Table of Contents

Advertisement

Quick Links

EN.IO.PCE.PRE.28.MODBUS

Revision 03.A.001

MAY 2023

USER'S MANUAL

SMART PRESSURE AND

DIFFERENTIAL PRESSURE TRANSMITTERS

PCE-28.Modbus, PRE-28.Modbus,

PCE-28.Modbus16, PRE-28.Modbus16,

PCE-28.Modbus-ALW

APLISENS S.A., 03-192 Warsaw, Morelowa 7 St.

tel. +48 22 814 07 77; fax +48 22 814 07 78

www.aplisens.com, e-mail:

export@aplisens.com

Advertisement

Table of Contents

Summary of Contents for Aplisens PCE-28.Modbus

- Page 1 EN.IO.PCE.PRE.28.MODBUS Revision 03.A.001 MAY 2023 USER’S MANUAL SMART PRESSURE AND DIFFERENTIAL PRESSURE TRANSMITTERS PCE-28.Modbus, PRE-28.Modbus, PCE-28.Modbus16, PRE-28.Modbus16, PCE-28.Modbus-ALW APLISENS S.A., 03-192 Warsaw, Morelowa 7 St. tel. +48 22 814 07 77; fax +48 22 814 07 78 www.aplisens.com, e-mail: export@aplisens.com...

- Page 2 ID: 0032 0001 0002 0000 0000 0000 0001 88 ID: 0037 0001 0002 0000 0000 0000 0001 73 https://www.aplisens.pl/ID/003200010002000000000000000188 https://www.aplisens.pl/ID/003700010002000000000000000173 PCE-28.Modbus (Exi) PRE-28.Modbus (Exi) ID: 0032 0002 0002 0000 0000 0001 0001 08 ID: 0037 0002 0002 0000 0000 0001 0001 90 https://www.aplisens.pl/ID/003700020002000000000001000190...

- Page 3 PCE-28.Modbus16 (Exi) PRE-28.Modbus16 (Exi) ID: 0069 0001 0002 0000 0000 0001 0001 25 ID: 0070 0001 0002 0000 0000 0001 0001 22 https://www.aplisens.pl/ID/006900010002000000000001000125 https://www.aplisens.pl/ID/007000010002000000000001000122 PCE-28.Modbus-ALW ID: 0068 0001 0002 0000 0000 0000 0001 77 https://www.aplisens.pl/ID/006800010002000000000000000177...

- Page 4 − possible mechanical impacts, excessive shocks and vibration; − excessive temperature fluctuation; − water vapor condensation, dusting, icing. Changes made to the manufacturing of products may be introduced before the paper version of the manual is updated. The up-to-date manuals are available on the manufacturer’s website: www.aplisens.com.

-

Page 5: Table Of Contents

EN.IO.PCE.PRE.28.MODBUS TABLE OF CONTENTS INTRODUCTION .......................... 8 1.1. Purpose of the document ....................... 8 SAFETY ............................8 TRANSPORT AND STORAGE ....................8 3.1. Delivery check ........................8 3.2. Transport ..........................8 3.3. Storage ..........................8 GUARANTEE ..........................9 IDENTIFICATION ......................... 9 5.1. - Page 6 8.4.10.3. Setting the fixed current mode ................36 8.4.10.4. Configuration write ....................36 8.5. Current loop 4-20 mA operation (applies to PCE-28.Modbus and PRE-28. Modbus) or with an internal 4-20 mA current controller (applies to PCE-28.Modbus-ALW) ......36 8.5.1. Set range ........................... 36 8.5.2.

- Page 7 EN.IO.PCE.PRE.28.MODBUS 8.7.3. Local Menu, error messages ..................... 40 8.7.4. Basic technical parameter display ..................40 MAINTENANCE ......................... 41 9.1. Periodic inspections ......................41 9.2. Non-periodic inspections ...................... 41 9.3. Cleaning/washing ........................ 41 9.4. Diaphragm cleaning ......................41 9.5. Spare parts .......................... 41 9.6.

