Table of Contents

Advertisement

Quick Links

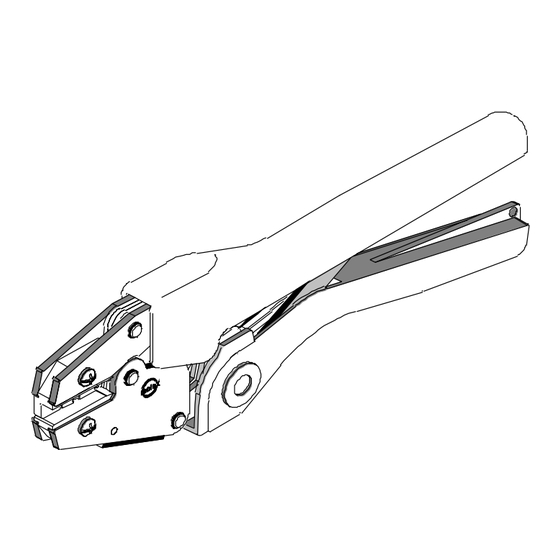

RHT7050 Hand Crimp Tool

FEATURES

Œ

Œ

A full cycle ratcheting hand tool ensures complete crimps

Œ

Long handles for comfortable crimping with reduced crimping force

A precision user-friendly terminal locator wire stop holds terminals in the proper crimping position

SCOPE

Nylon closed end connectors 12–22 AWG

Testing

Mechanical

The tensile test, or pull test, is a means of evaluating the mechanical properties of the crimped connections.

The following charts show the UL specifications for various wire sizes. The tensile strength is shown in

pounds and indicates the minimum acceptable force to break or separate terminal from the conductor.

The following is a partial list of the product part numbers and their specifications that this tool is designed to run.

We will be adding to this list and an up to date copy is available on www.molex.com

Doc No. 64001-0900 Release Date: 10-09-02

Revision: D

Revision Date: 05-11-05

Hand Crimp Tool Operating Instruction

And Specifications Sheet

Order No. 64001-0900

Eng. No. RHT 7050

(Replaces 19285-0053)

Wire Size (AWG)

22

20

18

16

14

12

* UL – 486 C – Closed end connectors and Wire Nuts.

Terminal

Terminal No.

Eng No. (REF)

19160-0009

NC-2212

12 - 22

19160-0010

NC-2212-L

12 - 22

19160-0011

NC-2212-BA

12 - 22

UNCONTROLLED COPY

UL – 486 C

8

10

10

15

25

35

Wire Size

Wire Combinations

AWG

mm²

(3.30-0.35)

See Chart 1

(3.30-0.35)

See Chart 1

(3.30-0.35)

See Chart 1

Page 1 of 7

Advertisement

Table of Contents

Summary of Contents for molex RHT 7050

- Page 1 * UL – 486 C – Closed end connectors and Wire Nuts. The following is a partial list of the product part numbers and their specifications that this tool is designed to run. We will be adding to this list and an up to date copy is available on www.molex.com Terminal Wire Size Terminal No.

-

Page 2: Operation

RHT7050 Hand Crimp Tool OPERATION Wire Combinations for Nylon- Insulated Closed End Connectors Part No. 191600009 (NC-2212) Wire Type Wire Gauge (AWG) Rating Wire Preparation Stranded or Solid UL & CSA Pre-twisted wire not required for OEM Stranded or Solid UL &... - Page 3 Figure 3 JAWS OPEN LOCATOR 3. Remove the crimp and inspect for proper crimp location, and check for insulation closure. Molex offers a Crimp Inspection Handbook for closed barrel industrial product. See our website or contact your sales engineer. Note: Whenever crimping without the locator, make sure the seam of the terminal is oriented up or down in the tool if using unbrazed product, as this will provide higher pull force values.

