Table of Contents

Advertisement

Quick Links

Assembly and operating instructions

Gripper Module GMQ 20

GMQ 20/RM 16

Translation of the Original Assembly Instructions EN

GMQ 20/K

◼

GMQ 20/P

◼

GMQ 20/P-01

◼

GMQ 12/K RM 12

◼

GMQ 20/P RM 16

◼

Assembly instructions EN

Rotary Gripper module

Order No.: 11010477

Order No.: 11010483

Order no.: 50409827

Order no.: 50094784

Order no.: 50094775

◼

GMQ 20 RM 16-25

◼

GMQ 20/RM 25

GMQ 20/P-01 RM 16

◼

GMQ 20/P RM 25

◼

GMQ 20/P-01 RM 25

◼

GMQ 20/K RM 25

◼

◼

◼

19.04.2023

V3.0

Order No.: 50410319

Order No.: 50094797

Order No.: 50410325

Order No.: 50094803

1–60

Advertisement

Table of Contents

Summary of Contents for Afag GMQ 20

- Page 1 Assembly and operating instructions Gripper Module GMQ 20 Rotary Gripper module ◼ GMQ 20/RM 16 GMQ 20/RM 25 Translation of the Original Assembly Instructions EN GMQ 20/K Order No.: 11010477 GMQ 20/P-01 RM 16 Order No.: 50410319 ◼...

- Page 2 Your Afag team © Subject to modifications The modules have been designed by Afag Automation AG according to the state of the art. Due to the constant technical development and improvement of our products, we reserve the right to make technical changes at any time.

-

Page 3: Table Of Contents

Dimensional drawings ................15 3.1.1 Gripper module GMQ 20 ..............15 3.1.2 Gripper module GMQ 20 / RM 16 ............16 3.1.3 Rotary gripper module GMQ 20 / RM 25 ..........17 Technical data .................... 18 3.2.1 Gripper module GMQ 20 ..............18 3.2.2 Rotary gripper module GMQ 20 / RM 16 .......... - Page 4 6.3.3 Stroke adjustment of the GMQ 20 grippers ......... 42 Conversion of the GMQ module ..............42 6.4.1 Conversion of the GMQ 20 to internal clamping ........43 6.4.2 Conversion of the GMQ 20 to double-acting ........44 Commissioning ....................45 Safety instructions for commissioning ............

- Page 5 9.3.2 Compressed air specifications ............. 50 9.3.3 Further maintenance ................51 Spare and wear parts lists ................51 9.4.1 Spare parts GMQ 20 ................52 9.4.2 Wear parts for RM 16 ................52 9.4.3 Wear parts for RM 16/360° ..............54 9.4.4 Wear parts RM 25 / RMZ 25/1 .............

-

Page 6: General

This note contains important additional information as well as useful tips for safe, efficient and trouble-free operation of the module. 6 – 60 ◼ ◼ ◼ Assembly instructions EN GMQ 20 RM 16-25 19.04.2023 V3.0... -

Page 7: Additional Symbols

In these assembly instructions the following symbols are used to highlight instructions, results, references, etc.. Symbol Description Instructions (steps ...) Results of actions References to sections ◼ Enumerations not ordered ◼ ◼ ◼ Assembly instructions EN GMQ 20 RM 16-25 19.04.2023 V3.0 7–60... -

Page 8: Applicable Documents

▪ Wear parts (e.g. shock absorbers) are excluded from the warranty.* The warranty covers the replacement or repair of defective Afag parts. Further claims are excluded. * However, a customer has a right to a defect-free product. This does also apply to defective accessories and wear parts. -

Page 9: Safety Instructions

2.2 Intended use The GMQ 20, GMQ 20 / RM 16 and GMQ 20 / RM 25 modules are used for shock-free rotating of loads in non-hazardous atmospheres under the ambient and operating conditions defined for these modules. -

Page 10: Obligations Of The Operator And The Personnel

▪ the operating company shall be solely responsible for such damage, and ▪ Afag does not accept any liability for damage caused by improper use. 2.4 Obligations of the operator and the personnel 2.4.1... -

Page 11: Personnel Requirements

▪ check the personal protective equipment for proper condition, and ▪ immediately notify the person responsible on site of any defects found on the personal protective equipment. ◼ ◼ ◼ Assembly instructions EN GMQ 20 RM 16-25 19.04.2023 V3.0 11–60... -

Page 12: Changes & Modifications

2.7 Changes & Modifications No changes may be made to the GMQ module which have not been described in these assembly instructions or approved in writing by Afag Automation AG. Afag Automation AG accepts no liability for unauthorised changes or improper assembly, installation, commissioning, maintenance or repair work. - Page 13 ▪ The operating company is responsible for ensuring that the permissible noise levels are observed. ▪ If the noise level exceeds 85 dB(A) in normal operation, the operator must wear hearing protectors at the workplace. ◼ ◼ ◼ Assembly instructions EN GMQ 20 RM 16-25 19.04.2023 V3.0 13–60...

