Subscribe to Our Youtube Channel

Summary of Contents for Danfoss D1P130

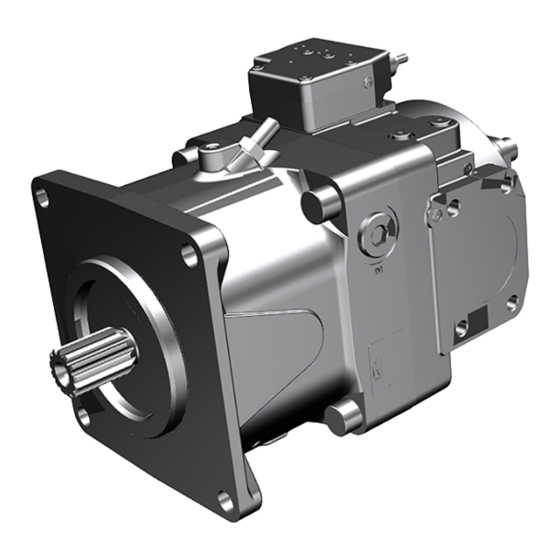

- Page 1 User Manual ATEX certified Axial piston pump, variable displacement D1P130/D1P145/193/260 www.danfoss.com...

- Page 2 User Manual ATEX certified D1P 130/145/193/260 Revision history Table of revisions Date Changed August 2021 First edition 0101 © Danfoss | August 2021 BC376161003883en-000101...

-

Page 3: Table Of Contents

ATEX certified D1P 130/145/193/260 Contents Introduction General information..................................4 Intended use...................................... 4 Marking of Danfoss D1 pumps...............................4 Production place and date of pump............................ 6 Example ATEX label - D1P................................ 6 Technical information ATEX technical specifications...............................7 T-codes and maximum surface temperature.........................7 Oil types / Operating fluids................................ -

Page 4: General Information

This identifying plate has to be maintained so that the data can be clearly read; consequently, a periodic cleaning of the plate is required. Marking of Danfoss D1 pumps The Danfoss hydraulic pumps are marked as equipment for Group II, category 2 for gas and dust environment and with ignition protection constructional safety and liquid immersion. ©... - Page 5 AN4 (temperature class T4) CE Ex II 3G Ex h IIA T5 Gc AN5 (temperature class T5) Viscosity and temperature for D1P pump on page 8 for more information about temperature classes. © Danfoss | August 2021 BC376161003883en-000101 | 5...

-

Page 6: Production Place And Date Of Pump

Examples of ATEX pump labels – Pump produced in People's republic of China 1. Manufacturer 2. Location of production 3. ATEX code 4. Material number 5. Model code, including unit and displacement 6. Production code © Danfoss | August 2021 BC376161003883en-000101... -

Page 7: Technical Information

D1P Technical Information document. Danfoss does not claim responsibility for the use of the pump in operating conditions not allowed according to the information shown in this document and the standard D1P Technical Information document. -

Page 8: Viscosity And Temperature For D1P Pump

Intermittent = Short term t < 3 min per incident. Cold start = Short term t < 3 min; p ≥ 50 bar; n ≤ 1000 min (rpm); please contact Danfoss Power Solutions especially when the temperature is below -25 °C [-13 °F]. -

Page 9: Filtering

It is necessary to keep the level of oil contamination at an acceptable level to ensure problem-free operation. The recommended maximum level of contamination in systems in the hydraulic pump is 22/20/16 (ISO 4406-1999). © Danfoss | August 2021 BC376161003883en-000101 | 9... -

Page 10: Installation, Operation And Maintenance

It is necessary to verify the perfect alignment between the pump input shaft and the counter part – the fitment between pump shaft and application’s driven shaft must be executed so that no radial or axial pre-load is generated – these extra loads reduce the bearings expected lifetime. 10 | © Danfoss | August 2021 BC376161003883en-000101... -

Page 11: Operation

6. Check to make sure the purity of the oil is greater than 22/20/16 (ISO 4406-1999) and always use a filter when replenishing the system. Warning The pump must be filled with fluid prior to any load applications. © Danfoss | August 2021 BC376161003883en-000101 | 11... -

Page 12: Start Up

The machine/system manufacturer is responsible for the proper project planning of the hydraulic system and its control. Danfoss recommends ongoing tests for optimal pump performance. 1. Regularly verify that the temperature of the ambient and the operating oil are those initially determined. - Page 13 In order to avoid mixing of different oils, when replacing the operating fluid. It is necessary to empty all the machinery and pipes, clean them carefully and clean the tank. © Danfoss | August 2021 BC376161003883en-000101 | 13...

-

Page 14: Service And Repair Of D1P Pump

Relieve pressure in the system before removing hoses, fittings, gauges, or components. Never use your hand or any other body part to check for leaks in a pressurized line. Seek medical attention immediately if you are cut by hydraulic fluid. 14 | © Danfoss | August 2021 BC376161003883en-000101... - Page 15 Phone: +86 21 2080 6201 Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to products already on order provided that such alterations can be made without subsequent changes being necessary in specifications already agreed.

Need help?

Do you have a question about the D1P130 and is the answer not in the manual?

Questions and answers