Subscribe to Our Youtube Channel

Summary of Contents for SMC Networks MXS6-X2578

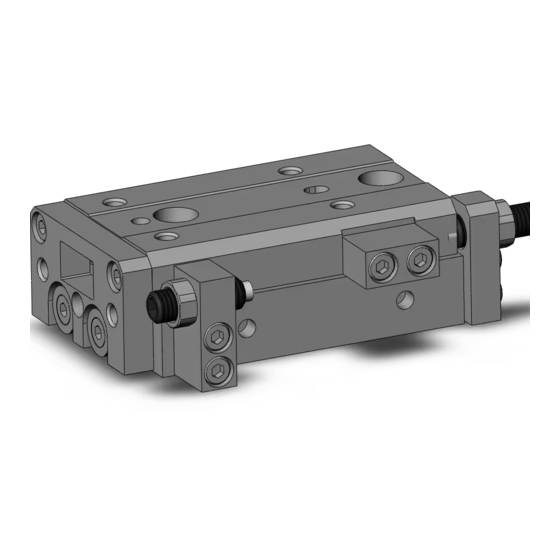

- Page 1 Doc. no.1082441 PRODUCT NAME Adjuster Side Mounting Type / Air Slide Table MODEL / Series / Product Number MXS6(L)-X2578 MXS8(L)-X2578 MXS12(L)-X2578 MXS16(L)-X2578 MXS20(L)-X2578 MXS25(L)-X2578...

-

Page 2: Table Of Contents

Contents Safety Instructions ........................3 1. Product Specifications ......................... 5 1-1. Specifications ........................5 1-2. Stroke adjuster ........................5 2. How to use ..........................6 2-1. Mounting ..........................6 2-2. Air supply ..........................8 2-3. Piping ........................... 9 2-4. Operating Environment......................9 2-5. -

Page 3: Safety Instructions

Safety Instructions These safety instructions are intended to prevent hazardous situations and/or equipment damage. These instructions indicate the level of potential hazard with the labels of “Caution,” “Warning” or “Danger.” They are all important notes for safety and must be followed in addition to International Standards (ISO/IEC) , and other safety regulations. - Page 4 Safety Instructions Caution We develop, design, and manufacture our products to be used for automatic control equipment, and provide them for peaceful use in manufacturing industries. Use in non-manufacturing industries is not covered. Products we manufacture and sell cannot be used for the purpose of transactions or certification specified in the Measurement Act.

-

Page 5: Product Specifications

1. Product Specifications 1-1. Specifications Model MXS6 MXS8 MXS12 MXS16 MXS20 MXS25 φ6 φ8 φ12 φ16 φ20 φ25 Bore size (mm) Port size M3×0.5 M5×0.8 Rc1/8,NPT1/8,G1/8 Fluid Action Double acting Operating pressure 0.15 to 0.7MPa Proof pressure 1.05MPa -10~60℃(No freezing) Ambient and fluid temperature 50 to 500mm/s Operating speed range... -

Page 6: How To Use

2. How to use Warning For general actuator use guidelines, be sure to refer to the Actuator/Precautions of the catalog (Best Pneumatics No.③) before using it. 2-1. Mounting (1) Mounting of body Three types of installation are available according to the machine or work piece. 1. - Page 7 2) How to mount the workpiece 1. Front mounting Maximum Thread depth: Model Bolt Tightening L(mm) MXS6(L) M3x0.5 0.7~0.9 MXS8(L) M4×0.7 1.7~2.1 MXS12(L) M5×0.8 3.5~4.4 MXS16(L) M6×1 5.9~7.4 MXS20(L) M6×1 5.9~7.4 12.5 MXS25(L) M8×1.25 14.5~18.0 14.5 2. Top mounting Guide Maximum Thread depth: Model...

-

Page 8: Air Supply

➆ Keep away objects that are affected by magnets. A magnet is built into the body or, in the case of a type with an auto switch, on the side of the guide block. Keep away magnetic discs, cards or tapes. Data may be erased. ➇... -

Page 9: Piping

➄ Avoid dew condensation Dew condensation can occur inside a pneumatic system when the temperature drops depending on the piping or operating conditions. This can deteriorate or wash away grease, resulting in shortened service life or malfunctions. For details, refer to the catalog “Precautionary measures against condensation in a pneumatic system”... -

Page 10: Lubricating

➁ Do not use the product in an environment directly exposed to foreign matter such as dust, cutting chips and spatter. This can result in play, increased operating resistance, air leakage, etc. If the product is used in such an environment, contact SMC. ➂... -

Page 11: Mounting Of Optional Adjuster

2-7. Mounting of optional adjuster Caution ➀ The stoke adjustment kit is shipped with the product. To correctly install the stroke adjuster, follow the steps below. ➁ The bolts for the adjustment block, mounted to the table, and the Stopper Block, mounted to the body, may be different lengths. - Page 12 2. Body mounted part Install the stopper block, with the adjustment bolt (or shock absorber), set piece, and set screw attached on it, onto the body. Adjustment bolt Shock absorber (BS) Stopper block Set screw Set piece Note) Install the set screw in a partially tightened state so that the adjustment bolt (or shock absorber) can be adjusted.

