Afag PG 12 Manual

Precision gripper modules

Hide thumbs

Also See for PG 12:

- Maintenance instructions manual (32 pages) ,

- Assembly and operating instructions manual (48 pages)

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Afag PG 12

- Page 1 Precision gripper modules PG 12 I PG 16 I PG 20 Declaration of Incorporation Assembly Instructions Operating Instructions Maintenance Instructions „Translation“ of the Original Operating Instructions © Copyright by Afag Automation AG...

- Page 2 PG 16 50332224 50332225 PG 20 Version of this documentation: PG 12-PG 16 -PG 20 - OI v 1.7 gb 20190314 Symbols: Assembly and initial start-up must be car- ried out by qualified Personnel only and according to these operating instructions.

-

Page 3: Table Of Contents

3.1.7 Training ......................25 3.1.8 Adjustment, retrofitting ..................26 3.1.9 Standard operation ................... 26 4.0.0 Maintenance Instructions .................. 27 4.1.0 Maintenance and servicing ................27 4.1.1 Maintenance ..................... 28 PG 12-PG 16 -PG 20 - OI v 1.7 gb 20190314... - Page 4 4.1.4 Delivery ......................30 4.1.5 Disassembly and repair ..................31 4.1.6 Disposal ......................31 5.0.0 Appendix ......................32 5.1.0 List of figures ....................32 5.1.1 List of tables ..................... 32 PG 12-PG 16 -PG 20 - OI v 1.7 gb 20190314...

-

Page 5: Ec Déclaration Of Incorporation (Document Original)

Niklaus Röthlisberger, Producte Manager Afag Automation AG, CH-4950 Huttwil Place/Date : Place/Date: Huttwil, 14.03.2019 Siegfried Egli Niklaus Röthlisberger Managing Director Producte Manager HT Afag Automation AG Afag Automation AG PG 12-PG 16 -PG 20 - OI v 1.7 gb 20190314... -

Page 6: Assembly Instructions

2.1.0 Safety instructions Modifications to the PG precision gripper that are not described in this operating manual or have not been approved in writing by the company Afag Automation AG are not permitted. In case of improper changes or assembly, installation, operation, maintenance or repairs, Afag Automation AG rejects all liability. -

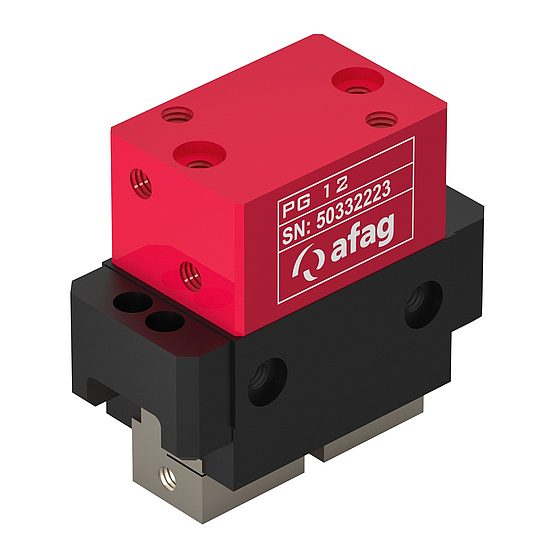

Page 7: Description Of The Module Parts

2.1.2 Description of the module parts The Afag PG precision gripper is the right solution when it comes to gripping and precise insertion of parts. The PG precision grippers are precise and compact gripping modules designed for gripping oriented serial parts. They can be combined with other modules from the Afag modular kit. -

Page 8: Parts Designation

If add-ons at the PG grippers could cause danger in connection with the gripper fingers a safe operation must be ensured. PG 12-PG 16 -PG 20 - OI v 1.7 gb 20190314... -

Page 9: Installation And Fastening Possibilities

2.1.5 Installation and fastening possibilities The PG precision grippers can be installed in a vertical and horizontal position. The Afag module components are provided with a precise module centring which guarantees a high and repetitive accuracy of fit during installation, operation and ex- change of a module. -

Page 10: Dimensional Drawing

2.1.6 Dimensional drawing PG 12 Figure 2: Installation and fastening possibilities PG 12-PG 16 -PG 20 - OI v 1.7 gb 20190314... -

