Summary of Contents for Landoll Brillion WL Series

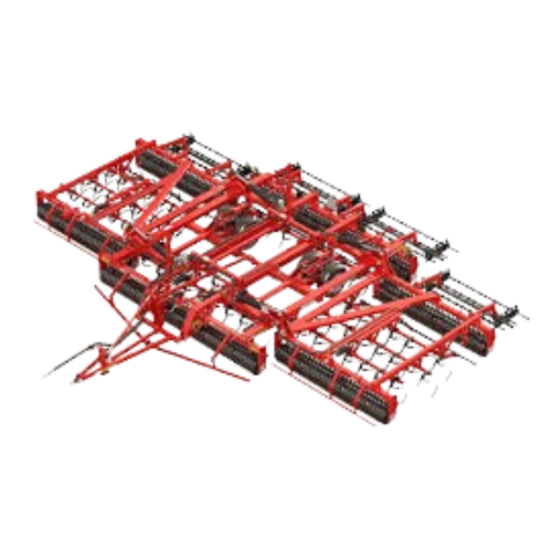

- Page 1 ‘ WL Folding Pulvi-Mulcher Models: WL, WCL, WLC, WCC, WLS, WCLS, WLCS, WCCS, W2603 and W3003 Operator’s Manual LANDOLL COMPANY, LLC 1900 North Street Marysville, Kansas 66508 (785) 562-5381 800-428-5655 ~ WWW.LANDOLL.COM 1K063-2407...

- Page 2 Manuals for WL Folding Pulvi-Mulcher Manual Number Manual Type 1K063 Operator’s Manual 1K064 Parts Manual...

- Page 3 DANGER DO NOT operate or perform any maintenance tasks on this equipment until you have completed the following: 1. Receive proper training to operate this equipment safely. 2. Read and understand the operator’s manual. 3. Be thoroughly trained on inspection and repair procedures. Failure to comply with this warning may result in serious injury or possibly death.

- Page 5 Table of Contents Safety Introduction ............1-1 Description of Unit .

- Page 6 TABLE OF CONTENTS Independent Tooth Control S-Tine Installation ......2-25 Independent Tooth Control C-Tooth Installation......2-26 Bracket Relationship per Tine Style - Independent .

- Page 7 TABLE OF CONTENTS Hydraulic System Maintenance........4-4 Purging Hydraulic System after repairs .

- Page 9 Failure to comply with this warning can result in within 10 days of retail purchase, using the Landoll personal injury or death, damage to the Corporation Ag Products on-line registration process.

- Page 10 TABLE OF CONTENTS SAFETY Safety • When applying decals to the implement, be sure to clean the surface to remove any dirt or residue. Where possible, sign placement should protect the NOTE sign from abrasion, damage, or obstruction from Investigation has shown that nearly 1/3 of all farm mud, dirt, oil etc.

- Page 11 TABLE OF CONTENTS SAFETY Safety Instructions for Towing Maintenance Safety Vehicles • Block the machine so it will not roll when working on or under it. The maximum travel speed is the lesser of • Make sure Transport Lock Pin is installed and •...

- Page 12 TABLE OF CONTENTS SAFETY High Pressure Fluid Safety Carriage Bolt, Escaping fluid under pressure can be nearly invisible and Drawbar 1-8 x 3-1/2 Tractor have enough force to penetrate the skin causing serious Drawbar injury. Use a piece of cardboard, rather than hands, to search for suspected leaks.

- Page 13 WARD OF 9J-257 ANGLE BRKTS.) ANGLE BRKTS.) ITEM 10 ITEM 9 ITEM 11 - 9J257 144193 2P151 MEMBER Landoll Company, LLC Marysville, Kansas www.landoll.com PULVERIZER MODEL # SERIAL # MADE IN USA 1-573-010006 FARM EQUIPMENT MANUFACTURERS A S S O C I A T I O N...

- Page 14 TABLE OF CONTENTS SAFETY Figure 1-5: WL2603-3003 Front View Decals (1 of 3) 1K063-2407...

- Page 15 TABLE OF CONTENTS SAFETY Figure 1-6: WL2603-3003 Rear View Decals (2 of 3) 1K063-2407...

- Page 16 TABLE OF CONTENTS SAFETY Figure 1-7: WL2603-3003 Rear View Decals - (Before 07/2016) (3 of 3) 1K063-2407...

