Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Friedrich VPR VRP07K

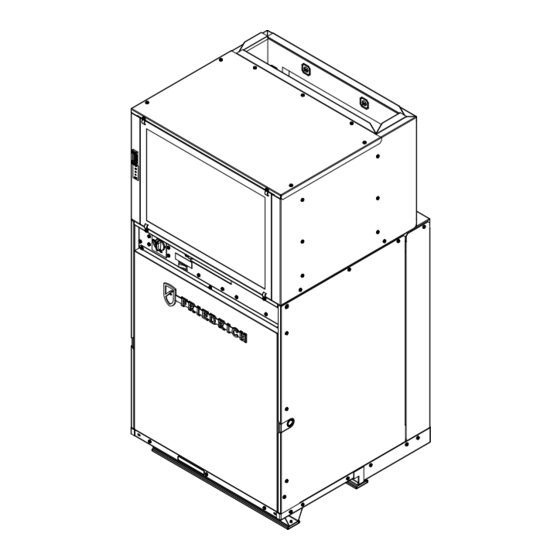

- Page 1 Variable Refrigerant Packaged Heat Pump Innovative | Intelligent | Inverter VRP07K/R For Commercial and Residen- tial Applications One or more of the following patents may apply: 10408504 10436457 10488083 Additional patents pending PRECISION VRP07 IOM 92000010_00...

-

Page 2: Table Of Contents

Table of Contents Warnings __________________________________________________________________________________ 3 General Specifications ______________________________________________________________________________ 4 Dimensions ________________________________________________________________________________ 5 Electrical Data _____________________________________________________________________________ 6 Air Flow Data ______________________________________________________________________________ 7 Installation Minimum Clearances ________________________________________________________________________ 8 Installation Orientations ______________________________________________________________________ 9 Rough Opening Dimensions __________________________________________________________________ 10 Preliminary Plumbing ______________________________________________________________________ 12 Wall Plenum Installation ____________________________________________________________________ 13 Drain Pan Installation _______________________________________________________________________ 17 Louver Installation _________________________________________________________________________ 19... -

Page 3: Warnings

Please carefully read and follow the installation instructions and safety warnings detailed in this manual. All applicable national and local mechanical and electrical codes should be followed and take precedence over any Friedrich requirements or recom- mendations regarding installation applications detailed in this manual. -

Page 4: Specifications

General Specifications Nomenclature -A00 Series Marketing Engineering Revision Revision VRP Heat Pump S= Standard L= Basepan Heat Nominal Capacity (Btu /Hr.) 07 = 3800 - 10000 Operating Range Plenum and Louver Configuration Voltage D= Standard (VRP07 Only) K = 230/208 V R = 265 V S= Standard Heater Watts... -

Page 5: Dimensions

Dimensions 21 in 23 in 5 in 21 1/4 in 1 in 9 5/8 in 43 in 44 in 29 1/2 in 31 1/8 in 31 3/8 in 2 3/4 in Model VRP07K/R VRP07K/R With Reheat Dimensions (W x D x H) 22 15/16"... -

Page 6: Electrical Data

Electrical Data Total Electric Electric Electric Heater Heating ID Blower OD Blower Heating MOP / MOCP VRP Model Voltage Watts Amps Amps Amps 2500 8530 11.5 VRP07K 14.4 2045 6980 10.6 3400 11600 15.4 19.3 2780 9490 14.1 VRP07R 2500 8530 12.5 3400... -

Page 7: Air Flow Data

VRP07 is designed to install through an exterior wall with a plenum (VPAWP1-8, VPAWP-14) and a Friedrich external louver . If the Friedrich designed plenum and louver combinations are not used, the selections and design must be evaluated by Friedrich to ensure the total pressure drop does not exceed the maximum allowable limits. -

Page 8: Minimum Clearances

72” must be kept. FENCE OUTDOOR MAJOR OBSTRUCTIONS CONDENSING UNIT The the example pictured above is for reference only and does not represent all possible installations. Please contact Friedrich Air Conditioning for information regarding effects of other installation arrangements. -

Page 9: Installation Orientations

Installation Orientations 23 1/8" 26 1/8" 3" 23 1/8" 27" 29 1/8" 3 23 1/8" ... -

Page 10: Rough Opening Dimensions

Exterior Wall Opening Dimensions Exterior Wall Rough Opening Dimensions Unit Width Heigth VPAWP1-* 24 5/8" 30 7/8" *8 or 14 NOTE: The distance between the rough opening and the finished floor/platform must be 3/4”. 3/4”... - Page 11 Interior (Closet) Wall Opening Dimensions Return Air Access Door Wall Cut-Out 27” 55 3/4” NOTE: To maintain ease of removal and serviceability, if the unit is installed on a platform ensure that the total height of the unit from the floor does not exceed the height of the interior rough opening.

