Table of Contents

Advertisement

Quick Links

Assembly and operating instructions

Translation of the Original Assembly Instructions EN

RM 25

Order no.: 11001780

◼

RMZ 25/1

Order no.: 11001781

◼

RMZ 25/2

Order no.: 11001782

◼

RM 32 Shaft

Order no.: 11001807

◼

RM 32 Flange

Order no.: 11001806

◼

Assembly instructions EN

Rotary modules

RM 25

◼

◼

RM 25 I RM 32

13.06.2023

I

RM 32

RMZ 32/1 Shaft

◼

RMZ 32/1 Flange

◼

RMZ 32/2 Shaft

◼

RMZ 32/2 Flange

◼

◼

V3.0

Order no.: 11001809

Order no.: 11001808

Order no.: 11001811

Order no.: 11001810

1–68

Advertisement

Table of Contents

Summary of Contents for Afag RM 25

- Page 1 ◼ ◼ RM 32 Shaft Order no.: 11001807 RMZ 32/2 Flange Order no.: 11001810 ◼ ◼ RM 32 Flange Order no.: 11001806 ◼ ◼ ◼ ◼ Assembly instructions EN RM 25 I RM 32 13.06.2023 V3.0 1–68...

- Page 2 Your Afag team © Subject to modifications The rotary modules have been designed by Afag Automation AG according to the state of the art. Due to the constant technical development and improvement of our products, we reserve the right to make technical changes at any time.

-

Page 3: Table Of Contents

Technical data ...................... 15 Rotary module RM 25................. 15 3.1.1 Dimensional drawing RM 25, RMZ 25/1, RMZ 25/2 ......15 3.1.2 Technical data RM 25, RMZ 25/1, RMZ 25/2 ........16 3.1.1 Preferred combinations RM 25, RMZ 25/1, RMZ 25/2 ......17 3.1.2 Module loads RM 25, RMZ 25/1, RMZ 25/2 ........ - Page 4 Product description ..................31 Function description (example RM 25)............33 Accessories ....................34 5.4.1 Accessories for RM 25 and RM 32 ............34 5.4.2 Accessories for RM 25 ................. 35 5.4.3 Accessories for RM 32 ................. 35 Installation, assembly & setting ................. 36 Safety Instructions for Installation &...

- Page 5 9.3.3 Further maintenance ................59 Wear parts and repair ................. 59 9.4.1 Wear parts for RM 25 / RMZ 25/1 (numbered parts) ......60 9.4.2 Wear parts for RMZ 25/2 (numbered parts) ......... 61 9.4.3 Wear parts for RM 32 / RMZ 32 (numbered parts) ......62 9.4.4 Wear parts for RMZ 32/1 (numbered parts) .........

-

Page 6: General

1.1 Contents and purpose of these assembly instructions These assembly instructions contain important information on assembly, commissioning, functioning and maintenance of the rotary modules RM 25, RM 32 to ensure safe and efficient handling and operation. Consistent compliance with these assembly instructions will ensure: ▪... -

Page 7: Additional Symbols

In these assembly instructions the following symbols are used to highlight instructions, results, references, etc.. Symbol Description Instructions (steps ...) Results of actions References to sections ◼ Enumerations not ordered ◼ ◼ ◼ Assembly instructions EN RM 25 I RM 32 13.06.2023 V3.0 7–68... -

Page 8: Applicable Documents

(VDE) and these safety and assembly instructions. 1.6 Liability No changes shall be made to the rotary modules RM 25, RM 32 unless described in this instructions manual or approved in writing by Afag Automation Afag Automation AG accepts no liability for unauthorized changes or improper assembly, installation, commissioning, operation, maintenance or repair work. -

Page 9: Safety Instructions

Failure to follow the directions and safety instructions given in this instructions manual may result in serious hazards. 2.2 Intended use The RM 25, RM 32 rotary modules are used for shock-free rotating of loads in non-hazardous atmospheres under the ambient and operating conditions defined for these modules. -

Page 10: Obligations Of The Operator And The Personnel

▪ the operating company shall be solely responsible for such damage, and ▪ Afag does not accept any liability for damages caused by improper use. 2.4 Obligations of the operator and the personnel 2.4.1... -