- Page 13 ➃ Install the retraction end stroke adjuster (AT, BT) by the appropriate method in accordance with the figure and table below. Defective installation may result in a decrease of the positioning accuracy, malfunction, or failure. 1. Table mounted part For shock absorber (BT), install the adjustment block on the table. If you have selected the both ends shock absorber (B) option or the extension end rubber stopper/retraction end shock absorber (ASBT) option, the extension end rubber stopper and the retraction end shock absorber may share the adjustment block, depending on the stroke of the product.

- Page 14 The adjustment block for the rubber stopper and the shock absorber are made from different materials. If you have selected the extension end rubber stopper and retraction end shock absorber (ASBT) options, pay attention to their mounting positions. Adjust block Adjust block Material: Hardening steel Material: Aluminum alloy...

-

Page 15: Handling Of Optional Adjuster

2-8. Handling of optional adjuster ●R ubber stopper Caution Tightening ➀ When replacing the bolt, do not replace it with a bolt other than Model torque N・m the designated adjust bolt. MXS 6 Impact force may cause play, damage, etc. 0.7~0.9 MXS 8 ➁... -

Page 16: Handling Of Symmetrical Type

2-9. Handling of symmetrical type Caution Ensure a minimum spacing of 3mm when mounting standard type and symmetrical type side by side. If there is not sufficient space between the adjusters, the auto switch may malfunction. Unit (mm) Model Mounting pitch: t MXS6(L) MXS8(L) MXS12(L) -

Page 17: Maintenance

3. Maintenance 3-1. Precautions for maintenance Caution ➀ Maintenance should be performed according to the procedure indicated in the Operation Manual. Improper handling can cause damage and malfunction of equipment and machinery. ➁ Removal of equipment, and supply/exhaust of compressed air When components are removed, first confirm that measures are in place to prevent workpieces from dropping and/or equipment running away, etc. -

Page 18: Construction/Parts List

3-3. Construction/Parts list Component parts Description Material Note Body Aluminum alloy Hard anodized Table Aluminum alloy Hard anodized End plate Aluminum alloy Hard anodized Rail Hardening steel Heat treated Guide Hardening steel Heat treated Stainless steel Pistion assembly With magnet on one side Seal support Brass Electroless nickel plated... - Page 19 Component parts: with extension end rubber stopper Description Material Note Stopper block Aluminum alloy Hard anodized Adjustment block Aluminum alloy Hard anodized Adjustment bolt Stainless steel Set screw Stainless steel Set piece Aluminum alloy Component parts: with retraction end rubber stopper Description Material Note...

-

Page 20: Adjuster Parts List

3-4. Adjuster parts list To replace the stroke adjuster, order the required parts from the tables below. Extension end rubber stopper Bore size(mm) Adjuster part no. MXS-AS6(L)-X2578 MXS-AS8(L)-X2578 MXS-AS12(L)-X2578 MXS-AS16(L)-X2578 MXS-AS20(L)-X2578 MXS-AS25(L)-X2578 Retraction end rubber stopper Bore size(mm) Adjuster part no. MXS-AT6(L)-X2578 MXS-AT8(L)-X2578 MXS-AT12(L)-X2578... -

Page 21: Replacement Parts List

3-5. Replacement parts list Replacement parts: Adjuster mounting screw set Model Kit no. Contents MXS6(L) MX-X2578-M4 M4 set screw + set piece MXS8(L) MXS12(L) MX-X2578-M5 M5 set screw + set piece MXS16(L) MXS20(L) MX-X2578-M6 M6 set screw + set piece MXS25(L) Replacement parts: set piece Model... - Page 22 Revision history Tel: + 81 3 5207 8249 Fax: +81 3 5298 5362 https://www.smcworld.com Note: Specifications are subject to change without prior notice and any obligation on the part of the manufacturer. © SMC Corporation All Rights Reserved...

Need help?

Do you have a question about the MXS6-X2578 and is the answer not in the manual?

Questions and answers