-

Page 14: Danger Due To Electricity

Poor or not regularly performed maintenance may cause component failures which may lead to injuries. ▪ The operator must exercise due care and only use trained maintenance to carry out the activities. 14 – 60 ◼ ◼ ◼ Assembly instructions EN GMQ 20 RM 16-25 19.04.2023 V3.0... -

Page 15: Technical Data

Technical data Technical data 3.1 Dimensional drawings 3.1.1 Gripper module GMQ 20 Fig. 1 Dimensional drawing - GMQ 20 ◼ ◼ ◼ Assembly instructions EN GMQ 20 RM 16-25 19.04.2023 V3.0 15–60... -

Page 16: Gripper Module Gmq 20 / Rm 16

Technical data 3.1.2 Gripper module GMQ 20 / RM 16 Fig. 2 Dimensional drawing - GMQ 20/RM 16 16 – 60 ◼ ◼ ◼ Assembly instructions EN GMQ 20 RM 16-25 19.04.2023 V3.0... -

Page 17: Rotary Gripper Module Gmq 20 / Rm 25

Technical data 3.1.3 Rotary gripper module GMQ 20 / RM 25 Fig. 3 Dimensional drawing - GMQ 20 / RM 25 ◼ ◼ ◼ Assembly instructions EN GMQ 20 RM 16-25 19.04.2023 V3.0 17–60... -

Page 18: Technical Data

Technical data 3.2 Technical data 3.2.1 Gripper module GMQ 20 Fig. 4 Technical data module GMQ 20 18 – 60 ◼ ◼ ◼ Assembly instructions EN GMQ 20 RM 16-25 19.04.2023 V3.0... -

Page 19: Rotary Gripper Module Gmq 20 / Rm 16

Technical data 3.2.2 Rotary gripper module GMQ 20 / RM 16 Fig. 5 Technical data module GMQ 20 / RM16 ◼ ◼ ◼ Assembly instructions EN GMQ 20 RM 16-25 19.04.2023 V3.0 19–60... -

Page 20: Rotary Gripper Module Gmq 20 / Rm 25

Technical data 3.2.3 Rotary gripper module GMQ 20 / RM 25 Fig. 6 Technical data module GMQ 20 / RM 25 20 – 60 ◼ ◼ ◼ Assembly instructions EN GMQ 20 RM 16-25 19.04.2023 V3.0... -

Page 21: Preferred Combinations Gmq 20

Technical data 3.3 Preferred combinations GMQ 20 Fig. 7 Preferred combinations GMQ 20 ◼ ◼ ◼ Assembly instructions EN GMQ 20 RM 16-25 19.04.2023 V3.0 21–60... -

Page 22: Gripper Loads Gmq 20

Technical data 3.4 Gripper loads GMQ 20 Fig. 8 Gripper loads - GMQ 20 22 – 60 ◼ ◼ ◼ Assembly instructions EN GMQ 20 RM 16-25 19.04.2023 V3.0... -

Page 23: Gripper Drive Gmq 20

Technical data 3.5 Gripper drive GMQ 20 Fig. 9 Gripper drive - GMQ 20 ◼ ◼ ◼ Assembly instructions EN GMQ 20 RM 16-25 19.04.2023 V3.0 23–60... -

Page 24: Transport, Packaging And Storage

Danger of injury when unpacking the rotary modules! The GMQ modules are packed in the original packaging (cardboard box). The GMQ 20/RM 16 and GMQ 20/RM 25 modules are delivered assembled and are not specially packaged. If handled incorrectly, the module may fall out of the box when unpacked and cause limb injuries. -

Page 25: Transport

Environmental damage can be caused by incorrect disposal of the packaging material. ▪ Dispose of the packaging material in an environmentally sensitive way in accordance with the local environmental regulations. ◼ ◼ ◼ Assembly instructions EN GMQ 20 RM 16-25 19.04.2023 V3.0 25–60... -

