Summary of Contents for AGCO SimplEbale

- Page 1 Workshop Service Manual SimplEbale North America 4205 River Green Parkway March 2024 Duluth GA 30096 USA 79037906A © AGCO 2024 Original Workshop Service Manual English...

-

Page 3: Table Of Contents

Table of Contents SimplEbale General ............................. 5 Safety........................... 7 1.1.1 Safety Icons.....................7 1.1.2 Safety Instructions....................7 1.1.3 General Safety ....................8 How to use this manual................... 9 Introduction......................13 1.3.1 Monitor information page ................13 1.3.2 Ag Co-Pilot monitor layout................13 1.3.3 Operation buttons...................14 1.3.4... - Page 4 Pins not used on the controller ................79 4.3.6 Diagnostics....................80 4.3.7 Fan .......................81 4.3.8 Ground ......................82 4.3.9 Ground 2 ......................83 4.3.10 Hydraulic system....................84 4.3.11 Knotter ......................85 4.3.12 Light system ....................86 4.3.13 Light system 2....................87 4.3.14 Light system 3....................88 4.3.15 CAN bus......................89 Index............................91 SimplEbale 79037906A...

-

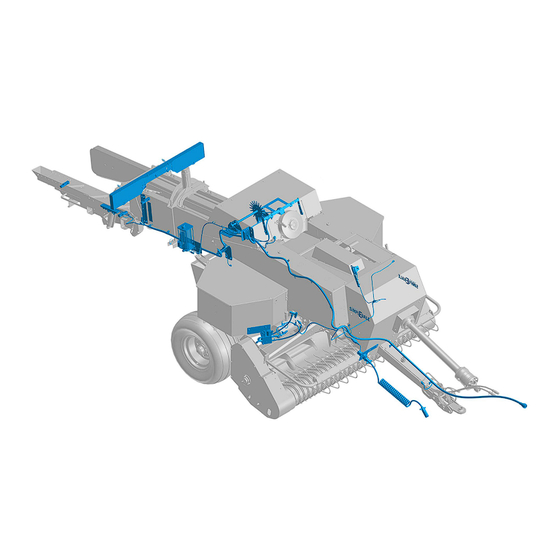

Page 5: General

Fan diagnostics ..................30 1.6.3.6 Lamp diagnostics ..................32 1.6.3.7 Automatic lubrication system diagnostics...........33 1.6.3.8 Bale pressure system diagnostics .............34 1.6.3.9 CAN bus diagnostics................37 1.6.4 Fault codes ......................38 1.6.4.1 Fault codes overview ................38 1.6.4.2 Erase a fault code..................38 1.6.4.3 Fault codes .....................38 SimplEbale 79037906A... - Page 6 Table of contents SimplEbale 79037906A...

-

Page 7: Safety

Vehicle modifications with impact to dimensions, weight and road- and user safety are prohibited. The manufacturer confirms that the described complete vehicle is intended to be used on the road and that it can be registered in EU member states. Subsequent changes without parts approvals or without SimplEbale 79037906A... -

Page 8: General Safety

Only use the brake release button to do the maintenance and servicing of the machine. • Make sure that you connect the air hoses for the pneumatic brake system (optional equipment). The pneumatic brake system does not operate when the air hoses are disconnected. SimplEbale 79037906A... -

Page 9: How To Use This Manual

You must read this manual before you operate or do work on the machine. If more assistance is necessary you should speak to your AGCO dealer. This manual is only applicable to the models specified on the front cover. - Page 10 Electrical wires, hydraulic hoses A component that you must move, and that is not necessary to remove from the machine. Sections Engines, drivetrain Where a cross-section of a component is necessary, this color shows the component that you see through. SimplEbale 79037906A...

- Page 11 • Part number - Component part number • Description - Component name • Quantity - Number of components required for the step ISO Hydraulic color definition Color Description Color Description Pump flow Suction flow Tank flow No flow SimplEbale 79037906A...

- Page 12 1 General Color Description Color Description Measured flow Reduced flow Intensified fluid SimplEbale 79037906A...

