Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Danfoss Vickers PVM

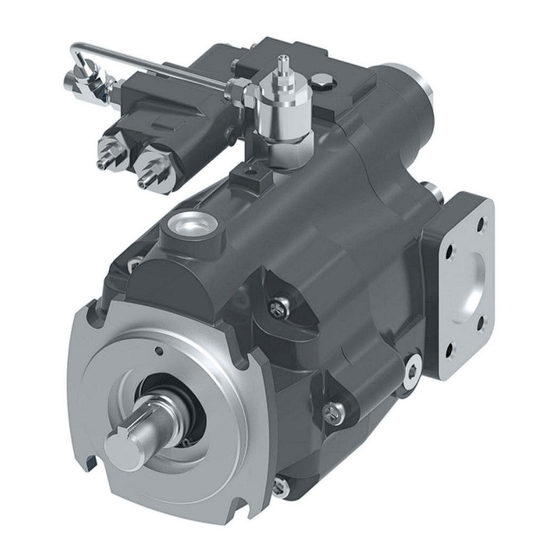

- Page 1 User Manual Vickers® by Danfoss PVM Variable Displacement Piston Pump ATEX / UKEX Certified PVM Code A & B, 18 – 141 cc ATEX Directive 2014/34/EU UKEX SI 2016 No. 1107 II 3G Ex h IIC T4 Gc X II 3G Ex h IIC T4 Gc X...

-

Page 2: Revision History

User Manual ATEX / UKEX Certified Variable Axial Piston Pumps for Industrial Applications – PVM 18 – 141 cc Revision History Table of Revisions Date Changed Feb 2024 First edition 0101 2 | Vickers by Danfoss | January 2024 BC479055194216en-000101... -

Page 3: Table Of Contents

Manufacturer Responsibility ..........................4 Product Safety ................................4 Intended Use ..................................4 Marking of Vickers by Danfoss PVM Pumps ..................... 4 Production Place and Date of Pump ........................5 Example ATEX / UKEX Label – PVM ........................5 Technical Information ATEX / UKEX Technical Specifications ........................... -

Page 4: General Information

The PVM hydraulic pumps are marked as equipment for Group II, category 3 for gas environment and with ignition protection constructional safety and liquid immersion. Temperature class/Maximum surface temperature depends on the operating conditions (ambient and fluid temperature) as well as application duty cycles. 4 | Vickers by Danfoss | January 2024 BC479055194216en-000101... -

Page 5: Production Place And Date Of Pump

Production Place and Date of Pump The production location is shown on the pump label as pictured below. The date of the pumps is not shown on the pump label; however it can be determined by contacting Danfoss and providing the serial number. - Page 6 ATEX / UKEX Certified Variable Axial Piston Pumps for Industrial Applications – PVM 18 – 141 cc Alternative PVM Black Anodized Aluminum Label For legend, see label above. Figure 2: PVM Anodized Aluminum Label Example Warning Avoid impact on the aluminum nameplate material to eliminate thermite sparks 6 | Vickers by Danfoss | January 2024 BC479055194216en-000101...

-

Page 7: Technical Information

PVM Technical Information and Technical Catalog documents. Danfoss does not claim responsibility for the use of the pumps in operating conditions not allowed according to the information shown in this document and the standard PVM Technical Information documents. -

Page 8: Oil Types / Operating Fluids

Table 3: Fluid Viscosity and Temperature Rating of PVM ATEX / UKEX Units and limitations. We recommend the use of an oil type having a viscosity of 16 – 40 mm²/s [83 – 187 SUS] at the actual operating temperature. 8 | Vickers by Danfoss | January 2024 BC479055194216en-000101... -

Page 9: Filtering

It is necessary to keep the level of oil contamination at an acceptable level to ensure problem-free operation. The recommended maximum level of contamination in systems in the hydraulic pumps is 20/18/13 (ISO 4406-1999). Further information can be found in the pump’s technical catalog. Vickers by Danfoss | January 2024 BC479055194216en-000101 | 9... -

Page 10: Installation, Operation And Maintenance

(ground) for any static electricity which occurs on the pump. If this is not possible, a grounding wire needs to be attached to the pump housing. Consult Danfoss for recommendations on connection placement. -

Page 11: Start-Up Procedure

Check to make sure the purity of the oil is greater than 20/18/13 (ISO 4406-1999) and always use a filter when replenishing the system. Warning The pumps must be filled with fluid prior to any load applications Vickers by Danfoss | January 2024 BC479055194216en-000101 | 11... -

Page 12: First Start-Up

The machine/system manufacturer is responsible for the proper project planning of the hydraulic system and its control. Danfoss recommends ongoing tests for optimal pump performance. Continuously verify that the temperature of the ambient and the operating oil are those initially determined. -

Page 13: Maintenance

In order to avoid mixing of different oils, when replacing the operating fluid. It is necessary to empty all the machinery and pipes, clean them carefully and clean the tank. Vickers by Danfoss | January 2024 BC479055194216en-000101 | 13... -

Page 14: Recommended Check Activities

For specific application inquiries contact Danfoss Technical Support. Pump components may only be replaced by genuine original Danfoss service parts which are also approved for use in explosive atmospheres. This also applies to the lubricants and service products used. -

Page 15: Safety Precautions

Relieve pressure in the system before removing hoses, fittings, gauges, or components. Never use your hand or any other body part to check for leaks in a pressurized line. Seek medical attention immediately if you are cut by hydraulic fluid. Vickers by Danfoss | January 2024 BC479055194216en-000101 | 15... - Page 16 Phone: +49 (0) 7221 682 233 Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to products already on order provided that such alterations can be made without sub sequential changes being necessary in specifications already agreed. All trademarks in this material are property of the respective companies.

Need help?

Do you have a question about the Vickers PVM and is the answer not in the manual?

Questions and answers