Page 26: Storage

▪ Relative air humidity: < 90% non condensing. ▪ Clean the module and protect the blank metal parts against corrosion using the appropriate means. ▪ Protect the module from dirt and dust. 26 – 60 ◼ ◼ ◼ Assembly instructions EN GMQ 20 RM 16-25 19.04.2023 V3.0... -

Page 27: Design And Description

7. Guide pin 3. Gripping jaws 8. Piston 4. Screws 9. Spring 5. Lifting stop All GMQ 20 are delivered from the factory with external tensioning and can be converted to another function as required ( Chapter 6.4). ◼ ◼... -

Page 28: Product Description Gmq 20

The piston diameter value is 20 mm. A built-in spring (Fig.4, 1) serves as a gripping force safety device in the depressurised state. The GMQ 20 is designed in such a way that it can be operated in external (Fig. 1), internal (Fig. 2) or double-acting (Fig. 3) mode. -

Page 29: Design Gmq 20/Rm 16 - Gmq 20/Rm 25

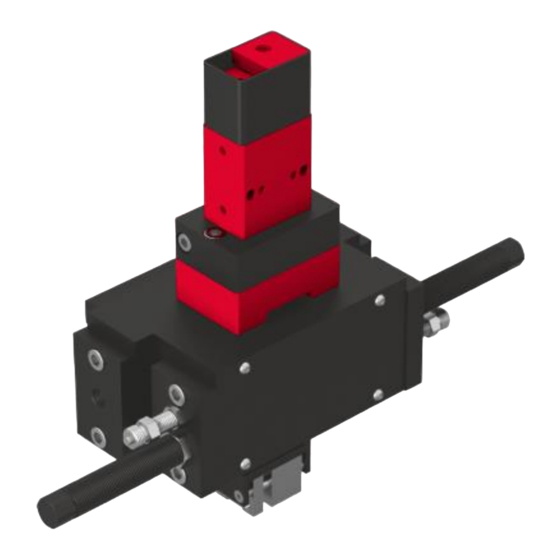

Design and description 5.3 Design GMQ 20/RM 16 - GMQ 20/RM 25 Fig. 13 Gripping rotary module (exemplary) 1. Gripper drive 5. Pneumatic connections RM 2. Pneumatic connections gripper drive 6. Mounting bracket 3. Rotary module 7. Stop screw 4. Gripping jaws 8. -

Page 30: Accessories

INI 8x8x38.5-Sn2.0-PNP-NO-M8x1 50338170 5.5.3 Accessories RM 25 Designation Order no. Mounting screws M6x56 11005015 Clamping holder RM 16/RM 25 11001672 INI d6.5x44-Sn1.5-PNP-NO-M8x1 11005439 INI 8x8x38.5-Sn2.0-PNP-NO-M8x1 50338170 30 – 60 ◼ ◼ ◼ Assembly instructions EN GMQ 20 RM 16-25 19.04.2023 V3.0... -

Page 31: Installation, Assembly And Setting

No liability for damages can be assumed for damages caused by improper installation/assembling work of the operator. Chap. 2 „Safety instructions“ in this Also observe the safety instructions in manual. ◼ ◼ ◼ Assembly instructions EN GMQ 20 RM 16-25 19.04.2023 V3.0 31–60... -

Page 32: Installation & Assembly

The GMQ modules can be mounted both in horizontal and vertical position. Attachment options There are following mounting options for each module: Fig. 14 Mounting options GMQ 20 / GMQ 20/RM 16 and/or RM 25 6.2.2 Module centering In order to ensure high and repetitive accuracy of fit during assembling, operation and exchanging of a module, the components of the Afag modules are provided with a precise module centering unit. - Page 33 The dimensions of the mounting holes and the distances between holes are Chap. 3 „Technical Data“. indicated in the dimensional drawings in ◼ ◼ ◼ Assembly instructions EN GMQ 20 RM 16-25 19.04.2023 V3.0 33–60...

-

Page 34: Tightening Torques For Screws

When connecting the compressed air supply for the first time, make sure that all compressed air throttles are closed. Vent the system slowly! The minimum compressed air quality shall comply with the specifications of ISO 8573-1:2010. 34 – 60 ◼ ◼ ◼ Assembly instructions EN GMQ 20 RM 16-25 19.04.2023 V3.0... - Page 35 4. Maintenance unit 2. Throttle check valve P. Compressed air connection 3. Directional control valve (standard 5/2) Pneumatic connections module GMQ 20/RM 16, GMQ 20/RM 25 Fig. 16 Pneumatic circuit diagram rotary gripper module 1. Gripper drive 4. Maintenance unit 2.