-

Page 13: Introduction

(3) Wireless internet connection ON/OFF and small square baler monitor wireless identification number Fig. 1 1.3.2 Ag Co-Pilot monitor layout (1) Buttons that the operator can configure (2) Keypad (3) Machine status indicators (4) Home screen data (5) Speaker Fig. 2 SimplEbale 79037906A... -

Page 14: Operation Buttons

Bale density increase (You can set the increments of the change in the hydraulic density control setup.) Knotter lubrication pump ON/OFF Day/Night mode Screen brightness decrease Screen brightness increase Alarm page Dye marker Return to the home screen SimplEbale 79037906A... -

Page 15: Navigate The Screen And

Fig. 4 1.3.5 Baler Keypad The keypad attached to the side of the machine can operate some of the SimplEbale functions. Fig. 5 (1) N/A (2) Knotter lubrication... -

Page 16: Specifications

1 General Specifications 1.4.1 Fuse schematic The location of the fuse box is on the right side of the machine. Fig. 6 1840 models SimplEbale 79037906A... - Page 17 1 General Fig. 7 1844 models Fig. 8 SimplEbale 79037906A...

- Page 18 1 General Fuses Fuse Description Accessory power Lamps Lubrication pump Knotter trip system ECU Accessory power Relays Relay Description Fan direction 1 Fan direction 2 Field lamps Lubrication pump Knotter trip system Service lamp SimplEbale 79037906A...

-

Page 19: Calibrations

If an implement is on the machine, lower the implement to the ground. Stop the engine and remove the ignition key. Calibration of the hydraulic density control is necessary when you: • Install the SimplEbale system. • Replace the hydraulic valve. •... -

Page 20: Calibrate The Bale Scale

OK button on the keypad. The calibration completes when the blue status bar fills the blue box. Result The scales total shows 0 and the weights for each load sensor also show 0. Fig. 10 SimplEbale 79037906A... -

Page 21: Troubleshooting

(6) 5 V sensor supply (7) Hydraulic pressure sensor (8) Star wheel sensor (9) 9 V sensor supply (10) Battery voltage (11) Field lamp output (12) Fan forward output (13) Needle carriage home status (14) Chamber pressure reduction cycle Fig. 11 SimplEbale 79037906A... -

Page 22: Scale Diagnostics Page

(3) Load sensor data (4) Load sensor data (5) Load sensor data (6) Tilt sensor data for X axis (7) Tilt sensor data for Y axis (8) Tilt sensor data for Z axis (9) Load sensor module software version Fig. 12 SimplEbale 79037906A... -

Page 23: Diagnostics

Is there unwanted Tighten the bearing movement of the star collars, replace the wheel? bearings if there is too much free play of the bearings. Go to step 4. SimplEbale 79037906A... -

Page 24: Pto Speed Diagnostics

Make sure that the guards are in position and always operate correctly. If a guard breaks or is missing, repair or replace it before you use the machine. CAUTION: Personal Protective Equipment is mandatory. This procedure can cause injury. Put on Personal Protective Equipment when you do this procedure. SimplEbale 79037906A... - Page 25 Do a check of the sensor Go to step 3. position. Is the distance Move the sensor to the from the sensor to the correct position. sprocket tooth 1 mm (0 in) to 3 mm (0.1 in)? SimplEbale 79037906A...

-

Page 26: Scale Diagnostics

Go to step 3. harnesses are connected Connect the wiring to the J2-J5 load cell ports harness. of the load cell module. Find the LEDs on the Go to step 5. module. Does the power Go to step 4. LED illuminate? SimplEbale 79037906A... - Page 27 Replace the port that has a fault. Communications LED status Flash type Status Flashes quickly Startup mode Always ON Standard operation LED flashes 1 time Source MAC address fault LED flashes 2 times CAN bus hardware fault LED flashes 3 times Standard operation SimplEbale 79037906A...

- Page 28 Go to step 5. scales to 0. Does the scale balance correctly? Do a check of the load Replace or repair the sensor or the load sensor components. wiring harness and Refer to your approved connectors. Are the dealer. components damaged? SimplEbale 79037906A...