- Page 17 Chapter 2 TABLE OF CONTENTS Assembly IMPORTANT CAUTION All Harnesses must be firmly attached to machine Do Not work on or under this machine unless frame members or Hydraulic Hoses so they do not securely blocked and supported by a hoist or sag or become torn loose by field debris.

- Page 18 TABLE OF CONTENTS ASSEMBLY Frame Assembly Frame Assembly Dimensions: See Figure 2-2. 1. Place Front and Rear Frame Tubes on supports approximately 2 feet high and spaced 10 feet a part. Ensure supports are rated at 2,000lbs each. 2. Position Inner Frame Tubes. Fasten Inner Frame Tubes to Front and Rear Tubes with 3/4-10 x 2 Bolts, Lock Washers, and Nuts.

- Page 19 TABLE OF CONTENTS ASSEMBLY Figure 2-1: Frame 1K063-2407...

- Page 20 TABLE OF CONTENTS ASSEMBLY Figure 2-2: Frame Assembly Dimensions 1K063-2407...

- Page 21 TABLE OF CONTENTS ASSEMBLY Rockshaft Installation 1. Place the Rockshaft under the frame Rockshaft Mounting Angles. 2. Coat the bearing surface of the Bearing Assemblies with grease before fastening Rockshaft to Frame with 5/8-11 x 7 Bolts, Lock Washers, and Nuts. 3.

- Page 22 TABLE OF CONTENTS ASSEMBLY Tire Installation WARNING Use a torque wrench to assure proper torque. Insufficient torque can cause stud breakage and damage the wheel pilots. Over torque can over stress the studs and strip the threads. NOTE All tire/wheel assemblies are mounted with the valve stem facing outward from Hub and Spindle.

- Page 23 TABLE OF CONTENTS ASSEMBLY Rockshaft Link 4. In the front hole of the Link, install Roller Assembly with a 1.375 x 1.66 x .688 Spacer on each side, place 1. On the front frame tube angle bottom hole, install .546 Thrust Washer on the outside of Link.

- Page 24 TABLE OF CONTENTS ASSEMBLY Roll Pin,1/4 x 2 Pin,1 x 5-1/16 Flat Washer, Bushing, 1" Narrow 1.75 x 1.03 x .75 Thrust Washer 1-1/4 x 12 Ga Link Pin,1.25 x 4.5 Roll Pin,1/4 x 2 Spacer, 1.375 x 1.66 x .688 Roller Assembly Transport Lock Pin...

- Page 25 TABLE OF CONTENTS ASSEMBLY Drawbar Installation 3. Install Jack onto the male swivel on the side of the Drawbar. The swivel on the top of the Drawbar is for 1. Attach the factory assembled Drawbar to the Frame storing the Jack. by removing and reinstalling the 1 x 7-7/16 Pins, Flat 4.

- Page 26 TABLE OF CONTENTS ASSEMBLY Spring Linkage Assembly the nut. This will need to be adjusted after the hydraulic system is hooked up. 2. Align Spring Linkage slot with Drawbar Center Mast. NOTE On the Center Mast place a flat washer on each side The purpose of the Spring Linkage is to cause the rear of of the Spring Linkage slot.

- Page 27 TABLE OF CONTENTS ASSEMBLY Table provided for general use. NOTES: 1K063-2407 2-11...

- Page 28 TABLE OF CONTENTS ASSEMBLY Wing Stop, Relief Valve, Fold Cylinder Installation 1. Install two shims to the outside of the two hole plate under each Center Frame Hinge, secure with 1/2-13 x 1-3/4 Bolts, Lock Washers and Nuts. The shims are a stop for the Wing down float.

- Page 29 TABLE OF CONTENTS ASSEMBLY Figure 2-10: Wing Stop, Relief Valve, Fold Cylinders 1K063-2407 2-13...

- Page 30 TABLE OF CONTENTS ASSEMBLY Hydraulic Fold and Lift Tightening Procedure For Swivel O-Ring Fittings 1. Lubricate O-Ring and install the fitting until the metal Installation washer which backs up the O-Ring contacts the face of the boss. IMPORTANT 2. Orient the fitting by turning counterclockwise up to 1 Unfold and lower the unit to the ground and relieve turn.

