Subscribe to Our Youtube Channel

Summary of Contents for Lincoln SKF GTP-C

- Page 1 Operating Instructions Mobile filler pump GTP-C following machinery directive 2006/42/EC To supply grease out of 5 gallon containers, Power supply 120 V /60 Hz Version 03 951-181-012-EN...

-

Page 2: Eu Declaration Of Conformity

EU Declaration of conformity EU declaration of conformity following machinery directive 2006/42/EC, Annex II Part 1 A The manufacturer, SKF Lubrication Systems Germany GmbH, Walldorf Facilities, Heinrich-Hertz-Str. 2-8, DE - 69190 Walldorf hereby declares that the equipment Designation: Mobile filler pump to supply lubricants out of separate grease containers Type: GTP-C Part number:... -

Page 3: Legal Disclosure

Phone: +1.314.679.4200 Notes on the operating instructions SKF spare parts Fax: +1.800.424.5359 The present operating instructions are E-mail: lincoln@lincolnindustrial.com original operating instructions of the manu- Liability for loss or damage resulting from www.lincolnindustrial.com facturer according to Machinery Directive the use of our products is limited to the www.skf.com/lubrication... -

Page 4: Table Of Contents

Table of contents Table of contents EU declaration of conformity ............. 2 Legal disclosure ................3 Explanation of symbols and signs ............6 Safety instructions ..............8 Lubricants ................18 General safety instructions ..............8 General information ................18 General behaviour when handling the product ........8 Selection of lubricants ................18 Intended use .................... - Page 5 Table of contents Assembly ................29 Cleaning ................43 Notes related to commissioning and operation ........29 Cleaning agents..................43 Inspections prior to commissioning ............30 Interior cleaning ..................43 Transport of the filler pump to the place of use ........31 Exterior cleaning ...................43 6.3.1 Lifting by means of the transport bracket ........32 Maintenance ...............

-

Page 6: Explanation Of Symbols And Signs

Explanation of symbols, signs and abbreviations Explanation of symbols and signs You will find these symbols, which warn of specific dangers to persons, material assets, or the environment, next to all safety instructions in these operating instructions. Please read and observe these instructions thoroughly. General warning Dangerous electrical voltage Risk of falling... - Page 7 Explanation of symbols, signs and abbreviations Abbreviations and conversion factors regarding °C degrees Celsius °F degrees Fahrenheit approx. approximately Kelvin Ounce i.e. that is Newton fl. oz. fluid ounce etc. et cetera hour inch poss. possibly second pounds per square inch if appl.

-

Page 8: Safety Instructions

1. Safety instructions 1. Safety instructions 1.1 General safety instructions ○ Any malfunctions which may affect safety ○ Any unclear points regarding proper ○ The owner must ensure that safety in- must be remedied immediately. In addi- condition or correct assembly/ operation formation has been read by any persons tion to these Instructions, general statu- must be clarified. -

Page 9: Intended Use

1. Safety instructions 1.3 Intended use 1.4 Foreseeable misuse ○ If protective and safety equipment has to The GTP-C filler pump is a compact, mobile Any usage differing from the one stated in be dismantled, it must be reassembled and powerful electric pump to supply lu- these Instructions is strictly prohibited, immediately after finishing the work, and bricants out of a separate 5 gallon grease... -

Page 10: Modifications Of The Product

1. Safety instructions 1.5 Modifications of the product 1.7 Inspections prior to delivery ○ in areas with harmful radiation (e. g. Unauthorized conversions or modifications The following inspections were carried out ionising radiation) may result in unforeseeable impacts on prior to delivery: safety. -

Page 11: Notes Related To The Type Identification Plate

1. Safety instructions 1.9 Notes related to the type identifica- 1.10 Notes related to the CE marking tion plate CE marking is effected following the require- Notes related to the Pressure Equipment The type identification plate states important ments of the applied directives: Directive 2014/68/EU characteristics such as type designation, Because of its performance data the product... -

Page 12: Persons Authorized To Operate The Pump

1. Safety instructions 1.11 Persons authorized to operate 1.11.3 Specialist in electrics 1.14 Order the pump Person with appropriate professional The following must be observed during 1.11.1 Operator education, knowledge and experience to commissioning and operation. A person who is qualified by training, detect and avoid the hazards that may arise ○... -

