Summary of Contents for Viega 8326.65

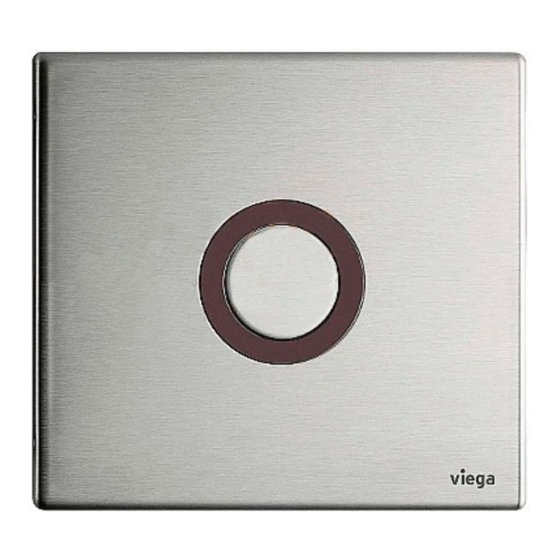

- Page 1 Instructions for Use Visign for Public equipment set for urinal flushing system Model Year built (from) 8326.65 12/2014...

-

Page 2: Table Of Contents

3.2.5 Connecting external sensors 3.3 Commissioning 3.3.1 Setting the infrared sensor 3.3.2 Setting the flush 3.3.3 Setting the Viega Hygiene function 3.4 Faults, faults and remedy 3.5 Care and maintenance 3.5.1 Care tips 3.5.2 Cleaning cartridge valve 3.6 Disposal Visign for Public equipment set... -

Page 3: About These Instructions For Use

This restriction does not extend to possible operating instructions. The installation of Viega products must take place in accordance with the general rules of engineering and the Viega instructions for use. -

Page 4: About This Translated Version

About these instructions for use This symbol gives additional information and hints. About this translated version This instruction for use contains important information about the choice of product or system, assembly and commissioning as well as intended use and, if required, maintenance measures. The information about the products, their properties and application technology are based on the current standards in Europe (e.g. -

Page 5: Product Information

Areas of application The equipment set is intended for the contact-free actuation of flushes in urinals. Physical environmental influences can impair the control function. The Viega Service Center will answer any further ques‐ tions on this subject. Visign for Public equipment set... -

Page 6: Maintenance

Product information Viega Hygiene function The Viega Hygiene function actuates a flush after 24 hours without use to prevent stagnation in the potable water pipelines. 2.3.2 Maintenance The cartridge valve should be cleaned once a year to ensure fault-free operation. See Ä... - Page 7 Product information Operating voltage Primary 100–240 V AC, 50–60 Hz, 180 mA Secondary 6 V DC/SELV Magnetic coil Flow pressure 0.05–0.5 MPa (0.5–5 bar) Calculated flow 0.3 l/s Flush flow, see Ä ‘Regulations 0.3–0.7 l/s from section: Technical data’ on page 5 Noise class, see Ä...

-

Page 8: Operating Mode

Product information 2.4.3 Operating mode Infrared actuation Flush actuation takes place without contact via the infrared sensor on the flush plate. The flush volume can be set in five stages. In order to actuate a flush, a person must be within the detection area of the infrared sensor for at least 8 seconds. -

Page 9: System Expansions

Stagnation can lead to the build up of germs (e.g. legionella) in potable water pipes. It is important to rinse the pipeline regularly to prevent the build up of bacteria. The Viega Hygiene function was developed for this reason. The Viega Hygiene function automatically actuates hygiene flushing after 24 hours without use. -

Page 10: Setting Options

Product information battery compartment The battery compartment model 8351.11 (article number 731 786) can also be connected as an alternative to the power pack. 2.4.5 Setting options Settings for the infrared sensor Range of the infrared sensor The following settings are possible: Close range, so that the flush cannot be inadvertently actuated. - Page 11 Product information The flush duration of the hygiene flush can be set in 5 steps to reach the required flush volume. Visign for Public equipment set...