- Page 31 TABLE OF CONTENTS ASSEMBLY Elbow, 90° 8MJ x 8MOR Hose Asm, 3/8 x 36 Hyd Cyl, Hyd Cyl, 3-1/2 x 16 3-1/2 x 16 Elbow, 90° 8MJ x 8MOR Breather, 8MOR Hose Asm,3/8 x 56 Hose Asm,3/8 x 56 Tee Branch, 8MJ x 8MJ x 8FJS Adapter,8MJ x 8MOR Elbow, 90°...

- Page 32 TABLE OF CONTENTS ASSEMBLY Purging the Fold and Lift DANGER DANGER Hydraulic System Falling wings can cause injury or death. Stand clear when wings are being raised or lowered. IMPORTANT Unfold and lower the unit to the ground and relieve system pressure before attempting to repair, adjust, DANGER DANGER...

- Page 33 TABLE OF CONTENTS ASSEMBLY Roller Installation 1. Center Bracket Assembly has a bearing on each side. End Bracket Assembly has a bearing on one side. Determine Roller Assemblies location based on the 2. Mount a Center Bracket Assembly to the center of the machine model.

- Page 34 TABLE OF CONTENTS ASSEMBLY C-Long Machine Model WL2603 9J523 9J523 9J522 9J523 1K029 1K029 1K029 1K029 WLS2603 WCL2603 9J832 9J833 9J522 9J523 1K074 1K029 1K075 1K029 WCLS2603 WLC2603 9J523 9J523 9J830 9J833 1K029 1K074 1K0029 1K075 WLCS2603 WCC2603 9J832 9J833 9J830 9J833 1K074...

- Page 35 TABLE OF CONTENTS ASSEMBLY Bracket Assembly - Center Assemble Tooth Tube Brackets to Center Frame Vertical Tubes. See Figure 2-18. Reversing some of these brackets will cause interference later when mounting the teeth. S-Tine Machines Assemble a 9J091 Tooth Tube Bracket to the front of each Front and Rear Vertical Center Frame Tube Support top and middle holes with 1/2-13 x 6 Bolts and Locknuts.

- Page 36 TABLE OF CONTENTS ASSEMBLY Tooth Tube Bracket Locations FRONT 9J090 or 9J091 Bracket REAR Figure 2-18: Tooth Tube Bracket Locations 2-20 1K063-2407...

- Page 37 TABLE OF CONTENTS ASSEMBLY Tooth Control Installation S-Tine Carriage Bolt, 1. After you have Tooth Tube Brackets assembled on the machine, pencil mark the tooth locations on the 1/2-13 x 3-1/2 tooth tubes. See Figure 2-23. Clamp 2. Slide the tooth tubes through the Brackets. Both of these tooth tubes must be centered on the machine, an equal length of tube extending out beyond the outer brackets.

- Page 38 TABLE OF CONTENTS ASSEMBLY Center Frame S-Tine Installation Duckfoot Tooth locations are shown in See Figure 2-23. For ease of installation, assemble points with 3/8-16 x 1-3/4 Plow Bolts and Flange Locknuts to spring tine before mounting onto tooth tube. See Figure 2-22. Put 11 Teeth on the front tube and 12 on the rear.

- Page 39 TABLE OF CONTENTS ASSEMBLY Center Frame C-Tooth Installation Tooth locations are shown in See Figure 2-23. Put 11 Teeth on the front tube and 12 on the rear. Secure each with a Tooth Clamp, a Clamp Strap, Lock Washers and Nuts.

- Page 40 TABLE OF CONTENTS ASSEMBLY Tooth Locations FRONT Clamp Clamp Strap Strap Tooth Tube Bracket Linkage Tooth Tube Tooth Tube Tooth Tube Bracket Bracket Clamp Clamp Strap Strap REAR TOP VIEW Figure 2-23: Tooth Locations - Center Frame 2-24 1K063-2407...

- Page 41 TABLE OF CONTENTS ASSEMBLY Independent Tooth Control S-Tine Installation Nut,5/8-11 Lock Washer,5/8 Rear Frame Tube 4-Hole Plate Hydraulic Cylinder Cylinder Tooth Control Bracket Pin,3/4 x 5-5/16 Bracket Bolt,5/8-11 x 8 Cotter Pin, 3/16 x 1-1/2 Washer,3/4 Nut,5/8-11 Lock Washer,5/8 Flat Washer,3/4 Cotter Pin, 3/16 x 1-1/2 Linkage...

