Summary of Contents for Bosch rexroth IH04E

- Page 1 Assembly instructions Press module for die cushion Type IH04E RE 63129-MON, Edition: 09.2022, Replaces: -, EN...

- Page 2 It must be remembered that our products are subject to a natural process of wear and aging. © All rights are reserved to Bosch Rexroth AG, also regarding any disposal, exploitation, reproduction, editing, distribution, as well as in the event of applications for industrial property rights.

-

Page 3: Table Of Contents

6.3.6 Protection class .................. 25 6.3.7 Dimensioning of nozzles .143, .148 and .181 ........... 25 6.3.8 Piping between cylinder piston side and port X1 ........ 25 6.3.9 Using the connection port DB .............. 25 6.3.10 Interaction with other functions ............... 25 RE 63129-MON, Edition 09.2022, Bosch Rexroth AG... - Page 4 Performing tests .................. 39 Disposal ����������������������������������������������������������������������������������������������� 40 Environmental protection ................. 40 Return to Bosch Rexroth AG .............. 40 Packaging .................... 40 Materials used .................. 40 Recycling .................... 41 Troubleshooting ����������������������������������������������������������������������������������� 42 How to proceed for troubleshooting ............ 42 Technical data �������������������������������������������������������������������������������������� 44 Alphabetical index ������������������������������������������������������������������������������� 45 Bosch Rexroth AG, Edition 09.2022, RE 63129-MON...

-

Page 5: About This Documentation

Directional spool valves, pilot-operated, with hydraulic or electro-hydraulic 24751 Data sheet actuation, type WEH and WH The press module type IH04E is a system component. ▶ Also observe the instructions for the other system components and the system manufacturer’s documentation for the overall machine/system. RE 63129-MON, Edition 09.2022, Bosch Rexroth AG... -

Page 6: Representation Of Information

Indicates a dangerous situation which may cause death or WARNING severe injury if not avoided. Indicates a dangerous situation which may cause minor or CAUTION medium (personal) injury if not avoided. Damage to property: The product or the environment NOTICE could be damaged. Bosch Rexroth AG, Edition 09.2022, RE 63129-MON... - Page 7 The following abbreviations are used in this documentation: Table 4: Abbreviations Abbreviation Meaning Pressure relief valve Rexroth document in the English language REXXXXX-B Rexroth operating instructions in English language REXXXXX-MON Rexroth assembly instructions in English language RE 63129-MON, Edition 09.2022, Bosch Rexroth AG...

-

Page 8: About This Chapter

• in accordance with the specified performance limits according to the system-specific circuit diagram and according to data sheet 63129 • using in the original state (apart from system-specific settings) and/or without damage The press module type IH04E is technical equipment and not intended for private use. Bosch Rexroth AG, Edition 09.2022, RE 63129-MON... -

Page 9: Intended Use

• Single stroke: manual feed and sampling • Automatic mode: manual feed and sampling • Automatic mode: automatic feed and sampling 2�2�2 Limits of use ▶ Observe the operating conditions and performance limits specified in data sheet 63129. RE 63129-MON, Edition 09.2022, Bosch Rexroth AG... -

Page 10: Improper Use

• Use of the press module type IH04E under aggressive oder corrosive environmental conditions Bosch Rexroth AG does not assume any liability for damage caused by improper use. The user assumes responsibility for all risks surrounding improper use. 2�4 Qualification of personnel The activities described in this documentation require basic knowledge of mechanics and hydraulics as well as knowledge of the appropriate technical terms. -

Page 11: General Safety Instructions

• ejection of machine components Pay attention to the main hazard zones specified in par. 4 of EN ISO 16092 and EN 289 standards, such as: • die area with moving parts • mechanical handling devices RE 63129-MON, Edition 09.2022, Bosch Rexroth AG... -

Page 12: Product- And Technology-Dependent Safety Instructions

▶ Do not use the press module type IH04E in areas with open fire (e.g. ignition sources ...) and only at a sufficient distance to hot heat sources. ▶ When dealing with hydraulic fluids, you must implicitly observe the information of the hydraulic fluid manufacturer. Bosch Rexroth AG, Edition 09.2022, RE 63129-MON... - Page 13 ▶ Allow the valves to cool down sufficiently before touching them. ▶ Observe the protective measures of the system manufacturer. ▶ If necessary, attach protective covers. RE 63129-MON, Edition 09.2022, Bosch Rexroth AG...

