Table of Contents

Advertisement

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Fisher & Paykel DS6021

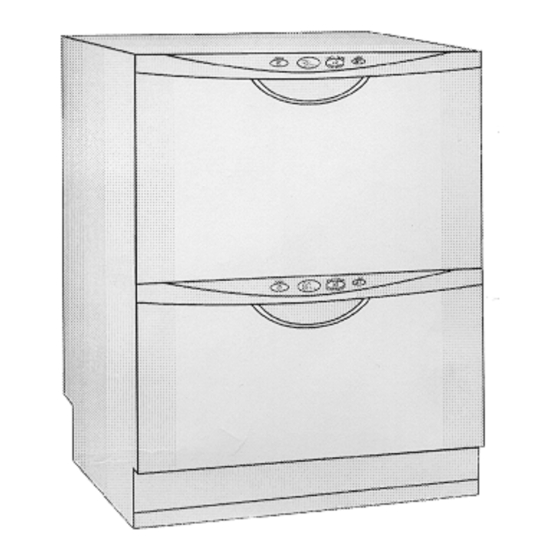

- Page 1 MODELS DD602 DD602I DS602 DS6021 200432...

- Page 2 Fisher & Paykel Appliances Ltd 27 Hubble, Irvine, CA 92618 Tel: (949) 790 8900 (888) 936 7872 Fax: (949) 790 8913 - 2 -...

-

Page 3: Table Of Contents

CONTENTS 1.0 SERVICE REQUIREMENTS ..................5 1.1 H & S .......................5 EALTH AFETY 1.1.1 Electrical Safety......................5 1.1.2 Electrostatic Discharge ....................5 1.1.3 Good Working Practices....................5 1.1.4 Isolate Water Supply ....................5 1.1.5 Water Leak Check....................... 5 1.1.6 Insulation Test ......................6 1.1.7 Solvent and Excessive Heat Damage................ - Page 4 3.14 ......................16 IRING OVER DIAGNOSTICS .......................16 4.1 S & D ....................16 ETUP IAGNOSTICS 4.2 F ......................16 AULT ODES 4.3 D ....................17 IAGNOSTIC ODES 4.3.1 Temperature Display Mode..................17 4.3.2 Rinse Aid / Tub-Open Beep Water Pressure Setup Mode ......... 17 4.3.3 Rinse Aid Setup......................

-

Page 5: Service Requirements

SERVICE REQUIREMENTS Health & Safety Note: When servicing the DishDrawer, health and safety issues must be considered at all times. Specific safety issues are listed below with their appropriate icon. These are illustrated throughout the service information to remind service people of the issues. 1.1.1 Electrical Safety Ensure the mains power has been disconnected before servicing... -

Page 6: Insulation Test

1.1.6 Insulation Test Megger test to check insulation. Warning: Short together the phase and neutral pins on the plug so as not to damage any electronic circuitry. 1.1.7 Solvent and Excessive Heat Damage Plastic surfaces can be damaged by solvents and excessive heat. 1.1.8 Sheet Metal Edges When working around cut sheet metal edges use appropriate gloves or... -

Page 7: Specialised Tools

Specialised Tools For servicing this product Specialised tools are required. 1.2.1 Static Strap: To be used as ESD protection when replacing or handling electronic components. 1.2.2 Down Load Pen Connection: P/N 425930C. To be used to retrieve data from the electronic controller along with the diagnostic program on your laptop. -

Page 8: Dimensions & Specifications

DIMENSIONS & SPECIFICATIONS Description Double Single Product Size Minimum Product Size Minimum Cavity Size Cavity Size 32 3/16 – 34 9/16 32 5/16 – 34 16 1/32” 16 5/32” Height 11/16 23 5/8” 23 5/8” 23 7/16” 23 5/8” Width 22 15/32”... - Page 9 Specifications Lid Seal 4.5 PSI – 6 PSI Detergent Dispenser 15-20 volt dc P/N525878 P/N 525675 (pulsed) 70 ± 5 Ohms Exhaust Valve 9-12 Volt dc (pulsed) P/N525415 70 ± 5 Ohms 0.18 ounces 0.36 ounces 0.54 ounces 0.18 ounces pre- rinse Lid Seal Air Pump 3-6 Volt dc (pulsed)

-

Page 10: Technical Overview

TECHNICAL OVERVIEW Electronics The DD602 electronic controller has two separate micro controllers on the main printed circuit board. One is for motor control and output switching and the other is for controlling interface and console functions. The user interface comprises a printed circuit board for front controls and a touch switch panel for internal controls. -

Page 11: Drawer Fronts

3.3.2 Drawer Fronts Prefinished drawer fronts are formed from a prepainted blank of steel. The drawer fronts are attached to the tub by means of formed hooks and two pins, which are inserted through either side of the tub. On the integrated model, the front panel supplied on each drawer is the mounting panel for the joinery finished drawer front. -