-

Page 36: Mounting The Initiators

Switching distance: 1.5mm Type Short circuit and reverse polarity protected The proximity switches can only be used with the stop screws of the AS series! 36 – 60 ◼ ◼ ◼ Assembly instructions EN GMQ 20 RM 16-25 19.04.2023 V3.0... - Page 37 Installation, assembly and setting Mounting the initiator 6.5 mm - GMQ 20 Fig. 18 Mounting the proximity switches (6.5 mm) To install the 6.5 mm proximity switch, proceed as follows: 1. Screw the initiator holder (1) onto the stop screw.

- Page 38 3. Push the initiator holder (7) with initiator onto the stop screw (8) as far as it will go and clamp it with screw (9). 4. Mount the connector (4). 5. Carry out function check. The initiator is mounted. 38 – 60 ◼ ◼ ◼ Assembly instructions EN GMQ 20 RM 16-25 19.04.2023 V3.0...

-

Page 39: Assembly Of The Gripping Jaws

Representation of the gripping fingers (exemplary) The length (L) and the offset (X) of the gripper fingers must not exceed the recommended masses in the gripping force diagrams! ◼ ◼ ◼ Assembly instructions EN GMQ 20 RM 16-25 19.04.2023 V3.0 39–60... -

Page 40: Settings

▪ Adjustment and conversion work may only be carried out by qualified personnel! Chap. 2 „Safety instructions“ in this Also observe the safety instructions in manual. 40 – 60 ◼ ◼ ◼ Assembly instructions EN GMQ 20 RM 16-25 19.04.2023 V3.0... -

Page 41: Adjusting The Stop Screw And Stop Pin

1. Adjust the stroke by adjusting the stop pin (3). One turn = 1 mm 2. Secure stop pin with locknut (4). Stopping accuracy: +- 0.01 mm The process is complete. ◼ ◼ ◼ Assembly instructions EN GMQ 20 RM 16-25 19.04.2023 V3.0 41–60... -

Page 42: Stroke Adjustment Of The Gmq 20 Grippers

If required, the modules can be converted to another function. Special tools must be used to convert the GMQ 20/RM 16 and GMQ 20/RM 25 modules. Therefore, these modules must be sent to Afag for conversion. -

Page 43: Conversion Of The Gmq 20 To Internal Clamping

Installation, assembly and setting 6.4.1 Conversion of the GMQ 20 to internal clamping To convert the GMQ 20 to internal clamping, proceed as follows: 1. Loosen screw (1+2). 2. Dismount the gripping jaw (3). 3. Loosen the screws (4+6). 4. Remove the guide pin (7). -

Page 44: Conversion Of The Gmq 20 To Double-Acting

Installation, assembly and setting 6.4.2 Conversion of the GMQ 20 to double-acting To convert the GMQ 20 to internal clamping, proceed as follows: 1. Loosen screw (1+2). 2. Dismount the gripping jaw (3). 3. Loosen the countersunk screws (6). 4. Remove the guide pin (7). -

Page 45: Commissioning

3. Make sure that there are no persons or tools within the working area of the rotary module. 4. Perform test run: Start with slow traversing movements. Then continue under normal operating conditions. Commissioning is completed. ◼ ◼ ◼ Assembly instructions EN GMQ 20 RM 16-25 19.04.2023 V3.0 45–60... -

Page 46: Fault Elimination

▪ The due diligence obligations of the user include ensuring that the personnel working on eliminating faults appropriately trained and qualified. Chap. 2 „Safety instructions“ in this Also observe the safety instructions in manual. 46 – 60 ◼ ◼ ◼ Assembly instructions EN GMQ 20 RM 16-25 19.04.2023 V3.0... - Page 47 Fault elimination 8.3 Table Fault causes and remedy GMQ 20, GMQ 20/RM16, GMQ 20/RM25 Defective components must be replaced exclusively by Afag original spare parts. Fault Possible cause Remedy: ▪ No compressed air ▪ Check connections Gripper does not open/close ▪...

