Graco A Series Instructions And Parts List

Hide thumbs

Also See for A Series:

- Instructions - parts manual (52 pages) ,

- Instructions-parts list manual (48 pages) ,

- Manual (36 pages)

Table of Contents

Advertisement

Quick Links

Instructions - Parts List

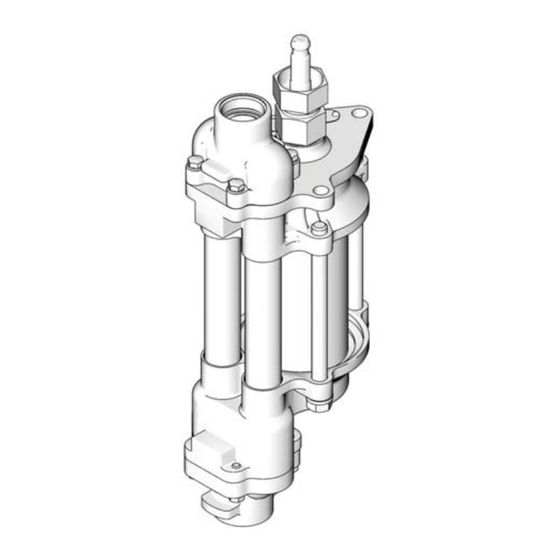

High-Flo

Designed for low pressure, medium volume circulation of finishing materials.

For professional use only.

Important Safety Instructions

Read all warnings and instructions in your High-Flo

Pump manual 311211. Save these instructions.

See page 2 for Table of Contents and page 2 for

List of Models and Maximum Working Pressures.

Patent Pending

®

Lowers

311690M

TI8732a

ENG

TI8733a

Advertisement

Table of Contents

Summary of Contents for Graco A Series

- Page 1 Instructions - Parts List ® High-Flo Lowers 311690M Designed for low pressure, medium volume circulation of finishing materials. For professional use only. Important Safety Instructions Read all warnings and instructions in your High-Flo Pump manual 311211. Save these instructions. See page 2 for Table of Contents and page 2 for List of Models and Maximum Working Pressures.

-

Page 2: Table Of Contents

Lower Reassembly ..... . 10 Graco Information ......22... -

Page 3: 1500Cc Lowers

Models 1500cc Lowers Maximum Pump Model Size Working Pressure Rod/Cylinder Parts Series Material Seat (cc) psi (MPa, bar) Material Connection Style Page 253034 Tungsten 1500 460 (3.2, 32) Chromex/Chrome Inlet: 1-1/2 in. npt Carbide Outlet: 1 in. npt 24E784 1500 460 (3.2, 32) Chromex/Chrome Inlet: 1-1/2 in. -

Page 4: Warnings

Warnings Warnings The following warnings are for the setup, use, grounding, maintenance, and repair of this equipment. The exclama- tion point symbol alerts you to a general warning and the hazard symbol refers to procedure-specific risk. Refer back to these warnings. Additional, product-specific warnings may be found throughout the body of this manual where applicable. - Page 5 Warnings WARNING MOVING PARTS HAZARD Moving parts can pinch or amputate fingers and other body parts. • Keep clear of moving parts. • Do not operate equipment with protective guards or covers removed. • Pressurized equipment can start without warning. Before checking, moving, or servicing equipment, follow the Pressure Relief Procedure in this manual.

-

Page 6: Repair

Repair Repair Hydraulic power supply: follow manufacturer’s recom- mendations. • To service the pump assembly, see manual 311211. Surge tank: use a ground wire and clamp. • To service the air motor, see manual 311238. Spray gun: ground through a connection to a properly grounded fluid hose and pump. -

Page 7: Disconnect The Lower

Repair guard retaining nut or hose end coupling to relieve 3. Insert the collars (G) into the coupling nut (K). pressure gradually, then loosen completely. Clear Tighten the coupling nut onto the piston rod (H) and torque to 90-100 ft-lb (122-135 N•m). hose or tip obstruction. -

Page 8: Reassemble The Coupling Rod And Tie Rods To The Motor

Repair 5. Insert the collars (G) and screw the coupling nut (K) onto the coupling rod (F) and torque to 90-100 ft-lb (122-135 N•m). 6. Torque the screws holding the adapter plate (J) to Viscount I+ the motor (E) to 15-17 ft-lb (20-23 N•m). Torque the Pump Shown tie rod locknuts (B) to 50-55 ft-lb (68-75 N•m). -

