Summary of Contents for Afag LM 32/200

- Page 1 Linear modules LM 32 - Declaration of Incorporation - Module Information - Montage Instructions Maintenance Instructions Translation of the Original Montage Instructions © Copyright by Afag Automation...

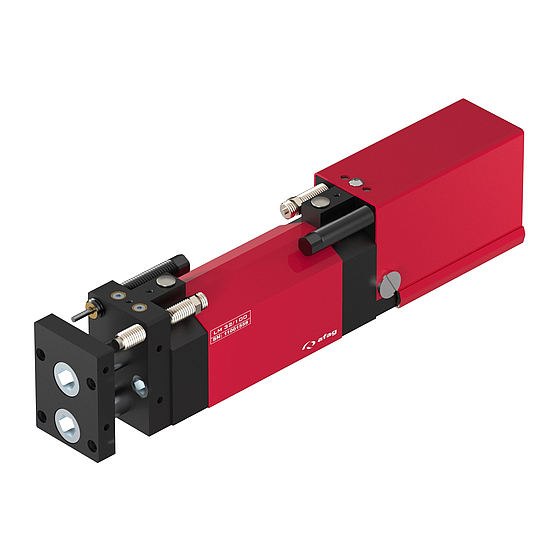

- Page 2 These Montage instructions apply to: Type Order No. LM 32/100 11001558 LM 32/200 11001559 LM 32/300 11001561 LM 32/400 11001562 Version of this documentation: LM 32-OI-vers. 3.5 gb. 20190314 Symbols: Assembly and initial start-up must be carried out by qualified Personnel only and according to these Montage Instructions.

-

Page 3: Table Of Contents

Table of contents 1.0.0 EC Declaration for Incorporation (Document Original)........5 1.1.0 According to 2006/42/EC ................5 2.0.0 Module Information .................... 6 2.1.0 Transport and storage (packing and unpacking) ..........6 2.1.1 Mounting variants for the LM 32 Module ............7 2.1.2 Mounting variants for the module LM 32 ............ - Page 4 3.3.2 Proximity switch mounting ................34 4.0.0 Maintenance Instructions ................. 36 4.1.0 Maintenance and servicing ................36 4.1.1 Servicing ...................... 37 4.1.1 Operating conditions (maintenance and care) ..........38 4.1.2 Special operations Module ................38 4.1.3 Accessories to LM 32 ................... 38 4.1.4 Trouble shooting ..................

-

Page 5: Ec Declaration For Incorporation (Document Original)

The manufacturer: Afag Automation AG, Fiechtenstrasse 32, CH-4950 Huttwil Designation: Linear Modules (pneumatic) Types: LM 32/100; LM 32/200; LM 32/300; LM 32/400 Consecutive serial No. 50xxxxxx Machinery Directive: 2006/42/EG Standard: EN ISO 12100:2010 (German Version) Safety of machinery General principles for risk assessment and risk reduction. -

Page 6: Module Information

2.0.0 Module Information 2.1.0 Transport and storage (packing and unpacking) CAUTION The LM 32 module is packed in the original cardbord box, if the module is not handled properly it may fall out of the box when unpacking and cause injuries to limbs or squeeze your fingers. LM 32 NOTE These Montage Instructions should be read carefully before carrying... -

Page 7: Mounting Variants For The Lm 32 Module

2.1.1 Mounting variants for the LM 32 Module Installation of base body from (M6 Thread) Mounting plates on the front, Grid: 48x48 mm, Holes: 4x 6,5 mm (for M6 cylinder screw) see Mass Drawing. LM 32-OI-vers. 3.5 gb. 20190314... -

Page 8: Mounting Variants For The Module Lm 32

2.1.2 Mounting variants for the module LM 32 The mounting position is freely selectable. 2.1.3 Mounting for the modules (centering bushings). Use the centering bushings included in the scope of supply to determine the position and insert these bushings in the opposite borings of the mounting grid. LM 32-OI-vers. -

Page 9: Tightening Torques For Bolts

2.1.4 Tightening Torques for bolts Further elements to be mounted can be attached to the slide plates or the slide plate. The screwed to be used for assembly must at least satisfy the following conditions: Standard: VDI 2230 Strength: class 8.8 Surface: galvanized blue, oiled or greased Thread... -

Page 10: Installation Of The Lm 32 In A Facility

Safety instructions Modifications on the LM 32 module that are not described in these Montage Instructions or have not been approved in writing by Afag Automation AG are not permitted. In case of improper changes or assembly, installation, operation and maintenance or repairs Afag rejects all liability. -

Page 11: Slide Unit Load Factors

2.1.6 Slide unit load factors LM 32-OI-vers. 3.5 gb. 20190314... -

Page 12: Montage Instructions

These operating instructions apply to: Product: Linear module (pneumatic) Type: LM 32/100; LM 32/200, LM 32/300, LM 32/400 Sequential series: No. 50xxxxxx This is an incomplete machine Who installs this incomplete machine or assemble with other machines, a risk... -

