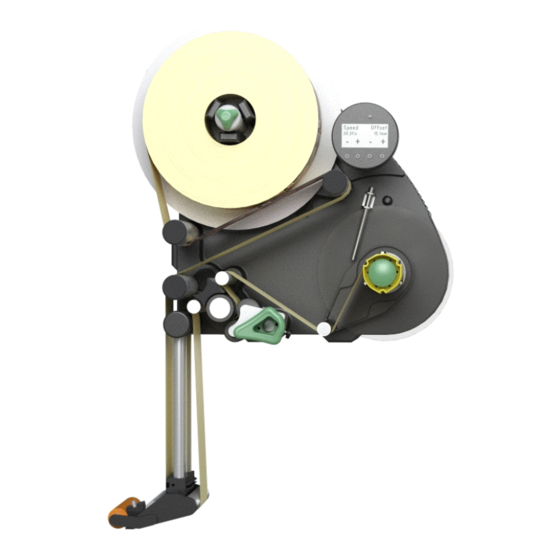

Avery Dennison ALS 204 Installation Manual

Labeller

Hide thumbs

Also See for ALS 204:

- Service and installation manual (224 pages) ,

- User manual (68 pages) ,

- Operating instructions manual (58 pages)

Summary of Contents for Avery Dennison ALS 204

- Page 1 NSTALLATION ANUAL Labeller 204/206 Edition 1 - 4/2013 - Original version...

-

Page 3: Table Of Contents

ONTENTS Please observe the following Adjustable dispensing edge holder ..19 2.1.5 Connecting to the mains power supply ..20 1.1 General information Checking the supply voltage setting ..21 Plugging in the power lead . -

Page 4: Please Observe The Following

The present service manual refers exclusively to the Printed in Germany ALS 204, ALS 206 and ALS 256 label dispensers. The service manual is to be referred to for correct installa- Manufacturer tion, set-up and adjustment of the label dispenser as well as for undertaking of repairs. -

Page 5: Conventions And Information

LEASE OBSERVE THE FOLLOWING 1.1 G ENERAL INFORMATION Conventions and information 1.1.2 Explanation of symbols Illustrations In order to facilitate legibility and an overview, the vari- When required, text passages are accompanied by il- ous types of information used herein are categorised lustrations. -

Page 6: Notes On Installation And Repair Work

LEASE OBSERVE THE FOLLOWING 1.1 G ENERAL INFORMATION Notes on installation and repair work 1.1.3 General information Environmental protection Before performing any maintenance or repair work: Avoid unnecessary waste, e.g. use cleaning cloths Block access to the working area of the machine to sparingly and reuse packing material. -

Page 7: Rules For Electromagnetic Compatibility

LEASE OBSERVE THE FOLLOWING 1.1 G ENERAL INFORMATION Rules for electromagnetic compatibility Connect all metallic parts to each other via large Shield all signal and control lines. surfaces, ensuring electric conductivity. Ground the shielding on both sides at its large sur- ... -

Page 8: Safety Instructions

LEASE OBSERVE THE FOLLOWING 1.2 S AFETY INSTRUCTIONS SAFETY INSTRUCTIONS Information and qualifications 1.2.1 Qualification Qualification for system integrators and service technicians („service personnel“) Ensure necessary qualifications Knowledge required to install the print dispens- Only allow appropriately qualified personnel to set ... -

Page 9: Pay Attention To The Information

LEASE OBSERVE THE FOLLOWING 1.2 S AFETY INSTRUCTIONS Pay attention to the information Information must be made available WARNING! This service guide must be made available to all persons who are ent- Reliable and efficient operation of the label- rusted with installing, setting up, adjusting, or repai- ler is only guaranteed if all necessary infor- ring the labeller. -

Page 10: Machine Operating Safety

Prevent personnel from reaching bet- visible shipment damage. Immediately in- ween dispensing edge and applicator by form Avery Dennison of any damage. installing higher-level protective equip- When installing the machine on a support ment stand, make sure that it can not tip over. -