- Page 42 TABLE OF CONTENTS ASSEMBLY Independent Tooth Control C-Tooth Installation Nut,5/8-11 Lock Washer,5/8 Rear Frame Tube 4-Hole Plate Hydraulic Cylinder Cylinder Bracket Bolt,5/8-11 x 8 C-Tooth Flat Washer,3/4 Cotter Pin, U-Bolt,5/8-11 3/16 x 1-1/2 Pin, 3/4 x 5-5/16 Lock Washer,5/8 Flat Washer,3/4 Nut,5/8-11 Cotter Pin, Linkage...

- Page 43 TABLE OF CONTENTS ASSEMBLY Bracket Relationship per Tine Style - Independent INDEPENDENT TOOTH CONTROL S-TINE LINKAGE LH Front Angle Rear Frame 9J108 Tube Rear Tooth RH Front Angel Bracket Cylinder Bracket Tooth 9J109 9J220 9J216 Linkage Hydraulic Cylinder or Rachet Jack FRONT S-Tine INDEPENDENT TOOTH CONTROL...

- Page 44 TABLE OF CONTENTS ASSEMBLY Attaching Wings hole. Align Link with the Wing Hinge. Place 1-1/4 Flat Washer on each side between the Link and Hinge LH and RH Wings Assemblies are pre-assembled from while inserting 1-1/4 x 8-3/4 Pin. Add 1-1/4 Flat the factory with Rollers and Inner and Outer Wing Washer on the outside of the Wing Hinge.

- Page 45 TABLE OF CONTENTS ASSEMBLY Bracket Assembly - Wing Assemble Tooth Tube Brackets to Wing Frame Verical Tubes. See Figures 2-28 and 2-29. Reversing some of these brackets will cause interference later when mounting the teeth. S-Tine Machines: Assemble a 9J091 Tooth Tube Bracket to the front of each Front and Rear Vertical Center Frame Tube Support top and middle holes using 1/2-13 x 6 Bolts and Locknuts.

- Page 46 TABLE OF CONTENTS ASSEMBLY 10" 10" LH Wing RH Wing Frame Frame 7-3/4" 7-3/4" FRONT HINGE Tooth Tooth 9J090 or Tube Tube 9J091 Bracket REAR HINGE 7-3/4" 7-3/4" 11-1/2" 11-1/2" Figure 2-30: Wing Bracket Mounting Dimensions 2-30 1K063-2407...

- Page 47 TABLE OF CONTENTS ASSEMBLY Wing Tooth Control Installation Spring Tooth LH Wing Shown in Figure 2-34 and 2-35. RH is a mirror image. 1. After you have Tooth Tube Brackets assembled on Tooth Clamp the Wing Frames, pencil mark the tooth locations on the Tooth Tubes.

- Page 48 TABLE OF CONTENTS ASSEMBLY Wing S-Tine Installation Wing C-Tooth Installation Wing Tooth locations are shown in Figures 2-34 and Wing Tooth locations are shown in Figures 2-34 and 2-35. For ease of installation, assemble points with 3/8-16 2-35. 2603 Models put 5 Teeth on the front Tooth Tube x 1-3/4 Plow Bolts and Flange Lock Nuts to spring tine and 4 on the rear Tooth Tube.

- Page 49 TABLE OF CONTENTS ASSEMBLY Wing Tooth Mounting Dimensions Wing Frame FRONT HINGE Tooth Tube Bracket Tooth Tube Bracket Clamp Strap Tooth Tube Tooth Tube Bracket Clamp Strap Clamp Strap REAR HINGE TOP VIEW MODEL 2603 Figure 2-34: 2603 Model Wing Tooth Locations 1K063-2407 2-33...

- Page 50 TABLE OF CONTENTS ASSEMBLY Wing Frame FRONT HINGE Tooth Tube Bracket Tooth Tube Bracket Clamp Tooth Strap Tube Tooth Tube Bracket Clamp Strap Clamp Strap REAR HINGE TOP VIEW MODEL 3003 Figure 2-35: 3003 Model Wing Tooth Locations 2-34 1K063-2407...

- Page 51 TABLE OF CONTENTS ASSEMBLY INDEPENDENT TOOTH CONTROL WING C-TOOTH LINKAGE Rear Wing Front Wing Frame Tube Frame Tube Tooth Control Bracket 9J218 Linkage Cylinder Bracket Strap 9J216 Front Bracket LH 9J163 Front Bracket RH Hydraulic Cylinder 9J164 or Rachet Jack Rear Bracket LH 9J159 Rear Bracket RH 9J160 FRONT...

