Subscribe to Our Youtube Channel

Summary of Contents for AGCO SimplEbale

- Page 1 Operator’s Manual SimplEbale March 2024 North America 79037889A Issue 1 4205 River Green Parkway Duluth GA 30096 USA © AGCO 2024 English Original Operator’s Manual...

- Page 2 AGCO ®, or its dealers, accept no responsibility for variations which may be evident in the actual...

- Page 3 General You must read this manual before you operate or do work on the machine. If more assistance is necessary you should speak to your AGCO dealer. This manual is only applicable to the models specified on the front cover.

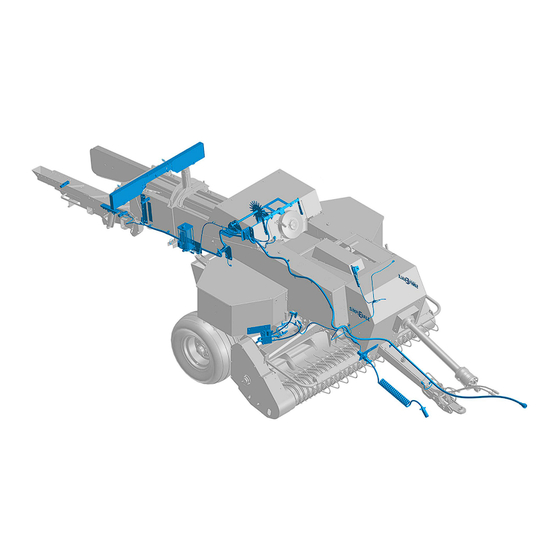

- Page 4 Coolant flow, water flow Where the temperature of liquid changes. • Blue - Cold • Red - Hot Pressure SCR system, hydraulic systems Where the pressure or state of gas changes. • Yellow - Low • Orange - High SimplEbale...

-

Page 5: Table Of Contents

Display settings page .................... 41 Baler options page ....................42 3.8.1 Baler options page ..................42 3.8.2 Set an optional function to ON or OFF..............42 SimplEbale web site....................43 3.10 Do this procedure before you make a bale ............44 Maintenance .......................... 49 SimplEbale... - Page 6 Automatic lubrication system diagnostics ............85 5.3.8 Bale pressure system diagnostics..............86 5.3.9 CAN bus diagnostics ..................89 Fault codes....................... 91 5.4.1 Fault codes overview ..................91 5.4.2 Erase a fault code ..................91 5.4.3 Fault codes....................91 Specifications ........................97 Fuse schematic ....................... 99 Index............................103 SimplEbale...

-

Page 7: Safety

Table of contents 1 Safety Safety Icons......................... 9 Safety Instructions ......................10 General Safety ........................11 SimplEbale... - Page 8 Table of contents SimplEbaleN...

-

Page 9: Safety Icons

CAUTION: Caution Shows data on a possible hazard that if you do not prevent can cause small or moderate injury or component or property damage. NOTE: This shows more data that can help. SimplEbale... -

Page 10: Safety Instructions

EU member states. Subsequent changes without parts approvals or without manufacturer approvals will invalidate the type approval. The issued Certificate of Conformity and corresponding data sheets are also invalidated. After modifications is the responsibility of the vehicle owner to ensure the vehicle operating permission. SimplEbale... -

Page 11: General Safety

Only use the brake release button to do the maintenance and servicing of the machine. • Make sure that you connect the air hoses for the pneumatic brake system (optional equipment). The pneumatic brake system does not operate when the air hoses are disconnected. SimplEbale... - Page 12 1 Safety SimplEbale...

-

Page 13: Introduction

Software ..........................16 Overview..........................17 2.3.1 Ag Co-Pilot overview....................17 2.3.2 Ag Co-Pilot monitor layout ..................17 Controls ..........................19 2.4.1 Operation buttons ....................19 2.4.2 Change the function of an operation button..............19 2.4.3 Navigate the screen and pages.................21 2.4.4 Baler Keypad......................21 SimplEbale... - Page 14 Table of contents SimplEbale...

