Summary of Contents for Danfoss D1 Series

- Page 1 Service Manual D1 High Power Open Circuit Pumps Size 65/130/145/193/260 www.danfoss.com...

- Page 2 0104 October 2017 Added Size 130 0103 June 2016 Added Size 260 0102 April 2016 Converted to Danfoss layout - DITA CMS 0101 July 2015 Added 145 cc information January 2014 First edition L1527453 | AX00000292en-CN0201 © Danfoss | July 2019...

-

Page 3: Table Of Contents

Secure the unit..................................... 5 Safety precautions....................................5 Unintended Machine Movement............................5 Flammable Cleaning Solvents..............................6 Fluid Under Pressure..................................6 Personal Safety.....................................6 Symbols used in Danfoss literature............................6 Design........................................6 Cross-section view................................... 8 Operation NPNN (Pressure Compensated Control)..........................9 NPSN (Pressure Compensated Control + Load Sensing Control).................11 NPNR (Pressure Compensated Control + Remote Pressure Compensated Control).......... - Page 4 Displacement limiter screws installation......................... 54 Plug and fitting installation................................56 193 TPE2 control..................................56 260 TPE2 control..................................57 130/145 TPSN control................................58 Plugs and fasteners..................................59 Fastener and torque chart..............................59 Plug size and torque chart..............................60 L1527453 | AX00000292en-CN0201 © Danfoss | July 2019...

-

Page 5: Overview

A worldwide Global Service Partner Network is available for major repairs. Major repairs require the removal of the unit’s endcap, which voids the warranty unless done by a Global Service Partner. Danfoss Global Service Partners are trained by the factory and certified on a regular basis. You can locate your nearest Global Service Partner using the distributor locator at www.danfoss.com. -

Page 6: Flammable Cleaning Solvents

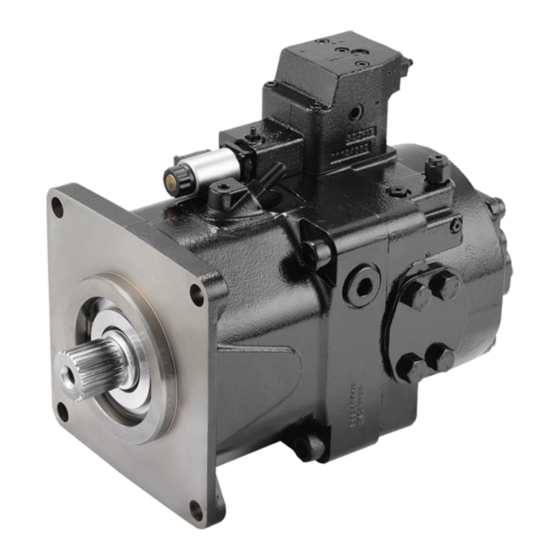

The legend above defines each symbol and explains its purpose. D1 pumps design Danfoss D1 high power open circuit piston pumps convert input torque into hydraulic power. Rotational force is transmitted through the input shaft to the cylinder block. The input shaft is supported by roller L1527453 | AX00000292en-CN0201 ©... - Page 7 The pump control, by varying the pressure at the servo piston, controls the displacement of fluid in the system circuit. L1527453 | AX00000292en-CN0201 | 7 © Danfoss | July 2019...

-

Page 8: Cross-Section View

9. Charge pump 10. Servo piston 11. Cylinder block 12. Maximum displacement limiter 13. Piston 14. Swashplate 15. Swashplate Bearing 16. Input shaft Some internal parts may be different depending on the pump size. L1527453 | AX00000292en-CN0201 © Danfoss | July 2019... -

Page 9: Operation

P setting. P characteristic Q max Pressure It is recommended that a relief valve be installed in the pump outlet for additional system protection. L1527453 | AX00000292en-CN0201 | 9 © Danfoss | July 2019... - Page 10 Pressure Compensated (PC) Control Response/Recovery Times* @80°C, 350 bar, 1500rpm Frame Size Response (msec) Recovery (msec) 130cc 145cc 193cc 260cc Tested at 1800rpm Values may vary depending on application conditions. For more information, please contact Danfoss Power Solutions. L1527453 | AX00000292en-CN0201 10 | © Danfoss | July 2019...