-

Page 12: Preliminary Plumbing

Preliminary Plumbing Standard (Front Install) The image to the right shows the installation closet for the standard (Front Install) configuration (where the wall plenum is opposite the service access door). A drainage system is required, and should provide a “P-trap” to prevent undesirable waste gas from entering into the residential area. -

Page 13: Wall Plenum Installation

Wall Plenum Installation Parts included in Plenum kit: Outside Plenum Half (Part A) Inside Plenum Half (Part B) Field Supplied Parts: Sealant, attachment screws, and flashing Flashing are field supplied. Silicone sealant is recommended. Sealant VPAWP1-8 adjusts for walls up to 4”- 8” thick. VPAWP1-14 adjusts for walls up to 8”... - Page 14 Wall Plenum Installation Step 1 - Outside Wall Plenum Half Note: The wall plenum is not designed to carry any structural load. A load bearing header must be built above the rough opening. 1) Prepare the rough opening. The rough opening should be lined with metal or wood. The plenum will warp if sealed against concrete or brick.

- Page 15 Wall Plenum Installation Step 2 - Inside Wall Plenum Half Caulk all 8 Flange Corners and Unused Holes Detail A 1) Apply sealant to all 4 flange corners and unused holes. See Detail A. 2) Flash the inside of the rough opening to ensure the proper fit and level. 3) Insert inside plenum half (Part B) into Outside Plenum Half (Part A).

- Page 16 Wall Plenum Installation Step 3 - Inside Wall Plenum (cont.) Detail B Note: Do not place any screws, fasteners, or penetrating holes through the top or bottom of the plenum assembly. 1) Drill pilot holes on the interior of the inside plenum half (Part B) as show in Detail B. Pilot holes should be located approximately 4”...

-

Page 17: Drain Pan Installation

VPDP2 Drain Kit Installation Note: VRP07 models require installation of the VPDP2 drain kit. Please reference the VPDP2 installation manual for more detailed instructions. Cut away gasket from the of the base of the inside wall plenum half the length of the drain kit beginning from the bottom right corner. - Page 18 Final Drain Installation Option 1 Option 2 Run condensate line Run condensate line to left of unit beneath unit platform Option 4 Option 3 Do not run Run condensate line condensate line to right of unit back toward unit NOTE: Failure to follow the following procedures may result in serious property damage. A field supplied secondary condensate pan may be required.

-

Page 19: Louver Installation

Installation of the louver PRIOR to Wall Plenum Installation Hold the louver up to the Outside Wall Plenum Part A and line up the louver top with the very top edge of the 3/4” flange. Line up Louver Installation the Wall Plenum holes with the threaded holes in the louver, install and tighten the 8 screws. Installation of the louver PRIOR to Wall Plenum Installation Attach louver with 8 screws provided... - Page 20 Final Wall Plenum and Architectural Louver Installation Louver NOTE: Ensure that the weather strip is undamaged and provides a continuous seal around the inner perimeter of the plenum. Apply silicone grease or other non-petroleum-based lubricants to the weather strip to enhance the sealing capability of the weather strip and ease installation of the air conditioner chassis.

-

Page 21: Unit Installation

Unit Installation Unit Placement Prior to Installation ( Front-Install Configuration) All louver, plenum, rough plumbing, VPDP2 installation, and rough wiring steps must be complete prior to final installation of the air conditioning chassis. - Page 22 Final Unit Installation Overview Unit Final Placement - Front Install Ensure that power if off at the junction box feeding power to the air conditioner until all process steps are completed. Move the unit from the shipping base and onto the installation site. Insert the unit’s rear extension into the wall plenum.

-

Page 23: Ductwork Installation

Ductwork Installation Supply air duct connection is the responsibility of the installer and should be installed per industry best practices. Sheet metal or duct board may be used for the transition from the discharge to 10” or larger diameter flexible ducting. Avoid sharp transitions in the ductwork to ensure optimal indoor blower performance. -

Page 24: Wall Controller Installation

Wall Controller Installation Proper Wiring of VRP unit to Wall Controller Use shielded and stranded CAT 6 cable with twisted pairs to wire the wall controller. Use the wire colors with the corresponding terminals on the wall controller to the VRP unit as shown in the table below. Table shows which wire pairs go with which screw terminal. - Page 25 Wall Controller Installation Wiring to the VRP Unit A. Strip the wire ends to 9/16" (15 mm). B. Insert the wire pairs into terminals as shown below. C. Insert ground shield wire into ground terminal (marked with a ground symbol). D.

