Table of Contents

Advertisement

Quick Links

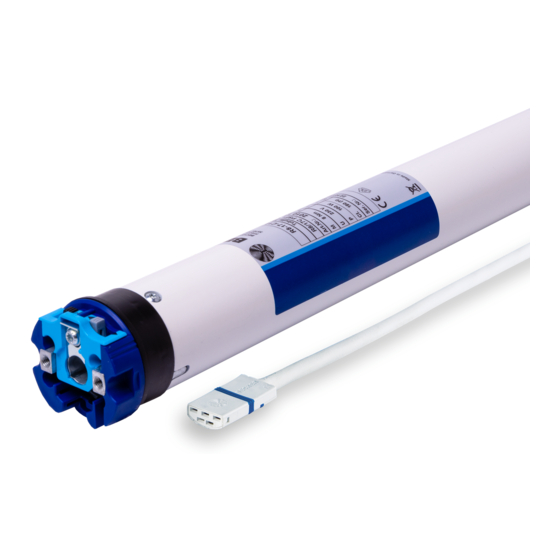

P5-20...R40-17

Model: C18 PLUS

Assembly and Operating Instructions

en

Tubular drive with integrated radio transceiver for

ZIP systems

Important information for:

• Fitters / • Electricians / • Users

Please forward accordingly!

These instructions must be kept safe for future reference.

2010 301 285 0c 20/10/2023

Becker-Antriebe GmbH

Friedrich-Ebert-Straße 2-4

35764 Sinn/Germany

www.becker-antriebe.com

Advertisement

Table of Contents

Summary of Contents for Becker C18 PLUS

- Page 1 P5-20...R40-17 Model: C18 PLUS Assembly and Operating Instructions Tubular drive with integrated radio transceiver for ZIP systems Important information for: • Fitters / • Electricians / • Users Please forward accordingly! These instructions must be kept safe for future reference.

-

Page 2: Table Of Contents

Table of contents General .................................... 3 Warranty ..................................... 4 Safety instructions ................................ 4 Instructions for the user.............................. 4 Instructions for installation and commissioning........................ 4 Intended use .................................. 6 Assembling and disassembling the plug-in connecting cable.................... 6 Assembly .................................... 7 Compatible Centronic transmitters ............................ 9 Commissioning with a CentronicPLUS transmitter ........................ -

Page 3: General

General These tubular drives are high-quality products with the following features: • Optimised for vertical ZIP applications • Individual, group and central radio control • No need to run wires to a switch or relay control device • Any combination of drive and transmitter possible •... -

Page 4: Warranty

Warranty Structural modifications and incorrect installation which are not in accordance with these and our other instructions can result in serious injuries, e.g., crushing of limbs. Therefore, structural modifications may only be carried out with our prior approval and strictly in accordance with our instructions, particularly the information contained in these Assembly and Operating Instructions. Any further processing of the products which does not comply with their intended use is not permitted. - Page 5 • Hazardous moving parts of the drive must be installed at a height of over 2.5 m above floor level or any other surface from which the drive can be accessed. • To ensure safe operation of the system after commissioning, the limit positions must be correctly set/ programmed in.

-

Page 6: Intended Use

Intended use The type of tubular drive described in these instructions is intended solely for the operation of vertical ZIP systems. It may only be used in networked systems if all the individual drives are exactly synchronised and reach the limit positions at the same time. -

Page 7: Assembly

Ø45/Ø58 Insert a suitable flathead screwdriver right into the recess of the locating latch, so that the latch releases the locating lug from the plug. Now you can pull out the connecting cable along with the flat- head screwdriver. A = locating latch Assembly Assembling the drive Attention... - Page 8 Assembling the drive adapter with safety catch on the Disassembling the drive adapter with safety catch on the drive shaft drive shaft Assembling and disassembling the drive adapter with drive adapter safety catch or screw connection Assembling and disassembling the drive Assembling and disassembling the drive adapter with separate drive adapter adapter with screw connection...