Page 11: Safe Operation

LEASE OBSERVE THE FOLLOWING 1.2 S AFETY INSTRUCTIONS Safe operation 1.2.3 Protect against injuries that can result Casing: Before opening the casing pull the power from electrical current plug. – The casing may only be opened by WARNING! trained personnel and when the machine Contact with energised components can re- is de-energised. -

Page 12: Protection Against Injuries That Can Result From Mechanical Actions

LEASE OBSERVE THE FOLLOWING 1.2 S AFETY INSTRUCTIONS Protection against injuries that can result from mechanical actions WARNING! Acute risk of injury and long-term bodily in- jury from working with heavy loads! Lift or carry the machine with a minimum ... -

Page 13: Installation And Deinstallation

NSTALLATION AND DEINSTALLATION 2.1 U NPACKING ASSEMBLING AND CONNECTING THE MACHINE NSTALLATION AND DEINSTALLATION UNPACKING, ASSEMBLING AND CONNECTING THE MACHINE Transport 2.1.1 CAUTION! To avoid damaging the machine during transport: Only transport the machine in its original packaging. Keep the original packaging for a later ... -

Page 14: Setting Up

NSTALLATION AND DEINSTALLATION 2.1 U NPACKING ASSEMBLING AND CONNECTING THE MACHINE Setting up 2.1.3 WARNING! Risk of injury from a tipping over support stand. When installing the machine on a support stand, make sure that it can not tip over. Fix the support stand onto the ground. -

Page 15: For Machines Held From The Rear Side

NSTALLATION AND DEINSTALLATION 2.1 U NPACKING ASSEMBLING AND CONNECTING THE MACHINE For machines held from the rear side – Order number for fixing bolt assembly [4A] (includ- ing screw and cylinder pins): A7621 Tools: – 17 mm hexagon socket driver –... - Page 16 NSTALLATION AND DEINSTALLATION 2.1 U NPACKING ASSEMBLING AND CONNECTING THE MACHINE WARNING! Danger of injury by the machine falling to ground. – This danger exists if the machine is to be mounted so as enable sideways swivel- ling, i.e. if the pin in the joint is vertical. If the machine is mounted incorrectly [7], it will fall to the ground as soon as the set screws clamping either the top or bottom...

-

Page 17: Holding Machine In Place By Side Plate Or Base Plate

NSTALLATION AND DEINSTALLATION 2.1 U NPACKING ASSEMBLING AND CONNECTING THE MACHINE Holding machine in place by side plate or base plate – Order number for flange plate assembly [10C] (in- cluding screws and washers): A7622 Tool: – 8 mm hexagon socket driver Screw the flange plate [10C] to the side or base of ... -

Page 18: Attaching The Dispensing Edge

NSTALLATION AND DEINSTALLATION 2.1 U NPACKING ASSEMBLING AND CONNECTING THE MACHINE Attaching the dispensing edge 2.1.4 L-shaped dispensing edge Tools: – 8 mm hexagon socket driver Both the dispensing edge holder [12D] and the mount- ing flange on the machine casing have two concentric rings of holes [12B] on the connecting surfaces. -

Page 19: V-Shaped Dispensing Edge

NSTALLATION AND DEINSTALLATION 2.1 U NPACKING ASSEMBLING AND CONNECTING THE MACHINE V-shaped dispensing edge Tool: – 8 mm hexagon socket driver Mount V-shaped dispensing edge as shown – The angle of the V-shaped dispensing edge cannot be changed. It is mounted without fixing pins. [14] V-shaped dispensing edge in place. -

Page 20: Connecting To The Mains Power Supply

NSTALLATION AND DEINSTALLATION 2.1 U NPACKING ASSEMBLING AND CONNECTING THE MACHINE Connecting to the mains 2.1.5 power supply WARNING! The machine is connected with the mains supply! Contact with energised components can result in life-endangering currents through the body as well as burns. Ensure that the machine is switched off ... -