-

Page 8: Introduction

1.1. Purpose of the document The subject of manual are pressure transmitters PCE-28.Modbus, differential pressure transmitters PRE-28.Modbus in standard, intrinsically safe Exi, flameproof Exd versions and PCE-28.Modbus16, PRE-28.Modbus16 in intrinsically safe Exi version, hereinafter referred jointly to as the transmitters. -

Page 9: Guarantee

The guarantee shall be repealed if the device is used against its intended use, failure to comply with user’s manual or interference with the structure of the device. IDENTIFICATION 5.1. Manufacturer’s address APLISENS S.A. 03-192 Warsaw Morelowa 7 St. Poland 5.2. -

Page 10: Installation

EN.IO.PCE.PRE.28.MODBUS INSTALLATION 6.1. General recommendations In order to avoid measurement errors caused by the accumulation of condensate (in gas installations) or gas bubbles (in liquid installations) in impulse lines, assembly solutions using constructions based on available engineering knowledge should be used. For a gas- eous medium, this may mean installing the transmitters above the pressure measuring point, and for liquids below this point. -

Page 11: Electrical Connection

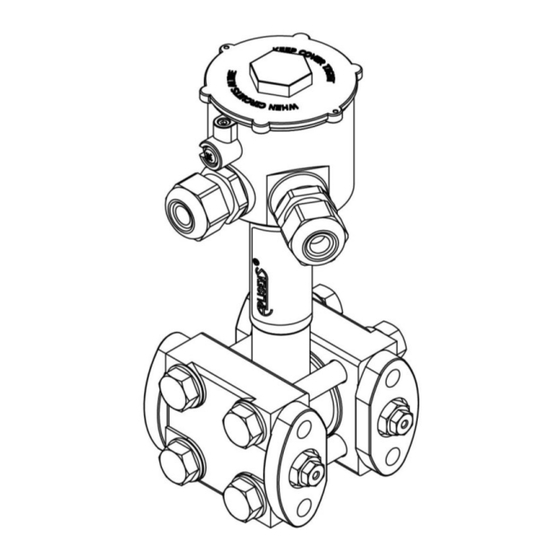

EN.IO.PCE.PRE.28.MODBUS ELECTRICAL CONNECTION 7.1. Cable connection to transmitter internal terminals All connection and installation operations shall be performed with disconnected supply voltage and other external voltages, if used. Failure to provide proper connection of the transmitter may result in danger. Risk of electric shock and/or ignition in potentially explosive atmospheres Figure 1. -

Page 12: Connection Of Transmitters With Pkd, Pz, Sg, Pm12 Type Connector (Cable Connection)

15.8 V DC bus16 and PRE-28.Modbus16 - current for Modbus mode < 3,6 mA for PCE-28.Modbus and PRE-28.Modbus; - current for Modbus mode < 23 mA for PCE-28.Modbus16 and PRE-28.Modbus16. - current for Modbus mode < 24 mA for PCE-28.Modbus-ALW. -

Page 13: Specifications Of Electrical Switching Terminals

(which are not protected by diodes connected between the line wires), additional protection is applied in the form of gas surge arresters. Additionally, an external protective device can be used, e.g. the UZ-2 system by APLISENS or others. 7.5. -

Page 14: Operation

8.1.3. Details of RS485 “half-duplex” To ensure the best possible efficiency in industrial environment, the transmitters from Aplisens S.A. are provided with RS485 transceivers with appropriately customized operating parameters. To provide compatibility and the best possible working conditions, the Master transceiver should conform to the specifications below. -

Page 15: Fail Safe" Mode

8.1.3.3. 1/16 of bus load Input impedance in RS485 transceivers used in the transmitters from Aplisens S.A., in receiving mode, is higher than the standard impedance to enable connecting up to 256 devices to the bus. 8.1.3.4. -

Page 16: Data Link Layer

This communication mode of the Master allows the Slave devices to receive and perform functions simultaneously, regardless of the Slave network address. In the APLISENS transmitters covered by this manual, the broadcast mode is used to make entries to the transmitters using the 101, 102, 103, 104, 105 functions. -

Page 17: Modbus Rtu Message Format

EN.IO.PCE.PRE.28.MODBUS 8.2.2. Modbus RTU message format All Modbus RTU messages are sent in the following format: Slave Address – network address of the Slave device. The address 0 is reserved for the broadcast in the query mode of the Master device. Slave devices, irrespective of their network address, should be able to perform the function of a write operation without sending back a response telegram in this mode. -