-

Page 4: Maintenance

RHT7050 Hand Crimp Tool Maintenance LUBRICATION POINTS (BOTH SIDES) It is recommended that each operator of the tool be made LIGHT OIL (EVERY aware of, and responsible for, the following maintenance 3 MONTHS OR 5,000 CRIMPS) steps: 1. Remove dust, moisture and other contaminants with a clean brush, or soft, lint-free cloth. -

Page 5: Tool Calibration

RHT7050 Hand Crimp Tool PIN GAUGE IN Tool Calibration CONDUCTOR CRIMP A Certificate of Calibration (see last page) was supplied with the tool. To recalibrate this tool, pin gauge measurements should be taken in each conductor nest and compared to this chart. The tool should be lubricated prior to recalibration to ensure consistent measurements. -

Page 6: Parts List

RHT7050 Hand Crimp Tool PARTS LIST Item Order No Description Quantity 64001-0900 Hand Crimp Tool (Fig. 6) 64000-0076 Repair Kit (Springs, Pins and E-Rings) 63810-0000 Handle 64001-0975 Locator Assembly 64001-0970 Tooling Kit Tooling Kit Only 64001-0901 Conductor Punch 64001-0902 Conductor Anvil M4 LOCKNUT W/ HEX NYLON INSERT RATCHET... -

Page 7: Certificate Of Calibration

Range Conductor Nest # 3 =______________Actual =______________ Technician_______________________ Date of Calibration__________________ Calibration should be done every 5,000 cycles or 3 months. Tools should be lubricated during this operation. Molex Application Tooling Group 1150 E. Diehl Road Naperville, IL 60563 Tel: (630) 969-4550 Fax: (630) 505-0049 UNCONTROLLED COPY Doc No. - Page 8 The following is a partial list of the product part numbers and their specifications that this tool is designed to run. We will be adding to this list and an up to date copy is available on www.molex.com Wire Size Terminal No.

-

Page 9: Crimping Terminals

AT7000 Air Crimp Tool Head Wire Combinations for Nylon- Insulated Closed End Connectors OPERATION Part No. 191600002 (NC-1610) Refer to the instruction manual for the 19279-0001 Wire Type Wire Gauge (AWG) Rating (AT200) for mounting this crimp tool head. Stranded or Solid UL &... - Page 10 Figure 2 Figure 1 JAWS OPEN 3. Remove the crimp and inspect for proper crimp location, and check for insulation closure. Molex offers a Crimp Inspection Handbook for closed barrel industrial product. See our website or contact you sales engineer.

- Page 11 AT7000 Air Crimp Tool Head such as 30 weight automotive oil used at the oil points shown in Figure 4, every 5,000 crimps or monthly will significantly enhance the tool life and ensure a stable calibration. 4. When tool is not in use store the tool in a clean, dry area. Tool Calibration A Certificate of Calibration (See last page) was supplied with the tool.

- Page 12 AT7000 Air Crimp Tool Head PARTS LIST Item Order No Description Quantity 64005-0600 Crimp Tool Head (Fig. 5) 64005-0000 Basic Air Tool Head 64001-0675 Locator Assembly 64001-0670 Tooling Kit 64005-0605 Guard 3MM by 6 Long Roll Pin M4 by 25 Long Freedrive Pan Head Screw Tooling Kit Only 64001-0601 Conductor Punch...

- Page 13 AT7000 Air Crimp Tool Head Parts List (Continued) Item Order No. Description Quantity 64005-0000 Basic Air Tool Head (Fig. 6) 64005-0103 Nose Guard 64000-0077 Repair Kit (Springs, Rods Pivots ,Rings, and Washers) M4 by 12LG. Freedrive Pan Head Screw M4 by 30LG. Freedrive Pan Head Screw 3/16”...

- Page 14 Technician ______________ Date of Calibration ______________ Calibration should be done every 5,000 cycles or 3 months. Tools should be lubricated during this operation. Molex Application Tooling Group 1150 E. Diehl Road Naperville, IL 60563 Tel: (630) 969-4550; Fax: (630) 505-0049 UNCONTROLLED COPY Doc No.

Need help?

Do you have a question about the RHT 7050 and is the answer not in the manual?

Questions and answers