Page 11: Personnel Requirements

▪ check the personal protective equipment for proper condition, and ▪ immediately notify the person responsible on site of any defects found on the personal protective equipment. ◼ ◼ ◼ Assembly instructions EN RM 25 I RM 32 13.06.2023 V3.0 11–68... -

Page 12: Changes & Modifications

2.7 Changes & Modifications No changes may be made to the rotary modules which have not been described in these assembly instructions or approved in writing by Afag Automation AG. Afag Automation AG accepts no liability for unauthorised changes or improper assembly, installation, commissioning, maintenance or repair work. - Page 13 ▪ The operating company is responsible for ensuring that the permissible noise levels are observed. ▪ If the noise level exceeds 85 dB(A) in normal operation, the operator must wear hearing protectors at the workplace. ◼ ◼ ◼ Assembly instructions EN RM 25 I RM 32 13.06.2023 V3.0 13–68...

-

Page 14: Danger Due To Electricity

Poor or not regularly performed maintenance may cause component failures which may lead to injuries. ▪ The operator must exercise due care and only use trained maintenance to carry out the activities. 14 – 68 ◼ ◼ ◼ Assembly instructions EN RM 25 I RM 32 13.06.2023 V3.0... -

Page 15: Technical Data

Technical data Technical data 3.1 Rotary module RM 25 3.1.1 Dimensional drawing RM 25, RMZ 25/1, RMZ 25/2 Fig. 1 Dimensional drawing - Rotary module RM 25 ◼ ◼ ◼ Assembly instructions EN RM 25 I RM 32 13.06.2023 V3.0... -

Page 16: Technical Data Rm 25, Rmz 25/1, Rmz 25/2

Technical data 3.1.2 Technical data RM 25, RMZ 25/1, RMZ 25/2 Fig. 2 Technical data rotary module RM 25 16 – 68 ◼ ◼ ◼ Assembly instructions EN RM 25 I RM 32 13.06.2023 V3.0... -

Page 17: Preferred Combinations Rm 25, Rmz 25/1, Rmz 25/2

Technical data 3.1.1 Preferred combinations RM 25, RMZ 25/1, RMZ 25/2 Fig. 3 Preferred combinations - Rotary module RM 25 ◼ ◼ ◼ Assembly instructions EN RM 25 I RM 32 13.06.2023 V3.0 17–68... -

Page 18: Module Loads Rm 25, Rmz 25/1, Rmz 25/2

Technical data 3.1.2 Module loads RM 25, RMZ 25/1, RMZ 25/2 Fig. 4 Swivel time diagrams RM 25 18 – 68 ◼ ◼ ◼ Assembly instructions EN RM 25 I RM 32 13.06.2023 V3.0... -

Page 19: Rotary Module Rm 32

3.2 Rotary module RM 32 3.2.1 Dimensional drawing RM 32 with flange, RM 32 with shaft Fig. 5 Dimensional drawing rotation module RM 32 with flange/shaft ◼ ◼ ◼ Assembly instructions EN RM 25 I RM 32 13.06.2023 V3.0 19–68... -

Page 20: Technical Data Rm 32 With Flange, Rm 32 With Shaft

Technical data 3.2.2 Technical data RM 32 with flange, RM 32 with shaft Fig. 6 Table technical data RM 32 with flange/shaft 20 – 68 ◼ ◼ ◼ Assembly instructions EN RM 25 I RM 32 13.06.2023 V3.0... -

Page 21: Dimensional Drawing Rmz 32/1 With Flange, Rm 32/1 With Shaft

Technical data 3.2.3 Dimensional drawing RMZ 32/1 with flange, RM 32/1 with shaft Fig. 7 Dimensional drawing rotary module RMZ 32/1 with flange/shaft ◼ ◼ ◼ Assembly instructions EN RM 25 I RM 32 13.06.2023 V3.0 21–68... -

Page 22: Technical Data Rmz 32/1 With Flange, Rmz 32/1 With Shaft

Technical data 3.2.4 Technical data RMZ 32/1 with flange, RMZ 32/1 with shaft Fig. 8 Technical data RMZ 32/1 with flange/shaft 22 – 68 ◼ ◼ ◼ Assembly instructions EN RM 25 I RM 32 13.06.2023 V3.0... -

