Beckhoff EL1918 Operation Manual

Twinsafe terminal with 8 digital fail-safe inputs

Hide thumbs

Also See for EL1918:

- Operating instructions manual (55 pages) ,

- Operating instructions manual (69 pages)

Summary of Contents for Beckhoff EL1918

- Page 1 Operation Manual | EN EL1918 and EL1918-2200 TwinSAFE Terminal with 8 digital fail-safe inputs 2023-03-06 | Version: 2.0.0...

-

Page 3: Table Of Contents

General safety instructions...................... 14 2.3.1 Before operation....................... 14 2.3.2 In operation ........................ 15 2.3.3 After operation........................ 15 3 System description .......................... 16 The Beckhoff EtherCAT Terminal system .................. 16 3.1.1 EtherCAT Bus Coupler..................... 17 3.1.2 EtherCAT Terminals...................... 18 3.1.3 E-bus.......................... 19 3.1.4 Power contacts......................... - Page 4 Alias devices ........................ 41 5.3.6 EL1918 parameters in TwinCAT .................. 42 5.3.7 Process image of the EL1918 .................. 44 5.3.8 EL1918: using the integrated TwinSAFE Logic functions .......... 45 TwinSAFE reaction times ........................ 46 Diagnosis ............................ 49 5.5.1 Status LEDs ........................ 49 5.5.2 Diagnostic LEDs.......................

-

Page 5: Notes On The Documentation

Notes on the documentation Disclaimer Beckhoff products are subject to continuous further development. We reserve the right to revise the operating instructions at any time and without prior announcement. No claims for the modification of products that have already been supplied may be made on the basis of the data, diagrams and descriptions in these operating instructions. -

Page 6: Limitation Of Liability

Modifications and changes to the hardware and/or software configuration that go beyond the documented options are prohibited and nullify the liability of Beckhoff Automation GmbH & Co. KG. The following is excluded from the liability: •... -

Page 7: Documentation Issue Status

The original documentation is written in German. All other languages are derived from the German original. Product features Only the product properties specified in the current operating instructions are valid. Further information given on the product pages of the Beckhoff homepage, in emails or in other publications is not authoritative. EL1918 and EL1918-2200 Version: 2.0.0... -

Page 8: Version History Of The Twinsafe Product

Date Software ver- Hardware Modifications sion version First release of the EL1918-2200 2022-03-25 02 • New function blocks SBT and SLP • Prevention of unauthorized firmware downgrade • Updating the modules 2018-08-03 01 First release of the EL1918... -

Page 9: Staff Qualification

• Independently identify, avoid and eliminate sources of hazard. • Apply relevant standards and directives. • Implement specifications from accident prevention regulations. • Evaluate, prepare and set up the workplaces. • Evaluate, optimize and execute work independently. EL1918 and EL1918-2200 Version: 2.0.0... -

Page 10: Safety And Instruction

Notes are used for important information on the product. The possible consequences of failure to observe these include: • Malfunctions of the product • Damage to the product • Damage to the environment Information This sign indicates information, tips and notes for dealing with the product or the software. Version: 2.0.0 EL1918 and EL1918-2200... -

Page 11: Beckhoff Support And Service

The employees support you in the programming and commissioning of sophisticated automation systems. Hotline: +49 5246/963-157 E-mail: support@beckhoff.com Web: www.beckhoff.com/support Training Training in Germany takes place in our training center at the Beckhoff headquarters in Verl, at subsidiaries or, by arrangement, at the customer's premises. Hotline: +49 5246/963-5000 E-mail: training@beckhoff.com Web: www.beckhoff.com/training... -

Page 12: For Your Safety

Products marked with a crossed-out waste bin must not be disposed of with domestic waste. The device is considered waste electrical and electronic equipment when it is disposed of. Observe the national regulations for the disposal of waste electrical and electronic equipment. Version: 2.0.0 EL1918 and EL1918-2200... -

Page 13: Safety Image Signs

For your safety Safety image signs On Beckhoff products you will find attached or lasered safety pictograms, which vary depending on the product. They serve to serve to ensure safety for people and to prevent damage to the products. Safety pictograms must not be removed and must be legible for the user. -