Page 11: Technical Data

2.1.7 Technical data PG 12 PG 12-PG 16 -PG 20 - OI v 1.7 gb 20190314... -

Page 12: Dimensional Drawing

2.1.8 Dimensional drawing PG 16 PG 12-PG 16 -PG 20 - OI v 1.7 gb 20190314... -

Page 13: Technical Data

2.1.9 Technical data PG 16 PG 12-PG 16 -PG 20 - OI v 1.7 gb 20190314... -

Page 14: Dimensional Drawing

2.2.0 Dimensional drawing PG 20 PG 12-PG 16 -PG 20 - OI v 1.7 gb 20190314... -

Page 15: Technical Data

2.2.1 Technical data PG 20 PG 12-PG 16 -PG 20 - OI v 1.7 gb 20190314... -

Page 16: Preferred Combinations To

2.2.2 Preferred combinations to PG 12 PG 12-PG 16 -PG 20 - OI v 1.7 gb 20190314... -

Page 17: Preferred Combinations To

2.2.3 Preferred combinations to PG 16 PG 12-PG 16 -PG 20 - OI v 1.7 gb 20190314... -

Page 18: Preferred Combinations To

2.2.4 Preferred combinations to PG 20 PG 12-PG 16 -PG 20 - OI v 1.7 gb 20190314... -

Page 19: Tightening Moments For Bolts

5,2 … 6,5 Nm 9,0 ... 11,3 Nm 21,6 … 27,3 Nm Table 1: Tightening moments for bolts 2.2.6 Assembly of the gripper fingers Example: connecting geometry gripper fingers PG 12-PG 16 -PG 20 - OI v 1.7 gb 20190314... -

Page 20: Pneumatic Connection

Carry out a leakage test. (P2) P1 = open (P1) P2 = close Compressed air connection One-way restrictor Maintenance unit Gripper (PG) 5/2 port directional control valve P1/P2 Air connection PG 12-PG 16 -PG 20 - OI v 1.7 gb 20190314... -

Page 21: Montage Instructions (Document Original)

EC directive: 2006/42/EC Standard: EN ISO 12100:2010 (German version) Agent: For the compilation of the technically relevant documents: Niklaus Röthlisberger, Products Manager Afag Automation AG, CH-4950 Huttwil PG 12-PG 16 -PG 20 - OI v 1.7 gb 20190314... -

Page 22: Intended Use

The applicable regulations for prevention of accidents and the other generally accepted safety-relevant and occupational safety and health regulations are to be followed. PG 12-PG 16 -PG 20 - OI v 1.7 gb 20190314... -

Page 23: Warranty

Wear parts (e.g. shock absorbers) are not covered by the warranty. * The warranty covers the replacement or repair of defective Afag parts. No further claims will be ac- cepted. The warranty will be voided in event of the following: ... -

Page 24: Preparation For Start-Up Of The Pg Precision Grippers

You can decide yourself whether the opening and closing position shall be checked. Proximity switch Clamp holder Allen key Contact screw for sensor PG 12-PG 16 -PG 20 - OI v 1.7 gb 20190314... -

Page 25: Start-Up

At first at slow traverse speed, afterwards under operating conditions. 3.1.7 Training The unit may only be installed and operated by persons who are familiar with the contents of these operating instructions. PG 12-PG 16 -PG 20 - OI v 1.7 gb 20190314... -

Page 26: Adjustment, Retrofitting

Due to the decentral controller the operator of the PG needs not to be near the product so that third persons might be endangered by the gripper operation. Do not reach into the system during standard operation. PG 12-PG 16 -PG 20 - OI v 1.7 gb 20190314... -

Page 27: Maintenance Instructions

Table 2: Maintenance works Further maintenance Under the ambient conditions mentioned below the PG precision module does not require any further maintenance: clean workshop atmosphere no splash water PG 12-PG 16 -PG 20 - OI v 1.7 gb 20190314... -

Page 28: Maintenance

Open guides and piston rods should be covered with a grease layer to avoid formation of rust. Recommendation: Clean and grease once a month! Afag standard: - Staburax NBU8EP (flat guides) - Blasolube 301 (piston rods) PG 12-PG 16 -PG 20 - OI v 1.7 gb 20190314... -

Page 29: Troubleshooting

Module defective Air escapes from module Leakage of air connection Check air connections and tighten if necessary Cylinder leaky Return module to Afag Table 3: Faults, causes, fault clearance PG 12-PG 16 -PG 20 - OI v 1.7 gb 20190314... -

Page 30: Spare Parts

4.1.3 Spare parts Repair of the PG precision grippers should only be carried out by Afag. There are no spare parts available. 4.1.4 Delivery Number Order No. Centering bushings Ø4x2 mm 50332257 (PG 12) Centering bushings Ø5x2.5 mm 50035831 (PG 16) Centering bushings Ø7x3 mm... -

Page 31: Disassembly And Repair

4.1.5 Disassembly and repair When the module is damaged it can be returned to Afag Automation AG for repair. CAUTION Switch off and secure the control system before the PG precision gripper is removed out of the system. Disconnect the cables only after the control system was switched off. -

Page 32: Appendix

5.1.1 List of tables Table 1: Tightening moments for bolts ..............19 Table 2: Maintenance works ..................27 Table 3: Faults, causes, fault clearance ..............29 Table 4: Accessories ....................30 PG 12-PG 16 -PG 20 - OI v 1.7 gb 20190314... - Page 33 Afag Automation AG Fiechtenstrasse 32 4950 Huttwil Switzerland Tel.: +41 (0)62 – 959 86 86 Fax.: +41 (0)62 – 959 87 87 e-mail: sales@afag.com Internet: www.afag.com...

Need help?

Do you have a question about the PG 12 and is the answer not in the manual?

Questions and answers