- Page 14 Risk of injury! ▶ Comply with the cleanliness classes required in the relevant data sheet. ▶ If necessary, flush the hydraulic system for commissioning. Bosch Rexroth AG, Edition 09.2022, RE 63129-MON...

-

Page 15: Personal Protective Equipment

• Effects of an emergency stop, how to free a person who has become entrapped in the die area, in particular as a result of bypassing or misuse of the safety equipment or after an emergency stop has been triggered, see EN 289, par. 7.2.3 RE 63129-MON, Edition 09.2022, Bosch Rexroth AG... -

Page 16: General Information On Damage To Property And Damage To Product

▶ Check the compatibility of the various hydraulic fluids and their compatibility with the components and seals. Mixing of hydraulic fluids may occur for example due to hydraulic fluid residues in a component. Bosch Rexroth AG, Edition 09.2022, RE 63129-MON... - Page 17 ▶ Before installation works, separate the device from the mains or from the voltage source or de-energize it. ▶ Do not plug in or pull off the electric plug-in connector as long as the voltage supply is activated. RE 63129-MON, Edition 09.2022, Bosch Rexroth AG...

-

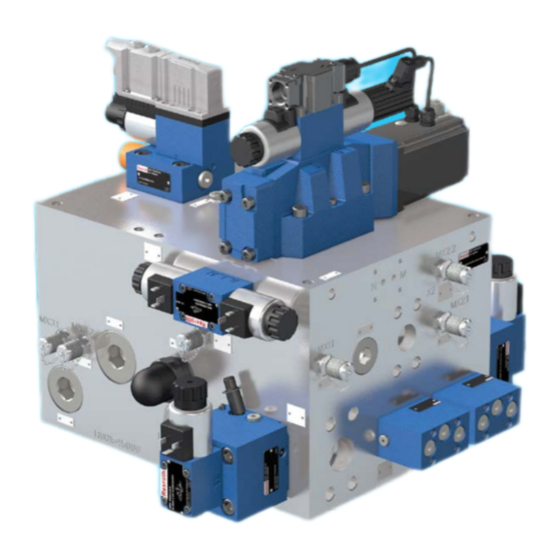

Page 18: Scope Of Delivery

For further information on the applicable documentation, see chapter 1.2 "Required and additional documentation". The warranty only applies to the delivered configuration. The claim to warranty expires if the product is assembled, commissioned and operated incorrectly, not used as intended and/or handled improperly. Bosch Rexroth AG, Edition 09.2022, RE 63129-MON... - Page 19 – performance level validated to EN ISO 13849-2:2012 • Optional attached and/or separate extension module .105 • Attached extension modules .230 and .270 .110 .230 .105 .270 .100 Fig. 1: Main components of the press module type IH04E RE 63129-MON, Edition 09.2022, Bosch Rexroth AG...

-

Page 20: Functional Safety For Hydraulic Presses

.130 to .132 Basic module 100 .170 .151 .171 .172 .180 .181 .150 Extension module 105 .148 .140 to .142 Basic module 100 + .162 extension module 105 .145 to .147 .143 Fig. 2: Example: IH04ES-10/16G2-NEND-RTE220E-NN-G24 Bosch Rexroth AG, Edition 09.2022, RE 63129-MON... - Page 21 (at least 10% above operating pressure).* additional documentation"; *only safety-relevant for dangerous downward movement; In the condition as supplied, the valve is set to 350 bar and sealed. Changes may only be made by accordingly qualified personnel. RE 63129-MON, Edition 09.2022, Bosch Rexroth AG...