Page 13: Shutdown, Disposal

1. Safety instructions 1.16 Transport, installation, maintenance, malfunctions, repair, ○ Ensure through suitable measures that ○ Observe possible abrasion points. Protect shutdown, disposal. movable or detached parts are immobilized the parts accordingly. during the work and that no limbs can ○... -

Page 14: Initial Commissioning / Daily Start-Up

1. Safety instructions 1.17 Initial commissioning / daily start-up 1.18 Cleaning ○ Risk of fire and explosion when using Ensure that: inflammable cleaning agents. Only use ○ All safety devices are completely available non-flammable cleaning agents suitable and functional for the purpose. ○... -

Page 15: Warning Label On The Product

1. Safety instructions 1.19 Warning label on the product The following warning labels are attached delay. Until then the product must not be to the product. Before the start-up of the put into service. system, verify the presence and integrity Order number and position, see positioning of the warning labels. -

Page 16: Residual Risks

1. Safety instructions 1.20 Residual risks Possible in life Residual risk Prevention/ remedy cycle Electric shock due to defective connection B, C, D, E, Before starting the product verify the connection cable and power plug for cable or power plug F, G, H damages. - Page 17 1. Safety instructions Possible in Residual risk Prevention/ remedy life cycle Be careful when filling the reservoir and when connecting or disconnecting lubricant Personal injury / damage to material due to B, C, D, F, G, feed lines. Always use suitable hydraulic screw connections and lubrication lines for the stated pressures.

-

Page 18: Lubricants

2. Lubricants 2. Lubricants 2.1 General information 2.2 Selection of lubricants Lubricants are used specifically for certain SKF considers lubricants to be an element You will avoid possible costly downtimes application purposes. In order to fulfil their of system design. A suitable lubricant is se- through damage to your machine/ system tasks, lubricants must fulfil various require- lected already when designing the machine... -

Page 19: Material Compatibility

2.Lubricants 2.3 Material compatibility 2.4 Ageing of lubricants Due to the multitude of possible Lubricants must generally be compatible After a prolonged downtime of the machine, additives, it is possible that with the following materials: the lubricant must be inspected prior to individual lubricants, which re-commissioning as to whether it is still ○... -

Page 20: Overview, Functional Description

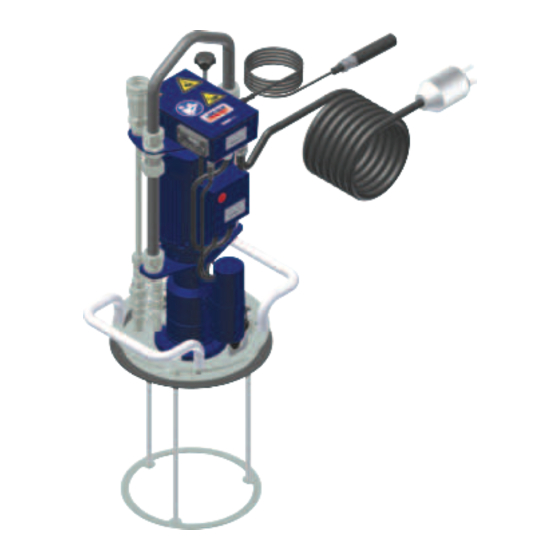

3. Overview, functional description 3. Overview, functional description Overview Fig. 2 Item Description Transport bracket Electrical terminal box (see page 21) Electric motor Gear Annular gear pump Grease follower plate with fixation (see page 22) Venting (see page 22) Handles Pump frame 10 Limit switch for low-level indicator Filling hose... - Page 21 3. Overview, functional description 3.1 Operating and control elements Overview Fig. 2.1 Pos. Designation/ function Graphic Power connection Serves to electrically connect the pump to a 105-127 V AC / 60 Hz power grid. The pump is available in two versions that differ in the power plugs. NEMA 5-15P NEMA 5-30P 15 Ampere,...