Page 13: Symbols

The LM 32 module can be installed in the horizontal or vertical position. Modifications on the LM 32 Linear module that are not described in these Montage Instructions or have not been approved in writing by Afag Automation AG are not permitted. In case of improper changes or assembly, installation, operation, maintenance or repairs, Afag Automation AG rejects all liability. -

Page 14: Functional Description

The guide shaft (2) and the piston rod (8), led through the housing (3) by lifetime lubricated bearing bushes, connect the front (4) and back (5) plates. The infinitely variable stops (6) limit the stroke. Afag shock absorbers (7) buffer the end of stroke. Included in the delivery: Pos. -

Page 15: Designated Use

The module may only be used in accordance with intended purpose. Modification on the module that are not described in these Montage Instructions or have not been approved in writing by Afag are not permitted. In case of inexpert changes or improper assembly, installation, operation, maintenance or repairs, Afag rejects all liability. -

Page 16: Warranty

Wear parts (e.g. shock absorbers) are not covered by the warranty. * The warranty covers the replacement or repair of defective Afag parts. No further claims will be accepted. The warranty will be voided in event of the following: ... -

Page 17: Dimension Drawing Lm 32

3.1.7 Dimension drawing LM 32 LM 32-OI-vers. 3.5 gb. 20190314... -

Page 18: Technical Data For The Lm 32

3.1.8 Technical data for the LM 32 LM 32-OI-vers. 3.5 gb. 20190314... -

Page 19: Preferred Combinations For Lm 32

3.1.9 Preferred combinations for LM 32 LM 32-OI-vers. 3.5 gb. 20190314... -

Page 20: Function Of The Module Linear Lm 32

The guide shaft (2) and the piston rod (8), led through the housing (3) by lifetime lubricated bearing bushes, connect the front (4) and back (5) plates. The infinitely variable stops (6) limit the stroke. Afag shock absorbers (7) buffer the end of stroke. Piston... -

Page 21: Pneumatic Connection Lm 32

3.2.1 Pneumatic connection LM 32 Die Pneumatik Anschlüsse liegen oben auf dem Modul (2 mal G1/8”) 1 Module LM 32 P = air connection 2 One-way restrictor 4 Compressed air connection 3 Direction valve 3.2.2 Pneumatic connection scheme intermediate stop ZA-module CAUTION Connection of compressed air and operation of pneumatic systems may cause unpredictable movements which may result in personal... -

Page 22: Function Specification For The Za 32

NOTE Minimal compressed air quality according to ISO 8573-1; 2010 (7-4-4) 3.2.3 Function specification for the ZA 32 A double acting pneumatic piston (8), coupled with the shock absorber (9) performs the vertical stroke. If the piston (8) is in the upper position, the stop crew (10) hits the shock absorber (9) and initiates the intermediate position. -

Page 23: Commissioning

3.2.4 Commissioning Ventilate the total system slowly Note the permissible values (see catalogue) regarding. Useful load Operating pressure Motion frequency Moment loads on the guide system CAUTION Limbs may be squeezed by moving components. Make sure that there are no persons or tools within the operative range oft he module. -

Page 24: Stroke Adjustment

3.2.6 Stroke adjustment The stroke length of the LM can be adjusted with stop screws. 3.2.7 Stop crew setting AS 12/60 These stop screws can be combined with a proximity switch holder and proximity switch 6,5 mm or with an angle proximity switch holder and 8x8 mm proximity switch for end of travel interrogation. - Page 25 LM 32-OI-vers. 3.5 gb. 20190314...

-

Page 26: Adjusting Shock Absorber

3.2.8 Adjusting shock absorber Nut M14x1 use here. Nut M14x1 use here. *At a stroke reduction of 25 mm is recommend that the shock absorber with a nut M14x1 Order No. 11012242 to fix a possible jamming of the SD-ram avoided. LM 32-OI-vers. - Page 27 Shock absorbers SD 14/16 To maintain a smoth stroke movement (H) of the LM the stroke against the stop screws (1-2) is absorbed by means of Afag shock absorbers (3,4). Adjusting shock absorbers 1. Adjust the stroke (H) according. 2. Apply compressed air to (P1). The carriage (5) of the LM move against the stop screw (1) in position (X).

- Page 28 Assembly the intermediate stop ZA 32 Intermediate stop ZA 32 The intermediate stop is an additional module for the linear module LM 32. The intermediate stop is used when in intermediate position within the stroke area of the LM is required. The symmetrical design of the intermediate stop ZA 32 allows four precise intermediate positions.

- Page 29 LM 32-OI-vers. 3.5 gb. 20190314...