- Page 29 Use a dealer. multimeter to measure the Replace the load sensor. resistance across the pins of the load sensor. Does the resistance measure 1000 Ω ± 200 Ω? NOTE: For the pin layout, see Load Cell Schematics. SimplEbale 79037906A...

-

Page 30: Needle Carriage Diagnostics

The fan does not turn in the forward direction Step Diagnostic Result Action Can the PTO speed be Go to step 2. identified? See PTO Speed NOTE: The PTO speed Diagnostics. must be >70% of the usual baler PTO speed to set the fan to ON. SimplEbale 79037906A... - Page 31 OFF, or set incorrectly? Is the fuse for the fan (F1) Go to step 4. defective? Replace the fuse. Does the fan reverse relay Go to step 5. operate correctly? Replace the relay. SimplEbale 79037906A...

-

Page 32: Lamp Diagnostics

Diagnostic Result Action Do the status lamp Go to step 2. indicators on the Go to step 3. diagnostic screen illuminate when lamps are set to ON? Are the keypad status Go to step 3. indicator lamps on? SimplEbale 79037906A... -

Page 33: Automatic Lubrication System Diagnostics

Bale Count. Do a manual lubrication Go to the Baler Settings cycle from the keypad. screen on the terminal Does the lubrication pump and change the operate for 15 seconds? lubrication pump duration and interval. SimplEbale 79037906A... -

Page 34: Bale Pressure System Diagnostics

Remove the air from the system, or before the first hydraulic system. Go to start of the machine? step 2. Is the hydraulic pressure Diagnostics complete. stable? Calibrate the hydraulic valve. To calibrate the hydraulic valve, see the Calibrations section. SimplEbale 79037906A... - Page 35 Diagnostics complete. valve. Does pressure Go to step 7. increase in the hydraulic system? Do a check of the Go to step 8. hydraulic density cylinder. Replace the hydraulic Does it operate correctly density cylinder. with no leaks? SimplEbale 79037906A...

- Page 36 70% of the standard Decrease the PTO speed. PTO speed? Does the compression For 1844 models: See cycle status indicator Hydraulics system not illuminate on the Baler building pressure Diagnostics page of the diagnostics. terminal? Refer to your approved dealer. SimplEbale 79037906A...

-

Page 37: Can Bus Diagnostics

CAN high. Do a check of the moisture sensor, the CAN bus Replace broken keypad, and the scale module. To see if a hardware hardware. device creates a CAN communication fault, disconnect each hardware device 1 at a time. SimplEbale 79037906A... -

Page 38: Fault Codes

Keyswitch battery Standard High Battery voltage is potential lower than 10.5 V Hydraulic pressure 1762 Standard High Valve pressure is higher than 200 psi Sensor power 2 fault 3509 Standard High Sensor voltage is lower than 4.5 V SimplEbale 79037906A... - Page 39 The keypad does not connect to the machine for more than 3 seconds while the machine is in operation. The machine can not connect to the keypad for more than 5 seconds after the machine is set to SimplEbale 79037906A...

- Page 40 Knotter trip relay 520905 Knotter system High Standard output fault fault. Continuous needles 520909 Knotter system High Baler is in operation cycling and on the twine tie cycle the start flake count of the bale is less than 1. SimplEbale 79037906A...

- Page 41 The PTO speed failure decreased faster than the approved value for the machine. No PTO speed 521009 Drives/gears The PTO speed detected signal is lower than 100 rpm, but the machine is in operation and it makes bales. SimplEbale 79037906A...

- Page 42 Fault title on Fault code System Fault level System condition display description Service light relay 521101 Lamps Standard output fault fault. Field light relay fault 521102 Lamps Standard output fault. Knotter lube relay 521201 Oilers High Standard output fault fault. SimplEbale 79037906A...

-

Page 43: Electrical System

Table of contents 2 Electrical system Adjust the star wheel sensor ..................45 Adjust the needle carriage sensor................48 Adjust the PTO speed sensor ..................51 Update the terminal software..................55 SimplEbale 79037906A... - Page 44 Table of contents SimplEbale 79037906A...