- Page 22 3. Overview, functional description Overview Fig. 2.2 Pos. Designation/ function Diagram Cable remote control Venting Serves to start or stop the filling procedure. To start the filling procedure, press the CLOSED button (3.6.1). To stop the filling procedure, release the button (3.6.1). The start delay between 2 motor starts is 5 seconds.

-

Page 23: Operating Principle Of The Product

3. Overview, functional description 3.1 Operating principle of the product see Fig. 3 filling hose (8) to the lubrication pump pro- In case of the GTP-C version with low level The GTP-C filler pump (1) is a compact, vided by the customer. indication (10) the pump switches off auto- mobile and powerful electric pump to fill As long as the pushbutton (4.1) remains... -

Page 24: Minimum Assembly Dimensions

3. Overview, functional description 3.2 Minimum assembly dimensions see Fig. 4 Ensure sufficient space for the operation of the GTP-C filler pump by adhering to the GTP-C filler pump Fig. 3 stated minimum free space dimensions. Minimum free space dimensions Fig. 4 4/4.1 Minimum free space dimensions = Pump width:... -

Page 25: Technical Data

4. Technical data 4. Technical data 4.1 General technical data Electric motor Supply voltage / frequency 105 to 127 V AC, 60 Hz 15 A for pump version 24-1560-3603, power plug according to NEMA 5-15P Fuse protection by the customer 30 A for pump version 24-1560-3601, power plug according to NEMA 5-30P Nominal current 6,7 A... - Page 26 4. Technical data Pump Pump Annular gear pump Gear Planetary gear i = 5:1 Recommended operating pressure max. 80 bar / 1200 psi Pressure control valve approx. 100 bar / 1450 psi (firmly adjusted) Operating temperature min. -10 °C /max. + 50 °C / min 15°F / max. 120 °F Operating position upright, deviation ±...

- Page 27 4. Technical data Lubricants Consistency class NLGI 1 or NLGI 2 Flow pressure max. 700 mbar (10 psi) Solids content 5 % maximum Material compatibility with: Steel, brass, copper, aluminium, NBR, FKM, PU Approved lubricants LGWM 2 Fuchs Gleitmo 585 K Mobil SHC 460 WT (transportable up to –...

-

Page 28: Delivery, Returns, And Storage

5. Delivery, returns, and storage 5. Delivery, returns, and storage 5.1 Delivery 5.3 Storage ○ dry, dust- and vibration-free in closed After receipt of the shipment, check the Before application inspect the shipment for damage and completeness ac- premises products with regard to possible cording to the shipping documents. -

Page 29: Assembly

6. Assembly 6. Assembly 6.1 Notes related to commissioning and operation When starting up the GTP-C filler pump o Ensure through suitable measures that o Immediately bind and remove any lubri- consider and adhere to the following movable or detached parts are immobilized cant leaked or spilled during assembly of information. -

Page 30: Inspections Prior To Commissioning

6. Assembly 6.2 Inspections prior to commissioning see Fig. 5 - all warning labels on the machine are o Damages, deformations, or cracks of the completely available, well visible and In order to warrant safety and function, a filling hose undamaged person assigned by the operator must inspect certain areas of the central lubrication system... -

Page 31: Transport Of The Filler Pump To The Place Of Use

6. Assembly 6.3 Transport of the filler pump to the place of use see Fig. 5 WARNING WARNING Normally, transportation of the GTP-C filler pump to the place of use is realized in a Personal injuries and damage to Danger to life transportation pump with two handles. -

Page 32: Lifting By Means Of The Transport Bracket

6. Assembly 6.3.1 Lifting by means of the transport bracket see Fig. 5 Lifting on the transport bracket, Fig. 5 • Secure the grease follower plate (1) by means of the fixing screw (2) • Make sure that the GTP-C filler pump (3) minimum has been fully lowered into the transpor- admissible tensile load... -

Page 33: Inserting The Gtp-C Filler Pump In A Grease Reservoir

6. Assembly 6.4 Inserting the GTP-C filler pump in a grease reservoir see Fig. 6 Before inserting the GTP-C filler pump • Open the fixation (2). in the grease reservoir check whether the WARNING grease reservoir is suitable for the grease The grease follower plate (1) sinks down Risk of crushing hands and fingers follower plates - see chapter 4 ,Technical data... -