Page 18: Error Handling

The response time in the APLISENS S.A. transmitters described in this document should be less than 5 ms, including the most disadvantageous conditions (data load, transfer rate). -

Page 19: Application Layer, Description Of Implemented Functions

EN.IO.PCE.PRE.28.MODBUS 8.3. Application layer, description of implemented functions 8.3.1. System functions 8.3.1.1. 0x03 (3) “Read Holding Register” This function used to read the continuous address space of a data block. The Master sets the register start address (2 bytes) and the number of 2-byte read registers. Registers with register addressing are accessible from addresses starting with 0x0000 or 0x9C41 (40001 dec), e.g. - Page 20 EN.IO.PCE.PRE.28.MODBUS COEFFICIENT NAME DESCRIPTION OF DATA0 … DATA3 NUMBER BIT7 0 = 3,9 … 20,5 mA operation 1 = 3,8 … 20,5 mA operation [TRF] - Transfer Function Code 0x00 Linear (y=x) 0x01 Square root (y=x ½ 0x04 Special (piecewise linear) 0x05 Square (y=x [PVU] - Primary Variable Unit...

-

Page 21: 0X65 (101) „Write Coefficients

EN.IO.PCE.PRE.28.MODBUS COEFFICIENT NAME DESCRIPTION OF DATA0 … DATA3 NUMBER 0x88 Auxiliary Coeffi- [SLDC_1_H][ SLDC_1_L][ SLDC2_H][ SLDC_2_L] cients_4 [SLDC_1_H] Most significant byte of Bus Communication Error Counter [SLDC_1_L] Least significant byte of Bus Communication Error Counter [SLDC_2_H] Most significant byte of Slave Exception Error Coun- [SLDC_2_L] Least significant byte of Slave Exception Error Counter 0x89... -

Page 22: 0X67 (103) „Set Speed, Parity, Stop

EN.IO.PCE.PRE.28.MODBUS 8.3.2.4. 0x67 (103) „Set Speed, Parity, Stop” Function used to configure the 3 coefficients that define the Modbus communication parameters. Set Speed, Parity, Stop | 7 bytes request, 7 bytes response | Req: [ADD][FC][RS_mode_1][RS_mode_2][RS_mode_3][CRC_H][CRC_L] Resp: [ADD][FC][RS_mode_1][RS_mode_2][RS_mode_3][CRC_H][CRC_L] COEFFICIENT DESCRIPTION OF COEFFICIENTS NAME [RS_mode_1] RS_mode_1... -

Page 23: Modbus Register Layout, Registers From 0X0000 Or 0X0100 Or 0X9C41 (40001 Dec) Address

EN.IO.PCE.PRE.28.MODBUS 8.3.3. Modbus register layout, registers from 0x0000 or 0x0100 or 0x9C41 (40001 dec) address Bytes Address Purpose Notes Format (hex) (2 bytes per register) 0x0000 User specific % of the controlled set range 4 bytes (2 registers) 0x0100 IEEE754 0x9C41 0x0002 Pressure or level process... -

Page 24: Request Message With The Function 0X03 For 3 Different Addresses Fields, Reading The Ieee754 Process Variable Stored In 2 Registers

EN.IO.PCE.PRE.28.MODBUS 8.3.3.1. Request message with the function 0x03 for 3 different addresses fields, reading the IEEE754 process variable stored in 2 registers Master request and Slave response, sensor 1 pressure read value. Request message Parameters Slave Function CRC(L) CRC(H) Starting Starting Number of Number of... -

Page 25: Received Data Based On Example 2, Assigned To The Relevant Registers

Venturi tubes or to calculate volumes in tanks of different shapes. For the PCE-28.Modbus-ALW transmitters, the set range is also related to the internal 4-20 mA current controller, where the start of the set range is assigned the value of 4 mA and it ends at 20 mA. This function allows readings to be displayed on the local LCD display in user-defined units relating to the entire or only part of the transmitter's basic range. -

Page 26: Register 0X0002 Or 0X0104 Or 0X9C43, Pressure Of Sensor 1

EN.IO.PCE.PRE.28.MODBUS 8.3.4.2. Register 0x0002 or 0x0104 or 0x9C43, pressure of sensor 1 Pressure or level process 0x0002, 0x0104, 0x9C43 Pressure of sensor 1 IEEE754 4 bytes (2 registers) variable Basic process variable (pressure or level) standardized for the selected physical unit. This value is sent in 4-byte floating point format conforming to IEEE754. -