-

Page 11: Npsn (Pressure Compensated Control + Load Sensing Control)

LS spool, the pump adjusts stroke to whatever position necessary to maintain system pressure at the LS setting. The pump is now in low pressure standby mode. (1) is not in the scope of supply. L1527453 | AX00000292en-CN0201 | 11 © Danfoss | July 2019... - Page 12 Response (msec) Recovery (msec) 130cc 145cc 193cc 260cc Tested with a LS setting of 20bar Values may vary depending on application conditions. For more information, please contact Danfoss Power Solutions L1527453 | AX00000292en-CN0201 12 | © Danfoss | July 2019...

-

Page 13: Npnr (Pressure Compensated Control + Remote Pressure Compensated Control)

The remote PC control is a two-stage control that allows multiple PC settings. Remote PC controls are commonly used in applications requiring low and high pressure PC operation. For this control, Danfoss recommends a load sense setting of 20bar. Remote Pressure Compensated Control (R) Operation The remote PC control uses a pilot line connected to an external hydraulic valve. - Page 14 If the pump’s outlet pressure reaches the pressure setting of the pressure compensator (PC) function, the PC function will take priority and limit the pump’s maximum pressure. L1527453 | AX00000292en-CN0201 14 | © Danfoss | July 2019...

-

Page 15: Tpsn (Power Control + Pressure Compensated Control + Load Sensing Control)

= working pressure • V = displacement C = constant The precise control with a hyperbolic control characteristic, provides an optimum utilization of available power. L1527453 | AX00000292en-CN0201 | 15 © Danfoss | July 2019... - Page 16 NPSN (Pressure Compensated Control + Load Sensing Control) on page 11 TPSN Priority The Pressure Compensated Control (P) has priority over the Power Control (T), Power Control has priority over Load Sensing Control (S). L1527453 | AX00000292en-CN0201 16 | © Danfoss | July 2019...

-

Page 17: Nnes (Electric Displacement Control + Load Sensing Control)

This pressure supply can be provided from different sources, such as an additional small gear or piston pump and a relief valve, or an accumulator. If E port is not connected, remove the shuttle valve L1527453 | AX00000292en-CN0201 | 17 © Danfoss | July 2019... - Page 18 Typical operating curve Hysteresis EDC Hysteresis Input hysteresis <4.5% Output hysteresis @50% displacement <4.0% Values may vary depending on application conditions. For more information, please contact Danfoss Power Solutions Response/Recovery Response/Recovery Times @ 1500rpm (50°C) Response 0%-100% 130cc (263 bar) 260 msec...

-

Page 19: Solenoid Specification

DEUTSCH W2S Socket contact (16 and 18 AWG) DEUTSCH 0462-201-16141 Danfoss mating connector kit K29657 The mating connector is not included in the delivery contents, this can be delivered by Danfoss on request. Compatible PLUS+1 ® controllers(see below): MC012 L1301095... -

Page 20: Standard Edc Valve

Both the Electric Displacement Control (EDC) and the Load Sensing Control (LS) are used to control the pump’s displacement. The pump will output the smallest displacement when both control functions are given control instruct. L1527453 | AX00000292en-CN0201 20 | © Danfoss | July 2019... -

Page 21: Tpe2/Tpe5 (Power Control + Pressure Compensated Control + Electric Displacement Control)

NNES (Electric Displacement Control + Load Sensing Control) on page 17 TPE2/TPE5 Priority The Pressure Compensated Control (P) has priority over the Power Control (T), and the Power Control (T) has priority over Electric Displacement Control (EDC). L1527453 | AX00000292en-CN0201 | 21 © Danfoss | July 2019... -

Page 22: Npe2/Npe0 (Pressure Compensated Control + Electric Displacement Control)

Displacement Control + Load Sensing Control) on page 17. To determine if an external control pilot supply is needed, please consult your Danfoss Power Solutions representative. D1P pumps configured with an NPE2 control will come with a shuttle valve installed at the E port. D1P pumps with an NPE0 control will not include the shuttle valve. -

Page 23: Operating Parameters

Working outside of the pump's operating parameters may result in shortened life expectancy of the pump. Always work within the operating conditions of the pump application. With accurate duty cycle information, your Danfoss Power Solutions representative can assist you in calculating expected pump life. D1P fluid overview Ratings and performance data for D1 pumps are based on operating with premium hydraulic fluids containing oxidation, rust, and foam inhibitors. -