Page 21: Checking The Supply Voltage Setting

NSTALLATION AND DEINSTALLATION 2.1 U NPACKING ASSEMBLING AND CONNECTING THE MACHINE Checking the supply voltage setting ALS 256: A power supply setting is not re- quired. ALS 20X: the labellers are designed for use with a supply voltage of 230 V (AC) or 110 V (AC). -

Page 22: Plugging In The Power Lead

NSTALLATION AND DEINSTALLATION 2.1 U NPACKING ASSEMBLING AND CONNECTING THE MACHINE Plugging in the power lead Ensure that the power switch [22A] is set to "O" (off). Using the power supply cable provided, connect the machine to a mains supply socket. (ALS 20x with splash guard) The power supply cable is connected by installing the splash guard. -

Page 23: Connecting The External Operator Panel

NSTALLATION AND DEINSTALLATION 2.1 U NPACKING ASSEMBLING AND CONNECTING THE MACHINE Connecting the external 2.1.6 operator panel The external operator panel is necessary, if the labeller is installed at an inaccessible place. The cable installed to the operator panel is 2.5 m long. CAUTION! If the connection cable is longer than 2.5 m, EMC-caused disturbances can occur. -

Page 24: Connecting The Sensors

NSTALLATION AND DEINSTALLATION 2.2 C ONNECTING THE SENSORS CONNECTING THE SENSORS Photoelectric label sensor 2.2.1 – Permitted sensor type: NPN – Photoelectric label sensor is included in the dis- pensing edge scope of delivery [27] Article numbers: – A101974: Sensor with bracket and cable (1.5 m) –... -

Page 25: Connection Diagram

NSTALLATION AND DEINSTALLATION 2.2 C ONNECTING THE SENSORS Connection diagram +24V +24V Label gap detection signal Label signal input LED current Current feed output back signal 0..20mA LED current setting Label sensor [31] Connection diagram for photoelectric label sensor The LED current at pin 2 controls the sensitivity of the sensor. -

Page 26: Adjusting The Avery Sensor

NSTALLATION AND DEINSTALLATION 2.2 C ONNECTING THE SENSORS Adjusting the Avery sensor Press the button [32A] for 2 s, until the status LEDs [32B] light permanently. – Notice: Don´t press the button for longer than 5 s, otherwise you risk to switch between NPN/PNP, see chapter “Switching the Avery sensor - PNP/NPN”... -

Page 27: Switching The Avery Sensor - Pnp/Npn

NSTALLATION AND DEINSTALLATION 2.2 C ONNECTING THE SENSORS Switching the Avery sensor - PNP/NPN Default setting: NPN Switching between NPN/PNP: Press the button [35A] for at least 6 s, until the status LEDs [35B] flash 2x. Finding out the current setting: Move some label material through the sensor fork ... -

Page 28: Adjusting The Wenglor Photoelectric Sensor Automatically

NSTALLATION AND DEINSTALLATION 2.2 C ONNECTING THE SENSORS Adjusting the Wenglor photoelectric sensor automatically Only for Wenglor sensors (old standard, replaced since 9/2011 by Avery sensor). MACHINE SETUP > Auto Sensor Adj. Call up – The label material is fed slowly until the next gap between labels (punch) is reached. -

Page 29: Alternative Label Sensor

NSTALLATION AND DEINSTALLATION 2.2 C ONNECTING THE SENSORS Alternative label sensor 2.2.2 Other suitable sensors can be used as an alternative to the throughbeam photoelectric sensor. – Permitted sensor types: PNP or NPN – Default setting: PNP Alternative label sensor and standard photo- electric sensor may both be connected at the same time. -

Page 30: Connection Diagram

NSTALLATION AND DEINSTALLATION 2.2 C ONNECTING THE SENSORS Connection Diagram +24V +24V NPN-Configuration 2,2k NPN-Signal 1,5k Signal Input Sensor connector PNP-Signal 2,2k PNP-Configuration Jumper (default: open) [39] Connection diagram alternativ label sensor. Jumper descrip- tion see ch. 2.2.3 (p. 32) Example: capacitive label sensor –... - Page 31 NSTALLATION AND DEINSTALLATION 2.2 C ONNECTING THE SENSORS Positioning the sensor holder: The sensor holder be varied in a wide range on the hol- ding rods. The most favorable position can be found as follows: – Label web is in stop position (position just after dis- pensing a label).