-

Page 9: Compatible Centronic Transmitters

All CentronicPlus receivers can be operated with the Centronic transmitters listed in the Centronic/CentronicPlus compatibility table at www.becker-antriebe.com/downloads As two fundamentally different radio technologies are linked in this case, the full performance of the CentronicPlus radio control system is not available in this combination. When using the Centronic transmitter with CentronicPlus receiver, the range perform- ance may be reduced under certain circumstances. -

Page 10: Establish Programming Mode

Connecting the tubular drive Connect the tubular drive to the power supply. 230V AC / 50 Hz 1 = blue 3 = black 2 = brown 4 = green / yellow Switch on the power. ► The tubular drive confirms. Establish programming mode This step is only necessary if one of the devices to be programmed is not yet part of the in- stallation. -

Page 11: Programming The Centronicplus Transmitter

Programming the CentronicPLUS transmitter With brand new products, devices from another installation or products that have been re- stored to factory settings, programming mode must be established beforehand (see Es- tablishing programming mode). Bring the transmitter as close as possible to the receiver to be programmed. Press the programming button for 3 seconds when it is ready to program. -

Page 12: Adding Additional Transmitters To The Installation

Adding additional transmitters to the installation If installation data already exists for the transmitter being programmed, the procedure will be terminated. Termination is indicated by the red flashing of the LED ring. In this case, the transmitter will need to be restored to factory settings (see corresponding transmitter in- structions). -

Page 13: Checking That The Running Direction Is Correct

Checking that the running direction is correct The direction of rotation can only be changed if no limit position has been set. There are several ways to change the direction of rotation: • Changing direction of rotation via the direction switch •... -

Page 14: Intelligent Installation Management

Intelligent installation management Completion of installation following automatic setting of limit positions The drive saves the limit position permanently once the upper limit position is reached 3 times in succession. Installation is then complete. If the limit position is set above a point, this is stored permanently. Limit position status indicator A brief stopping and restarting indicates that no limit position has been set in that direction of movement. -

Page 15: Changing The Set Limit Positions

Lower point to upper stop Select the required receiver as described in the chapter Selection of the receiver for the setting mode [} 12]. Close to the desired lower limit position. Press the programming button and, within 3 seconds, also press the button and hold the two buttons down. -

Page 16: Deleting The Limit Positions

2) Extending the range of travel (the desired limit position is located outside the current range of travel) Attention When both or individual limit positions are deleted, all the other set functions (intermediate position I, intermediate position II) are deleted as well. Select the required receiver as described in the chapter Selection of the receiver for the setting mode [} 12]. -

Page 17: Intermediate Positions I + Ii

Deleting both limit positions Any additional functions that may have been set are deleted at the same time, or are reset to the factory default settings. Select the required receiver as described in the chapter Selection of the receiver for the setting mode [} 12]. -

Page 18: Restoring The Wireless Memory Of The Tubular Drive To Factory Settings

Deleting the desired intermediate position Move the shading solution to the intermediate position that is to be deleted. Now press the STOP button and, within 3 seconds, also press the travel button as- signed to the intermediate position and hold the two buttons down. ▻... - Page 19 Briefly press the programming button to change to the setting mode. ▻ The receiver confirms. ▻ The LED ring of the transmitter slowly pulses light blue. ▻ The receiver now enters dead-man mode. ▻ The setting mode is now active. Then press the programming button and also the button, the STOP button and the button for approximately 3 seconds.