Page 24: Viscosity

SAE J183, M2C33F or G automatic transmission fluids (ATF), Dexron II (ATF) meeting Allison C-3 or Caterpillar T0‑2 requirements, and certain specialty agricultural tractor fluids. For more information on hydraulic fluid selection, see Danfoss Power Solutions publications 520L0463 Hydraulic Fluids and Lubricants, Technical Information, and 520L0465 Experience with Biodegradable Hydraulic Fluids, Technical Information. -

Page 25: Technical Specifications

(t<1s) outlet pressure allowed. If the application requires the higher inlet pressure than 5 bar [72.5psi] (up to 30 bar [435psi]), please contact.Danfoss Power Solutions. Counterclockwise (CCW) & Clockwise (CW) directions as viewed from the shaft end of the pump. -

Page 26: D1P Fluid Specifications

Intermittent = Short term t < 3min per incident. Cold start = Short term t < 3min, p ≤ 30 bar [435 psi], n ≤ 1000 min (rpm) , please contact Danfoss Power Solutions especially when the temperature is below -25 °C [-13 °F]. -

Page 27: Fluid And Filter Maintenance

Dispose of used hydraulic fluid properly. Never reuse hydraulic fluid. Change filters whenever the fluid is changed or when the filter indicator shows that it is necessary to change the filter. Replace all fluid lost during filter change. L1527453 | AX00000292en-CN0201 | 27 © Danfoss | July 2019... -

Page 28: Pressure Measurements

0-600 bar [0-8702.26 psi] gauge port Suction pressure gauge port M12x1.5 0-600 bar [0-8702.26 psi] D1P 65 port locations with TPSN control Load sensing signal port X Outlet port B Inlet port S L1527453 | AX00000292en-CN0201 28 | © Danfoss | July 2019... -

Page 29: Port Locations And Gauge Installation (130/145)

Servo piston chamber M12x1.5 6 mm 0-600 bar [0-8702.26 psi] 130/145 Port locations, Control type: TPSN S : Inlet port X : Load sensing signal port B : Outlet port P400254 L1527453 | AX00000292en-CN0201 | 29 © Danfoss | July 2019... -

Page 30: Port Locations And Gauge Instalation (193/260)

Port S : Inlet Port B : Outlet Port 193/260 Port location, Control type: TPSN X : Load Sensing Signal Port S : Inlet Port B : Outlet Port P400092 L1527453 | AX00000292en-CN0201 30 | © Danfoss | July 2019... -

Page 31: Initial Start-Up Procedures

10. Shut down the prime mover and remove the pressure gauge. Replace plug at port MB. 11. Check the fluid level in the reservoir; add clean filtered fluid if necessary. The pump is now ready for operation. L1527453 | AX00000292en-CN0201 | 31 © Danfoss | July 2019... -

Page 32: Troubleshooting

Check external relief valve. External relief valve setting below PC Adjust external relief valve according setting. to manufacturer’s recommendations. External relief valve must be set above PC setting to operate properly. L1527453 | AX00000292en-CN0201 32 | © Danfoss | July 2019... -

Page 33: Actuator Response Is Sluggish

Relief valve setting must be above PC setting to operate properly. Check external relief valve. Chattering external relief valve may Adjust or replace relief valve. cause unstable feedback to pump control. L1527453 | AX00000292en-CN0201 | 33 © Danfoss | July 2019... -

Page 34: System Operating Hot

High fluid viscosity causes high inlet Select fluid with appropriate viscosity acceptable limits. vacuum. for expected operating temperature. Caution High inlet vacuum causes cavitation which can damage internal pump components. L1527453 | AX00000292en-CN0201 34 | © Danfoss | July 2019... -

Page 35: Calculate Power Control Start Point Pressure And Corresponding Flow In Advance

Use the average value (170+320)/2=245 bar. 3. Calculate corresponding flow by using the following formula: P • Q Power [kW] = 600 • η 245 • Q 90 = 600 • (.912) Q=201 l/min L1527453 | AX00000292en-CN0201 | 35 © Danfoss | July 2019... -

Page 36: Electric Displacement Control Adjustment

The pump must be at full displacement at this point. Danfoss recommends a prime mover speed of 1500rpm (unless specified otherwise). The testing setup must be plumbed in a way so the EDC function works properly. Please refer to Electric Displacement Control (E) Operating Instruction. - Page 37 Displacement Input Current Size 130 Size 145 Size 193 Size 260 400mA+/-8 mA 67.5cc+/-5cc 67.5cc+/-5cc 92.5 cc+/-5cc 140.5 cc+/-5cc 500mA+/-8 mA 101cc+/-5cc 101cc+/-5cc 115.5 cc+/-5cc 172.5 cc+/-5cc L1527453 | AX00000292en-CN0201 | 37 © Danfoss | July 2019...