- Page 52 TABLE OF CONTENTS ASSEMBLY Figure 2-38: Wing Independent Tooth Control - S-Tine 2-36 1K063-2407...

- Page 53 TABLE OF CONTENTS ASSEMBLY Figure 2-39: Wing Independent Tooth Control - C-Tooth 1K063-2407 2-37...

- Page 54 TABLE OF CONTENTS ASSEMBLY Table provided for general use. NOTES: 2-38 1K063-2407...

- Page 55 TABLE OF CONTENTS ASSEMBLY Hydraulic Independent Tooth Plumb the Independent Tooth Control Circuit Control 1. Install O-Ring x Male JIC Fitting into each Cylinder NOTE Port. See Figure 2-41. Relieve system pressure before attempting to repair, 2. Install hoses and the rest of the fittings. Route them adjust, or disconnect components.

- Page 56 TABLE OF CONTENTS ASSEMBLY Hose Asm, Hose Asm, 3/8 x 196 3/8 x 30 Hose Asm, 3/8 x 136 Adapter, 8MJ x 8MOR Adapter, 8MJ x 8MOR Hyd Cyl, Hyd Cyl, 3 x 8 3 x 8 RH WING LH WING CENTER Elbow, 90°...

- Page 57 TABLE OF CONTENTS ASSEMBLY Rear Notched Wheel Scraper Scraper and a Scraper Bracket. Secure the Scrapers to the Brackets with 3/8-16 x 3-1/2 Bolts, Flat Installation Washers, Lock Washers, and Nuts. These Scrapers are fixed and cannot be moved side to side. NOTE 3.

- Page 58 TABLE OF CONTENTS ASSEMBLY Lock Washer,1/2 Nut,1/2-13 LH Scraper Bracket Bolt, 3/8-16 x 3-1/2 Scraper, 2" Wide Flat Washer,1/2 Bolt,1/2-13 x 1-3/4 U-Bolt,3/8-16 Lock Washer,3/8 RH Scraper Bracket Tube Scraper 2" Wide Nut,3/8-16 Scraper 2-1/2" Wide Flat Washer,3/8 Figure 2-43: Wing Scrapers 2-42 1K063-2407...

- Page 59 TABLE OF CONTENTS ASSEMBLY Warning Lamp Installation IMPORTANT All harnesses must be firmly attached to machine 1. Install a Tall Lamp Bracket approximately 31 inches frame members, or hydraulic hoses, so they do not from center line on each side of the rear frame tube sag or become torn loose by field debris.

- Page 60 TABLE OF CONTENTS ASSEMBLY Figure 2-45: Warning Lamp Installation - Detail 2-44 1K063-2407...

- Page 61 TABLE OF CONTENTS ASSEMBLY Figure 2-46: Warning Lamp Installation 1K063-2407 2-45...

- Page 62 TABLE OF CONTENTS ASSEMBLY Rear Hitch - Optional 1. Remove the U-Bolts that mount the diagonal braces to the Inner Frame Tubes. 2. Attach the Rear Hitch between the Inner Frame Tubes, with 5/8-11 x 6 Bolts, Lock Washers, and Nuts.

- Page 63 TABLE OF CONTENTS ASSEMBLY Land Leveler - Optional 2. Assemble Left and Right Hand Adjusting Angles to the Brackets with 1/2-13 x 1-1/2 Bolts, Lock Washers and Nuts. NOTE 3. Center Leveler Angle in front of the Center Frame and If the soil pushes ahead of the bar it is set too low.

- Page 64 TABLE OF CONTENTS ASSEMBLY Bracket LH RH WING Note: All views are from the top. Bracket RH 3J552 3J551 RH Outer Frame Tube Angle RH 12-1/2" 3J556 Angle LH Leveler Angle 3J557 9D307 (2603 Models) LH WING 9D752 (3003 Models) Bracket RH Bracket LH 3J551...

- Page 65 TABLE OF CONTENTS ASSEMBLY V-Leveler - Optional NOTE If the soil pushes ahead of the bar it is set too low. 1. Place the V-Leveler Bracket on top of the center Drawbar Tube behind the Drawbar Brace Tubes with 3/4-10 Lock Washers, and Nuts. Do not tighten at this time.

- Page 66 TABLE OF CONTENTS ASSEMBLY Figure 2-50: V-Leveler Assembly - Optional 2-50 1K063-2407...