Page 12: Dispensing Detergent

Dispensing Detergent The dispenser is mounted in the front wall of the wash tub. The detergent dispenser consists of two detergent chambers, one for pre wash and the other for the main wash. The detergent dispenser door is opened manually for detergent loading and then manually closed ready for the detergent to be transported to the wash tub by the inlet water. -

Page 13: Wash Cycle

Wash Cycle 3.7.1 The tub is the main cavity where all the wash activity occurs. The tub is a plastic recepticle which has a wash pump and sprayarm at the base. The tub also has guide vanes around its walls which direct falling water from the wash cycle in a clockwise direction around the filter plate. -

Page 14: Overheating Control

3.8.4 Overheating Control The heater plate is only activated during the wash cycles. It is not used for drying. The temperature is maintained by the thermistor. The element circuit is continuously monitored by the electronic controller and will switch a fail-safe relay if a fault is detected in the heater circuit. -

Page 15: Drying Cycle

3.11 Drying Cycle Immediately after water from the final hot rinse has been drained from the tub, the drying system begins operation. The fan draws air through the tub, where it absorbs water from the dishload. The moisture laden air is then mixed with a larger quantity of ambient air (from the kitchen), to minimise the amount of vapour visible when exiting from the drawer front. -

Page 16: Wiring Cover

3.14 Wiring Cover The wiring cover protects the customer from the 120V mains supply which passes over the link assembly and under the lockring to the front of the tub. It also serves to protect the motor assembly, drain and fill hoses from damage when opening and closing drawers. The wiring cover acts as a cosmetic part of the product. -

Page 17: Diagnostic Modes

Diagnostic Modes 4.3.1 Temperature Display Mode During a wash cycle, the current water temperature can be displayed on the LCD instead of the time remaining. To enter temperature display mode, start a wash cycle as normal. Initiate a keylock by pushing and holding the Keylock button for 4 seconds. Once in keylock mode push and hold Start/Pause for 8 seconds to enter temperature display mode. -

Page 18: 4.3.5. Water Pressure Set Up

4.3.5. Water Pressure Set Up The DishDrawer can be set to either High (Standard) or Low inlet water pressure. The LCD displays the current water pressure setting. If “HP” is displayed then the setting is High Pressure. If “LP” is displayed then the setting is Low Pressure. Low pressure is generally less than 50kPa or 7.25 PSI equivalent to that supplied by a ceiling tank. -

Page 19: Clearing Fault Logs

4.3.9 Clearing Fault Logs To Clear the current Fault press the Keylock button until a beep is sounded. This action moves the Current Fault into the Previous Fault while clearing the Current Fault. To Clear the Previous Fault press Keylock once more until the beep is sounded. Warning: Once a fault has been cleared it is permanently removed from Memory and cannot be recovered. -

Page 20: 4.3.12 Continuous Cycle Life Test Mode

Heavy Norm Fast Deli Hardware Output ------------------------------------------------------------------------------------------- Exhaust Valve Fill Water Valve Detergent Diverter Valve Lid Seal Pump Rinse Aid Dispenser (dispenses current setting) Motor Wash direction (2300-2850 rpm) Motor Drain direction (4200 rpm) DC drying fan (On 100% duty) Element Relay ‘temp’... - Page 21 Cycle Count Retrieval To display the cycle count on the LCD screen, Pause the dishwasher while running a Continuous Cycle. The two bytes of the cycle count will be displayed alternately, in synchronization with the changing backlight. The Low byte is displayed when the backlight is Green. The High byte is displayed when the backlight is Orange.

-

Page 22: Diagnostics Quick Reference Flow Chart

Diagnostics Quick Reference Flow Chart - 22 -... -

Page 23: Diagnostics Quick Reference Flow Chart Cont'd

Diagnostics Quick Reference Flow Chart cont'd - 23 -... -

Page 24: Fault Codes

Fault Codes Fault Code LED Display Fault Possible Causes ----# The flood switch has · A leak has occurred in the been activated. base of the dishwasher. · The fill valve has failed open. · The flood switch is faulty. ·... - Page 25 Fault Code LED Display Fault Possible Causes #---# Fill fault. The motor · The water supply is not turned has not primed after a given time. · The machine is siphoning. · The sprayarm is not in place. · Excessive foaming. ·...

- Page 26 - 26 -...

- Page 27 This fault is monitored when the motor is running. It is looking for 10 stalls in a row. It is not monitored during diagnostics. The rotor has not been sensed as rotating. Is the rotor jammed? Note* Free or replace Substitute Rotor the rotor.

- Page 28 - 28 -...

- Page 29 No temperature increase has been sensed while the element is on. Does the element heat in diagnostics? Test the resistance Test the resistance of the sensor as per of the element at the the temperature controller as per the chart specifications Not OK Not OK...

- Page 30 Inter-communication fault. Replace the electronic controller. If this occurs while you are servicing the Dishdrawer, you may have induced the fault , so ignore it. RAM fault. Replace the electronic controller - 30 -...

