Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for molex MOLEX

-

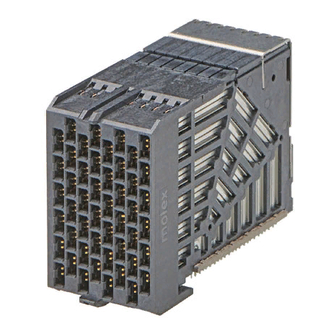

Page 1: Impact™ Backplane And Daughtercard

Impact™ Backplane and Daughtercard Tooling IMPACT™ Backplane and DaughterCard Installation and Repair Tooling Operation Manual Order No. 62201-8799 Description Operation Maintenance UNCONTROLLED COPY Doc. No: TM-622018799 Release Date: 08-31-09 Page 1 of 35 Revision: G Revision Date: 06-16-14... -

Page 2: Safety Warnings And Information

Impact™ Backplane and Daughtercard Tooling Safety Warnings and Information Read and understand all of the instructions and safety information in this manual before operating or servicing this tool. Keep this manual available when using this tool. Replacement manuals are available for download at no charge at www.molex.com. - Page 3 Call Toll Free 1-800-786-6539 (US) 1-630-969-4550 (Global). This assistance is limited to the operation and set-up of a customer’s Molex Tools tool. Questions with regard to Molex connector products or how to identify the proper tooling and/ or tooling documentation should be directed to your local Molex personnel or Customer Service Representative.

-

Page 4: Table Of Contents

Impact™ Backplane and Daughtercard Tooling Table of Contents IMPACT™ Backplane and DaughterCard ............................... 1 Order No. 62201-8799 ..................................... 1 Safety Warnings and Information ................................2 Table of Contents ....................................4 Section 1 ........................................5 General Description ..................................... 6 Description ..................................... 6 Features .................................... -

Page 5: Section 1

Impact™ Backplane and Daughtercard Tooling Section 1 Press Requirements for Impact™ Connectors Description Features Technical Specifications Delivery Check Tools Press Requirements UNCONTROLLED COPY Doc. No: TM-622018799 Release Date: 08-31-09 Page 5 of 35 Revision: G Revision Date: 06-16-14... -

Page 6: General Description

1.1 Description 1.6 Press Requirements This manual covers the tooling available to press Molex All Impact™ insertion tools are designed to fit in a flat platen Impact™ Backplane Power Modules, Backplane (or flat rock) press. Connectors, Daughtercard and Coplanar Modules into printed circuit boards. -

Page 7: Section 2

Impact™ Backplane and Daughtercard Tooling Section 2 Installation and Operation Printed Circuit Board Support Press Stroke Adjustment Installation Operation UNCONTROLLED COPY Doc. No: TM-622018799 Release Date: 08-31-09 Page 7 of 35 Revision: G Revision Date: 06-16-14... -

Page 8: Printed Circuit Board Support

The support fixture should have some method of locating the PCB consistently. Due to the custom nature of each application, Molex does not supply support and locating fixtures. The customer normally fabricates the fixture to fit their application. -

Page 9: Operation

Impact™ Backplane and Daughtercard Tooling TOOLING HOLDER M3 x 8mm LONG TYPICAL INSERTION SET SCREWS (3) MODULES EVENLY SPACED Figure 2-4 Figure 2-3 TYPICAL INSERTION MOUNTING INSERT MODULE IN TOOL ASSEMBLY A MOUNTING BLOCK 3. Tighten the M3 set screws against the modules with two (2) set screws evenly spaced on a 10mm wide insertion tool and at least three (3) set screws evenly spaced on a 25mm wide insertion tool. - Page 10 Impact™ Backplane and Daughtercard Tooling Cycle the insertion press. Press the header assembly until there is less than 0.10mm (.004 in) clearance between the bottom of the plastic housing and the surface of the printed circuit board. Remove the loaded support pallet.

- Page 11 Impact™ Backplane and Daughtercard Tooling Vertical Power Module Press-In Tooling CAUTION: Vertical Power Module must be installed separately without any backplane or daughtercard assemblies in the combinations. ALONE TOOLING WITH HOLDER 62201-95XX RAIL PRESS-IN VERTICAL PRESS-IN TOOL PRESS-IN TOOL TOOL...

- Page 12 Impact™ Backplane and Daughtercard Tooling 3. Carefully insert, by hand, the power module(s) into the printed circuit board hole pattern. 4. Place the application tool on top of the power module with the back guide surface of the tool against the back of the power module.