-

Page 15: Monitor Information Page

2 Introduction Monitor information page (1) Software version and build date (2) QR code for wireless internet connection (3) Wireless internet connection ON/OFF and small square baler monitor wireless identification number Fig. 1 SimplEbale... -

Page 16: Software

2 Introduction Software AGCO continue to update the Ag Co-Pilot monitor. There is no charge to update the software. You can download the updates from the AGCO Access service portal: https://access.agcocorp.com You can install the updates to the software on the Ag Co-Pilot with a Wi-Fi approved device. -

Page 17: Overview

The Ag Co-Pilot is a monitor that supplies information to the operator. The information lets the operator see the baler data and make changes from the operator's seat. Fig. 2 2.3.2 Ag Co-Pilot monitor layout (1) Buttons that the operator can configure (2) Keypad (3) Machine status indicators (4) Home screen data (5) Speaker Fig. 3 SimplEbale... - Page 18 2 Introduction (1) Side area to hold with hand (2) Mounting bracket surface (3) 48 pin electrical connector (4) Identification decal Fig. 4 SimplEbale...

-

Page 19: Controls

Return to the home screen 2.4.2 Change the function of an operation button You can set the 4 buttons above the home screen to do some of the baler functions. There are 9 baler functions that you can set the buttons to use. SimplEbale... - Page 20 2 Introduction Procedure Use the directional keypad to move the cursor to the icon below the necessary button. Select the necessary button, then press the OK button on the keypad. Fig. 5 Fig. 6 SimplEbale...

-

Page 21: Navigate The Screen And

To move to a different screen the operator can press the left or right arrow on the keypad. Fig. 8 2.4.4 Baler Keypad The keypad attached to the side of the machine can operate some of the SimplEbale functions. SimplEbale... - Page 22 2 Introduction Fig. 9 (1) N/A (2) Knotter lubrication Activates the lubrication system for the knotter (3) N/A (4) N/A (5) Chamber pressure release Releases the pressure in the bale chamber (6) Field/Work lamps Field/Work lamps ON/OFF SimplEbale...

-

Page 23: Operation

Display settings page ..................... 41 Baler options page......................42 3.8.1 Baler options page ....................42 3.8.2 Set an optional function to ON or OFF ...............42 SimplEbale web site ......................43 3.10 Do this procedure before you make a bale..............44 SimplEbale... - Page 24 Table of contents SimplEbale...

-

Page 25: Home Page

5 bales weighed. Flake counter Bale flake count and the flake count of the last bale. This is a correct flake value that removes empty plunger strokes that can occur in irregular windrows or when on headlands. SimplEbale... -

Page 26: Machine Status And Indicators

Length of the bale in the baler and the length of last bale made. Flake size Dimension of the last flake made. 3.1.3 Machine status and indicators The machine status icons show the machine status. This data shows as values and indicators where applicable. The applicable icons show the values. Fig. 2 SimplEbale... - Page 27 Shows the PTO speed to give the operator data to set the machine speed for the conditions. Bale chamber pressure reduction/Automatic lubrication/Work lamps Indicators for each function if installed. Field bale counter Shows the bale count for the field. You can reset the counter from the Counter page. SimplEbale...

-

Page 28: Counter Page

NOTE: This is the same counter which shows on the Home page. Bale counter 1 The bale counter 1 shows the quantity of bales made since the counter was last reset. Bale counter 2 The bale counter 2 shows the quantity of bales made since the counter was last reset. SimplEbale... -

Page 29: Reset The Counters

Use the keypad to navigate to the applicable counter icon Press and hold the OK button on the keypad to start the reset procedure. Result The counter icon will start to fill in with a blue color Fig. 4 SimplEbale... - Page 30 3 Operation The procedure completes when the counter icon shows in a fully blue color Fig. 5 Release the OK button on the keypad. SimplEbale...

-

Page 31: Hydraulic Page

(1) Hydraulic page menu icon (6) Manual voltage mode (2) Mode selection for bale density control (7) Automatic weight mode (3) Target value setting (8) Automatic pressure mode (4) Pressure value (9) Bale chamber pressure release (5) Voltage value (10) Hydraulic valve calibration SimplEbale... -

Page 32: Release The Hydraulic Pressure On The Bale Chamber

The live voltage value and bar graph for the solenoid valve on the control manifold that controls the hydraulic system pressure for the bale density. 3.3.2 Release the hydraulic pressure on the bale chamber Procedure Use the keypad to go to the hydraulic control menu. SimplEbale... -

Page 33: Calibrate The Hydraulic Density Control

If an implement is on the machine, lower the implement to the ground. Stop the engine and remove the ignition key. Calibration of the hydraulic density control is necessary when you: • Install the SimplEbale system. • Replace the hydraulic valve. •... - Page 34 Press and hold the OK button to start the calibration. NOTE: A blue status bar fills until it is fully blue. When fully blue, the calibration is done. Fig. 8 After finishing the procedure • The operator can continue to bale with the machine. SimplEbale...