Page 27: Register 0X0011 Or 0X0122 Or 0X9C52, Pressure Of Sensor 1 - Binary Format, Integer And Sign

EN.IO.PCE.PRE.28.MODBUS 8.3.4.10. Register 0x0011 or 0x0122 or 0x9C52, pressure of sensor 1 – binary format, integer and sign Integer, 1/100 of the 0x0011, 0x0122, 0x9C52 Pressure of sensor 1 Signed 16-bit int 2 bytes (1 register) pressure or level unit Value of the primary process variable (pressure) standardized for the selected physical unit of pressure (or level). -

Page 28: Register 0X0017 Or 0X012E Or 0X9C58, Standby

− 1st byte – insignificant, always 0; − 2nd byte – manufacturer’s number acc. to HCF, APLISENS number: 188 dec (BC hex); − 3rd byte – device type number, number for the transmitters described in this document: 125 dec (7D hex);... -

Page 29: Configuration Mode

➔ 8.3. Application layer, description of imple- mented functions. However, to make out specific settings or calibration operations, the transmitter must be adjusted using the APLISENS S.A. software. (link to software): https://aplisens.pl/download/pliki_do_pobrania/Modbus%20Configurator%20Setup.exe. Modbus Configurator to the configuration mode by pressing the respective program key. For operation... - Page 30 EN.IO.PCE.PRE.28.MODBUS When searching the network, a list of Modbus transmitters from Aplisens S.A., connected to the net- work, will be displayed. If you know the network address of the transmitter to be set up, click on the appropriate transmitter in the scanned list. A list of registers will appear with read-out parameters from Modbus registers.

- Page 31 EN.IO.PCE.PRE.28.MODBUS Searching for a transmitter in the Modbus mode is carried out with a broadcast = 0. Therefore, only one transmitter may be connected, when scanning through a communication bus. Where there are a larger number of transmitters operating in the Modbus mode connected to the bus and set to the same trans- mission parameters - sending a broadcast address will make transmitters respond to a request mes- sage at the same time, causing data corruption and an unreadable answer.

-

Page 32: Transmitter Identification Data

EN.IO.PCE.PRE.28.MODBUS Configuration mode view 8.4.2. Transmitter identification data Identification data frames (example). Read-only values are shaded. Read-only information fields: Manufacturer ID - manufacturer’s code according to HCF (HART) specifications. Device ID - transmitter’s serial number. Software revision - CPU software version. Hardware revision - transmitter’s PCB version. -

Page 33: Reading The Transmitter's Limit Values Process Variables

EN.IO.PCE.PRE.28.MODBUS 8.4.3. Reading the transmitter’s limit values process variables Frame containing process variables and limit values (example) Lower sensor limit A read-only value. If exceeded, accuracy of measurements using the transmitter cannot be guaranteed. However, the transmitter will continue to process measuring signals up to 50% of the basic range below this point. -

Page 34: Damping And Transfer Function

Pressure sensor calibration. − Analogue output calibration. In case of changing the set range in PCE-28.Modbus-ALW, the local LCD display must be recalibrated. The procedure of this calibration is described in chapter ➔ 8.7. Operating the LCD display (applies to PCE-28.Modbus-ALW). -

Page 35: Additional Operation

With the calibration wizard, you can perform a two-point calibration of the low (4 mA) or high (20 mA) current. For the PCE-28.Modbus-ALW transmitters with an on-board LCD, it is not advisable to use the analogue output calibration function. However, if it is used, the local LCD must be recalibrated afterwards. -

Page 36: Setting The Fixed Current Mode

3.600 and 23.000 mA for testing purposes, e.g. 4.000 mA and 20.000 mA. In the PCE-28.Modbus-ALW transmitters, this option is useful for calibrating the local LCD display (after changing the set range, after analogue output calibration, after the analogue output reset to factory defaults, after changing analogue output conversion curve or if the local LCD display unit change is required). -

Page 37: Table 4. Set Range And Measurement Limits

EN.IO.PCE.PRE.28.MODBUS Table 4. Set range and measurement limits Set range and measurement limits Item Abbr. Meaning "Lower Range Value" – the value of the set range expressed in physical units corresponding to the current of 4,000 mA, i.e. 0% of the output setpoint. The set range cannot exceed the set range limits. -