-

Page 13: Section 3

Impact™ Backplane and Daughtercard Tooling Section 3 Maintenance Cleaning Lubrication Troubleshooting UNCONTROLLED COPY Doc. No: TM-622018799 Release Date: 08-31-09 Page 13 of 35 Revision: G Revision Date: 06-16-14... -

Page 14: Cleaning

3.2 Lubrication There is no lubrication required on any of the Impact™ tooling. However, presses may have their own requirements for lubrication and maintenance. The instruction manual for the specific press being used should be referred to. 3.3 Troubleshooting Symptom ... -

Page 15: Section 4

Standard Press-In-Tools Table 4-1 Assembly Tooling for Impact™ Signal and Power Assemblies Table 4-2 Standard Tool Holders for Molex Press Fit Insertion Tools Table 4-3 Field Repair Tooling for Impact™ Backplane and Daughtercard Assemblies Standard Tool Ordering Procedure UNCONTROLLED COPY Doc. -

Page 16: Standard Press-In-Tools

Impact™ Backplane and Daughtercard Tooling 4.1 Standard Press-In-Tools Standard Insertion Tools All the applicable Impact™ connectors and the standard tooling required for each connector are located in these tables. TABLE 4-1 Assembly Tooling (For use in standard tool holder) Refer to the individual instruction sheets for more information on Individual tools. - Page 17 Impact™ Backplane and Daughtercard Tooling Impact™ 100 Ohm Products – Insertion Tools Pair Column Product Module Type Series Tool Width Illustration 11.80mm 100 Ohm Orthogonal 76860 62201-8744 (0.46 In.) 15.0mm 100 Ohm Ortho Direct 171573 62203-0026 (0.59 In.) 76855 12.0mm...

- Page 18 Impact™ Backplane and Daughtercard Tooling Impact™ 100 Ohm Products – Insertion Tools Pair Column Product Module Type Series Tool Width Illustration 76152 11.2mm 100 Ohm Conventional 76155 62201-8679 (0.44 In.) 171294 100 Ohm Conventional 76160 11.75mm 62201-8748 (0.46 In.) 100 Ohm Orthogonal...

- Page 19 Impact™ Backplane and Daughtercard Tooling Impact™ 100 Ohm Products – Insertion Tools Pair Column Product Module Type Series Tool Width Illustration 76055 15.1mm 100 Ohm Conventional 62201-8854 171296 (0.59 In.) 76985 20.95mm 100 Ohm Orthogonal 62203-0580 171352 (0.82 In.) 76055 18.8mm...

- Page 20 Impact™ Backplane and Daughtercard Tooling Impact™ 100 Ohm Products – Insertion Tools Pair Column Product Module Type Series Tool Width Illustration 30.25mm 100 Ohm Conventional 76060 62201-8659 (1.19 In.) 76285 20.95mm 100 Ohm Orthogonal 62203-0495 171356 (0.82 In.) 76142 18.8mm...

- Page 21 Impact™ Backplane and Daughtercard Tooling Impact™ 85 Ohm Plus Products – Insertion Tools Pair Column Product Module Type Series Tool Width Illustration 15.05mm 85 Ohm Plus Conventional 171065 62201-8841 (0.59 In.) 18.8mm 85 Ohm Plus Conventional 171065 62201-8844 (0.74 In.) 18.9mm...

- Page 22 Impact™ Backplane and Daughtercard Tooling Impact™ 85 Ohm Plus Products – Insertion Tools Pair Column Product Module Type Series Tool Width Illustration 170332 18.8mm 85 Ohm Plus Conventional 170335 62201-8790 (0.74 In.) 170515 18.9mm 85 Ohm Plus Conventional 170340 62201-8641 (0.74 In.)

- Page 23 Impact™ Backplane and Daughtercard Tooling Impact™ 85 Ohm Plus Products – Insertion Tools Pair Column Product Module Type Series Tool Width Illustration 170472 170475 22.7mm 85 Ohm Plus Conventional 62201-8804 170517 (0.89 In.) 170518 18.8mm 85 Ohm Plus Conventional 170480 62201-8735 (0.74 In.)

