…7, follow these steps. a. Loosen door screws. b. Gently pry the door open to remove 2. To access the control, continue with these steps. a. Lift the Human Interface Module (HIM) cradle. b.

-

Page 56: Drive Device Port

P30 and S30 Low Voltage VSD Section 7:Installation 7.3.2 DRIVE DEVICE PORT Connectors, embedded devices, and installed option modules, such as I/O and communication adapters, have unique port number assignments. Connectors and embedded devices have fixed port numbers that cannot be changed. Option modules are assigned a port number when installed. -

Page 57: Option Module Installation

P30 and S30 Low Voltage VSD Section 7:Installation Port Device Description Host drive Fixed port for the drive Fixed port at HIM cradle connector. Splitter cable connector provides Port 01 when HIM cradle connector is unused. Handheld or remote HIM connection. Splitter cable DPI port connection Splitter cable... -

Page 58: Confirmation Of Wiring

P30 and S30 Low Voltage VSD Section 7:Installation b. Recommended screwdriver = T15 Hexalobular Note Option modules are assigned a port number when installed. Avoid swapping the module to a different port after it is installed. When the module is swapped to another port, it can cause a hardware configuration change alarm in the drive, inhibiting drive to start. -

Page 59: Start-Up Test

P30 and S30 Low Voltage VSD Section 7:Installation 7.5 START-UP TEST Potential Severity: Light Potential Loss: Assets Hazard Category: Electrical Prior to releasing an electrical drive system for regular operation after installation, the system should be given a start-up test by qualified personnel. This start-up test assures correct operation of the equipment, system reliability, and safe performance. -

Page 60: Section 8: Start-Up And Commissioning

Potential Loss: Assets, Personnel, Reputation Hazard Category: Electrical, Explosives Troubleshooting or servicing a Sensia VSD must be performed by qualified personnel. Qualified personnel is defined as those who have attended and successfully completed the required trainings. Completion of this training course is NOT a substitute for field experience. Course-trained personnel should be accompanied and mentored by experienced personnel until deemed competent to work unsupervised. -

Page 61: Pre-Power Up Checks For Initial Startup

P30 and S30 Low Voltage VSD Section 8:Start-up and Commissioning Tool Description Details Combination wrench 10 mm, 17 mm Phillips screw #2, 492-C driver/bit Pozidriv #2, M3 x 7 Torque wrench 1...12 N•m (8.8…106 lb•in) Torque wrench 6...50 N•m (53…443 lb•in) Other equipment or tools generally used in start-up are listed in the VSD Tools Kit (PN 100072064). -

Page 62: Communication Settings

P30 and S30 Low Voltage VSD Section 8:Start-up and Commissioning Item Description Check () There is an adequately sized protective earth (ground) conductor between the motor and the drive, and the conductor has been connected to appropriate terminal, and the terminal has been tightened. (Pull on the conductors to check.) Proper grounding has also been measured according to the regulations. -

Page 63: Commissioning Procedures

P30 and S30 Low Voltage VSD Section 8:Start-up and Commissioning 3. Make sure that it is safe to connect voltage. Ensure that • cabinet doors are closed • nobody is working on the drive or circuits that have been wired from outside into the drive cabinet cover of the motor terminal box is in place •... - Page 64 P30 and S30 Low Voltage VSD Section 8:Start-up and Commissioning 4. Start the VSD. 5. Perform necessary calibration to the connected sensor. These sensors must be calibrated to provide the correct output signal. 6. Once all external signals and subsystems have been connected to the drive, run the motor auto-tune routine, and perform direction test.

-

Page 65: Section 9: Optional And Combinable Equipment

P30 and S30 Low Voltage VSD Section 9:Optional and Combinable Equipment Section 9: Optional and Combinable Equipment The following table provides information about optional equipment that is available for the drives. Description Remarks Item Code Dynamic Braking Resistor Door mounted HIM Default option DV/DT Filter EMC Core... -

Page 66: Section 10: Maintenance

Potential Loss: Assets, Personnel, Reputation Hazard Category: Electrical, Machinery equipment hand tools Troubleshooting or servicing a Sensia VSD must be performed by qualified personnel. Qualified personnel is defined as those who have attended and successfully completed the required trainings. Completion of the training course is NOT a substitute for field experience. -

Page 67: Table 10-1: Descriptions Of Symbols

Section 10:Maintenance The maintenance and component replacement intervals assume that the equipment is operated within the specified ratings and ambient conditions. Sensia recommends annual drive inspections to ensure the highest reliability and optimum performance. This annual preventive maintenance program includes the following primary tasks: a visual inspection of all drive components visible from the front of the unit •... -