- Page 31 - 31 -...

- Page 32 The tub drawer has been sensed as open during the cycle or the exhaust valve is open circuit. Is the drawer open? Check the Shut the drawer. microswitch is working in diagnostics. Not OK Check the mechanical Replace the operation of the microswitch.

- Page 33 - 33 -...

- Page 34 Poor Dry Performance Rinse aid not being dispensed In Diagnostics, does the dispenser pump run? Is there rinse aid in Check the continuity of the the dispenser ? wiring and pump solenoid by removing the connections at the PCB and testing with a meter. Replace Not OK dispenser...

- Page 35 Poor Wash Performance Detergent not flushing out of Pre Wash or Main Wash chambers In Diagnostics active the fill valve and note which side of the dispenser the water comes out. Then turn off the fill valve and activate the diverter valve(dd), re-active the fill valve to see if the Not OK water now exits the other side of...

- Page 36 - 36 -...

-

Page 37: Wiring Diagram

WIRING DIAGRAM - 37 -... -

Page 38: Service Procedures

SERVICE PROCEDURES 6.1. Drawer Front Removal 6.1.1 Slide open drawer. 6.1.2 Locate draw pin on either side of the tub. 6.1.3 Using a sharp pair of long nose pliers or slip jaw pliers grasp the center dividing web of the pin and pull away from the tub to remove the pin. Support the drawer front with your hand while doing this. -

Page 39: Drying Fan Removal

Drying Fan Removal 6.3.1 Remove the drawer front as per instructions in 6.1. 6.3.2 Slide forward the drying fan duct and remove. 6.3.2 Disconnect the two wire harness from the electronic controller 6.3.3 Release the three securing tabs that hold the drying fan in place while applying forward pressure on the drying fan. -

Page 40: Electronic Controller

Electronic Controller 6.5.1 Remove the drawer front and handle as per instructions in 6.1 & 6.2. 6.5.2 Placing a finger either side of the top sides of the controller, pull it forward until the controller clears the top edge of the tub. 6.5.3 Disconnect the wiring connectors down the left side of the controller. -

Page 41: Wiring Cover Removal

Wiring Cover Removal 6.8.1 Remove the drawer front as per instructions in 6.1. 6.8.2 Unclip the front two legs of the wiring cover from under the electronic controller and the front left hand side of the tub. 6.8.3 Release the three clips on the underside of the tub, which retain the wiring cover. 6.8.4 The wiring cover may now be moved forward to release it from the link assembly at the rear. -

Page 42: Tub Removal

6.11 Tub Removal 6.11.1 Remove the drawer front as per instructions in 6.1. 6.11.2 Remove the wiring cover as per instructions in 6.8. 6.11.3 Disconnect the fill hose from the dispenser (water may drip) 6.11.4 Disconnect the mains harness and chassis harness connectors from the electronic controller. -

Page 43: Lid Assembly Removal

6.13 Lid Assembly Removal 6.13.1 Remove tub assembly as per instructions in 6.11 6.13.2 Disconnect the lid plumbing off the exhaust valve and air pump above the ‘Y’ joint. 6.13.3 Release two locking tabs securing the front of the lid to the chassis. 6.13.4 To do this, push back the tab in the center of the rectangular slot at the front of the lid molding, using a blade screwdriver, then apply downward pressure to the lid while holding the tab back. -

Page 44: Slide Runner Replacement

6.15 Slide Runner Replacement 6.15.1 Remove the Tub as per instructions 6.11 6.15.2 Bottom slide runners only. Remove the two large Philips head screws securing the slide runner at the front. The backing plate that the screws locate into may come loose. -

Page 45: Link Assembly Removal

6.18 Link Assembly Removal 6.18.1 Remove tub as in instructions 6.11. 6.18.2 Release clips on side of link assembly to allow the lid of the assembly to hinge open. 6.18.3 Using a blade screwdriver to wedge out the spigots in the hinge point of the bracket connecting to the rear of the dishwasher. -

Page 46: Exhaust Valve Removal

6.20 Exhaust Valve Removal Note: This component maybe serviced by two Methods. 6.20.1 Method 1: Remove tub assembly as per instructions in 6.11. 6.20.2 Method 2: Remove lower kick strip as per instructions in 6.7. 6.20.3 Remove the clip pegs from the slide retainers. 6.20.4 Slide the DishDrawer from the cavity to allow servicing from the rear. -

Page 47: Emi Filter Removal

6.23 EMI Filter Removal 6.23.1 Remove the lower tub as per instructions in 6.11. 6.23.2 The EMI filter is located at the rear left hand side of the chassis base. 6.23.3 Remove the screw in the rear access panel of the chassis. 6.23.4 Raise the insulating cover to expose the EMI filter.

Need help?

Do you have a question about the DS6021 and is the answer not in the manual?

Questions and answers