-

Page 45: Adjust The Star Wheel Sensor

Make sure that the guards are in position and always operate correctly. If a guard breaks or is missing, repair or replace it before you use the machine. CAUTION: Personal Protective Equipment is mandatory. This procedure can cause injury. Put on Personal Protective Equipment when you do this procedure. SimplEbale 79037906A... - Page 46 2 Electrical system Before starting the procedure Number Part number Description Quantity ACX4656760 Guide tool Procedure Get access to the star wheel sensor. Fig. 1 1840 models Fig. 2 1844 models SimplEbale 79037906A...

- Page 47 11. Tighten the 2 fasteners to the approved torque. Fig. 4 12. Do a check to make sure that the star wheel sensor operates correctly. IMPORTANT: Make sure that the wiring harness is connected to the star wheel sensor. SimplEbale 79037906A...

-

Page 48: Adjust The Needle Carriage Sensor

Make sure that the guards are in position and always operate correctly. If a guard breaks or is missing, repair or replace it before you use the machine. CAUTION: Personal Protective Equipment is mandatory. This procedure can cause injury. Put on Personal Protective Equipment when you do this procedure. SimplEbale 79037906A... - Page 49 2 Electrical system Procedure Get access to the needle carriage sensor. Fig. 5 1840 models Fig. 6 1844 models SimplEbale 79037906A...

- Page 50 The needle carriage sensor clearance is set correctly when: • The LED is ON when the needle carriage is in the home position. • The LED is OFF when the needle carriage is not in the home position. SimplEbale 79037906A...

-

Page 51: Adjust The Pto Speed Sensor

Make sure that the guards are in position and always operate correctly. If a guard breaks or is missing, repair or replace it before you use the machine. CAUTION: Personal Protective Equipment is mandatory. This procedure can cause injury. Put on Personal Protective Equipment when you do this procedure. SimplEbale 79037906A... - Page 52 2 Electrical system Procedure Open the cover. ⸰ For 1840 models: lift and turn the fastener. Open the cover. ⸰ For 1844 models: Turn the 2 fasteners and open the cover. Fig. 9 1840 models Fig. 10 1844 models SimplEbale 79037906A...

- Page 53 2 Electrical system Get access to the PTO speed sensor. Fig. 11 1840 models Fig. 12 1844 models SimplEbale 79037906A...

- Page 54 The PTO speed sensor clearance is set correctly when: • The LED is ON when the sensor is adjacent to a sprocket tooth. • The LED is OFF when the sensor is not adjacent to a sprocket tooth. SimplEbale 79037906A...

-

Page 55: Update The Terminal Software

2 Electrical system Update the terminal software Terminal information page Fig. 15 Buttons that the operator can configure Keypad Machine status indicators Home screen data Speaker Fig. 16 SimplEbale 79037906A... - Page 56 AGCO service portal. NOTE: AGCO will update the Ag Co-Pilot software. Software updates are available to download from the AGCO service portal at no cost. You can install the software updates on the Ag Co-Pilot with an applicable wireless phone or tablet computer.

- Page 57 Show options. When you press Show options on the wireless device, it will automatically copy the link provided by the QR code on the Ag Co-Pilot terminal. Fig. 19 SimplEbale 79037906A...

- Page 58 2 Electrical system Select Update on the SimplEbale portal. Fig. 20 Update the software with a PC Fig. 21 Update the software with an Android phone SimplEbale 79037906A...

- Page 59 Ag Co-Pilot terminal. Search for the file that was downloaded in step Fig. 22 Update the software with a PC Fig. 23 Update the software with an Android phone SimplEbale 79037906A...

- Page 60 10. The status of the software update is shown as the update is in progress. When the update is complete the Ag Co-Pilot terminal will automatically restart. NOTE: Check the new software version number on the Ag Co-Pilot terminal information screen. 11. After the software update is complete, disconnect the wireless device from the Ag Co-Pilot terminal. SimplEbale 79037906A...

-

Page 61: Hydraulic System

Table of contents 3 Hydraulic system Release the hydraulic pressure on the bale chamber ..........63 Bleed the air from the hydraulic density control valve .......... 64 SimplEbale 79037906A... - Page 62 Table of contents SimplEbale 79037906A...