Page 38: Alarm Signal Levels

8.5.2. Alarm signal levels With the PCE-28.Modbus-ALW transmitters, the current alarm signals are software disabled, as the current signal of the internal current regulator is only used to control the local LCD indicator. In other types of Modbus transmitters, where the controller current signal is routed outside, alarm signals can be detected with an external controller. -

Page 39: Display Configuration

EN.IO.PCE.PRE.28.MODBUS 8.7.2. Display configuration The user can change the display settings using the buttons below the display. The buttons can be accessed by unscrewing the display cover. The buttons are marked with symbols: [↓], [↑] and [●]. The buttons [↓], [↑] are used to move up and down the MENU structure, and the button [●] confirms and executes the selected option. -

Page 40: Local Menu, Error Messages

EN.IO.PCE.PRE.28.MODBUS 8.7.3. Local Menu, error messages Local Menu Description EXIT Return from local Menu to display the process variable. Set up of units. PRESS Switching to the selection of pressure units. TEMP Switching to the selection of temperature units. MISC Switching to the selection of different units. -

Page 41: Maintenance

EN.IO.PCE.PRE.28.MODBUS MAINTENANCE 9.1. Periodic inspections Periodic inspections shall be carried out in accordance with applicable standards. During the inspection, the condition of the pressure (absence of loosened elements and leaks) and electrical (check of con- nections reliability and condition of gaskets and glands) connectors, condition of separating diaphragms (tarnish, corrosion) and stability of fixing of the housing and mounting bracket (if used) shall be checked. -

Page 42: Scrapping, Disposal

EN.IO.PCE.PRE.28.MODBUS SCRAPPING, DISPOSAL Worn or damaged devices shall be scrapped in accordance with WEEE Directive (2012/19/EU) on waste electrical and electronic equipment or returned to the manufacturer. HISTORY OF REVISIONS Revision Document revision Description of changes Initial document version. Replaces the revision 1_01.D.011_2020-01. - Page 43 EN.IO.PCE.PRE.28.MODBUS The set range is defined in the Configuration mode: The set range may be equal to or lower than the basic range. It is defined mostly to configure a trans- mitter to operate in the 4-20 mA current loop mode. In this mode, the start of the set range corresponds to the current of 4mA and the control percentage of 0%, whereas the end of the set range corresponds to the current of 20mA and the control percentage of 100%.

-

Page 44: Appendix 1. Explosion-Proof Device Manual En.ix.pce.pre.28.Modbus

3.1. Transmitters PCE-28.Modbus, PRE-28.Modbus with PK, PKM, PKD, PM12, SG, SGM, PZ connection. Minimum transmitters supply voltage 4 V DC. The transmitter is an intrinsically safe device with protection level "ia" when the power supply circuit has protection level "ia". - Page 45 EN.IO.PCE.PRE.28.MODBUS EN.IX.PCE.PRE.28.MODBUS - for power supply with rectangular and trapezoidal characteristics: Ui ≤ 5 V, Ii ≤ 0.4 A b) Permissible input and output parameters for RS485 transmission (blue VA, yellow VB): Ui ≤ 10 V, Ii ≤ 0.2 A, Uo ≤ 10 V*, Io ≤ 0.4 A* * the output parameters of the transmitters Uo, Io are equal to the output parameters Uo, Io of the power supply used.

- Page 46 EN.IO.PCE.PRE.28.MODBUS EN.IX.PCE.PRE.28.MODBUS Fig. PK, PKD, SG and PM12 type connection. Fig. Type of PZ, PZ4 electrical connection Revision 03.A.001/2023.05...

- Page 47 EN.IO.PCE.PRE.28.MODBUS EN.IX.PCE.PRE.28.MODBUS Fig. Diagram of connecting the transmitters in the Modbus network in Exi version The PCE-28.Modbus16, PRE-28.Modbus16 transmitter with PZ, PZ4 type electrical connection has a 560Ω resistor, which can be used as a line/bus terminator. Switching on the resistor can be done using the DIP 1-position switch by switching to the ON position.

Need help?

Do you have a question about the PCE-28.Modbus and is the answer not in the manual?

Questions and answers