-

Page 22: Product Identification

Fig. 3: Schematic illustration of a name plate 1 Manufacturer's logo 5 Area / works number 2 Material number 6 Date of production 3 Type designation 7 Designation of origin 4 Serial number 8 Customer material number Bosch Rexroth AG, Edition 09.2022, RE 63129-MON... -

Page 23: System Design And Installation

– Assemble the press module type IH04E as close to the cylinder as possible. – Position or house the press module type IH04E in such a way that hazards due to liquids spraying out under high pressure are avoided. Ensure that the X1 line is as short as possible. RE 63129-MON, Edition 09.2022, Bosch Rexroth AG... -

Page 24: Limitation Of The Operating Pressure

▶ Ensure that leakage through the safety-relevant valves .140, .142 and .170, when in a safe (rest) position, does not cause any motion faster than 1 mm/s. – Design the system accordingly depending on cylinder dimensions, own weight and system pressure. Bosch Rexroth AG, Edition 09.2022, RE 63129-MON... -

Page 25: Reaction Time (Response Time) Of Stop Function

EN ISO 16092-3, paragraph 5.2.3.3 and the piping of the external valves meets the requirements of EN ISO 16092-1, paragraph 5.2.1.7, e.g. fixed piping without cutting-ring connectors and hoses. 6�3�10 Interaction with other functions ▶ Consider possible interactions with other functions. RE 63129-MON, Edition 09.2022, Bosch Rexroth AG... -

Page 26: Electrical Control System

▶ Ensure that the solenoids of the valves .142, .147 and .170 are safely separated from the energy supply during the emergency stop. In this case, Bosch Rexroth recommends that all other valve solenoids be de-energized. In case of loss in the ▶... -

Page 27: Safety Signals

▶ Do not continue to operate the press until all faults have been corrected. ▶ Ensure that all safety-relevant valves in the standstill are in the safe position and that these are confirmed by the corresponding limit switch signals. RE 63129-MON, Edition 09.2022, Bosch Rexroth AG... -

Page 28: Malfunction Caused By Safety-Relevant Faults

5 mm/s. Slow start-up of the cylinder when safety-relevant valves are • Leakage at valves .144, .149 in the safe position. Bosch Rexroth AG, Edition 09.2022, RE 63129-MON... -

Page 29: Commissioning

▶ Ensure that the retraction of the cylinder does not exceed 1 mm/s in normal operation and 5 mm/s in the event of component failure. ▶ Always keep the time spent in the danger zone as short as possible. ▶ Always use a mechanical restraint device for all work. RE 63129-MON, Edition 09.2022, Bosch Rexroth AG... - Page 30 08012, for reliability characteristics MTTFD for functional safety according to EN ISO 13849, see chapter 1.2 "Required and additional documentation". Bosch Rexroth AG, Edition 09.2022, RE 63129-MON...

-

Page 31: First Commissioning

IH04E can exit. Mechanical damage due to inadmissibly high acceleration of the hydraulic fluid and the valve spools is thus avoided and the life cycle of the press module type IH04E is increased. RE 63129-MON, Edition 09.2022, Bosch Rexroth AG... -

Page 32: Commissioning Of The Basic Module .100 And Extension Module .105

– Then update the changed nozzle fitting in the technical documentation of the machine (hydraulic circuit diagram/parts list). The load pressure is the sum of the weight of the die cushion and the lower tool relative to the effective piston chamber surface. Bosch Rexroth AG, Edition 09.2022, RE 63129-MON... - Page 33 ▶ Start the pump(s), which are now running in depressurized circulation via the cartridge valve with pressure function .130. ▶ Adjust the pump(s) so that the maximum operating pressure can be achieved, depending on the type of pump used and with minimum flow rate. RE 63129-MON, Edition 09.2022, Bosch Rexroth AG...

-

Page 34: Setting The Pressure Limitation Against Pressure Intensification .150/.151

(pilot valve) .142 must be de-energized. The safe reduced velocity (<10 mm/s) is controlled by the valves .170 (Y17a) and .145/.147 (Y147), in order to enable the safety function "safe reduced velocity" up to PLd/category 3 according to EN ISO 13849. Bosch Rexroth AG, Edition 09.2022, RE 63129-MON... - Page 35 ▶ Remove the pressure gauge from the measuring points MX1 and MX2 and reassemble the protective caps. – Ensure that the measuring points MX1 and MX2 are closed without leaks. ▶ Select the operating mode "OFF". RE 63129-MON, Edition 09.2022, Bosch Rexroth AG...