-

Page 63: Release The Hydraulic Pressure On The Bale Chamber

Release the hydraulic pressure on the bale chamber Procedure Use the keypad to go to the hydraulic control menu. Select the icon to release the hydraulic pressure in the bale chamber. You can also operate this function with the baler keypad. Fig. 1 SimplEbale 79037906A... -

Page 64: Bleed The Air From The Hydraulic Density Control Valve

Make sure that the guards are in position and always operate correctly. If a guard breaks or is missing, repair or replace it before you use the machine. CAUTION: Personal Protective Equipment is mandatory. This procedure can cause injury. Put on Personal Protective Equipment when you do this procedure. SimplEbale 79037906A... - Page 65 Hydraulic oil and air bubbles will slowly release from the port. When there are no air bubbles in the hydraulic oil coming out, install the bleed screw and tighten to the approved torque. Decrease the PTO speed. Fig. 4 Disengage the PTO. SimplEbale 79037906A...

- Page 66 11. Remove the applicable container from below the hydraulic density control valve. 12. Clean the hydraulic oil that spilled during the bleed process. After finishing the procedure • Examine the level of the hydraulic oil. Add more hydraulic oil if it is necessary. SimplEbale 79037906A...

-

Page 67: Diagrams

Pins not used on the controller ..................79 4.3.6 Diagnostics ......................80 4.3.7 Fan.........................81 4.3.8 Ground ........................82 4.3.9 Ground 2 ........................83 4.3.10 Hydraulic system .....................84 4.3.11 Knotter........................85 4.3.12 Light system......................86 4.3.13 Light system 2 ......................87 4.3.14 Light system 3 ......................88 4.3.15 CAN bus .........................89 SimplEbale 79037906A... -

Page 68: Electrical Component List

4 Diagrams SimplEbale 79037906A... - Page 69 4 Diagrams SimplEbale 79037906A...

- Page 70 4 Diagrams SimplEbale 79037906A...

-

Page 71: Wiring Diagram

DT06-4S-CE06 52_TW05 005 CAN-GN-0.75 CAN_1 LOW TR REF/SIMILAR SIMILAR TO DESIGNER CAT NO/FAMILIA CAT NO DRAWN DATE DDMONYY TITLE DESCRIPTION ORIG PROD DESIGN CONTROL NOME ORIG PROD ADDITIONAL DESCRIPTION EXP NO/PROJETO X000 DRAWING NO 000000000 REVISION Fig. 1 SimplEbale 79037906A... - Page 72 4 Diagrams SimplEbale 79037906A...

-

Page 73: Subsystem Diagrams

4 Diagrams Subsystem diagrams SimplEbale 79037906A... - Page 74 4 Diagrams SimplEbale 79037906A...

-

Page 75: Sensors

X18:3 14/29 14/29 A1.J1:G4 X101:14 G4/48 G4/48 AI_2 282087-1 03 001 WH-0.75 BALE LENGTH 03 002 WH-0.75 BALE LENGTH 282087-1 HDB36-24-29PE HD34-24-29SE 643203311 BALE LENGTH DRAWING NUMBER: VERSION: SSC-SB13 SUBCIRCUIT DESCRIPTION: SHEET: 5V Sensors ZUKEN E3.CABLE Fig. 2 SimplEbale 79037906A... -

Page 76: Sensors

SENSOR RTN 9V KNOT DETECTION DT06-3S-CE06 X01:17 X12:C 17/29 17/29 A1.J1:H3 X101:17 H3/48 H3/48 AI_3 WH-0.75 KNOT DETECTION WH-0.75 KNOT DETECTION DT06-3S-CE06 HDB36-24-29PE HD34-24-29SE 643203311 DRAWING NUMBER: VERSION: SSC-SB15 SUBCIRCUIT DESCRIPTION: SHEET: TitleSheet 9V Sensors ZUKEN E3.CABLE Fig. 3 SimplEbale 79037906A... -