- Page 24 Impact™ Backplane and Daughtercard Tooling Impact™ Power Modules – Insertion Tools Pair Product Module Type Series Tool Width Illustration Right Angle Header 78211 11.0mm Right Angle Header 78347 62201-8649 (0.43 In.) Right Angle Receptacle 78348 18.2mm Power Vertical Receptacle 78212 62201-8648 (0.72 In.)

- Page 25 Tool Holder 62201-9511 304.8mm (12.0 In.) Tool Holder 62201-9512 406.4mm (16.0 In.) TABLE 4-3 Field Repair Tooling for Impact™ Signal and Power Assemblies Impact™ 85 Ohm, 100 Ohm, and Power Products – Repair Tools Pair Product Module Type Series Tool...

- Page 26 Impact™ Backplane and Daughtercard Tooling Impact™ 85 Ohm, 100 Ohm, and Power Products – Repair Tools Pair Product Module Type Series Tool Illustration Pliers for Pin Removal: Newark 96F8903 or MSC 00321885 76855 76856 100 Ohm Orthogonal 62100-9620 Extractor 171344...

- Page 27 Impact™ Backplane and Daughtercard Tooling Impact™ 85 Ohm, 100 Ohm, and Power Products – Repair Tools Pair Product Module Type Series Tool Illustration 100 Ohm Conventional 76060 100 Ohm Orthogonal 76990 62202-4300 Extractor 85 Ohm plus Conventional 170480 76055, 76163...

- Page 28 Impact™ Backplane and Daughtercard Tooling Impact™ 85 Ohm, 100 Ohm, and Power Products – Repair Tools Pair Product Module Type Series Tool Illustration 62100-5800 Signal Pin Inserter 76142 100 Ohm Conventional 76145 Pliers for Pin Removal: 171298 Newark 96F8903 or MSC 00321885...

-

Page 29: Standard Tool Ordering Procedure

Impact™ Backplane and Daughtercard Tooling 4.2 Standard Tool Ordering Procedure Stacking Tooling All the insertion tooling listed in Table 4-1 can be stacked in any combination to be able to simultaneously press in any arrangement of stacked connectors. Tooling holders are available in various lengths. Figure 4-1 shows a typical setup for a 4 pair by 8 column backplane signal module in a standard tool holder. -

Page 30: Section 5

Impact™ Backplane and Daughtercard Tooling Section 5 Repair and Replacement Backplane Repair Procedure Daughtercard Repair Procedure Glossary of Terms UNCONTROLLED COPY Doc. No: TM-622018799 Release Date: 08-31-09 Page 30 of 35 Revision: G Revision Date: 06-16-14... -

Page 31: Impact™ Backplane Repair Procedure

Signal Pin Replacement Tool 62100-5800 (100 Ohm) Signal Pin Replacement Tool 62100-5850 (85 Ohm) Needle nose pliers (miniature) * CONNECTOR Tweezers * * Not supplied by Molex Removal SIGNAL PINS To remove damaged signal pins, grasp them with the needle nose FIGURE 5-1 pliers and pull straight up from the board. - Page 32 Impact™ Backplane and Daughtercard Tooling INSERTION TOOL CONTACT POSITIONED IN THE GROOVE OF THE HOUSING INSERTION TOOL Figure 5-4 INSERTION TOOL FLUSH WITH HOUSING 6. There is a clearance groove on the opposite side of the tool. When inserting the signal contact, make sure the adjacent row is positioned in this groove.

- Page 33 Impact™ Backplane and Daughtercard Tooling Figure 5-7 Correct Position of Jaw Tools REMOVAL TOOL FRONT FRONT 3 PAIR CLOSED JAW TOOL POSITION TOOL BACK TOOL BACK JAW TEETH INSERTED TOOL 2-PAIR INTO SLOT MODULE 2 PAIR OF MODULE JAW TEETH INSERTED...

- Page 34 Impact™ Backplane and Daughtercard Tooling 2. Position the 62202-4300 Removal Tool over the defective module with the toothed jaw located over the mating end of the connector and the slotted jaw over the stiffener on the opposite end of the module.

-

Page 35: Glossary Of Terms

(or tools) necessary to properly apply pressure where required to push Upper Tooling the connector’s compliant terminals and locking posts into the holes in the printed circuit board. Visit our Web site at http://www.molex.com UNCONTROLLED COPY Doc. No: TM-622018799 Release Date: 08-31-09...

Need help?

Do you have a question about the MOLEX and is the answer not in the manual?

Questions and answers