-

Page 36: Commissioning Of Extension Modules .230 And .270

Denomination Function Features Sandwich plate Rapid traverse with regenerative circuit Directional valve Regenerative circuit On/Off Pilot-operated, see data sheet 24751. Pressure relief valve Protection against overpressure See data sheet 25402. .230 .235 .231 Fig. 4: Extension module .230 with regenerative circuit Bosch Rexroth AG, Edition 09.2022, RE 63129-MON... - Page 37 ▶ Select the operating mode "OFF". ▶ Remove the pressure gauge from the measuring point MX2 and assemble the protective cap again. – Ensure that the measuring point MX2 is closed without leaks. RE 63129-MON, Edition 09.2022, Bosch Rexroth AG...

-

Page 38: Extension Module .270 With Load Sensing

In order to use the load sensing function, you need a pump control with flow controller for your machine/system. ▶ Check the exact pump type. ▶ Please refer to the relevant data sheet for the correct setting of the pump. Bosch Rexroth AG, Edition 09.2022, RE 63129-MON... -

Page 39: Performing Tests

Also check the following locations for leakage: • Cylinder seals or piping/fittings • Pressure relief valves .150/.151 • Threaded coupling MX1 • Crack in the manifold RE 63129-MON, Edition 09.2022, Bosch Rexroth AG... -

Page 40: Disposal

Due to ecological reasons, disposable packaging should not be used for returning products to Bosch Rexroth. 8�4 Materials used Hydraulic components from Bosch Rexroth do not contain any hazardous materials that could be released during intended use. Normally, no negative effects on human beings and on the environment are to be expected. -

Page 41: Recycling

Due to the high metal content, hydraulic products can mostly be recycled. In order to achieve an ideal metal recovery, disassembly into individual assemblies is required. The metals contained in electric and electronic assemblies can be recovered by means of special separation procedures as well. RE 63129-MON, Edition 09.2022, Bosch Rexroth AG... -

Page 42: Troubleshooting

▶ If you cannot remedy the error, please contact one of the contact addresses you find at www.boschrexroth.com Bosch Rexroth AG Service Bgm.-Dr.-Nebel-Str. 8 97816 Lohr am Main Phone +49 (0) 9352 - 40 - 50 60 service@boschrexroth.de Bosch Rexroth AG, Edition 09.2022, RE 63129-MON... - Page 43 • Nozzle .171 or .172 too large. • Nozzles set with incorrect own weight (closing/extending with minimum load pressure and opening/retraction with maximum load pressure). In case of faults in individual components, please consult the documentation of the respective component. RE 63129-MON, Edition 09.2022, Bosch Rexroth AG...

-

Page 44: Technical Data

The admissible technical data of the respective press module type IH04E can be found in the respective data sheet, see chapter 1.2 "Required and additional documentation". The data sheet can be found on the Internet at www.boschrexroth.com/mediadirectory For further information, refer to the online product catalog www.boschrexroth.com Bosch Rexroth AG, Edition 09.2022, RE 63129-MON... -

Page 45: Alphabetical Index

- Packaging ......... 40 piston side and port X1 .... 25 - Recycling ........ 41 Prevention of access in the - Return to Bosch Rexroth AG .. 40 danger zone ........ 24 Product description .... 19 Product identification .... 22 Electrical control system .... 26 Protection class ... - Page 46 - Avoidance of unintended start-up from the rest position .... 20 - Safe reduced velocity ... 20, 26, 34 Using the connection port DB .. 25 - Stopping of the dangerous closing movement .... 20 Bosch Rexroth AG, Edition 09.2022, RE 63129-MON...

- Page 47 Alphabetical index | Press module Type IH04E 47/48 RE 63129-MON, Edition 09.2022, Bosch Rexroth AG...

- Page 48 Bosch Rexroth AG Industrial Hydraulics Zum Eisengießer 1 97816 Lohr a. Main Germany Tel. +49 (0) 9352/40 30 20 my.support@boschrexroth.com www.boschrexroth.com Subject to change without notice Printed in Germany RE 63129-MON/09.2022...

Need help?

Do you have a question about the rexroth IH04E and is the answer not in the manual?

Questions and answers