Page 14: General Safety Instructions

Approved engineering tools are TwinCAT 3.1 and TwinSAFE Loader. Procedures or engineering tools that deviate from this are not covered by the certificate. This is especially true for externally generated xml files for the TwinSAFE import. Version: 2.0.0 EL1918 and EL1918-2200... -

Page 15: In Operation

De-energize and switch off components before working on them Check all safety-relevant equipment for functionality before working on the TwinSAFE component. Secure the working environment. Secure the machine or plant against being inadvertently started up. Observe the chapter Decommissioning [} 57]. EL1918 and EL1918-2200 Version: 2.0.0... -

Page 16: System Description

System description The Beckhoff EtherCAT Terminal system The Beckhoff EtherCAT Terminal system is used for decentralized connection of sensors and actuators to a controller. The components of the Beckhoff EtherCAT Terminal system are mainly used in industrial automation and building management systems. As a minimum, a bus station consists of an EtherCAT Coupler and connected EtherCAT Terminals. -

Page 17: Ethercat Bus Coupler

Fig. 2: Bus Coupler (EtherCAT) Connection technology Bus Coupler Wiring Spring-loaded system Connection cross-section 0.08 mm² ... 2.5 mm², stranded wire, solid wire Fieldbus connection EtherCAT Power contacts 3 spring contacts Current load 10 A Nominal voltage 24 V EL1918 and EL1918-2200 Version: 2.0.0... -

Page 18: Ethercat Terminals

Bus Terminal Wiring Spring-loaded system Connection cross-section typically 0.08 mm² – 2.5 mm², stranded wire, solid wire Communication E-bus Power contacts Up to 3 blade/spring contacts Current load 10 A Nominal voltage Depending on terminal type (typically 24 V Version: 2.0.0 EL1918 and EL1918-2200... -

Page 19: E-Bus

3.2.1 The I/O construction kit is extended safely The integrated TwinSAFE safety solution is the logical continuation of the open, PC-based Beckhoff control philosophy. Due to their modularity and versatility, the TwinSAFE components fit seamlessly into the Beckhoff control system. The I/O components are available in the formats Bus Terminal, EtherCAT Terminal, EtherCAT plug-in module and EtherCAT Box. -

Page 20: The Fail-Safe Principle (Fail Stop)

The basic rule for a safety system such as TwinSAFE is that failure of a part, a system component or the overall system must never lead to a dangerous condition. CAUTION Safe state! The safe state of the TwinSAFE system is always the switched-off and de-energized state. Version: 2.0.0 EL1918 and EL1918-2200... -

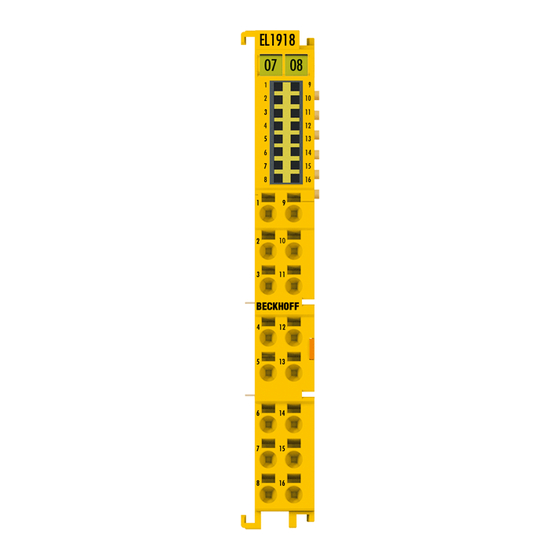

Page 21: Product Description

Fig. 4: EL1918 – TwinSAFE Terminal with 8 fail-safe inputs EL1918 variants The EL1918 has an integrated safety control that can be used for user-specific applications directly on the component. The variant EL1918-2200 does not have this functionality and represents a pure I/O component. -

Page 22: Intended Use

. Failure to observe this can result in a loss of safety. WARNING Commissioning test Before the EL1918 can be used for safety-related tasks, a commissioning test must be carried out by the user so that faulty sensor wiring can be ruled out. CAUTION Follow the machinery directive! The TwinSAFE components may only be used in machines as defined in the machinery directive. - Page 23 Note on approval according to EN 81-20, EN 81-22 and EN 81-50 • The release does not apply to the EL1918-2200, EL2911-2200 and EP1957-2222 variants. • The TwinSAFE components may only be used in machines that have been designed and installed in accordance with the requirements of the EN 60204-1 standard.

