Table of Contents

Summary of Contents for Lissmac LWSH 1600

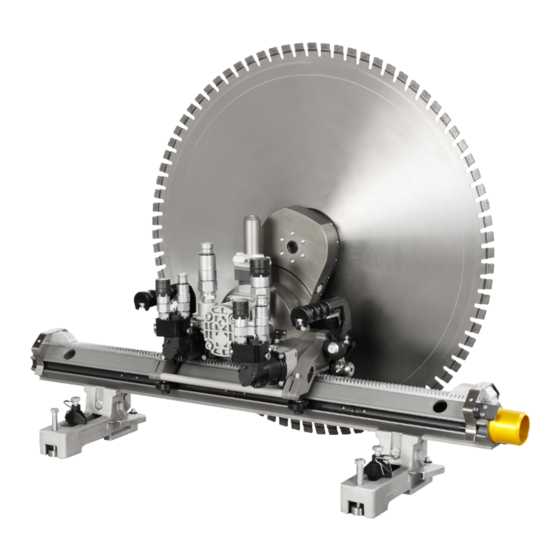

- Page 1 CONSTRUCTION TECHNOLOGY OPERATING MANUAL WALL SAW hydraulic LWSH 1600 LISSMAC Maschinenbau GmbH Lanzstrasse 4 D-88410 Bad Wurzach Telefon +49 (0) 7564 / 307-0 Telefax +49 (0) 7564 / 307-500 lissmac@lissmac.com www.lissmac.com 1/50...

- Page 2 Page 2...

- Page 3 Safety DANGER Failure to comply with the safety instructions may result in serious injury or even death. X Please ensure that the safety instructions have been read and understood in full. DANGER Cuts from the saw blade. X Always wear protective gloves when working on the wall saw, particularly when working on the saw blade.

-

Page 4: Wall Saw System

Description Wall saw system Wall saw for professional use. Not suitable for use in explosive atmoshperes. Wall saw Index Masch.- Nr. Baujahr Gewicht. CH-8330 Pfäffikon ZH Made in Switzerland Components 1 Feed motor, travel Feed motor, swivel 2 Water connection Grip / lock unit 3 Saw blade holder Chassis... -

Page 5: Adjusting The Guide Rollers

Assembly / disassembly Place the wall saw on the guide rail 2. If the grips fail to engage or the wall saw sits too loosely on the guide rail: adjust the guide rollers. Adjusting the guide rollers * The guide rollers must sit in the guide groove, and it must be possible to turn them by hand. Page 5... -

Page 6: Mount The Drive Motor

Mount the drive motor Mount the saw blade DANGER It can cause death or serious injury if the saw blade flies away. X Only use original screws and bolts . DANGER Serious injury can be caused by sudden start-up of the saw blade. X Switch off the drive unit before working on the saw blade. - Page 7 3.4.2 Preassemble the saw blade unit The direction of rotation of the saw blade must match the direction of rotation of the machine. Correct alignment: Countersinking of the fastening bores against the blade cover. For normal cuts with saw blades up to Ø 1000 mm 40 Nm For normal cuts with saw blades larger than Ø...

- Page 8 For flush cuts 15 Nm 3.4.3 Fastening the saw blade unit DANGER It can cause death or serious injury if the saw blade flies away. X Check whether the sleeve and central screw are countersunk. X Tighten the central screw to a torque of 60 Nm. 60 Nm Page 8...

- Page 9 Disassembling saw blade unit WARNING Injuries can be caused if the saw blade drops down. X Lift out the saw blade unit to the top when removing it. 2. Disassemble the saw blade unit in the reverse order to the installation/assembly process. Mount the blade guard Page 9...

- Page 10 Connecting the wall saw to the drive unit 9 The drive unit is isolated from the power supply. 9 Couplings are clean. 9 Hoses are undamaged. Page 10...

-

Page 11: Servicing And Maintenance

X Check water line for cleanliness and leak-tightness X Blow out water Saw blade X Clean with water X Check for wear Service X To be performed by LISSMAC After 100 / 300 / 500 / 700 hours or an authorised workshop Page 11... -

Page 12: Replacing The Guide Rollers

Lubricate lock unit Change gear oil The use of unsuitable oil can damage the wall saw. X Use only Klüber EG 4-150 T (10 cl). Replacing the guide rollers X Replacing the guide rollers. Page 12... - Page 13 Technical data Dimensions Measurements in mm Design Design Parameter Value Construction Light aluminium/steel construction Rotatable swivel arm 360° Power transmission Gear wheel Blade drive transmission 1:2,6 Carrying handles 2-piece with locking function Guide rollers Low-wearing, suitable for all VS and VAS rails Rail mounting Locking and safety function on grip Main motor...

- Page 14 Weight Weight Parameter Value 29 kg Wall saw head complete With blade drive motor, 22 ccm Blade drive motor Blade drive motor Parameter Value Hydraulic motors 1100 to 3333 rpm max. Size Displacement 12 to 30 cm Operating pressure 260 bar Type External geared motor Rotational speeds, hydraulic motors for wall saws...

-

Page 15: Feed Motor, Travel

Feed motor, travel Feed motor, travel Parameter Value Hydraulic motors 40 rpm Type Geroller with integral planetary gears, brake and overload coupling Operating pressure max. 120 bar Output torque 150 Nm Feed force 5000 N Feed Toothed wheel on rail Feed motor, swivel Feed motor, swivel Parameter... - Page 16 Lubricating grease (lock unit) Penetration 265 to 295NLGI NLGI Connectable drive units The wall saw must only be operated with the coordinated drive units from LISSMAC. Drive unit power requirements Parameter Value Minimum output: 20 kW (max. operating pressure 260 bar) Maximum performance 25 kW (max.

-

Page 17: Translation Of The Original Declaration Of Conformity

LISSMAC wall saw LWSH 1600. This declaration relates exclusively to the machine in the state in which it was placed on the market, and excludes components which are added and/or operations carried out subsequently by the final user. It is confirmed that the machine conforms to the relevant provisions of Directive 2006/42/EC and 2004/14/EC.

Need help?

Do you have a question about the LWSH 1600 and is the answer not in the manual?

Questions and answers