-

Page 35: Moisture Page

(7) Sensor ON (symbol shows) Fig. 9 (1) Bale moisture (2) Alarm limit (3) Moisture value offset (4) Bale width setting (5) Crop type (6) Air calibration button (7) Sensor ON (symbol shows) (8) Software version for the moisture sensor Fig. 10 SimplEbale... -

Page 36: Bale Scale Page

Bale weight • Load sensor weight • Calibration and zero information for the load sensors. Fig. 11 (1) Scale total (4) Load sensor values (2) Scale offset adjustment (5) Hours in operation from the last calibration (3) Scale calibration button SimplEbale... -

Page 37: Calibrate The Bale Scale

3 Operation Icon Description Scale total The bale scale total for all the load sensors in use. Scale offset adjustment The manual offset adjustment of the scale total input by the operator. When a known weight is on the scale, the operator can enter an offset made by the calculated percentage difference of the scale total against the known weight value. - Page 38 When you select the calibration button, press and hold the OK button on the keypad. The calibration completes when the blue status bar fills the blue box. Result The scales total shows 0 and the weights for each load sensor also show 0. Fig. 12 SimplEbale...

-

Page 39: Baler Settings Page

3 Operation Baler settings page (1) Target flake count (2) Target bale length (3) Knotter fan reverse interval (4) Knotter lubrication interval (5) Knotter lubrication duration (6) Maintenance interval counter (7) Maximum operating pressure Fig. 13 Icon Description Target flake count You must set the target for the flake count of a bale. - Page 40 The counter starts when you set the total operating hours and counts down from the total. Maximum operating pressure You can set the maximum hydraulic pressure. The maximum pressure changes for the machine model. SimplEbale...

-

Page 41: Display Settings Page

3 Operation Display settings page (1) Display brightness (2) Volume (3) Language (4) Units Fig. 14 SimplEbale... -

Page 42: Baler Options Page

Press the up and down arrows on the keypad to go to the necessary optional function. Result The selected optional function shows with a blue square. Press and hold the OK button until the icon changes to the icon. SimplEbale... -

Page 43: Simplebale Web Site

3 Operation SimplEbale web site Scan to QR code to go to the SimplEbale web site. The web site contains documents and information for the SimplEbale. Fig. 16 SimplEbal... -

Page 44: Do This Procedure Before You Make A Bale

Set the necessary baler options to ON if the baler has the necessary components. Fig. 17 (1) Moisture sensor (2) Bale scale (3) Knotter fan (4) Knotter lubrication (5) Bale chamber pressure monitor (6) Bale chamber pressure control (7) Baler model SimplEbale... - Page 45 Set the baler settings to the correct values. Fig. 18 (1) Target flake count (2) Target bale length (3) Knotter fan reverse interval (4) Knotter lubrication interval (5) Knotter lubrication duration (6) Maintenance interval counter (7) Maximum bale density operating pressure SimplEbale...

- Page 46 Adjust the bale scale settings if it is necessary. Fig. 19 (1) Scale total (2) Scale offset adjustment (3) Scale calibration button (4) Load sensor values (5) Hours in operation from the last calibration SimplEbale...

- Page 47 (4) Automatic pressure mode (5) Bale chamber pressure release ON/OFF (6) Voltage value (7) Pressure value (8) Target value setting (9) Mode selection for bale density Set the PTO to ON. Set the PTO speed to the correct value. SimplEbale...

- Page 48 10. Adjust the ground speed of the machine if the bale flake dimension is not correct. Result The correct bale flake dimension is when the bars are near to the center of the chart range. 11. Continue to examine the bale parameters as you make the bales. Adjust the machine if it is necessary. SimplEbale...