Page 34: Installation Of The Cable Remote Control

6. Assembly 6.5 Installation of the cable remote control see Fig. 7 The cable remote control represents a Insert the GTP-C filler pump Fig. 6 Installation of the cable remote control Fig. 7 fix part of the pump, which does not run without the remote control. - Page 35 6. Assembly 6.7 Installation of the filling hose to the GTP-C filler pump see Fig. 8 Installation of the filling hose Fig. 8 WARNING Hydraulic pressure Before assembly check the filling hose with regard to damage or contamination. Do not mount defective filling hose! Remove any contamination before the assembly! 6.7.1 Installation of the filling hose by means of a quick coupling •...

-

Page 36: Installation Of Adapters To The Lubrication Pump Provided By

6. Assembly 6.6 Installation of adapters to the lubrication pump provided by the customer as well as to the filling hose of the GTP-C 6.6.1 Lubrication pumps of the SKF series KFG and P203 with adapter G1/4 see Fig. 9, also see chapter 15 - Accessories Installation of the G1/4 adapter, Fig. -

Page 37: Lubrication Pumps Of The Skf Series Kfg With Adapter 20X1.5

6. Assembly 6.6.2 Lubrication pumps of the SKF series KFG with adapter 20x1.5 see Fig. 10, also see chapter 15 - Accessories Mount the coupling G1/2 to the filling hose of the GTP-C filler pump Installation of adapter 20 x 1.5, Fig. 10 If necessary, remove the existing adapter from the filling hose •... -

Page 38: Lubrication Pumps Of The Skf Series P203, P223, P233, P243, P603 Und P653

6. Assembly 6.7 Lubrication pumps of the SKF series P203, P223, P233, P243, P603 und P653 see Fig. 11, also see chapter 15 - Accessories Mount the connection sleeve to the filling hose of the GTP-C filler pump Installation of adapter 22 x 1.5, Fig. 11 If necessary, remove the existing adapter from the filling hose •... -

Page 39: Initial Start-Up

7. Initial start-up 7. Initial start-up In order to warrant safety and function, a WARNING CAUTION person assigned by the operator must carry out the following inspections. Immediately eliminate detected deficiencies. Deficiencies Electric shock Risk of falling or tripping may be remedied by an authorized and quali- Do not touch cables or plugs of the When working pay attention to the fied maintenance and repair specialist only. -

Page 40: Initial Start-Up

7. Initial start-up 7.2 Initial start-up see Fig. 12 The mobile filler pump type GTP-C is During the initial start-up or after longer factory-tested with testing oil with regard to pump downtimes there may arise system- ATTENTION its functionality. Therefore, during the initial related supply problems. -

Page 41: Order

8. Order 8. Order SKF products operate automatically to the ATTENTION CAUTION greatest possible extent. Basically, activities during standard Risk of falling or tripping operation are limited to the control of the Execution, required protective When working pay attention to the filling level and the timely refilling of the clothes, cleaning agents and position of the filling hose. -

Page 42: Operation Of The Gtp-C Filler Pump

8. Order Operation of the GTP-C filler pump see Fig. 12 • When reaching the maximum filling level • Insert the filler pump into the grease release the pushbutton of the cable Operation of the GTP-C filler pump, Fig. 12 reservoir following chapter 6.4 remote control (2) •... -

Page 43: Cleaning

9. Cleaning 9. Cleaning 9.1 Cleaning agents Cleaning agents compatible with the material may be used only (materials, ATTENTION WARNING see chapter 2.3). Electric shock Carry out cleaning works only on Execution, required protective Thoroughly remove residues of depressurized products that have clothes, cleaning agents and cleaning agents from the product been disconnected from the power... -

Page 44: Maintenance

10. Maintenance Maintenance Regular and appropriate maintenance is a prerequisite to detect and clear faults in time. The specific timelines have to be determined, verified at regular intervals and adapted, if necessary, by the operator based on the operating conditions. If needed, copy the table for regular maintenance activities. Maintenance check list Activity to be done Electrical connection carried out correctly. -

Page 45: Troubleshooting

11. Faults Troubleshooting The following charts give an overview over ATTENTION ATTENTION possible malfunctions and their causes. If it is not possible to remedy the malfunction, Only original SKF spare parts may be used. Disassembly of the product (pump, gear, please contact the SKF Service Department. - Page 46 11. Faults Troubleshooting Cause Remedy No lubricant supply o Pump with low level signal • Check and, if applicable, mount the sensor correctly or replace it o Plug of low level signal not installed correctly or sensor defective (yellow light flashing) o Pump without low level signal •...

