Table of Contents

Advertisement

Quick Links

P5-16...R40-17

Model: B01

Assembly and Operating Instructions

en

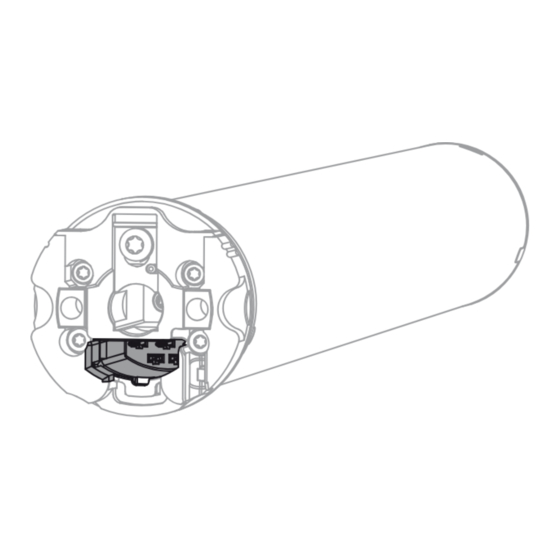

Roller shutter drive with integrated radio

transceiver

Important information for:

• Fitters / • Electricians / • Users

Please forward accordingly!

These instructions must be kept safe for future reference.

2010 300 564 0 16/09/2022

Becker-Antriebe GmbH

Friedrich-Ebert-Straße 2-4

35764 Sinn/Germany

www.becker-antriebe.com

Advertisement

Table of Contents

Summary of Contents for Becker P5-16-B01

- Page 1 Roller shutter drive with integrated radio transceiver Important information for: • Fitters / • Electricians / • Users Please forward accordingly! These instructions must be kept safe for future reference. 2010 300 564 0 16/09/2022 Becker-Antriebe GmbH Friedrich-Ebert-Straße 2-4 35764 Sinn/Germany www.becker-antriebe.com...

-

Page 2: Table Of Contents

Table of contents General .................................... 3 Warranty ..................................... 3 Safety instructions ................................ 4 Instructions for the user.............................. 4 Instructions for installation and commissioning........................ 4 Intended use .................................. 5 Assembling and disassembling the plug-in connecting cable.................... 6 Assembly .................................... 7 Preparation for Commissioning ............................. 9 Checking that the running direction is correct........................ -

Page 3: General

General These tubular drives are high-quality products with the following features: • Optimised for roller shutter operation • Can be operated with any suitable KNX transmitter • Individual, group and central radio control • No need to run wires to a switch or relay control device •... -

Page 4: Safety Instructions

Safety instructions The following safety instructions and warnings are intended to avert hazards and to prevent property damage and personal injury. Instructions for the user General information • The drive must be disconnected from its power source during cleaning and maintenance and when re- placing parts. -

Page 5: Intended Use

• If the drive is used for shading solutions in a specially marked area (e.g., escape routes, hazard zones, safety areas), compliance with all applicable regulations and standards must be ensured. • Once the drive has been installed, the fitter must mark the used tubular drive in the “Technical data” chapter and make a note of the installation position. -

Page 6: Assembling And Disassembling The Plug-In Connecting Cable

Assembling and disassembling the plug-in connecting cable Caution The power supply to the connecting cable must be disconnected prior to assembly/disas- sembly. Assembling the plug-in connecting cable Ø35/Ø45/Ø58 Insert the dead connecting cable into the drive head until the locating lug clicks into place in the drive. If necessary, use a suitable flathead screwdriver to assist with insertion. -

Page 7: Assembly

Assembly Assembling the drive Attention To connect the drive to the driven part, solely mechanical accessory components made by the drive manufacturer from the current product catalogue may be used. Prior to mounting, the fitter must ensure that the masonry and the system being motorised are sufficiently robust (drive torque plus weight of the shading solution). - Page 8 Assembling the drive adapter with safety catch on the Disassembling the drive adapter with safety catch on the drive shaft drive shaft Assembling and disassembling the drive adapter with drive adapter safety catch or screw connection Assembling and disassembling the drive Assembling and disassembling the drive adapter with separate drive adapter adapter with screw connection...

-

Page 9: Preparation For Commissioning

Preparation for Commissioning The tubular drive can be operated with any suitable KNX transmitter The commissioning (e.g. setting the limit positions etc.) and later configurations are, however, only possible with a B-Tronic trans- mitter. The running direction must be correct. When setting the limit positions, the tubular drive runs with the limit position status indicator. -

Page 10: Checking That The Running Direction Is Correct

Readying the tubular drive for programming Readying the tubular drive for programming by switching on the power Switch on the power. ► The tubular drive is ready to program for 3 minutes Readying the tubular drive for programming with the radio switch Switch the radio switch to the inside position. -

Page 11: Limit Position Settings And Configurations

Limit position settings and configurations The commissioning (e.g. setting the limit positions etc.) and later configurations are only possible with a B-Tronic transmitter. Please find the appropriate description in the instructions for the B-Tronic transmitter. Attention When operating the tubular drive without the drive adapter for obstacle detection, if using springs a point must be set in the lower limit position. -

Page 12: Maintenance

Maintenance These drives are maintenance-free. Technical data dia. 35 Tubular drive P5-16 P9-16 Model Type PROF+ KNX Rated torque [Nm] Output speed [rpm] Limit switch range 64 revolutions Supply voltage 230 V AC / 50 Hz Connected load [W] Rated current consumption [A] 0.36 0.47 Mode... -

Page 13: What To Do If

What to do if...? Problem Remedy Tubular drive does not move. Program new transmitter. Bring transmitter within range of the tubular drive. Insert battery/batteries correctly in the transmitter or insert new battery/batteries. Check electrical connection. Thermal protection switch in tubular drive has tripped. Wait until the thermal protection switch in the tubular drive is reactivated. -

Page 14: Sample Wiring Diagram

Sample wiring diagram 14 - en... -

Page 15: Declaration Of Conformity

Declaration of conformity 15 - en...

Need help?

Do you have a question about the P5-16-B01 and is the answer not in the manual?

Questions and answers