-

Page 49: Maintenance

Sensor adjustments ......................51 4.1.1 Adjust the star wheel sensor ..................51 4.1.2 Adjust the needle carriage sensor ................53 4.1.3 Adjust the PTO speed sensor ...................56 Bleed the air from the hydraulic density control valve .......... 61 Update the terminal software..................64 SimplEbale... - Page 50 Table of contents SimplEbale...

-

Page 51: Sensor Adjustments

Make sure that the guards are in position and always operate correctly. If a guard breaks or is missing, repair or replace it before you use the machine. CAUTION: Personal Protective Equipment is mandatory. This procedure can cause injury. Put on Personal Protective Equipment when you do this procedure. SimplEbale... - Page 52 4 Maintenance Before starting the procedure Number Part number Description Quantity ACX4656760 Guide tool Procedure Get access to the star wheel sensor. Fig. 1 1840 models Fig. 2 1844 models SimplEbale...

-

Page 53: Adjust The Needle Carriage Sensor

Before you go into the area between the machine and the implement: Park the machine on a clean, hard and level area. Put the parking brake to ON. If an implement is on the machine, lower the implement to the ground. Set the ignition to OFF. Install the wheel chocks. SimplEbale... - Page 54 Make sure that the guards are in position and always operate correctly. If a guard breaks or is missing, repair or replace it before you use the machine. CAUTION: Personal Protective Equipment is mandatory. This procedure can cause injury. Put on Personal Protective Equipment when you do this procedure. SimplEbale...

- Page 55 4 Maintenance Procedure Get access to the needle carriage sensor. Fig. 5 1840 models Fig. 6 1844 models SimplEbale...

-

Page 56: Adjust The Pto Speed Sensor

Before you go into the area between the machine and the implement: Park the machine on a clean, hard and level area. Put the parking brake to ON. If an implement is on the machine, lower the implement to the ground. Set the ignition to OFF. Install the wheel chocks. SimplEbale... - Page 57 Make sure that the guards are in position and always operate correctly. If a guard breaks or is missing, repair or replace it before you use the machine. CAUTION: Personal Protective Equipment is mandatory. This procedure can cause injury. Put on Personal Protective Equipment when you do this procedure. SimplEbale...

- Page 58 4 Maintenance Procedure Open the cover. ⸰ For 1840 models: lift and turn the fastener. Open the cover. ⸰ For 1844 models: Turn the 2 fasteners and open the cover. Fig. 9 1840 models Fig. 10 1844 models SimplEbale...

- Page 59 4 Maintenance Get access to the PTO speed sensor. Fig. 11 1840 models Fig. 12 1844 models SimplEbale...

- Page 60 Result of the procedure The PTO speed sensor clearance is set correctly when: • The LED is ON when the sensor is adjacent to a sprocket tooth. • The LED is OFF when the sensor is not adjacent to a sprocket tooth. SimplEbale...

-

Page 61: Bleed The Air From The Hydraulic Density Control Valve

Make sure that the guards are in position and always operate correctly. If a guard breaks or is missing, repair or replace it before you use the machine. CAUTION: Personal Protective Equipment is mandatory. This procedure can cause injury. Put on Personal Protective Equipment when you do this procedure. SimplEbale... - Page 62 Hydraulic oil and air bubbles will slowly release from the port. When there are no air bubbles in the hydraulic oil coming out, install the bleed screw and tighten to the approved torque. Decrease the PTO speed. Fig. 17 Disengage the PTO. SimplEbale...

- Page 63 11. Remove the applicable container from below the hydraulic density control valve. 12. Clean the hydraulic oil that spilled during the bleed process. After finishing the procedure • Examine the level of the hydraulic oil. Add more hydraulic oil if it is necessary. SimplEbale...

-

Page 64: Update The Terminal Software

4 Maintenance Update the terminal software Terminal information page Fig. 18 Buttons that the operator can configure Keypad Machine status indicators Home screen data Speaker Fig. 19 SimplEbale... - Page 65 AGCO service portal. NOTE: AGCO will update the Ag Co-Pilot software. Software updates are available to download from the AGCO service portal at no cost. You can install the software updates on the Ag Co-Pilot with an applicable wireless phone or tablet computer.