-

Page 24: Technical Data

Output current of the clock outputs typically 3 mA, max. 6.5 mA Input process image 7 bytes Output process image 6 bytes Supply voltage of the EL1918 (PELV) 24 V (–15% / +20%) Signal voltage "0" inputs -3 V to 5 V (EN 61131-2, type 3) see chapter Characteristic curve of the inputs [} 26] Signal voltage "1"... -

Page 25: Safety Parameters

Product description Safety parameters Key data EL1918 and EL1918-2200 Lifetime [a] Prooftest Interval [a] not required 3.00 E-09 4.90 E-05 MTTF High High Performance level PL e Category Classification element Type B 1. Special proof tests are not required during the entire service life of the EtherCAT Terminal. -

Page 26: Characteristic Curve Of The Inputs

Product description Characteristic curve of the inputs The characteristic curve of the inputs is similar to type 3 according to EN 61131-2. Fig. 5: Characteristic curve of the inputs Version: 2.0.0 EL1918 and EL1918-2200... -

Page 27: Dimensions

Product description Dimensions Fig. 6: EL1918 dimensions Width: 12 mm (side-by-side installation) Height: 100 mm Depth: 68 mm EL1918 and EL1918-2200 Version: 2.0.0... -

Page 28: Operation

Please ensure that the digital TwinSAFE components are only transported and stored under the specified environmental conditions (see technical data). 5.2.3 Mechanical installation WARNING Risk of injury! Bring the bus system into a safe, de-energized state before starting installation, disassembly or wiring of the devices! Version: 2.0.0 EL1918 and EL1918-2200... -

Page 29: Fig. 7 Spring Contacts Of Beckhoff I/O Components

• Each bus station must be terminated on the right side with the EL9011 or EL9012 end cap to ensure the protection class and ESD protection. Fig. 7: Spring contacts of Beckhoff I/O components 5.2.3.2 Control cabinet / terminal box The TwinSAFE terminals must be installed in a control cabinet or terminal box with IP54 protection class according to IEC 60529 as a minimum. -

Page 30: Fig. 8 Installation Position And Minimum Distances

The key parameter is always the maximum permitted internally measured temperature of 110°C, above which the TwinSAFE components switch to safe state and report an error. The internal temperature can be read from the TwinSAFE components via CoE. Version: 2.0.0 EL1918 and EL1918-2200... - Page 31 EtherCAT Coupler or the power supply terminal with high E-bus load. The additional external heating of the TwinSAFE terminals by the adjacent power supply units increases the internal terminal temperature, which can lead to the maximum permissible temperature being exceeded. This leads to the diagnosis message "Overtemperature". EL1918 and EL1918-2200 Version: 2.0.0...

-

Page 32: Fig. 9 Thermally Unfavorable Arrangement Of The Twinsafe Terminals

The following arrangement is thermally optimized, as terminals with low current consumption and therefore low waste heat are attached between the EtherCAT Coupler/power supply terminal and terminals with higher waste heat. Fig. 10: Thermally favorable arrangement of the TwinSAFE terminals Version: 2.0.0 EL1918 and EL1918-2200... -

Page 33: Fig. 11 Installation On The Mounting Rail

When installing the components, make sure that the locking mechanism doesn't come into conflict with the fixing bolts of the mounting rail. For fastening mounting rails with a height of 7.5 mm under the terminals and couplers, use flat fastening components such as countersunk head screws or blind rivets. EL1918 and EL1918-2200 Version: 2.0.0... -

Page 34: Electrical Installation

(e.g. analog Bus Terminals or digital 4-channel Bus Terminals) do not or not fully loop through the power contacts. Potential supply terminals (EL91xx, EL92xx) interrupt the power contacts and thus represent the start of a new supply rail. Version: 2.0.0 EL1918 and EL1918-2200... -

Page 35: Fig. 13 Pe Power Contact

The PE power contact must not be used for other potentials! 5.2.4.2 Overvoltage protection If protection against overvoltage is necessary in your plant, provide a surge filter for the voltage supply to the Bus Terminal blocks and the TwinSAFE terminals. EL1918 and EL1918-2200 Version: 2.0.0... -