-

Page 26: Electrical Connection

Electrical Installation Electrical Installation Remove and discard hole knock-out from the side of the unit (Detail A) Remove and discard hole knock-out from the side of the unit (Detail A) Remove the Electrical Access Panel (Detail B) to Remove the front unit panel expose the Incoming Power Terminal Block to expose the incoming power (Detail C, see below) -

Page 27: Return Air Door Installation

Return Air Door Installation Option 1 Option 2 The door panel is supported along one edge by the provided hinge. The opposite edge has a latch which secures the panel to the adjacent framed structure. The kit contains hinge bracket for mounting the door with the return air openings low (shown in option 1) or high (shown in Option 2) on the door. -

Page 28: Freshaire™ And Basepan Heater Operation

FreshAire™ System Set-Up and Operation (Optional Feature) FreshAire™ System Set-Up and Operation If equipped with the FreshAire™ System, the unit will come with a FreshAire filter. Detail A If equipped with the FreshAire™ System, the unit will come with a FreshAire Filter and Blank Off Plate. Blank Off Plate must be removed before use. - Page 29 Basepan Heater Basepan Heat Thermostat VRP model numbers that end with the ‘L’ character will come equipped with a basepan heater. The basepan heat engages and disengages automatically based on outdoor ambient and base-pan temperatures.

-

Page 30: Electrical Wiring Diagrams

Electrical Wiring Diagram - 208/230V 2.5kW, 3.4 kW & 5.0 kW FUSE FUSE... - Page 31 Electrical Wiring Diagram - 265V 2.5kW, 3.4 kW & 5.0 kW FUSE FUSE MAIN CONTROLLER 4770F SEQ (80)

-

Page 32: Final Installation Checklist

(F option) outdoor air fan and filter, or dual leaves the module through a filter and enters the operator of the equipment. Friedrich Warranty Service Company in the area (D option) outdoor air fans and filters. indoor space in front of the indoor conditioning coil. -

Page 33: Service And Warranty

Service & Warranty Servicing / Chassis Quick Change Outs To Remove the Chassis from the Closet: The chassis is designed for quick disconnect A. Switch the wall controller off. and change out. For minor electrical service, B. Disconnect the power coming into the unit from the Electrical Access Panel is easily removable the main breaker panel or the closet mounted once the screws are removed. -

Page 34: Accessories

Accessories ITEM DESCRIPTION QTY. CHECK LIST VPDP2 Drain Kit Require One per Unit VPAWP1-8 Wall Plenum for 4” to 8” thick wall Require One of these Wall Plenums per unit VPAWP1-14 Wall Plenum for 8” to 14” thick wall VPAL2 Require One of these Architectural louver (30˚... - Page 35 Accessories TYPE ITEM DESCRIPTION CHECK LIST WALL VRPXWCT Wall Controller CONTROLLER Required one per unit VRPXEMRT2 VRP Energy Management Wired Wall Controller with Occupancy Sensor Require One of the Controllers per unit VRPXEMWRT2 VRP Energy Management Wireless Wall Controller with Occupancy Sensor EMOCT Online Connection Kit –...

-

Page 36: Diagnostic Error Codes

Diagnostic Error Codes Code Description Return air thermistor open/shorted Indoor coil (cool inlet) thermistor open/shorted Outdoor coil (heat inlet) thermistor open/shorted Discharge air thermistor open/shorted Outdoor ambient thermistor open/shorted Indoor coild (heat cond.) thermistor open/shorted Compressor discharge thermistor open/shorted Compressor suction thermistor open/shorted Liquid cool thermistor open/shorted Liquid heat thermistor open/shorted Humidity sensor open/shorted... -

Page 37: Vrp Limited Warranty

FRIEDRICH will repair or replace, at its option, any defective part without charge for the part. Replacement parts are warranted for the remainder of the original warranty period. - Page 38 THIS PAGE INTENTIONALLY LEFT BLANK.

- Page 39 Variable Refrigerant Packaged Heat Pump Innovative | Intelligent | Inverter Friedrich Air Conditioning Co. | 10001 Reunion Place, Suite 500 | San Antonio, TX 78216 | 877.599.5665 | www.friedrich.com VRP07 IOM 92000010_00...

Need help?

Do you have a question about the VPR VRP07K and is the answer not in the manual?

Questions and answers