- Page 66 Show options. When you press Show options on the wireless device, it will automatically copy the link provided by the QR code on the Ag Co-Pilot terminal. Fig. 22 SimplEbale...

- Page 67 4 Maintenance Select Update on the SimplEbale portal. Fig. 23 Update the software with a PC Fig. 24 Update the software with an Android phone SimplEbale...

- Page 68 Firmware Update page, the downloaded software update file will be necessary to update the Ag Co-Pilot terminal. Search for the file that was downloaded in step Fig. 25 Update the software with a PC Fig. 26 Update the software with an Android phone SimplEbale...

- Page 69 10. The status of the software update is shown as the update is in progress. When the update is complete the Ag Co-Pilot terminal will automatically restart. NOTE: Check the new software version number on the Ag Co-Pilot terminal information screen. 11. After the software update is complete, disconnect the wireless device from the Ag Co-Pilot terminal. SimplEbale...

- Page 70 4 Maintenance SimplEbale...

-

Page 71: Troubleshooting

Fan diagnostics .......................83 5.3.6 Lamp diagnostics.....................85 5.3.7 Automatic lubrication system diagnostics..............85 5.3.8 Bale pressure system diagnostics ................86 5.3.9 CAN bus diagnostics....................89 Fault codes ........................91 5.4.1 Fault codes overview ....................91 5.4.2 Erase a fault code ....................91 5.4.3 Fault codes ......................91 SimplEbale... - Page 72 Table of contents SimplEbale...

-

Page 73: Baler Diagnostics Page

(6) 5 V sensor supply (7) Hydraulic pressure sensor (8) Star wheel sensor (9) 9 V sensor supply (10) Battery voltage (11) Field lamp output (12) Fan forward output (13) Needle carriage home status (14) Chamber pressure reduction cycle Fig. 1 SimplEbale... -

Page 74: Scale Diagnostics Page

(3) Load sensor data (4) Load sensor data (5) Load sensor data (6) Tilt sensor data for X axis (7) Tilt sensor data for Y axis (8) Tilt sensor data for Z axis (9) Load sensor module software version Fig. 2 SimplEbale... -

Page 75: Diagnostics

Is there unwanted Tighten the bearing movement of the star collars, replace the wheel? bearings if there is too much free play of the bearings. Go to step 4. SimplEbale... -

Page 76: Pto Speed Diagnostics

Make sure that the guards are in position and always operate correctly. If a guard breaks or is missing, repair or replace it before you use the machine. CAUTION: Personal Protective Equipment is mandatory. This procedure can cause injury. Put on Personal Protective Equipment when you do this procedure. SimplEbale... - Page 77 Do a check of the sensor Go to step 3. position. Is the distance Move the sensor to the from the sensor to the correct position. sprocket tooth 1 mm (0 in) to 3 mm (0.1 in)? SimplEbale...

-

Page 78: Scale Diagnostics

Go to step 3. harnesses are connected Connect the wiring to the J2-J5 load cell ports harness. of the load cell module. Find the LEDs on the Go to step 5. module. Does the power Go to step 4. LED illuminate? SimplEbale... - Page 79 Replace the port that has a fault. Communications LED status Flash type Status Flashes quickly Startup mode Always ON Standard operation LED flashes 1 time Source MAC address fault LED flashes 2 times CAN bus hardware fault LED flashes 3 times Standard operation SimplEbale...

- Page 80 Go to step 5. scales to 0. Does the scale balance correctly? Do a check of the load Replace or repair the sensor or the load sensor components. wiring harness and Refer to your approved connectors. Are the dealer. components damaged? SimplEbale...

- Page 81 Use a dealer. multimeter to measure the Replace the load sensor. resistance across the pins of the load sensor. Does the resistance measure 1000 Ω ± 200 Ω? NOTE: For the pin layout, see Load Cell Schematics. SimplEbale...

-

Page 82: Needle Carriage Diagnostics

Position the sensor so the Does the needle carriage needle carriage status on status on the terminal the terminal shows when show a green dot when the LED on the rear of the the LED on the sensor sensor illuminates. illuminates? SimplEbale... -

Page 83: Fan Diagnostics

Do a check of the reverse Change the settings. time setting on the baler Go to step 3. settings on the terminal. Is the reverse function set to OFF, or set incorrectly? SimplEbale... - Page 84 Go to step 3. set to OFF? Does the fan stop when you remove a relay? Is there damage to the Repair or replace the harness? harness or fan. Refer to your approved dealer. SimplEbale...