-

Page 38: Pressure Compensated Control Adjustment

LS control adjusting screw, torque the control lock nut to 21.6~24.6 N•m [191-218 lbf•in]. 4. Adjust Power control and pressure compensated control (if used). L1527453 | AX00000292en-CN0201 38 | © Danfoss | July 2019... - Page 39 5. After Step 4, slowly operate a hydraulic function that will demand approximately half flow from the pump, but keep outlet pressure below the power control pressure starting point (if Power control is used). Danfoss recommends loading the outlet pressure to 50bar. Warning Escaping hydraulic fluid under pressure can have sufficient force to penetrate your skin causing serious injury and/or infection.

- Page 40 4 mm Pressure compensated Load sensing adjustment screw control lock nut Load sensing 4 mm 13 mm lock nut 21.6 - 24.6 N·m 13 mm 21.6 - 24.6 N·m L1527453 | AX00000292en-CN0201 40 | © Danfoss | July 2019...

- Page 41 Lock Nut 13 mm Load Sensing Lock Nut 21.6 - 24.6 N·m 13 mm 21.6 - 24.6 N·m P400255 Please refer to Operation for information about the other control options. L1527453 | AX00000292en-CN0201 | 41 © Danfoss | July 2019...

-

Page 42: Displacement Limiters Adjustment

5 mm 8 mm 8 mm 17 mm 17 mm 24 mm 24 mm Nuts 43~48 N·m 43~48 N·m 180~206 N·m 180~206 N·m [380.58~424.84 lbf·in] [380.58~424.84 lbf·in] [1593.13~1823.25 lbf·in] [1593.13~1823.25 lbf·in] L1527453 | AX00000292en-CN0201 42 | © Danfoss | July 2019... -

Page 43: Minor Repairs

Shaft seal (F222) and carrier (F221) are set as one group. remove and discard group. 5. Danfoss recommends screwing in the max displacement limiter enough so to prevent internal component movement during the shaft removal. Remove shaft and front bearing assembly (E000T) after shaft seal group has been removed. -

Page 44: Shaft Installation

(F210) in housing. 5. If the pump has an impeller, reinstall it after the shaft installation is complete. F210 F221 F220 F222 F230 E000T P400617 L1527453 | AX00000292en-CN0201 44 | © Danfoss | July 2019... -

Page 45: Shaft Seal Replacement

Install seal with the cupped side toward the shaft bearing. Do not damage the seal during installation. 5. Using the appropriate snap ring pliers, install the seal retaining ring. 6. Remove the installation sleeve. F230 F220 F210 P400096 L1527453 | AX00000292en-CN0201 | 45 © Danfoss | July 2019... -

Page 46: Auxiliary Flange And Charge Pump Replacement

5. Install the drive coupling (H200) if present. 6. Install the cover (H150) with seal (H130), lubricate the seal with petroleum jelly. 7. Install the screws (H140) and torque to required torques. L1527453 | AX00000292en-CN0201 46 | © Danfoss | July 2019... - Page 47 H110 H110 H200 H100 H120 H100 H110 H120 H130 H200 H100 H150 H125 H120 H110 H130 H140 H100 H200 H120 H140 H110 H130 H100 H150 H140 H120 H130 H150 H140 L1527453 | AX00000292en-CN0201 | 47 © Danfoss | July 2019...

- Page 48 H200 H105 H120 H107 H110 H130 H130 H200 H100 H150 H150 H110 H120 H140 H130 H140 H100 H150 H120 H130 H140 H150 H140 * E3 option is only for 260. L1527453 | AX00000292en-CN0201 48 | © Danfoss | July 2019...

