Table of Contents

Advertisement

Quick Links

Instructions

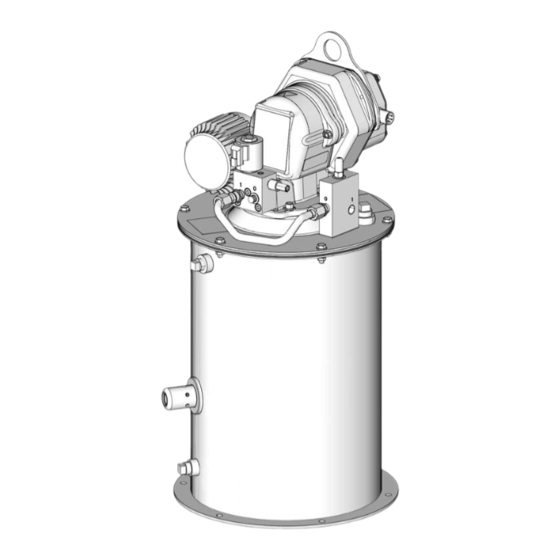

Dyna-Star

Pump System

Provides lubricant flow and pressure to operate a single line parallel automatic lubrication

system. For automatic lubrication systems only.

Not approved for use in European explosive atmosphere locations.

Models

77X202 - 60 lb

77X203 - 90 lb

24VDC, Injector module with pump, tube-in-tube, vent

valve, auto-fill shutoff, low level, 60 lb. or 90 lb. reservoir.

3500 psi (24.1 MPa, 241 bar) Maximum Working Pres-

sure

5000 psi (34 MPa, 344.7 bar) Maximum Refilling Inlet

Pressure

Important Safety Instructions

Read all warnings and instructions in this

manual, the Dyna-Star HP and HF Pump

instruction manual and all related component

manuals (listed below). Save all instructions.

Related Manuals

Manual

332514

Dyna-Star HP and HF Pump

Dyna-Star HP and HF Auto-Fill Shut

332518

Off Kit

332519

Dyna-Star HP Vent Valve Kit

333393

Fill Valve

334998

Power Cable Kit

334999

Cable Harness Kit

3A2960

GLC2200 Lubrication Controller

®

HP

Description

3A3956C

EN

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Graco Dyna-Star 77X202

- Page 1 Instructions ® Dyna-Star Pump System 3A3956C Provides lubricant flow and pressure to operate a single line parallel automatic lubrication system. For automatic lubrication systems only. Not approved for use in European explosive atmosphere locations. Models 77X202 - 60 lb 77X203 - 90 lb 24VDC, Injector module with pump, tube-in-tube, vent valve, auto-fill shutoff, low level, 60 lb.

- Page 2 Warnings Warnings The following warnings are for the setup, use, grounding, maintenance, and repair of this equipment. The exclama- tion point symbol alerts you to a general warning and the hazard symbols refer to procedure-specific risks. When these symbols appear in the body of this manual or on warning labels, refer back to these Warnings. Product-specific hazard symbols and warnings not covered in this section may appear throughout the body of this manual where applicable.

- Page 3 Warnings EQUIPMENT MISUSE HAZARD Misuse can cause death or serious injury. • Do not operate the unit when fatigued or under the influence of drugs or alcohol. • Do not exceed the maximum working pressure or temperature rating of the lowest rated system com- ponent.

-

Page 4: Typical Installation

Typical Installation Systems with Pressure Relief Valve in the Refilling Line The installation shown is only a guide for selecting and installing system components. Contact your Graco distributor for assistance in planning a system to suit your needs. NOTE: The remote filling station pump stalls (dead-heads) when the reservoir is full. If the pump does not stall (dead-head) there is a leak in the system. - Page 5 Warnings Key: Lubricant outlet connection (marked with an “0”) Pump Ignition switch C1 Fuse High-pressure lubricant supply lines Injector banks Lubrication controller Fill port (not used with Auto-Fill Shut Off) Overflow port (not used with Auto-Fill Shut Off) Breather Reservoir Vent Valve Motor Fluid overflow container...

- Page 6 Typical Installation Systems with Fill Valve in the Refilling Line The installation shown is only a guide for selecting and installing system components. Contact your Graco distributor for assistance in planning a system to suit your needs. NOTE: The remote filling station pump stalls (dead-heads) when the reservoir is full. If the pump does not stall (dead-head) there is a leak in the system.

-

Page 7: Installation

Installation Pressure Relief Procedure System Configuration and Wiring NOTE: Cable wiring harness kits are available from Follow the Pressure Relief Procedure whenever Graco. See Parts page 20 for a complete list of available you see this symbol. kits. Fuses NOTICE Fuses (user supplied) are required on all models. - Page 8 Installation Pump Connection with Graco Wiring Harness 77X546 See F Wire Connection Table Wire Color Connection Orange Signal + Black Power - Power + Blue Signal - 3A3956C...