-

Page 85: Lamp Diagnostics

Go to step 2. lubrication enabled on the Activate the automatic Baler Options on the lubrication function on the terminal? Baler Options on the terminal. Can the PTO speed be Go to step 3. identified? See PTO Speed Diagnostics. SimplEbale... -

Page 86: Bale Pressure System Diagnostics

If an implement is on the machine, lower the implement to the ground. Stop the engine and remove the ignition key. CAUTION: Personal Protective Equipment is mandatory. This procedure can cause injury. Put on Personal Protective Equipment when you do this procedure. SimplEbale... - Page 87 ± 1 V from the voltage that shows on the terminal. Is the pressure sensor in Do a check of the fault mode or does the pressure transducer. display show 0 psi? Replace the transducer if necessary. Go to step 6. SimplEbale...

- Page 88 Refer to your approved dealer. Bale chamber pressure reduction does not function correctly Step Diagnostic Result Action Is the PTO speed less Go to step 2. than 70% of the standard Decrease the PTO speed. PTO speed? SimplEbale...

-

Page 89: Can Bus Diagnostics

Are the 2 resistors Go to step 2. installed on the CAN bus? Install the 2 resistors on There is a resistor at the the CAN bus. aft of the baler and a resistor on the cab harness connector. SimplEbale... - Page 90 CAN high. Do a check of the moisture sensor, the CAN bus Replace broken keypad, and the scale module. To see if a hardware hardware. device creates a CAN communication fault, disconnect each hardware device 1 at a time. SimplEbale...

-

Page 91: Fault Codes

System condition display description Keyswitch battery Standard High Battery voltage is potential higher than 16 V Keyswitch battery Standard High Battery voltage is potential lower than 10.5 V Hydraulic pressure 1762 Standard High Valve pressure is higher than 200 psi SimplEbale... - Page 92 Keypad The keypad does not connect to the machine for more than 3 seconds while the machine is in operation. The machine can not connect to the keypad for more than 5 seconds after the machine is set to SimplEbale...

- Page 93 Knotter trip relay 520905 Knotter system High Standard output fault fault. Continuous needles 520909 Knotter system High Baler is in operation cycling and on the twine tie cycle the start flake count of the bale is less than 1. SimplEbale...

- Page 94 High The PTO speed failure decreased faster than the approved value for the machine. No PTO speed 521009 Drives/gears The PTO speed detected signal is lower than 100 rpm, but the machine is in operation and it makes bales. SimplEbale...

- Page 95 Fault title on Fault code System Fault level System condition display description Service light relay 521101 Lamps Standard output fault fault. Field light relay fault 521102 Lamps Standard output fault. Knotter lube relay 521201 Oilers High Standard output fault fault. SimplEbale...

- Page 96 5 Troubleshooting SimplEbale...

-

Page 97: Specifications

Table of contents 6 Specifications Fuse schematic ........................ 99 SimplEbale... - Page 98 Table of contents SimplEbale...

-

Page 99: Fuse Schematic

6 Specifications Fuse schematic The location of the fuse box is on the right side of the machine. Fig. 1 1840 models SimplEbale... - Page 100 6 Specifications Fig. 2 1844 models Fig. 3 SimplEbale...

- Page 101 6 Specifications Fuses Fuse Description Accessory power Lamps Lubrication pump Knotter trip system ECU Accessory power Relays Relay Description Fan direction 1 Fan direction 2 Field lamps Lubrication pump Knotter trip system Service lamp SimplEbale...

- Page 102 6 Specifications SimplEbale...

-

Page 103: Index

........... 10 fuse schematic ............99 scale diagnostics page..........74 sensor ..............51, 53 set an optional function to ON or OFF......42 SimplEbale web site ..........43 software............16, 64 general safety............11 speed sensor............56 star wheel .............. 51 home page available data ............ - Page 104 Index update..............64 SimplEbale...

- Page 106 © AGCO Corporation, 2024. All rights reserved. 79037889A Issue 1 (English) March 2024...

Need help?

Do you have a question about the SimplEbale and is the answer not in the manual?

Questions and answers