Page 36: Fig. 14 Connection Of A Cable To A Terminal Point

The permissible conductor cross-sections can be taken from the following table. Wire cross-section (solid) 0.08 ... 1.5 mm Wire cross-section (stranded wire) 0.25 ... 1.5 mm Wire cross-section (core wire with ferrule) 0.14 ... 0.75 mm Strip length 8 ... 9 mm Version: 2.0.0 EL1918 and EL1918-2200... -

Page 37: Fig. 15 El1918 Connection

Operation 5.2.4.4 Connection Fig. 15: EL1918 connection Terminal point Input Signal Input 1+ (clock output) Input 1- (safe input) Input 3+ (clock output) Input 3- (safe input) Input 5+ (clock output) Input 5- (safe input) Input 7+ (clock output) Input 7- (safe input) -

Page 38: Fig. 16 Cable Routing

The common routing of signals together with other clocked signals in a common cable also reduces the maximum propagation, since crosstalk of the signals can occur over long cable lengths and cause diagnostic messages. Version: 2.0.0 EL1918 and EL1918-2200... -

Page 39: Configuration Of The Terminal In Twincat

See TwinCAT automation software documentation. 5.3.3 Adding an EL1918 An EL1918 is added in exactly the same way as any other Beckhoff EtherCAT Terminal. Open TwinSAFE Terminals item in the list and select the EL1918. Fig. 17: Adding an EL1918 EL1918 and EL1918-2200... -

Page 40: Address Settings On Twinsafe Terminals With 1023 Possible Addresses

TwinSAFE terminal. TwinSAFE addresses between 1 and 1023 are available. DIP switch Address 1023 WARNING TwinSAFE address Each TwinSAFE address may only be used once within a network / a configuration! The address 0 is not a valid TwinSAFE address! Version: 2.0.0 EL1918 and EL1918-2200... -

Page 41: Alias Devices

The alias devices are created in the safety project when the dialog is closed via OK. Alternatively, the user can create the alias devices individually. To this end select Add and New item from the context menu, followed by the required device. EL1918 and EL1918-2200 Version: 2.0.0... -

Page 42: El1918 Parameters In Twincat

Fig. 21: Creating alias devices by the user 5.3.6 EL1918 parameters in TwinCAT After creating the alias device, it can be parameterized according to the user specifications. The FSoE address is set under the Linking tab, and the link to the physical device is created. -

Page 43: Fig. 23 Connection Tab Of The Alias Device

Fig. 23: Connection tab of the alias device The Safety Parameters tab contains the parameters of the EL1918 to be set. The parameters are set separately for each input. Objects 0x8000 and 0x8001 are available for input 1. For all other inputs, the CoE index is increased by 10 hex each, so that objects 0x8070 and 0x8071 are available for input 8. -

Page 44: Process Image Of The El1918

0x0002 / 0.1 ms Input filter for the test pulse signal 5.3.7 Process image of the EL1918 The process image of the EL1918 consists of 7 bytes process data in the input and 6 bytes process data in the output. Fig. 25: Process image of the EL1918 The assignment of the individual signals in the safe data is listed in the following table. -

Page 45: El1918: Using The Integrated Twinsafe Logic Functions

Information on creating a safety user program can be found in the documentation for the EL6910 (see References). The default project, so that the EL1918 once again behaves as a safe input terminal, can be reactivated by deleting the safety-related user program from the TwinSAFE component. To do this, select the entry Safe Logic, Mapping and Parameter Data in the dialog for deleting the project. -

Page 46: Twinsafe Reaction Times

NOTE Project development TwinCAT 3.1 Build 4022.25 or newer is required to use the internal logic functions. If the EL1918 is used as TwinSAFE slave with the default project, at least an EL6910, EK1960 or newer logic component is required as TwinSAFE master. -

Page 47: Fig. 28 Worst-Case Reaction Time

This error is detected at the output following the expiry of the watchdog time and leads to the switch-off. This results in the following equation for the worst-case reaction: ReactionTime Comm Comm Actuator with, for example EL1918 and EL1918-2200 Version: 2.0.0... - Page 48 Operation ReactionTime Version: 2.0.0 EL1918 and EL1918-2200...