- Page 67 TABLE OF CONTENTS ASSEMBLY Bracket LH RH WING Note: All views are from the top. Bracket RH 3J552 3J551 RH Outer Frame Tube Angle RH 12-1/2" 3J556 Angle LH Leveler Angle 3J557 9D307 (2603 Models) LH WING 9D752 (3003 Models) Bracket RH Bracket LH 3J551...

- Page 68 TABLE OF CONTENTS ASSEMBLY Table provided for general use. NOTES: 2-52 1K063-2407...

- Page 69 Chapter 3 TABLE OF CONTENTS Operation DANGER DANGER CAUTION Never allow anyone a ride on the Pulvi-Mulcher at When transporting farm implements on public any time. Allowing a person to ride on the machine roads, it is the responsibility of the operator to can inflict serious personal injury or death to that abide by state and local laws concerning wide person.

- Page 70 TABLE OF CONTENTS OPERATION Attaching to the Tractor • If an operator plugs in the 7-Pin Connector, but the lights do not seem to work right, check the 1. Align the Tractor Drawbar with the machine. Raise or above items to make sure there is a good lower the hitch, as needed, using the jack.

- Page 71 TABLE OF CONTENTS OPERATION General Operation DANGER DANGER Watch out for Overhead Electrical Wires and other Overhead Obstructions when folding and unfolding Pulvi-Mulcher Wings. 1. The minimum horsepower requirement is 6-8 horsepower per foot. Horsepower requirements will vary due to speed, moisture, residue and types of soils.

- Page 72 TABLE OF CONTENTS OPERATION Hydraulic System Lift and Fold Circuit • The purpose of the Relief Valve is to protect the IMPORTANT Rockshaft from damage. Unfold and lower the unit to the ground and relieve • The wing fold cylinders are equipped with restrictors system pressure before attempting to repair, adjust, to prevent uncontrolled falling of wing frames when or disconnect components.

- Page 73 TABLE OF CONTENTS OPERATION for repair such as cylinder, hose, or fitting replacement/repair. Front Frame Spacer Hairpin Cotter Tube Angles • Do not loosen hoses/fittings after the Hydraulic Circuit has been purged. • Recheck tractor reservoir oil level. Transport Lock (After 07/2016) Field to Road 1.

- Page 74 TABLE OF CONTENTS OPERATION Transport Lock (Before Road to Field 1. Unfold the Wings then raise the machine slightly to 07/2016) loosen the Transport Lock Pin. 2. Remove the Transport Lock Pin from the Link second CAUTION hole from the rear (transport lock position). Insert the Pin in the Link rear hole (storage position).

- Page 75 TABLE OF CONTENTS OPERATION Depth Control NOTE The center frame links and wing links must always be in S-Tine and C-Tooth depth is controlled by adjusting the "agreement" or the spring teeth on wings will work at a position of the 3 x 8 Cylinder Striker Plate limiting the different depth than center frame.

- Page 76 TABLE OF CONTENTS OPERATION Notched Wheel Scraper Land Leveler / V-Leveler – Adjustment Optional NOTE NOTE Rear Notched Roller Wheel Scrapers are standard and The Leveler is set too low if the soil pushes ahead of the reversible. Front Notched Roller Scrapers are optional. Leveler Angle.

- Page 77 TABLE OF CONTENTS OPERATION Frame Weldment Drawbar Pin,1 x 12-1/2 4" 3" Setting Soil Soil Surface Surface Clevis Pin, Wing 1 x 2-1/2 Leveler V-Leveler Front Roller Figure 3-8: V-Leveler Side View 1K063-2407...

- Page 78 TABLE OF CONTENTS OPERATION Transport 6. Before transporting: • Know the transport height and width of the unit 1. Check and follow all federal, state, and local before transport. Use caution when transporting requirements before transporting the Pulvi-Mulcher. near bridges and power lines. 2.

- Page 79 Chapter 4 TABLE OF CONTENTS Maintenance General Torque Specifications (rev. 4/97) This chart provides tightening torques for general purpose applications when special torques are not specified on process or drawing. Assembly torques apply to plated nuts and capscrews assembled without supplemental lubrication (as received condition). They do not apply if special graphite moly-disulfide or other extreme pressure lubricants are used.

- Page 80 TABLE OF CONTENTS MAINTENANCE Hydraulic Fitting Torque Specifications 37 degree JIC, ORS, & ORB (REV. 10/97 This chart provides tightening torques for general purpose applications when special torques are not specified on process or drawing. Assembly torques apply to plated nuts and capscrews assembled without supplemental lubrication (as received condition). They do not apply if special graphite moly-disulfide or other extreme pressure lubricants are used.