Page 23: Dimensional Drawing Rmz 32/2 With Flange, Rm 32/2 With Shaft

Technical data 3.2.5 Dimensional drawing RMZ 32/2 with flange, RM 32/2 with shaft Fig. 9 Dimensional drawing rotary module RMZ 32/2 with flange/shaft ◼ ◼ ◼ Assembly instructions EN RM 25 I RM 32 13.06.2023 V3.0 23–68... -

Page 24: Technical Data Rmz 32/2 With Flange, Rm 32/2 With Shaft

Technical data 3.2.6 Technical data RMZ 32/2 with flange, RM 32/2 with shaft Fig. 10 Technical data RMZ 32/2 with flange/shaft 24 – 68 ◼ ◼ ◼ Assembly instructions EN RM 25 I RM 32 13.06.2023 V3.0... -

Page 25: Preferred Combinations Rm 32

Technical data 3.2.7 Preferred combinations RM 32 Fig. 11 Preferred combinations RM 32 ◼ ◼ ◼ Assembly instructions EN RM 25 I RM 32 13.06.2023 V3.0 25–68... -

Page 26: Module Loads Rm 32

Technical data 3.2.8 Module loads RM 32 Fig. 12 Swivel time diagram RM 32 26 – 68 ◼ ◼ ◼ Assembly instructions EN RM 25 I RM 32 13.06.2023 V3.0... -

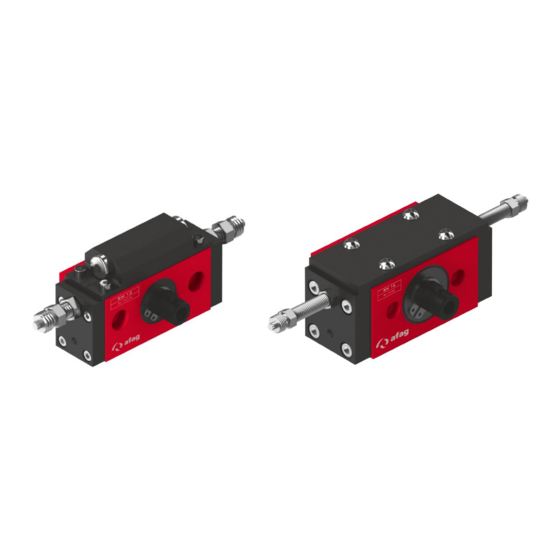

Page 27: Transport, Packaging And Storage

4.2 Scope of supply The rotary modules are supplied with an operating and assembly manual and a safety data sheet (see scope of supply below). Fig. 13 Scope of delivery rotary modules RM 25 / RM 32 [Unt] RM 25 [Unt]... -

Page 28: Transport

Environmental damage can be caused by incorrect disposal of the packaging material. ▪ Dispose of the packaging material in an environmentally sensitive way in accordance with the local environmental regulations. 28 – 68 ◼ ◼ ◼ Assembly instructions EN RM 25 I RM 32 13.06.2023 V3.0... -

Page 29: Storage

▪ Clean the rotary modules and protect the blank metal parts against corrosion using the appropriate means. ▪ Protect the rotary modules from dirt and dust. ◼ ◼ ◼ Assembly instructions EN RM 25 I RM 32 13.06.2023 V3.0 29–68... -

Page 30: Design And Description

This chapter provides an overview of the rotary modules RM 25, RM 32 and of the variant’ structure and functioning. The RM 25 / RM 32 series of rotary modules is used for the shock-free rotary movement of fixed loads in the environmental and operating conditions defined for this purpose, see technical data. -

Page 31: Product Description

5.2 Product description Rotary module series 25 The RM 25 rotary module is a pneumatically driven module for rotating middle loads in confined spaces. With torques of maximum 2.5 Nm, loads can be rotated from 0-180° - depending on the variant also with intermediate positions. - Page 32 Fig. 16 Three variants of the RM 32 RM 32 180° module with shaft or flange, both end positions damped with Afag shock absorbers (Fig.5 and 6). RMZ 32/1 180° module with shaft or flange and an additional intermediate position. All three positions damped with Afag shock absorbers (Fig.