-

Page 49: Diagnosis

Diag 3 Global fault or global shutdown No global fault or global (red) on µC1 shutdown on µC1 Diag 4 Global fault or global shutdown No global fault or global (red) on µC2 shutdown on µC2 EL1918 and EL1918-2200 Version: 2.0.0... -

Page 50: Flash Code Display

Both the control entries and the history itself can be found in the CoE object 0x10F3. The entry Newest Message (0x10F3:02) contains the subindex of 0x10F3, which contains the latest diagnostic message, e.g. 0x06 for diagnostic message 1. Version: 2.0.0 EL1918 and EL1918-2200... - Page 51 Dynamic parameters in the diagnostic messages Type Data type Description Flags parameter 1 UINT16 Describes the type of parameter 1 Bits 12 to 15 = Bits 0 to 11 = data type of parameter 1 EL1918 and EL1918-2200 Version: 2.0.0...

-

Page 52: Fig. 30 Esi/Xml Message Text

The sending of emergency messages to the EtherCAT master is activated by adding the CoE object 0x10F3:05 to the startup list (Transition IP, value 0x0001). If new diagnostic messages arrive, they are entered in object 0x10F3 and additionally sent by emergency to the EtherCAT master. Fig. 31: Startup list Version: 2.0.0 EL1918 and EL1918-2200... -

Page 53: Diag History Tab

Messages with the Info status are not saved in the diag history • disable Warnings Messages with the Warning status are not saved in the diag history • disable Errors Messages with the Error status are not saved in the diag history EL1918 and EL1918-2200 Version: 2.0.0... -

Page 54: Maintenance

If the TwinSAFE component was subjected to unacceptable soiling it may no longer be operated! WARNING Have soiled terminals checked! Cleaning of the TwinSAFE component by the user is not permitted! Please send soiled terminals to the manufacturer for inspection and cleaning! Version: 2.0.0 EL1918 and EL1918-2200... -

Page 55: Service Life

YY: Year of manufacture Year: 2011 SW: Software version Software version: 05 HW: Hardware version Hardware version: 00 In addition the TwinSAFE terminals bear a unique serial number. 00000000 17110500 Fig. 34: Unique serial number of a TwinSAFE terminal EL1918 and EL1918-2200 Version: 2.0.0... -

Page 56: Maintenance And Cleaning

Cleaning by the manufacturer only Do not operate the TwinSAFE component if it is impermissibly dirty according to protection class IP20. Send impermissibly dirty TwinSAFE components to the manufacturer for cleaning. TwinSAFE components are basically maintenance-free. Version: 2.0.0 EL1918 and EL1918-2200... -

Page 57: Decommissioning

In accordance with the WEEE-2012/19/EU directives, you can return used devices and accessories for professional disposal. The transport costs are borne by the sender. Send the used devices with the note "For disposal" to: Beckhoff Automation GmbH & Co. KG Gebäude „Service“ Stahlstraße 31... -

Page 58: Appendix

If this data is confidential, the scrapping of the product after usage is recommended to protect this data. Version: 2.0.0 EL1918 and EL1918-2200... -

Page 59: Focus Of Certificates

(ELxxxx-abcd). This is applicable for all components like EtherCAT Terminals, EtherCAT Boxes, EtherCAT plug-in modules and Bus Terminals. If you regard the example EL1918 in the picture, the certificate is valid for both the EL1918 and the available variant EL1918-2200. -

Page 60: Certificates

Appendix Certificates Fig. 35: EL1918 EC Declaration of Conformity Version: 2.0.0 EL1918 and EL1918-2200... - Page 61 Slot and key system and screwless (spring-loaded) connection system ........Fig. 2 Bus Coupler (EtherCAT) ......................Fig. 3 Overview of EtherCAT Terminals....................Fig. 4 EL1918 – TwinSAFE Terminal with 8 fail-safe inputs ..............Fig. 5 Characteristic curve of the inputs....................Fig. 6 EL1918 dimensions........................Fig. 7 Spring contacts of Beckhoff I/O components ................

- Page 63 More Information: www.beckhoff.com/EL1918 Beckhoff Automation GmbH & Co. KG Hülshorstweg 20 33415 Verl Germany Phone: +49 5246 9630 info@beckhoff.com www.beckhoff.com...

Need help?

Do you have a question about the EL1918 and is the answer not in the manual?

Questions and answers