Summary of Contents for SMC Networks MGC Seires

- Page 1 Doc. no. MGC*-OM0002C-2 PRODUCT NAME Guide Cylinder MODEL / Series / Product Number MGC Series...

-

Page 2: Table Of Contents

Contents Safety Instructions Product Features 1. How to Order 2. Model/Stroke 3. Specifications 4. Theoretical Output 5. Weight 6. Moving Parts Weight 7. Allowable Kinetic Energy by Air Cushion Mechanism 8. Design/Selection 9. Installations/Adjustment 10. Piping 11. Lubrication 12. Air Supply 13. -

Page 3: Safety Instructions

Safety Instructions These safety instructions are intended to prevent hazardous situations and/or equipment damage. These instructions indicate the level of potential hazard with the labels of “Caution,” “Warning” or “Danger.” They are all important notes for safety and must be followed in addition to International Standards (ISO/IEC) , and other safety regulations. - Page 4 Safety Instructions Caution The product is provided for use in manufacturing industries. The product herein described is basically provided for peaceful use in manufacturing industries. If considering using the product in other industries, consult SMC beforehand and exchange specifications or a contract if necessary. If anything is unclear, contact your nearest sales branch.

-

Page 5: Product Features

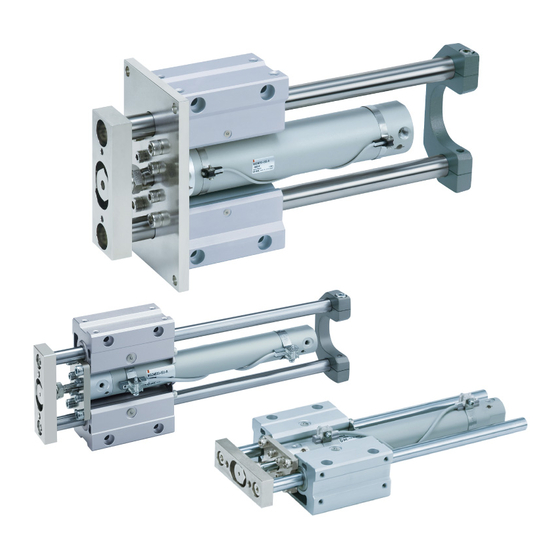

Product Features Guide Cylinder/Compact Type MGC Series φ20, φ25, φ32, φ40, φ50... -

Page 6: How To Order

1. How to Order WEB catalog for details. Applicable Auto Switches /Refer to WEB catalog for further information on auto switches. WEB catalog. WEB catalog. -

Page 7: Model/Stroke

2. Model/Stroke 3. Specifications 4. Theoretical Output... -

Page 8: Weight

5. Weight 6. Moving Parts Weight 7. Allowable Kinetic Energy by Air Cushion Mechanism WEB catalog. -

Page 9: Design/Selection

8. Design/Selection 1) Confirm the specifications. Products represented in this catalog are designed only for use in compressed air systems (including vacuum). Do not operate at pressures, temperatures, etc., beyond the range of specifications, as this can cause damage or malfunc tion. Please contact SMC when using a fluid other than compressed air made by pneumatic equipment (including vacuum). -

Page 10: Installations/Adjustment

14) When a cylinder is used in a clamping, sus pending, or lifting mechanism There is a danger of workpieces dropping if there is a decrease of thrust due to a drop in circuit pressure caused by a power outage, etc. Therefore, safety equipment should be in stalled to prevent damage to machinery and/or human injury. - Page 11 1) Operation manual Install the product and operate it only after reading the operation manual carefully and understanding its contents. Also, keep the manual in a location where it can be referred to as necessary. 2) Ensure sufficient space for maintenance activities. When installing the products, allow access for maintenance and inspection.

-

Page 12: Piping

10) Mount in locations where maintenance will be easy. Ensure enough clearance around the cylinder to allow for unobstructed maintenance and inspection work. 11) Do not adjust the rod stroke by moving the rear plates, as doing so will cause the rear plates to come into direct contact with the guide body or the bracket mounting bolt. -

Page 13: Lubrication

11. Lubrication 1) Lubricating lube type cylinders Install a lubricator in the circuit, and use class 1 turbine oil (with no additives) ISO VG32. Do not use machine oil or spindle oil. If turbine oil is used, refer to the Safety Data Sheet (MSDS) of the oil. 2) Lubricating non-lube type cylinders These cylinders have been lubricated for life at the factory and can be used without any further lubrication. -

Page 14: Operating Environment

13. Operating Environment 1) Do not use in an atmosphere containing corrosive gases, chemicals, sea water, water, or water vapor as the generation of rust, corrosion, etc., may occur as a result. Direct contact with the above must also be avoided. About plated carbon steel machining The long machined parts (end threads of piston rods, double-sided chamfer portions, tie rod threads, etc.) are not plated. -

Page 15: Troubleshooting

15. Troubleshooting Nonconformity Causes Countermeasures Lower operating speed Consider providing low speed than the limit specification. No smooth operation Increase Pressure. High load factor Use larger cylinder. Meter-in speed controller Change it to meter-out. High ambient temperature Use heat resistant cylinder. Use cold resistant cylinder. -

Page 16: Construction: With Rear Plate

16. Construction: With Rear Plate -15-... -

Page 17: Auto Switch Mounting

17. Auto switch Mounting 17-1. Minimum Auto Switch Mounting Stroke 17-2. Operating Range -16-... - Page 18 17-3. Auto Switch Mounting Bracket: Part No. Bore size(mm) Auto switch model D-M9□(V) Note 1) Note 1) Note 1) Note 1) Note 1) D-M9□W(V) BMA3-020 BMA3-025 BMA3-032 BMA3-040 BMA3-050 D-A9□(V) (A set of a,b,c,d) (A set of a,b,c,d) (A set of a,b,c,d) (A set of a,b,c,d) (A set of a,b,c,d) Note 2)

- Page 19 Revision history Initial release 1998.8.26 Revision 1 2023.1.20 4-14-1, Sotokanda, Chiyoda-ku, Tokyo 101-0021 JAPAN Tel: + 81 3 5207 8249 Fax: +81 3 5298 5362 https://www.smcworld.com Note: Specifications are subject to change without prior notice and any obligation on the part of the manufacturer. ©...

Need help?

Do you have a question about the MGC Seires and is the answer not in the manual?

Questions and answers