Advertisement

Installation, Operation & Maintenance Manual

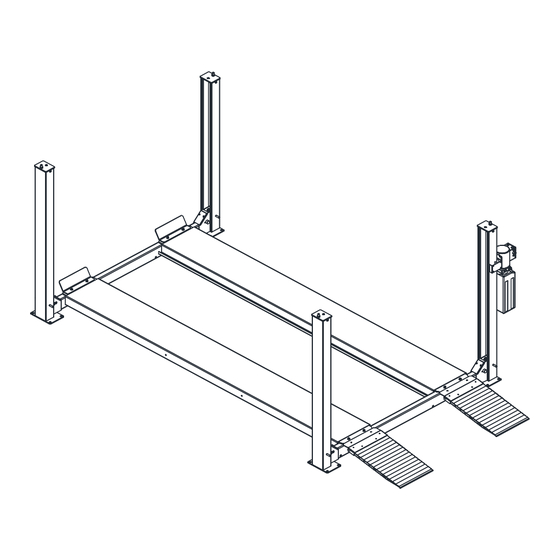

Four Post

Surface Mounted Lift

Models Q4P07

(7,000 lb. Capacity)

2311 South Park Rd Louisville, Kentucky 40219

Email:sales@challengerlifts.com

Web

site:www.challengerlifts.com

/

Office 800-648-5438

502-625-0700 Fax 502-587-1933

IMPORTANT:

READ THIS MANUAL COMPLETELY BEFORE

INSTALLING or OPERATING LIFT

Rev. 2024/03/21

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Challenger Lifts Q4P07

- Page 1 Installation, Operation & Maintenance Manual Four Post Surface Mounted Lift Models Q4P07 (7,000 lb. Capacity) 2311 South Park Rd Louisville, Kentucky 40219 Email:sales@challengerlifts.com site:www.challengerlifts.com Office 800-648-5438 502-625-0700 Fax 502-587-1933 IMPORTANT: READ THIS MANUAL COMPLETELY BEFORE INSTALLING or OPERATING LIFT Rev. 2024/03/21...

-

Page 2: General Specifications

Model Q4P07 Installation, Operation and Maintenance ENERAL PECIFICATIONS SPECIFICATIONS Q4P07 195½” [16’-3 1/2”] Length Overall 100 1/2” (8’-4 1/2”) Width Overall 92 1/8” Inside Columns 147 ½” [12’-3 1/2”] Between Columns 79 1/2” Height of Columns 5 ¾” min – 70 1/2” max Height of Runway, Floor to runway top 20”... - Page 3 Model Q4P07 Installation, Operation and Maintenance Fig 2 – Drive Under Height (On Locks) Q4P07-IOM-Q.doc Rev. 2024/03/21...

-

Page 4: Vertical Clearance

Model Q4P07 Installation, Operation and Maintenance ERTICAL LEARANCE AFETY OTICES AND ECALS Check the height of the area where the lift is to be For your safety, and the safety of others, read and installed. Clearance should be calculated based on understand all of the safety notices and decals the full raised height of the lift. -

Page 5: Installation

Model Q4P07 Installation, Operation and Maintenance Receiving Component Packing List The shipment should be thoroughly inspected as ITEM QTY/ soon as it is received. The signed bill of lading is DESCRIPTION LIFT acknowledgement by the carrier of receipt in good IDLER RUNWAY ASS’Y... - Page 6 Model Q4P07 Installation, Operation and Maintenance 4) Check the lock release bar to ensure it is secure and that the lock pawl is in the correct position as shown in Fig 4. Adjust if necessary. Verify the lock moves freely and make sure the lock pawl return spring doesn’t over-travel and interfere...

- Page 7 Model Q4P07 Installation, Operation and Maintenance 10) Remove the four (4) cross beam sheaves (one sheave from each beam end). DO NOT REMOVE THE RUNWAY SHEAVE PINS. 11) Place the mechanical lock release rod into the saddles located on the inside of the cross beams, Fig 8.

- Page 8 Model Q4P07 Installation, Operation and Maintenance 19) Center cross beam bolts with slots in runway NCHORING PTIONAL and tighten. (Be careful not to move runways.) NOTE: Lift must be anchored in place if slope is grater then 1/8” per 1 foot.