Page 68: Requesting Maintenance Support

InTouchSupport.com so that the field user can complete a hardcopy version on site and enter the information on the InTouchsupport.com database upon returning to the Sensia service center or shop. Refer to B.2 Application Data and Issue identification Table for the necessary information required to request assistance from LCS engineers. -

Page 69: Drive Maintenance

P30 and S30 Low Voltage VSD Section 10:Maintenance 10.4 DRIVE MAINTENANCE The drive shall be kept free of contamination as far as practical. If inspection reveals that dust, dirt, moisture, or other contamination has reached the control equipment, the cause must be eliminated. This contamination can indicate an incorrect or ineffective enclosure, unsealed enclosure openings (conduit or other), or incorrect operating procedures. -

Page 70: Figure 10-1: Bus Capacitor Reforming Guidelines

P30 and S30 Low Voltage VSD Section 10:Maintenance Figure 10-1: Bus Capacitor Reforming Guidelines Table 10-4: Drive Storage Duration and Reforming Recommendation (1)(2) Duration Guideline Under 1 year No reforming required 1…2 years Apply rated voltage, per the normal method, for 60 minutes under no load. 2…3 years Using a DC power supply that is connected directly to the DC terminals of the product, ramp up voltage from 0…100% of DC bus voltage (see Table 10-5) in... -

Page 71: Motor Controller Maintenance

P30 and S30 Low Voltage VSD Section 10:Maintenance 10.7 MOTOR CONTROLLER MAINTENANCE Refer to the respective controller manual for detailed maintenance routines that should be performed periodically or as required: INSTRUCT PCP Intelligent Controller Hardware Installation Manual (LCS-ENG-M0017) • • INSTRUCT PCP Intelligent Controller Configuration Manual (LCS-ENG-M0018) •... -

Page 72: Section 11: Troubleshooting

Potential Loss: Assets, Personnel, Reputation Hazard Category: Electrical, Explosives, Machinery equipment hand tools Troubleshooting or servicing a Sensia VSD must be performed by qualified personnel. Qualified personnel is defined as those who have attended and successfully completed the required trainings. Completion of the training course is NOT a substitute for field experience. -

Page 73: Pre-Power Up Checks

P30 and S30 Low Voltage VSD Section 11:Troubleshooting 11.3 PRE-POWER UP CHECKS Perform the following checks before applying any power to the drive. Potential Severity: Major Potential Loss: Personnel, Reputation Hazard Category: Electrical, Explosives Use appropriate lockout/tag out procedures (refer to SEN-HSE-S027) to ensure that VSD power is OFF before proceeding with the following checks and procedures. -

Page 74: Setting Factory Defaults

P30 and S30 Low Voltage VSD Section 11:Troubleshooting 1. Access the Status screen on HIM. 2. Use the key to scroll to the port of the device you want to reset (for example, Port 00 for the host drive). 3. Press the key to display its last-viewed folder. -

Page 75: Troubleshooting The Controller

P30 and S30 Low Voltage VSD Section 11:Troubleshooting 7. Use the key to select the appropriate action. Host and Ports (Preferred): Selects the host device and all ports for a factory default action. • This Port Only: Selects only this port for a factory default action. •... -

Page 76: Section 12: Appendixes

P30 and S30 Low Voltage VSD Section 12:Appendixes Section 12: Appendixes To supplement this P30 and S30 Low Voltage VSD Installation, Operation & Maintenance Manual, the following appendixes are provided: Appendix A:Menu Maps • Appendix B:Reference Material • Appendix C:VSD Module Catalogue Number Explanation •... -

Page 77: Appendix A: Menu Maps

Appendix A:Menu Maps P30 and S30 Low Voltage VSD Appendix A: Menu Maps Refer to the respective controller manual for the menu maps: INSTRUCT PCP Intelligent Controller Hardware Installation Manual (LCS-ENG-M0017) • INSTRUCT PCP Intelligent Controller Configuration Manual (LCS-ENG-M0018) • INSTRUCT SRP Intelligent Controller User Manual (LCS-ENG-M0019) •... -

Page 78: Appendix B: Reference Material

Appendix B:Reference Material P30 and S30 Low Voltage VSD Appendix B: Reference Material This appendix contains documents that do not readily belong in the main sections of the manual. Often, newly released information will be included in reference material before being incorporated to the main manual sections. - Page 79 Appendix B:Reference Material P30 and S30 Low Voltage VSD 15. What is the point of common coupling for the harmonic measurements (PCC 1-7)? Refer to Figure B-1: VSD Points of Common Coupling...