-

Page 33: Function Description (Example Rm 25)

Its index (9) engages with the rack (4) when actuated and is carried along by it in a horizontal line. The stroke limit of the intermediate position cylinder is adjusted with a second pair of stop screws (10) and braked with two Afag shock absorbers (Fig.15). -

Page 34: Accessories

Design and description 5.4 Accessories 5.4.1 Accessories for RM 25 and RM 32 Stop screws Shock absorber Initiator 34 – 68 ◼ ◼ ◼ Assembly instructions EN RM 25 I RM 32 13.06.2023 V3.0... -

Page 35: Accessories For Rm 25

Design and description 5.4.2 Accessories for RM 25 Article Order Number Clamping holder RM 16, RM 25 11001672 (s. catalogue) Mounting screws M6x56 11005015 (s. catalogue) 5.4.3 Accessories for RM 32 Article Order Number Universal adapter UA RM 32 50077150 (s. catalogue) Rotary flange RM 32 11001821 (s. -

Page 36: Installation, Assembly & Setting

No liability for damages can be assumed for damages caused by improper installation/assembling work on the part of the operator. chap. 2 „Safety instructions“ in this Also observe the safety instructions in manual. 36 – 68 ◼ ◼ ◼ Assembly instructions EN RM 25 I RM 32 13.06.2023 V3.0... -

Page 37: Installation & Assembly

6.2 Installation & assembly 6.2.1 Assembly & attachment The rotary modules RM 25 and RM 32 can be mounted both in horizontal and vertical position. The RMZ 25/1; RMZ 32/ 1 and RMZ 32/2 rotary modules can only be installed in a horizontal position. -

Page 38: Module Centering

6.2.2 Module centering In order to ensure high and repetitive accuracy of fit during assembling, operation and exchanging of a module, the components of the Afag modules are provided with a precise module centering unit. Centring bushing and hole grid... -

Page 39: Tightening Torques For Screws

When connecting the compressed air supply for the first time, make sure that all compressed air throttles are closed. Vent the system slowly! The minimum compressed air quality shall comply with the specifications of ISO 8573-1:2010. ◼ ◼ ◼ Assembly instructions EN RM 25 I RM 32 13.06.2023 V3.0 39–68... - Page 40 Installation, assembly & setting Pneumatic connections RM 25 (without intermediate pos.) Fig. 19 Pneumatic circuit diagram rotary module RM 25 (without int. pos.) 1. Module 4. Maintenance unit 2. Throttle check valve P. Compressed air connection 3. Directional control valve (standard 5/2) Pneumatic connections RM 25 (with intermediate pos.)

- Page 41 Pneumatic circuit diagram rotary module RM 32 (without int. pos.) 1. Module (intermediate pos. cylinder) 4. Maintenance unit 2. Throttle check valve P. Compressed air connection 3. Directional control valve (standard 5/2) ◼ ◼ ◼ Assembly instructions EN RM 25 I RM 32 13.06.2023 V3.0 41–68...

- Page 42 Pneumatic circuit diagram rotary module RM 32 with int. pos. 1. Module (intermediate pos. cylinder) 4. Maintenance unit 2. Throttle check valve P. Compressed air connection 3. Directional control valve (standard 5/2) 42 – 68 ◼ ◼ ◼ Assembly instructions EN RM 25 I RM 32 13.06.2023 V3.0...

-

Page 43: Mounting The Initiators

Determining the switching type depending on the control type Technical data Operating voltage range 10-30 VDC Switching distance: 1.5mm Type Short circuit and reverse polarity protected ◼ ◼ ◼ Assembly instructions EN RM 25 I RM 32 13.06.2023 V3.0 43–68... - Page 44 2. Insert the initiator (2,3) into the initiator holder as far as it will go. 3. Slightly tighten the initiator holder (1). 4. Mount the connector (4). 5. Carry out function check. The initiator is mounted. 44 – 68 ◼ ◼ ◼ Assembly instructions EN RM 25 I RM 32 13.06.2023 V3.0...