Page 77: After The Ignition Switch

SWITCHED POWER FUSED 2 Amp MOISTURE 15300027 643203311 OR-0.75 ECU PWR FUSED OR-0.75 ECU PWR FUSED DT06-4S-CE06 KEYPAD OR-0.75 ECU PWR FUSED DT06-4S-CE06 SCALE MODULE DRAWING NUMBER: VERSION: SSC-SB02 SUBCIRCUIT DESCRIPTION: SHEET: Switched Power ZUKEN E3.CABLE Fig. 4 SimplEbale 79037906A... -

Page 78: Power Supply

01 001 RD-0.75 +12V POWER SSC-SB29 01F 003 RD-2.0 12V POWER FUSED C749 15300027 643203311 I/O MANUAL SWITCH 2/10 52A 003 RD-6.0 +12V POWER VC1-01 DRAWING NUMBER: VERSION: SSC-SB11 SUBCIRCUIT DESCRIPTION: SHEET: Unswitched Power ZUKEN E3.CABLE Fig. 5 SimplEbale 79037906A... -

Page 79: Pins Not Used On The Controller

A1.J1:B3 X101:22 B3/48 B3/48 DI/FI_3 WH-0.75 25/29 25/29 A1.J1:H4 X101:25 H4/48 H4/48 AI_4 WH-0.75 28/29 28/29 A1.J1:J3 X101:28 J3/48 J3/48 AI_5 WH-0.75 HDB36-24-29PE HD34-24-29SE 643203311 DRAWING NUMBER: VERSION: SSC-SB17 SUBCIRCUIT DESCRIPTION: SHEET: Controller Spares ZUKEN E3.CABLE Fig. 6 SimplEbale 79037906A... -

Page 80: Diagnostics

S103 32 005 OR-0.75 SWITCHED POWER S107 51_TW104 003 CAN-YE-0.75 CAN_1 HIGH S103 S108 SSC-SB02 / PSC-SB03 52_TW104 003 CAN-GN-0.75 CAN_1 LOW S107 SSC-SB01 S108 SSC-SB01 DRAWING NUMBER: VERSION: SB20 SUBCIRCUIT DESCRIPTION: SHEET: Diagnostic ZUKEN E3.CABLE Fig. 7 SimplEbale 79037906A... -

Page 81: Fan

FAN REV RELAY C749 C749 Control Monitor X101 X01:9 X04:C 9/29 9/29 A1.J1:B1 X101:9 B1/48 B1/48DI/FI_1 WH-0.75 GEARBOX SPEED WH-0.75 GEARBOX SPEED DT06-3S-CE06 HDB36-24-29PE HD34-24-29SE 643203311 GEARBOX RPM DRAWING NUMBER: VERSION: SSC-SB18 SUBCIRCUIT DESCRIPTION: SHEET: ZUKEN E3.CABLE Fig. 8 SimplEbale 79037906A... -

Page 82: Ground

90 009 WH-0.75 LIGHT GROUND DT06-2S-CE06 X206 STOP/TAIL RH S201 90 006 WH-0.75 LIGHT GROUND DT06-3S-CE06 DRAWING NUMBER: VERSION: X207 SSC-SB23 S201 HAZ/TURN RH 90 007 WH-0.75 LIGHT GROUND SUBCIRCUIT DESCRIPTION: SHEET: DT06-2S-CE06 Grounding ZUKEN E3.CABLE Fig. 9 SimplEbale 79037906A... -

Page 83: Ground 2

LIGHT GROUND DT06-2S-CE06 DT04-08PA-C015 DT06-08SA 382567 X206 STOP/TAIL RH S201 98 006 WH-0.75 LIGHT GROUND DT06-3S-CE06 X207 S201 HAZ/TURN RH 98 007 WH-0.75 LIGHT GROUND DT06-2S-CE06 DRAWING NUMBER: VERSION: PSC-SB24 SUBCIRCUIT DESCRIPTION: SHEET: Grounding ZUKEN E3.CABLE Fig. 10 SimplEbale 79037906A... -