-

Page 49: Control (193/260)

(D180) NPNR (130-260) Gasket (D145) 5 short bolts (D175) Torque requirements Bolt Torque D175 22.5-27.5 N·m [199-243 lbf·in] D170 22.5-27.5 N·m [199-243 lbf·in] D180 22.5-27.5 N·m [199-243 lbf·in] L1527453 | AX00000292en-CN0201 | 49 © Danfoss | July 2019... - Page 50 D1 High Power Open Circuit Pumps Size 65/130/145/193/260 Minor repairs 193/260 TPE2 Control D145 22.5-27.5 N ·m · D170 D180 22.5-27.5 N ·m P400293 193/260 TPSN Control D145 D175 22.5-27.5 N. P400294 L1527453 | AX00000292en-CN0201 50 | © Danfoss | July 2019...

-

Page 51: Control (130/145)

Service Manual D1 High Power Open Circuit Pumps Size 65/130/145/193/260 Minor repairs Control (130/145) 130/145 TPSN Control D150 D140 22.5-27.5 N·m D175 P400259 L1527453 | AX00000292en-CN0201 | 51 © Danfoss | July 2019... -

Page 52: Shuttle Valve Or Plug

4. If the shuttle valve is not used, replace it with the plug (D900). The shuttle valve must also be installed in NNES and TPE2/TPE5 controls if the application requires this feature. To determine if a shuttle valve is needed, please consult with your Danfoss representative. - Page 53 G254 G255 Wrench size and torque Item Wrench size Torque G254 6mm hex 9.9-12.1 Nm G255 6mm hex 30.6-37.4 Nm D900 6mm hex 30.6-37.4 Nm D901 22mm hex 30.6-37.4 Nm L1527453 | AX00000292en-CN0201 | 53 © Danfoss | July 2019...

-

Page 54: Displacement Limiters

5 mm (screws) 17 mm 43~48 N·m [380.58~424.84 lbf·in] (nuts) 193cc 8 mm (screws), 24 mm 180~206 N·m [1593.13~1823.25 lbf·in] (nuts) 260cc 8 mm (screws), 24 mm 180~206 N·m [1593.13~1823.25 lbf·in] (nuts) L1527453 | AX00000292en-CN0201 54 | © Danfoss | July 2019... - Page 55 Service Manual D1 High Power Open Circuit Pumps Size 65/130/145/193/260 Minor repairs F120 F110 F110 F120 P400265 L1527453 | AX00000292en-CN0201 | 55 © Danfoss | July 2019...

-

Page 56: Plug And Fitting Installation

Drain port L3 (M33 x 2) 17 mm hex 68.4-83.6 Nm F150 Drain port L2 (M33 x 2) 17 mm hex 68.4-83.6 Nm G250 Servo orifice plug (M12 x 1.5) 6 mm hex 22.5-27.5 Nm L1527453 | AX00000292en-CN0201 56 | © Danfoss | July 2019... -

Page 57: 260 Tpe2 Control

Drain port L3 (M33 x 2) 17 mm hex 68.4-83.6 Nm F150 Drain port L2 (M33 x 2) 17 mm hex 68.4-83.6 Nm F160 Drain port L1 (M33 x 2) 17 mm hex 68.4-83.6 Nm L1527453 | AX00000292en-CN0201 | 57 © Danfoss | July 2019... -

Page 58: 130/145 Tpsn Control

Drain port L3 (M26 x 1.5) 12 mm hex 68.4-83.6 Nm F150 Drain port L2 (M26 x 1.5) 12 mm hex 68.4-83.6 Nm F160 Drain port L1 (M26 x 1.5) 12 mm hex 68.4-83.6 Nm L1527453 | AX00000292en-CN0201 58 | © Danfoss | July 2019... -

Page 59: Plugs And Fasteners

4 mm screw internal hex internal hex internal hex internal hex D470 T adjusting 4 mm 4 mm 4 mm 4 mm screw internal hex internal hex internal hex internal hex L1527453 | AX00000292en-CN0201 | 59 © Danfoss | July 2019... -

Page 60: Plug Size And Torque Chart

25 N·m M12X1.5 6 mm 25 N·m M12X1.5 6 mm 25 N·m M12X1.5 6 mm 25 N·m internal [221.27 internal [221.27 internal [221.27 internal [221.27 G235 lbf·in] lbf·in] lbf·in] lbf·in] L1527453 | AX00000292en-CN0201 60 | © Danfoss | July 2019... - Page 61 Phone: +86 21 3418 5200 Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to products already on order provided that such alterations can be made without subsequent changes being necessary in specifications already agreed.

Need help?

Do you have a question about the D1 Series and is the answer not in the manual?

Questions and answers