-

Page 48: Maintenance And Repair

▪ Before starting any activities, switch off the media supply (pneumatics) and secure it from being switched on again! Chap. 2 „Safety instructions“ in this Also observe the safety instructions in manual. 48 – 60 ◼ ◼ ◼ Assembly instructions EN GMQ 20 RM 16-25 19.04.2023 V3.0... -

Page 49: Maintenance Activities And Maintenance Intervals

The modules are almost maintenance-free. Nevertheless, some maintenance work must be carried out to ensure an optimum operating condition of the modules. 9.3.1 Overview of the maintenance points Maintenance GMQ 20 – GMQ 20/RM16 Fig. 25 System Interval Maintenance point... -

Page 50: Compressed Air Specifications

If the modules are used in an ionised air environment, there is a risk that exposed parts could corrode. ▪ Always grease exposed parts e.g., flanges, shafts, guides and jaws regularly. ▪ Afag standard lubrication: Staburax NBU8EP (flat guides), Blasolube 301 (piston rods) 9.3.2 Compressed air specifications The modules are lifetime lubricated and can be operated with lubricated or non- lubricated compressed air. -

Page 51: Further Maintenance

Afag for warranty repair within the warranty period. After expiry of the warranty period, the customer may replace or repair defective modules or wear parts himself or send them to the Afag repair service. Please note that Afag does not assume any warranty for modules that have... -

Page 52: Spare Parts Gmq 20

Maintenance and repair 9.4.1 Spare parts GMQ 20 Item Designation Dimensions Supplier number Order no. Housing Afag 11009183 Piston Afag 11009080 Piston rod Afag 11009081 Guide pin Afag 11009082 Lifting stop Afag 11009085 Bearing bush Afag 11009086 Cover Afag 11009087... - Page 53 Wear parts for RM16 Item Designation Supplier number Order no. Wear parts Afag 11002514 Wear parts Afag 11007844 Fig. 27 Wear parts RM 16 ◼ ◼ ◼ Assembly instructions EN GMQ 20 RM 16-25 19.04.2023 V3.0 53–60...

-

Page 54: Wear Parts For Rm 16/360

Wear parts for RM 16/360° Item Designation Supplier number Order no. Wear parts Afag 11002514 Wear parts Afag 11007844 Fig. 28 Wear parts RM 16/ 360° 54 – 60 ◼ ◼ ◼ Assembly instructions EN GMQ 20 RM 16-25 19.04.2023 V3.0... -

Page 55: Wear Parts Rm 25 / Rmz 25/1

Wear parts RM 25 / RMZ 25/1 Item Designation Supplier number Order no. Wear parts Afag 11002517 Wear parts Afag 11002519 Fig. 29 Wear parts RM 25 / RMZ 25/1 ◼ ◼ ◼ Assembly instructions EN GMQ 20 RM 16-25 19.04.2023 V3.0 55–60... -

Page 56: Wear Parts Rmz 25/2

Maintenance and repair 9.4.5 Wear parts RMZ 25/2 Item Designation Supplier number Order no. Wear parts Afag 11002519 Fig. 30 Wear parts RM 25/2 56 – 60 ◼ ◼ ◼ Assembly instructions EN GMQ 20 RM 16-25 19.04.2023 V3.0... -

Page 57: Decommissioning, Disassembly, Disposal

▪ Disconnect the media supply (electrics, pneumatics) before removing the rotary modules! ▪ Disassembling should only be carried out by qualified personnel! ▪ Only remove module when the controller is switched off and secured! ◼ ◼ ◼ Assembly instructions EN GMQ 20 RM 16-25 19.04.2023 V3.0 57–60... -

Page 58: Disposal

▪ Electronic parts, electrical scrap, auxiliary and operating materials must be disposed of by approved specialist companies. ▪ Information on proper disposal can be obtained from the responsible local authorities. 58 – 60 ◼ ◼ ◼ Assembly instructions EN GMQ 20 RM 16-25 19.04.2023 V3.0... -

Page 59: Declaration Of Incorporation

Product description Gripping modules / rotary gripper modules (pneumatic) Type: GMQ 20 / GMQ 20/RM 16, GMQ 20/RM 25 Consecutive serial no. 50XXXXXX complies with the following essential health and safety requirements of the Machinery Directive 2006/42/EC at the time of declaration: 1.1;... - Page 60 Afag Automation Americas Afag Automation APAC Schaeff Machinery & Services LLC. Afag Automation Technology (Shanghai) Co., Ltd. 883 Seven Oaks Blvd, Suite 800 Room 102, 1/F, Bldg. 56, City Of Elite Smyrna, TN 37167 No.1000, Jinhai Road, Pudong New District...

Need help?

Do you have a question about the GMQ 20 and is the answer not in the manual?

Questions and answers