Page 9: Repair Kits

Repair 11. Lubricate the throat packings and glands. Install one 4. Remove the four capscrews (9) and washers (8) male gland (19†), then five v-packings with the lips from around the outlet manifold (22). facing down: one UHMWPE (20†), one leather 5. -

Page 10: Clean And Inspect Parts

Repair the positioning of the seat, ensuring that the vent CAUTION hole (V) is not blocked by part of the housing. See . 5. If the pressure relief valve in the seat (6) is clogged or filled with material, soak the seat in a compatible sol- vent. - Page 11 Repair 8. Lubricate the inside of the cylinder (4). Slide the pis- washers (8) and screws (9), and torque to 25-30 ton assembly into the cylinder. Rotate the piston as ft-lb (34-40 N•m). shown in F . 6. Seat (24) is reversible. 15.

- Page 12 Repair Apply lubricant to all packings. Apply Loctite 243 (blue) to threads. Allow to cure for at least 12 hours before use. Apply Loctite 263 or 2760 (red) to threads. Allow to cure for at least 12 hours before use. Tighten uniformly until cylinder (4) is seated.

- Page 13 Repair OUTLET TI7668a-1 TI7666a INLET 311690M...

-

Page 14: Lower Parts

Lower Parts Lower Parts 750cc Lower parts list, see page 15 1000cc Lower parts list, see page 16 1500cc Lower parts list, see page 17 2000cc Lower parts list, see page 18 Apply lubricant to all packings. Apply Loctite 243 (blue) to threads. Allow to cure for at least 12 hours before use. - Page 15 Lower Parts 750cc Lowers Part No. 289366, Series A, Stainless Steel Ref. Part No. Description Qty. 183049 CYLINDER, pump, sst 108526 PACKING, o-ring; PTFE 183085 TUBE, fluid; sst 181875 GASKET, cylinder; UMWPE 101968 BALL, intake; 1.25 in. dia; sst 253483 SEAT, intake valve, with relief valve;...

- Page 16 Lower Parts 1000cc Lowers Part No. 253033, Series A, Stainless Steel Part No. 253061, Series A, Carbon Steel Part No. 253398, Series A, Stainless Steel Part No. 253423, Series A, Stainless Steel Part No. 253520, Series A, Stainless Steel Part No. 253523, Series A, Stainless Steel Part No.

- Page 17 Lower Parts 1500cc Lowers Part No. 253034, Series A, Stainless Steel Part No. 253062, Series A, Carbon Steel Part No. 253085, Series A, Stainless Steel Part No. 253397, Series A, Stainless Steel Part No. 253521, Series A, Stainless Steel Part No. 253524, Series A, Stainless Steel Part No.

- Page 18 Lower Parts 2000cc Lowers Part No. 253035, Series A, Stainless Steel Part No. 253063, Series A, Carbon Steel Part No. 253086, Series A, Stainless Steel Part No. 253396, Series A, Stainless Steel Part No. 253522, Series A, Stainless Steel Part No. 253525, Series A, Stainless Steel Part No.

- Page 19 Lower Parts 311690M...

-

Page 20: Pump Seal Kits

Pump Seal Kits Pump Seal Kits Pump Seal Repair Kit 289548 Pump Seal Repair Kit 277362 Pump PTFE Seal Conversion Kit 289549 Pump PTFE Seal Conversion Kit 277363 Lower Model 289366 Lower Models: 253034, 253062, 253085, 253397, 253521, 253524, 253569 Part No. -

Page 21: Throat Packing Kits

Throat Packing Kits Throat Packing Kits Throat Packing Kit 239868 Throat Packing Kit 277356 With leather throat packings. With leather throat packings. For pumps with 750cc lowers. For pumps with 1000cc, 1500cc and 2000cc lowers. Part No. Description Qty. Part No. Description Qty. -

Page 22: Graco Standard Warranty

With the exception of any special, extended, or limited warranty published by Graco, Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment determined by Graco to be defective.

Need help?

Do you have a question about the A Series and is the answer not in the manual?

Questions and answers