Page 84: Hydraulic System

136 001 WH-0.75 DECOMPRESS CONTROL A1.J1:L3 26/29 26/29 X28:1 643203311 36 002 WH-0.75 LOAD DUMP HD34-24-29SE HDB36-24-29PE HYDRAULIC BLOCK X01:12 DT06-2S-CE06 X01:26 141 001 WH-0.75 LOAD DUMP CAPPED DT06-2S-CE06 DRAWING NUMBER: VERSION: PSC-SB06 SUBCIRCUITDESCRIPTION: SHEET: ZUKEN E3.CABLE Fig. 11 SimplEbale 79037906A... -

Page 85: Knotter

LUBE POWER FUSED PSC-SB12 C749 C749 X06:10 22/48 15/48 X20:A X06:15 LUBE PUMP 125 001 RD-1.5 LUBE POWER PSC-SB24 X01:18 21/48 16/48 PSC-SB24 12015792 C749 C749 DRAWING NUMBER: VERSION: SUBCIRCUIT DESCRIPTION: SHEET: PSC-SP30 TitleSheet ZUKEN E3.CABLE Fig. 12 SimplEbale 79037906A... -

Page 86: Light System

FIELD LIGHTING POWER 129 001 WH-0.75 SERVICE LIGHTING RELAY PSC-SB24 C749 C749 DT06-2S-CE06 FIELD LIGHT LH 114 003 GY-0.75 FIELD LIGHTING POWER PSC-SB24 DT06-2S-CE06 FIELD LIGHT RH DRAWING NUMBER: VERSION: PSC-SB26 SUBCIRCUIT DESCRIPTION: SHEET: Lighting ZUKEN E3.CABLE Fig. 13 SimplEbale 79037906A... -

Page 87: Light System 2

SSC-SB23 DT06-2S-CE06 PU LIGHT 12 004 GY-0.75 FIELD LIGHTING POWER SSC-SB23 DT06-2S-CE06 FIELD LIGHT LH 12 003 GY-0.75 FIELD LIGHTING POWER SSC-SB23 DT06-2S-CE06 FIELD LIGHT RH DRAWING NUMBER: VERSION: SSC-SB28 SUBCIRCUIT DESCRIPTION: SHEET: Lighting ZUKEN E3.CABLE Fig. 14 SimplEbale 79037906A... -

Page 88: Light System 3

SSC-SB23 DT06-2S-CE06 PU LIGHT 12 004 GY-0.75 FIELD LIGHTING POWER SSC-SB23 DT06-2S-CE06 FIELD LIGHT LH 12 003 GY-0.75 FIELD LIGHTING POWER SSC-SB23 DT06-2S-CE06 FIELD LIGHT RH DRAWING NUMBER: VERSION: SSC-SB25 SUBCIRCUIT DESCRIPTION: SHEET: Lighting ZUKEN E3.CABLE Fig. 15 SimplEbale 79037906A... -

Page 89: Can Bus

52_TW105 003 CAN-GN-0.75 CAN_1 LOW 52_TW103 003 CAN-GN-0.75 CAN_1 LOW 52_TW101 001 CAN-GN-0.75 CAN_1 LOW DT06-3S-CE06 HDB36-24-29PE HD34-24-29SE S108 DT06-3S-CE06 Term. Resistor Term. Resistor S105 MOISTURE Control Monitor DRAWING NUMBER: VERSION: SB01 SUBCIRCUIT DESCRIPTION: SHEET: ZUKEN E3.CABLE Fig. 16 SimplEbale 79037906A... - Page 90 4 Diagrams SimplEbale 79037906A...

-

Page 91: Index

............. 38 fuse schematic ............16 safety icons ..............7 safety instructions .............7 scale diagnostics page..........22 general safety............8 sensor ..............45, 48 ground..............82 software..............55 ground 2 ..............83 speed sensor............51 star wheel .............. 45 SimplEbale 79037906A... - Page 92 Index terminal ..............55 update..............55 wiring diagram ............71 SimplEbale 79037906A...

- Page 94 © AGCO Corporation, 2024. All rights reserved. 79037906A (English) March 2024...

Need help?

Do you have a question about the SimplEbale and is the answer not in the manual?

Questions and answers