- Page 45 2. Push the initiator holder (7) with initiator (5) onto the stop screw (8) as far as it will go and clamp it with screw (9). 3. Mount the connector (4). 4. Carry out function check. The initiator is mounted. ◼ ◼ ◼ Assembly instructions EN RM 25 I RM 32 13.06.2023 V3.0 45–68...

-

Page 46: Settings

Also observe the safety instructions in manual. 6.3.2 Adjust RM 25, RM 32 The rotation angle of the rotary modules can be adjusted between 0° and 180° with the stop screws. For end position sensing, the stop screws AS 08/25 and AS 08/40 can be combined with a proximity switch holder and a 6.5 mm proximity switch or... - Page 47 Installation, assembly & setting Example of setting a 160° angle rotation on the RM 25 Fig. 26 Setting the angle of rotation To set a 160° rotation angle, proceed as follows: 1. Unscrew the shock absorber (1). 2. Compressed air at (P1).

-

Page 48: Adjust Shock Absorbers Sd 14/16

The shock absorbers must not be used as a stop as they can be damaged. ▪ The limitation of the angle of rotation must be done by the stop screws. Adjustment of the shock absorber using the RM 25 as an example: Fig. 27 Adjustment of shock absorber To set the shock absorbers, proceed as follows: ... -

Page 49: Rmz With One Intermediate Position (Example Rmz 25/1)

7. Secure shock absorber with lock nut (8) (Fig. 27, 33-2). The shock absorber is set. 6.3.4 RMZ with one intermediate position (example RMZ 25/1) Fig. 28 RMZ 25/1 with one intermediate position ◼ ◼ ◼ Assembly instructions EN RM 25 I RM 32 13.06.2023 V3.0 49–68... - Page 50 9. Release compressed air at (P2) and give it to (P4). The intermediate position cylinder (5) is uncoupled and moves to the initial position (Fig. 28, 34-4). The process is complete. 50 – 68 ◼ ◼ ◼ Assembly instructions EN RM 25 I RM 32 13.06.2023 V3.0...

-

Page 51: Rmz With Two Intermediate Pos. (Example Rmz 25/2)

Pinion shaft (3) rotates clockwise until it is limited by the stop screw (6). The intermediate position cylinder (5) is guided to the right (Fig. 29, 29- 6. Adjust the stop screw (7). The pinion shaft (3) rotates anticlockwise. ◼ ◼ ◼ Assembly instructions EN RM 25 I RM 32 13.06.2023 V3.0 51–68... -

Page 52: Intermediate Position With Additional Cylinder

The process is complete. 6.3.6 Intermediate position with additional cylinder The intermediate position B must be to the right of the intermediate position 52 – 68 ◼ ◼ ◼ Assembly instructions EN RM 25 I RM 32 13.06.2023 V3.0... -

Page 53: Intermediate Position With Cylindrical Pin

Installation, assembly & setting 6.3.7 Intermediate position with cylindrical pin The intermediate position B must be to the right of the intermediate position ◼ ◼ ◼ Assembly instructions EN RM 25 I RM 32 13.06.2023 V3.0 53–68... -

Page 54: Commissioning

3. Make sure that there are no persons or tools within the working area of the module. 4. Perform test run: Start with slow traversing movements Then continue under normal operating conditions. Commissioning is completed. 54 – 68 ◼ ◼ ◼ Assembly instructions EN RM 25 I RM 32 13.06.2023 V3.0... -

Page 55: Fault Elimination

Also observe the safety instructions in manual. 8.3 Table Fault causes and remedy Faults caused by defective components may only be remedied by replacing these components. Defective components must be replaced exclusively by Afag original spare parts. Fault Possible cause Remedy: ▪... -

Page 56: Maintenance And Repair

▪ Before starting any activities, switch off the media supply (pneumatics) and secure it from being switched on again! chap. 2 „Safety instructions“ in this Also observe the safety instructions in manual. 56 – 68 ◼ ◼ ◼ Assembly instructions EN RM 25 I RM 32 13.06.2023 V3.0... -

Page 57: Maintenance Activities And Maintenance Intervals

5 million load cycles. Incorrectly adjusted, missing or defective shock absorbers impair the function of the module and can lead to its destruction! ◼ ◼ ◼ Assembly instructions EN RM 25 I RM 32 13.06.2023 V3.0 57–68... -