-

Page 80: Figure B-1: Vsd Points Of Common Coupling

Appendix B:Reference Material P30 and S30 Low Voltage VSD Figure B-1: VSD Points of Common Coupling In this diagram, PCCs listed on the left identify common points of coupling. -

Page 81: Application Data And Issue Identification Table

Appendix B:Reference Material P30 and S30 Low Voltage VSD APPLICATION DATA AND ISSUE IDENTIFICATION TABLE Figure B-2: Application Data and Issue Identification Table (p.1 of 2) provided here is used in the Troubleshooting section of this manual. This table provides information for InTouch to assist in the diagnosis and solution of a problem in the field. -

Page 82: Figure B-2: Application Data And Issue Identification Table

Appendix B:Reference Material P30 and S30 Low Voltage VSD Figure B-2: Application Data and Issue Identification Table (p.1 of 2) -

Page 83: Figure B-3: Application Data And Issue Identification Table

Appendix B:Reference Material P30 and S30 Low Voltage VSD Figure B-3: Application Data and Issue Identification Table (p. 2 of 2) -

Page 84: Appendix C: Vsd Module Catalogue Number Explanation

Appendix C:VSD Module Catalogue Number Explanation P30 and S30 Low Voltage VSD Appendix C: VSD Module Catalogue Number Explanation Note Appendix C references content from the following Rockwell Automation document: • 750-TD001 PowerFlex 750-Series AC Drives Technical Data The Catalogue Number of the power module is displayed at the product label attached to the module. The Catalogue Number explanation follows:... - Page 85 Appendix C:VSD Module Catalogue Number Explanation P30 and S30 Low Voltage VSD...

-

Page 86: Appendix D: Vsd Modbus/Tcp Adapter Status Indicator

Appendix D:VSD Modbus/TCP Adapter Status Indicator P30 and S30 Low Voltage VSD Appendix D: VSD Modbus/TCP Adapter Status Indicator Note Appendix D references content from the following Rockwell Automation document: 20COMM-UM014C 20-COMM-M Modbus/TCP Adapter User Manual • The adapter has four status indicators. They can be viewed on the adapter. Status Item Description... -

Page 87: Mod Status Indicator

Appendix D:VSD Modbus/TCP Adapter Status Indicator P30 and S30 Low Voltage VSD Status Cause Corrective Action Steady The drive has refused an I/O Important: Cycle power to the drive (or adapter if connection from the adapter. mounted in a DPI External Comms Kit) after making any of the following corrections. -

Page 88: Net B Status Indicator

Appendix D:VSD Modbus/TCP Adapter Status Indicator P30 and S30 Low Voltage VSD the adapter needs an IP • Correctly connect the Ethernet cable to the Ethernet address. connector. • Set a unique IP address using a BOOTP server or by disabling BOOTP and using adapter parameters. -

Page 89: Appendix E: Vsd Dual-Port Ethernet/Ip Option Module Status Indicator

Appendix E:VSD Dual-port Ethernet/IP Option Module Status Indicator P30 and S30 Low Voltage VSD Appendix E: VSD Dual-port Ethernet/IP Option Module Status Indicator Note Appendix E references content from the following Rockwell Automation document: 750COM-UM008 PowerFlex 20-750-ENETR Dual-port EtherNet/IP Option Module User Manual •... -

Page 90: Port Status Indicator

Appendix E:VSD Dual-port Ethernet/IP Option Module Status Indicator P30 and S30 Low Voltage VSD PORT STATUS INDICATOR This red/green bicolor status indicator indicates the status of the option module connection to the drive as shown in this table. Status Cause Corrective Action The option module is not •... -

Page 91: Net A Status Indicator

Appendix E:VSD Dual-port Ethernet/IP Option Module Status Indicator P30 and S30 Low Voltage VSD Status Cause Corrective Action • Place the scanner in RUN mode. Flashes The option module is operating • Program the controller to recognize and transmit Green normally, but is not transferring I/O data I/O to the option module. -

Page 92: Net B Status Indicator

Appendix E:VSD Dual-port Ethernet/IP Option Module Status Indicator P30 and S30 Low Voltage VSD NET B STATUS INDICATOR This green status indicator indicates the status of the option module that is transmitting on the network as shown this table. Status Cause Corrective Actions The option module is not... -

Page 93: Appendix F: P30 And S30 Vsd Support Resources

Well Production System – ALS-ESP • Surface Electrical helpdesk. HOW TO REACH US You can find more information about Sensia and the P30 and S30 Drives information here: Sensia Home Page: https://www.sensiaglobal.com/ Sensia Lift Control Solutions Page: https://www.sensiaglobal.com/Sensia-Lift-Control-Systems...

Need help?

Do you have a question about the INSTRUCT P30 INTELLIGENT VSD and is the answer not in the manual?

Questions and answers