- Page 9 Installation User Supplied Wiring Harness 24 VDC With Signal Input ti21392b . 6: Pump control switch shown in signal mode *A Vent Valve is only used in an injector-based system. 24 VDC With External Relay ti21393b . 7: Pump controls switch shown in power mode *A Vent Valve is only used in an injector-based system.

- Page 10 Installation Motor Control Board • SIG - Turns pump on when voltage is applied to: + (Positive) Power Input - SIG IN - - SIG IN + - (Negative) Power Input Blue Motor Wire Connection Turn On Signal - Yellow Motor Wire Connection Turn On Signal + Green Motor Wire Connection Red (Fault) LED - Blinks type of fault (See Fault Table)

-

Page 11: Current Control And Flow Motor Control Settings

Installation Fault Table: Red LED (E) Fault Blinks Over Current Locked Rotor Low or High Voltage High Motor temp Missing Temp Sensor High Board Temp Bad Hall Cable Pump Control Operation NOTICE To avoid equipment damage, remove power before switching modes from signal to power or power to sig- 2. - Page 12 Installation Reservoir Mounting 3. The lubrication controller (F) terminates the signal to the pump (B) and power to the vent valve (L). 4. The vent valve (L) opens. 5. Pressure in the supply line (D) is relieved back into the reservoir, resetting all injectors (E). LIFTING HAZARD This equipment is heavy.

- Page 13 There is still lubricant in the tank and A Pressure Relief Kit: 247902 is available from Graco. immediate shutdown is not required. Contact your distributor or Graco Customer Service for additional information about this kit.

- Page 14 Installation Low Level Sensor Wiring with GLC2200 Lube Controller Pin Connector . 11 . 12 . 13 3A3956C...

-

Page 15: Auto-Fill Shut Off

Installation Auto-Fill Shut Off Refilling the Reservoir The Auto-Fill Shut Off (S) is used for refilling the grease Refilling Systems without a Fill Valve tank/reservoir in an automatic lubrication system. When the grease level in the tank is full, the Auto-Fill Shut Off 1. - Page 16 Installation b. Close ball valve (bv) when all pressure has been relieved. NOTE: The pin may not drop and the Auto-Fill Shut Off may not reset because the tank is full. However, when the pump begins using the grease, the pin resets. The pin must reset 4.

- Page 17 Service NOTE: If the pump does not stall (dead-head) there is a leak in the system. Use only Genuine Graco Repair Parts. See separate system component manuals for service instructions. For pump service see manual 332514. For vent valve service see manual 332519.

-

Page 18: Troubleshooting

Troubleshooting Troubleshooting Problem Cause Solution Pump (B) malfunction. Refer to the pump manual 332514. Pump (B) is not running; i.e., not cycling, there is no lubricant output, pump runs slow, the control board’s red LED fault is illuminated, etc. Blockage in the line. Check for blockage in the line. - Page 19 Troubleshooting Problem Cause Solution Low level alarm did not come on but Check sensor LED. If green, tank has Low level sensor malfunction pump cavitates (runs out of grease). grease but pump is not able to pump grease. See Troubleshooting instruc- tions in pump manual 332514.

-

Page 20: Parts List

Parts List: Parts List: Ref. Part No. Description 77X011 KIT, pump and vent valve, 60#, includes 1a and 1b 77X012 KIT, pump and vent valve, 90#, includes 1a and 1b PUMP, Dyna-Star, see instruction manual 332514 VENT VALVE, see instruction manual 332519 RESERVOIR, grease, includes 3a-3l, . -

Page 21: Technical Data

Technical Data Technical Data Dyna-Star Pump Metric Maximum working pressure 3500 psi 24.1 MPa, 241 bar Grease capacity 60 lb. 27 kg 90 lb 41 kg Lubricant outlet port size 3/8 npt (f) Fill port size (Auto-Fill Shut Off) 3/8 npt (F . - Page 22 Dimensions Dimensions ti24349 60 lb Models 90 lb Models US (inch) Metric (cm) US (inch) Metric (cm) 77.47 96.52 30.5 38.0 14.5 36.83 14.5 36.83 19.4 49.28 27.0 68.6 Ø Ø six, 7/16 inch hole six, 7/16 inch hole 13 7/8 inch bolt circle 13 7/8 inch bolt circle 14.5 36.83...

- Page 23 Notes Notes 3A3956C...

-

Page 24: Graco Standard Warranty

With the exception of any special, extended, or limited warranty published by Graco, Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment determined by Graco to be defective.

Need help?

Do you have a question about the Dyna-Star 77X202 and is the answer not in the manual?

Questions and answers