- Page 9 Model Q4P07 Installation, Operation and Maintenance 32) For installs on the front of the column (Fig 16), rout the power unit supply line to the bulkhead shown below. Attach the 90 degree fitting at a slight angle downward and secure the hose to the fitting.

- Page 10 Model Q4P07 Installation, Operation and Maintenance 37) Connect the power unit to a suitable electrical power source. The standard power unit is 115 volt 50/60 Hz single phase requiring a dedicated single throw circuit breaker to operate lift at full capacity. For 230V power unit, refer to Fig 22.

-

Page 11: Operation Procedure

Model Q4P07 Installation, Operation and Maintenance Fig 22 – NON STANDARD 230V WIRING DIAGRAM The Owner/Employer shall maintain the periodic PERATION ROCEDURE inspection and maintenance records recommended by the manufacturer or ANSI/ALI ALOIM, American AFETY OTICES AND ECALS National Standard for Automotive Lifts-Safety... - Page 12 Model Q4P07 Installation, Operation and Maintenance IFTING A EHICLE AINTENANCE Place entrance ramps in the slotted holes on the To avoid personal injury, permit only qualified front of the ramp. Drive vehicle onto lift. Set parking personnel perform maintenance this brake.

- Page 13 Model Q4P07 Installation, Operation and Maintenance (Q4P09CS) PTIONAL CCESSORIES OBILITY 1) This set of four casters when attached to the (Q4P09DT) cross beams of an unloaded lift, Fig 27, pick 1) Place drip tray between runways in the Jack rail, the lift up and allow it to be rolled to a different Fig 24.

- Page 14 Parts Breakdown Models Q4P07 IMPORTANT!!! Replace all worn, damaged, or broken parts with parts approved by Challenger Lifts Inc. or with parts meeting Challenger Lifts Inc. specifications. Contact your local Challenger Lifts Parts Distributor for pricing and availability. (Call Challenger Lifts Inc. (502) 625-0700 for the Parts Distributor in your area) Q4P07-IOM-Q.doc...

- Page 15 Model Q4P07 Installation, Operation and Maintenance Parts Breakdown Fig A. General Layout Q4P07-IOM-Q.doc Rev. 2024/03/21...

- Page 16 3/8-18 NPT x M14x1.5 90 DEGREE HYD. FITTING TCS4-12-00 REMOVABLE WHEEL STOP Replace all worn, damaged, or broken parts with parts approved by Challenger Lifts Inc. or with parts meeting Challenger Lifts Inc. specifications. Contact your local Challenger Lifts Parts Distributor for pricing and availability.

- Page 17 X10-040 M12 NUT M18 NUT Replace all worn, damaged, or broken parts with parts approved by Challenger Lifts Inc. or with parts meeting Challenger Lifts Inc. specifications. Contact your local Challenger Lifts Parts Distributor for pricing and availability. (Call Challenger Lifts Inc. (502) 625-0700 for the Parts Distributor in your area) Q4P07-IOM-Q.doc...

- Page 18 RUNWAY SHEAVE SPACER – TALL TCS3-5-07-02 RUNWAY SHEAVE SPACER - SHORT Replace all worn, damaged, or broken parts with parts approved by Challenger Lifts Inc. or with parts meeting Challenger Lifts Inc. specifications. Contact your local Challenger Lifts Parts Distributor for pricing and availability.

- Page 19 Model Q4P07 Installation, Operation and Maintenance PARTS BREAKDOWN (continued) Fig D. Cross Beams Q4P07-IOM-Q.doc Rev. 2024/03/21...

- Page 20 TCS3-5-21 ROLL PIN, Ø6mm X 24mm Lg. Replace all worn, damaged, or broken parts with parts approved by Challenger Lifts Inc. or with parts meeting Challenger Lifts Inc. specifications. Contact your local Challenger Lifts Parts Distributor for pricing and availability.

- Page 21 Model Q4P07 Installation, Operation and Maintenance REVISIONS 2020/08/10 – UPDATED THE 115V POWER UNIT PART NUMBER. 2020/12/15 – CHANGED POWER UNIT FORM 31368-19 TO AB-9367-DLH. UPDATED WIRING DIAGRAM AND PARTS BREAKDOWN. 2023/12/01 – UPDATED ANSI/ALI REFERENCE MATERIAL. UPDATED ANCHORING REFERENCE MATERIAL.

Need help?

Do you have a question about the Q4P07 and is the answer not in the manual?

Questions and answers