Page 58: Compressed Air Specifications

If the rotary modules are used in an ionised air environment, there is a risk that exposed parts could corrode. ▪ Always grease exposed parts e.g. flanges, shafts, guides and jaws regularly. ▪ Afag standard lubrication: Staburax NBU8EP (flat guides), Blasolube 301 (piston rods). 9.3.2 Compressed air specifications The rotary modules are lifetime lubricated and can be operated with lubricated or non-lubricated compressed air. -

Page 59: Further Maintenance

Afag for warranty repair within the warranty period. After expiry of the warranty period, the customer may replace or repair defective modules or wear parts himself or send them to the Afag repair service. Please note that Afag does not assume any warranty for modules that have... -

Page 60: Wear Parts For Rm 25 / Rmz 25/1 (Numbered Parts)

Maintenance and repair 9.4.1 Wear parts for RM 25 / RMZ 25/1 (numbered parts) Item Designation Supplier number Order no. Wear parts Afag 11002517 Wear parts Afag 11002519 60 – 68 ◼ ◼ ◼ Assembly instructions EN RM 25 I RM 32 13.06.2023... -

Page 61: Wear Parts For Rmz 25/2 (Numbered Parts)

Maintenance and repair 9.4.2 Wear parts for RMZ 25/2 (numbered parts) Item Designation Supplier number Order no. Wear parts Afag 11002519 ◼ ◼ ◼ Assembly instructions EN RM 25 I RM 32 13.06.2023 V3.0 61–68... -

Page 62: Wear Parts For Rm 32 / Rmz 32 (Numbered Parts)

Maintenance and repair 9.4.3 Wear parts for RM 32 / RMZ 32 (numbered parts) Item Designation Supplier number Order no. Wear parts Afag 11002526 62 – 68 ◼ ◼ ◼ Assembly instructions EN RM 25 I RM 32 13.06.2023 V3.0... -

Page 63: Wear Parts For Rmz 32/1 (Numbered Parts)

Maintenance and repair 9.4.4 Wear parts for RMZ 32/1 (numbered parts) Item Designation Supplier number Order no. Wear parts Afag 11007845 ◼ ◼ ◼ Assembly instructions EN RM 25 I RM 32 13.06.2023 V3.0 63–68... -

Page 64: Wear Parts For Rmz 32/2 (Numbered Parts)

Maintenance and repair 9.4.5 Wear parts for RMZ 32/2 (numbered parts) Item Designation Supplier number Order no. Wear parts Afag 11002526 64 – 68 ◼ ◼ ◼ Assembly instructions EN RM 25 I RM 32 13.06.2023 V3.0... -

Page 65: Decommissioning, Disassembly, Disposal

▪ Disassembling should only be carried out by qualified personnel! ▪ Only remove the rotary module when the control unit is switched off and secured! ◼ ◼ ◼ Assembly instructions EN RM 25 I RM 32 13.06.2023 V3.0 65–68... -

Page 66: Disposal

▪ Electronic parts, electrical scrap, auxiliary and operating materials must be disposed of by approved specialist companies. ▪ Information on proper disposal can be obtained from the responsible local authorities. 66 – 68 ◼ ◼ ◼ Assembly instructions EN RM 25 I RM 32 13.06.2023 V3.0... -

Page 67: Declaration Of Incorporation

The relevant technical documentation was created according to Annex VII, Part B of the above-mentioned Directive . Authorised representative for compiling the technical documentation: Niklaus Röthlisberger, Product Manager, Afag Automation AG, CH-6144 Zell Zell, 31.05.2023 Adrian Fuchser Klaus Bott... - Page 68 Afag Automation Americas Afag Automation APAC Schaeff Machinery & Services LLC. Afag Automation Technology (Shanghai) Co., Ltd. 883 Seven Oaks Blvd, Suite 800 Room 102, 1/F, Bldg. 56, City Of Elite Smyrna, TN 37167 No.1000, Jinhai Road, Pudong New District...

Need help?

Do you have a question about the RM 25 and is the answer not in the manual?

Questions and answers