-

Page 12: Handling

Handling Handling Assembly information 3.1.1 Mounting conditions External sensors (optional) If external sensors are to be connected to the control, their connection cables must be laid through to the revision opening before tiling is begun. Minimum intervals The following minimum distances must be complied with to ensure the infrared sensor works perfectly: A minimum distance of 1000 mm must be maintained to the opposite walls. -

Page 13: Required Material And Tools

Handling 3.1.2 Required material and tools Tool The following tools are required for mounting: Flat-blade screwdriver Torx screwdriver (T 10) Fork spanner (size 17) Fork spanner (size 32) Assembly 3.2.1 Insert cartridge valve Requirements: the pre-wall element has been mounted the revision opening is freely accessible the tiling work is completed. -

Page 14: Mounting The Power Pack

Handling ▶ Place the cartridge valve on straight and carefully screw in (fine thread). ▶ Screw in cartridge valve (SW 32). 3.2.2 Mounting the power pack DANGER! Danger due to electrical current An electric shock can lead to burns and serious injury and even death. - Page 15 Handling ▶ Push the connection cables into the terminals and screw them down. ▶ Connect the terminals of the connection cables and power pack. ▶ Push the power pack into the revision opening. Visign for Public equipment set...

-

Page 16: Mounting The Basic Panel

Handling 3.2.3 Mounting the basic panel In the next step, the basic panel of the flush plate must be mounted. Requirements: The cartridge valve is mounted. The power pack is connected. ▶ Align basic panel horizontally and screw together. Visign for Public equipment set... -

Page 17: Mounting The Flush Plate

Handling 3.2.4 Mounting the flush plate Observation of the prescribed connection sequence is required. The power supply must always be connected last, to ensure that all of the connected components func‐ tion. ▶ Connect the cartridge valve to the control. ▶... - Page 18 Handling ▶ Screw cover plate onto the basic panel. Visign for Public equipment set...

-

Page 19: Connecting External Sensors

Handling 3.2.5 Connecting external sensors NOTICE! Damage to property due to excess voltage If you apply voltage to the connection cable for the external button, you will damage the control. Do not apply any external voltage! Requirements: On site button with closing function or potential-free contact avail‐ able Extension cable model 2241.95 available ▶... - Page 20 Handling Observe the following features during programming: Only one value can be set per programming step. The settings are retained, even if there is an interrup‐ tion in the power supply. The programming procedure can be interrupted without changing the settings by covering the infrared sensor until the flashing signal has stopped for more than 2 seconds.

-

Page 21: Setting The Flush

Handling 3.3.2 Setting the flush Programming the settings Using the guide values from the table below, you can determine the flush volume on the basis of flow pressure and flush duration: Flow flush duration flush duration flush duration flush duration flush duration pres‐... -

Page 22: Setting The Viega Hygiene Function

Handling 3.3.3 Setting the Viega Hygiene function Programming the settings You can define the hygiene flush volume on the basis of the flow pres‐ sure and flush duration using the values in the table: Flow Flush duration Flush duration Flush duration... -

Page 23: Faults, Faults And Remedy

Handling Faults, faults and remedy Error Cause Remedy Urinal does not flush No supply voltage check plug connections Shut-off valve closed Open shut-off valve Sensor field dirty or damaged Clean cover plate, if necessary, replace Ä Chapter 3.5.1 ‘Care tips’ on page 24 Cartridge valve dirty or damaged Clean cartridge valve, if necessary,... -

Page 24: Care And Maintenance

Handling Care and maintenance 3.5.1 Care tips Normal soap or a mild cleaning agent can be used for regular care and prevention of lime scale on the flush plate. Under no circumstances should scouring agent or scratching objects be used. Strong stains can be removed using typical household cleaner. - Page 25 Handling ▶ Close shut-off. ▶ Disconnect cartridge valve and power supply from the control. ▶ Unscrew cartridge valve. ▶ Rinse cartridge valve under running water. Remove coarse dirt with a soft brush. Visign for Public equipment set...

- Page 26 Handling ▶ Place the cartridge valve on straight and carefully screw in (fine thread). ▶ Screw in cartridge valve (SW 32). ▶ Connect the cartridge valve to the control. ▶ Connect the power pack to the control. ▷ The infrared sensor is calibrated for approx. 10 seconds. While calibrating, ensure you are stood to the side of the panel so that you are not in the sensor’s detection area.

-

Page 27: Disposal

Handling ▶ Screw cover plate onto the basic panel. Disposal Separate the product and packaging materials (e. g. paper, metal, plastic or non-ferrous metals) and dispose of in accordance with valid national legal requirements. Visign for Public equipment set... - Page 28 Viega GmbH & Co. KG service-technik@viega.de viega.com INT • 2022-09 • VPN220324...

Need help?

Do you have a question about the 8326.65 and is the answer not in the manual?

Questions and answers