-

Page 20: Commissioning With A Centronic Transmitter

Commissioning with a Centronic transmitter Explanation of symbols UP button STOP button DOWN button Programming button (on the transmitter) Receiver confirms once or multiple times by "clicking" or "shifting" 1 = direction switch 2 = radio switch Attention The tubular drives are designed for short-time operation. An inbuilt thermal protection switch prevents overheating of the tubular drive. -

Page 21: Programming The Master Transmitter

Readying the tubular drive for programming with the radio switch Switch the radio switch to the inside position. If the radio switch is already in this posi- tion, switch it to the outside and back to the inside position. ► The tubular drive is ready to program for 3 minutes. Programming the master transmitter Press the programming button for 3 seconds when it is ready to programme. -

Page 22: Intelligent Installation Management

Changing direction of rotation via master transmitter Press the button. ▻ The shading solution runs in the desired direction. ► The running direction is OK. If the shading solution runs in the wrong direction, the running direction must be changed. Proceed as follows: First, press the programming button, then within 3 seconds also press the button for 3 seconds. -

Page 23: Deleting The Limit Positions

Lower point to upper stop Close to the desired lower limit position. Press the programming button and, within 3 seconds, also press the button and hold the two buttons down. ▻ The tubular drive acknowledges. Then open as far as the permanent stop. ▻... -

Page 24: Programming Additional Transmitters

Travelling to the desired intermediate position Press the travel button for the desired intermediate position twice within one second. ► The curtain runs to the intermediate position assigned to the travel button. Deleting the desired intermediate position Move the shading solution to the intermediate position that is to be deleted. Now press the STOP button and, within 3 seconds, also press the travel button as- signed to the intermediate position and hold the two buttons down. -

Page 25: Overwriting The Master

Deleting all transmitters (except the master transmitter) Press the programming button on the master transmitter for 3 seconds. ▻ The tubular drive acknowledges. Re-press the programming button on the master transmitter for 3 seconds. ▻ The tubular drive acknowledges. Re-press the programming button on the master transmitter for 10 seconds. ▻... -

Page 26: Setting The Limit Positions With Auto-Install (For Zip Applications With Heavy End Strip)

Setting the limit positions with Auto-install (for ZIP applications with heavy end strip) For proper execution of the auto-install function, the necessary torque in the lower limit position must be at least 1/3 of the rated torque of the tubular drive used. Example: Tubular drive 12 Nm, barrel diameter 85 mm (r= 0.0425 m, no part of the shading solution is on the barrel when uncoiled). -

Page 27: Additional Functions With Centronicplus / Centronic

Programming the run times This function is available with all CentronicPlus EasyControl transmitters and with Centronic devices only equipped with "MemoControl" transmitters from the Becker range of control units. Both limit positions must be set before the Memo function is set. -

Page 28: Deleting The Run Times With A Centronicplus Transmitter

5 seconds. Activating / deactivating the run times with a Centronic transmitter This function is only available with MemoControl transmitters from the Becker Centronic range of control units. The Memo function is activated and deactivated via the slide switch. The last changeover to be performed is valid. -

Page 29: Restoring The Factory Settings Of The Tubular Drive

Restoring the factory settings of the tubular drive The factory settings can only be restored via the universal programming unit (Item no. 4935 000 001 0). Connect the wires of the tubular drive to those of the same colour in the programming unit. -

Page 30: Disposal

The packaging material must be disposed of properly. Maintenance These drives are maintenance-free. Technical data dia. 35 Tubular drive P5-20 P5-30 P9-16 Model C18 PLUS Type C PSOF1 Z1 Rated torque [Nm] Output speed [rpm] Limit switch range 64 revolutions Supply voltage 230 V AC / 50 Hz... -

Page 31: Error Messages

Error messages The tubular drive is blocked. ► The transmitter confirms with 10 red flashes of the LED ring. The tubular drive is overheated. ► The transmitter confirms with 5 red / yellow flashes of the LED ring. The tubular drive is not responding. ►... -

Page 32: Sample Wiring Diagram

Problem Remedy Tubular drive does not run in the right direction. Tubular drive is overheated. The tubular drive is operational again after a few minutes. Tubular drive is faulty (does not run even after standing still for a long period of time). Replace the tubular drive. Clear and remove the obstruction and set the drive in the direc- tion required. -

Page 33: Declaration Of Conformity

Declaration of conformity 33 - en...

Need help?

Do you have a question about the C18 PLUS and is the answer not in the manual?

Questions and answers