-

Page 30: Mounting For Za 32

3.2.9 Mounting for ZA 32 The symmetrical design of the intermediate stop ZA 32 allows four precise intermediate positions. 3.3.0 Adjusting the intermediate stop ZA 32 (Example. back)) 1. Mount the intermediate positions module ZA 32 (1) and the back stop screw module (2) on the LM 32 module. - Page 31 LM 32-OI-vers. 3.5 gb. 20190314...

-

Page 32: Proximity Switches Assembly

3.3.1 Proximity switches assembly To end the query LM are plug and screw 6,5 mm (1) or 8x8 mm (2) with proximity switch and proximity holder (3) used. (These are not included). CAUTION LM’s and proximity switches must not be used in an explosive environment. - Page 33 LM 32-OI-vers. 3.5 gb. 20190314...

-

Page 34: Proximity Switch Mounting

3.3.2 Proximity switch mounting Proximity switch 6.5mm (Fig. 20) 1. Proximity holders (1) to intermediate stop screw bolts. 2. Proximity switch (2) to the touch in proximity holder stuck. 3. Proximity holder (1) easy to tighten. 4. Connector (4) mounted 5. - Page 35 LM 32-OI-vers. 3.5 gb. 20190314...

-

Page 36: Maintenance Instructions

4.0.0 Maintenance Instructions The shock absorbers and stop screws must undergo regular functionality checks, and be replaced if required. We recommend replacing the shock absorber after a maximum of 5 million load cycles. If shock absorbers are missing, defective or incorrectly set up, the functionality of the module will be compromised and may lead to its destruction! 4.1.0 Maintenance and servicing CAUTION... -

Page 37: Servicing

Open guides and piston rods should be covered with a grease layer to avoid formation of rust. Standard greasing Afag: - Staburax NBU8EP (flat guides) - Blasolube 301 (piston rods) LM 32-OI-vers. 3.5 gb. 20190314... -

Page 38: Operating Conditions (Maintenance And Care)

4.1.1 Operating conditions (maintenance and care) When connecting compressed air for the first time make sure that all air chokes are closed. Ventilate the system slowly. Use the linear module undr the following conditions are maintenance free: Cleaning workshop atmosphere No water spray No output or process dusts and fumes Ambient conditions according to technical catalog... -

Page 39: Trouble Shooting

4.1.4 Trouble shooting Defective components must only be replaced by Afag original spare parts. Fault Possible Rectifying action Module does not travel No compressed Check compressed air in/out connections Module pneumatic connecting wrong Check pneumatic links End of travel signal... -

Page 40: Disassembly And Repair

4.1.5 Disassembly and repair When the module is damaged it can be returned to Afag AG for repair. CAUTION The module may only be disassembled when the system is ventilated and deactivated. If pneumatic connections are disconnected when they are under pressure, this may result in serious personal injury owing to fast movements of moving parts. -

Page 41: Expendale Parts-Set The Lm 32

4.1.6 Expendale parts-Set the LM 32 Module type LM 32/100 LM 32/200 LM 32/300 LM 32/400 Order No. 11011210 11011210 11011210 11011210 Block Management * O-Ring 34x1,5 (2x) Intermediate part * O-Ring 18x1 (1x) Piston rod * Guide ring d=32 (1x) - Page 42 Exchanging wearing parts on the LM32 When you change the parts wear, we recommend that you wear all the parts simultaneously and carefully to change, so that the functional parts are not damaged. Disassembly: 1. Screw (20) solve connection protection rmove 2.

-

Page 43: Wear Parts Za Intermediate Stop

(2) can move. Tightness test on the repaired module with compressed air before installation to All information to the repair instructions without guarantee, because the Afag works with special mounting tools. LM 32-OI-vers. 3.5 gb. 20190314... - Page 44 Replacement parts zu ZA 32 Spare parts ZA 32 Order No. 11013003 O-Ring (2x) Sealing ring (2x) * The wear parts kit 11013003 LM 32-OI-vers. 3.5 gb. 20190314...

-

Page 45: Disposal

5.0.0 Disposal NOTE LMs which are of no further use should not be disposed on fas a complete unit but dismantled into individual parts according to the type of material and recycled should be correctly disposed of. Non-recyclable materials, animal waste. LM 32-OI-vers. - Page 46 LM 32-OI-vers. 3.5 gb. 20190314...

- Page 47 LM 32-OI-vers. 3.5 gb. 20190314...

- Page 49 Afag Automation AG Fiechtenstrasse 32 CH - 4950 Huttwil Schwitzerland Tel.: +41 62 959 86 86 Fax.: +41 62 959 87 87 e-mail: sales@afag.com Internet: www.afag.com...

Need help?

Do you have a question about the LM 32/200 and is the answer not in the manual?

Questions and answers