-

Page 47: Vent The Pump

11. Faults 11.2 Vent the pump see Fig. 13 During the initial start-up or after longer To do so, proceed as follows: • Turn the tube bend (5) back again pump downtimes there may arise system- related supply problems. In this case imme- •... -

Page 48: Repairs

11. Faults / 12. Repairs Repairs In case a repair is required, it may be car- ried out by the SKF service only (see legal Fig. 13 notice). - 48 - 951-181-012-EN Version 03... -

Page 49: Shutdown And Disposal

13. Shutdown and disposal Shutdown and disposal 13.1 Temporary shutdown 13.3 Disposal Temporarily shut the system down by: Disposal should be avoided or minimized Dispose of or recycle electrical ○ Switching off the GTP-C wherever possible. Disposal of products components following WEEE contaminated with lubricant must be effected directive 2012/19/EU. -

Page 50: Spare Parts

14. Spare parts Spare parts The spare parts assemblies may be used exclusively for replacement of identical defective parts. Modifications with spare parts on existing products are not allowed. Spare parts, Legend 1 of 2 to Fig. 14 GTP-C spare parts, Fig. 14 Spare parts GTP-C Pos. - Page 51 14. Spare parts Spare parts, Legend 2 of 2 to Fig. 14 Pos. Description A = Quick coupling B = Transport bracket C = Pump frame Pump GTP-C mobile assy., NEMA 5-30, 5 gal. 799-000-3161 Pump GTP-C stationary assy., NEMA 5-15, 5 gal. 799-000-3162 Pump GTP-C mobile, NEMA 5-30, 5 gal.

-

Page 52: Accessories

15. Accessories Accessories Accessories, chart 1 of 4 SKF lubrication pump KFG and SKF lubrication pump P 203, connection G 1/4 Installation to the filling hose Fig. Description Order number Pos. Filler coupling sleeve assy. 24-0159-2111 Installation to the pump provided by the customer KFG filler stud G 1/4 995-000-705 P203 filler coupling G 1/4... - Page 53 15. Accessories Accessories, chart 2 of 4 SKF lubrication pumps KFGS/KFGL/KFGC for wind turbine generators Installation to the filling hose Fig. Description Order number Pos. G1/2“ for filling connection 24-0159-2112 Positions 5 and 6 5/ 6 Straight filling connection M20 x 1.5 169-000-174 (Length 45 mm + 14 mm screw-in depth) Straight filling connection (short) M20 x 1.5...

- Page 54 15. Accessories Accessories, chart 3 of 4 Connection to SKF lubrication pump types P 203/ P 223/ P 233/ P 243/ P 603/ P 653 Installation to the filling hose Pos. Fig. Description Order number Coupling stud assy. 24-0159-2110 Installation to the pump provided by the customer Straight filling connection M22 x 1.5 538-36763-1 (P 203, 2 l)

- Page 55 15. Accessories Accessories, chart 4 of 4 Connection to SKF lubrication pump types P 203/ P 223/ P 233/ P 243/ P 603/ P 653 Installation to the pump provided by the customer Pos. Fig. Description Order number 90 ° Filling connection, long 538-36763-4 (for 2 l flat, 4 l, and 8 l reservoirs) Coupling plug G1/2 for installation on pump...

- Page 56 The Power of Knowledge Engineering Drawing on five areas of competence and application-specific expertise amassed over more Bearings Lubrication than 100 years, SKF brings innovative solutions to OEMs and production facilities in every major Seals and bearing systems industry worldwide. These five areas of competence include bearings and bearing units, seals, units lubrication systems, mechatronics (combining mechanics and electronics into intelligent systems), and a wide range of services, from 3-D computer modelling to advanced condition monitoring...

Need help?

Do you have a question about the SKF GTP-C and is the answer not in the manual?

Questions and answers