- Page 81 TABLE OF CONTENTS MAINTENANCE Tires Lubrication Maintenance Recommended Tire Size: 11L x 15 - 12 Ply • Lubricate Rockshaft bearings with quality grease daily or if machine is not used for an extended Tire Inflation Pressure: 52 PSI period. Greaseable components are the same on When Re-Installing 1/2-20 x 1 Wheel Bolts tighten to each side.

- Page 82 TABLE OF CONTENTS MAINTENANCE Hydraulic System 1. Check the hydraulic fluid level per tractor owner's manual and after any leakage. Check hydraulic fluid Maintenance level when the C-Teeth or S-Tines are raised, wings are folded and machine is raised for transport. IMPORTANT 2.

- Page 83 TABLE OF CONTENTS MAINTENANCE Clamp Tightening Procedure C-Tooth Point Replacement The tightening procedure and torque requirement is As the C-Tooth Point wears, a replacement reversible critical in keeping the clamp tight. point is available for installation. Place the reversible point on the front of the C-Tooth, Clamp Tightening Procedure: line-up the two bolt holes, insert two 3/8-16 x 1-3/4 1.

- Page 84 TABLE OF CONTENTS MAINTENANCE Warning Lamps Storage When plugging in the 7-Pin Warning Lamp Connector: 1. The service life of the Pulvi-Mulcher will be extended by proper off-season storage practices. Prior to 1. Make sure the Tractor has a good clean Receptacle, storing the unit, complete the following procedures: free of dirt and corrosions.

- Page 85 Chapter 5 TABLE OF CONTENTS Specifications Quick Reference Standard Machine Specifications Transport Height - 6' 2" 4" Roller Axles S-Tine Models: 1-3/8" Points Standard Transport Length - 19' 10" Nominal Teeth Spacing - 6" Dual Transport Wheels 20" Notched Ductile Iron Wheels Maximum Tooth Depth of Operation - 6"...

- Page 86 TABLE OF CONTENTS SPECIFICATIONS Accessories and Optional Equipment Part Approximate Description Number Weight (lbs) Points 2J149 1-3/8" Heavy-Duty Reversible S-Tine Point with Hardware* 2J150 2-3/4" Shovel with Hardware for S-Tines* Optional Equipment 1K086 Front Scraper Kit for 21' 8" Models (For Notched Rollers) 196.0 1K087 Front Scraper Kit for 25' Models (For Notched Rollers)

- Page 87 TABLE OF CONTENTS SPECIFICATIONS Model Specifications WL 2603, WLC 2603, WLS 2603, WLCS 2603, Product Attributes WCL 2603, WCC 2603 WCLS 2603, WCCS 2603 Approximate Weight WL 2603: 10,760 lbs. (4,881 kg) WLS 2603: 10,684 lbs. (4,846 kg) WLC 2603:10,406 lbs. (4,720 kg) WLCS 2603: 10,330 lbs.

- Page 88 TABLE OF CONTENTS SPECIFICATIONS WL 3003, WLC 3003, WLS 3003, WLCS 3003, Product Attributes WCL 3003, WCC 3003 WCLS 3003, WCCS 3003 Approximate Weight WL 3003: 11,585 lbs. (5,255 kg) WLS 3003: 11,499 lbs. (5,216 kg) WLC 3003: 11,462 lbs. (5,199 kg) WLCS 3003: 11,376 lbs.

- Page 89 Document Control Revision Log: Date Form # Improvement(s): Description and Comments 01/2017 1K063-0117 Revised Template 03/2020 1K063-0320 *Revision Format “Year/Month” Updated ISO logos to ISO 9001:2015 (Revised 05/2024) 07/2024 1K063-2407 ECN 50017 - Decals Changes (QR Code, FEMA, 20mph) Revised Template...

- Page 90 Equipment from Landoll Company, LLC is built to exacting standards ensured by ISO 9001:2015 registration at all Landoll manufacturing facilities. WL Folding Pulvi-Mulcher Models: WL, WCL, WLC, WCC WLS, WCLS, WLCS, WCCS W2603 and W3003 Operator’s Manual Re-Order Part Number 1K063...

Need help?

Do you have a question about the Brillion WL Series and is the answer not in the manual?

Questions and answers