-

Page 32: Changing Light/Dark Switching At The Product Sensor Or The Alternativ Label Sensor

NSTALLATION AND DEINSTALLATION 2.2 C ONNECTING THE SENSORS Changing light/dark switching 2.2.3 at the product sensor or the alternativ label sensor Basically, sensors can be assigned to three dif- ferent groups regarding the function of pin 2: a) Pin 2 has no function b) Pin 2 = input, e.g. -

Page 33: Gen. 2

NSTALLATION AND DEINSTALLATION 2.2 C ONNECTING THE SENSORS Gen. 2 Z1020 Z1018 CN2604 CN2601 CN2603 CN2602 CN2605 CN2604 CN2601 C2723 C2623 F402 L402 F401 R2725 C2611 C2616 C2630 L2601 C2634 L2607 C403 C2623 C2628 C2615 C2618 C2632 L2605 L2606 H401 R2647 R2628 Z1012... -

Page 34: Photoelectric Product Sensor

NSTALLATION AND DEINSTALLATION 2.2 C ONNECTING THE SENSORS Photoelectric product sensor 2.2.4 – Permitted sensor types: PNP or NPN – Preset: PNP – Order no.: A7112 [47] Connecting the photoelectric sensor Plug the product sensor in to the connector shown ... -

Page 35: Photoelectric Roll Diameter Sensor

NSTALLATION AND DEINSTALLATION 2.2 C ONNECTING THE SENSORS Photoelectric roll diameter 2.2.5 sensor Both, ALS 20X as well as ALS 256 can be used with an optional photoelectric sensor to check the outer diame- ter (OD sensor) of the label roll. The OD sensor gives a display message when less than a certain residual diameter is left on the label roll. -

Page 36: Connecting The Od Sensor

NSTALLATION AND DEINSTALLATION 2.2 C ONNECTING THE SENSORS Connecting the OD sensor Plug the roll diameter sensor in to the connector shown [52A]. Alternatively, the OD sensor can be connected to the optional applicator interface (see chapter “Pin assign- ment for machine status connection”... -

Page 37: Enabling

NSTALLATION AND DEINSTALLATION 2.2 C ONNECTING THE SENSORS Enabling Set MACHINE SETUP > OD sensor warn. to „Warning“. MACHINE SETUP > OD Sens.polarity to „Level low ac- tive“. If the optional applicator interface board is installed, but the standard signal interface is supposed to be used: Set SIGNAL INTERFACE >ACTIVE INPUTS >... -

Page 38: Function Test

NSTALLATION AND DEINSTALLATION 2.2 C ONNECTING THE SENSORS Function test Prerequisite: – Machine is in dispensing mode. – OD sensor is activated (settings according to chap- ter “Enabling” auf Seite 37). If the light beam of the sensor [50B] meets the reflector [50A], the following message appears after the next la- bel has been dispensed: ONLINE... -

Page 39: Rotary Encoder

– Order no.: 045565 Suitable mounting [57B]: – Type: 9213 – Order no.: 045492 Avery Dennison article number for the above [57] Recommended rotary encoder from Pepperl + Fuchs mentioned encoder including measuring wheel A Measuring wheel and mounting: A7770. -

Page 40: Connecting The Rotary Encoder

NSTALLATION AND DEINSTALLATION 2.2 C ONNECTING THE SENSORS Connecting the rotary encoder CAUTION! To avoid damage to the electronics: Switch the machine off before connecting the rotary encoder. Plug the rotary encoder in to the connector shown [58A]. No changeover is necessary for a Push-Pull ro- tary encoder. -

Page 41: Decommissioning, Dismantling, Disposal

NSTALLATION UND EINSTALLATION 2.3 D ECOMMISSIONING ISMANTLING ISPOSAL DECOMMISSIONING, DISMANTLING, DISPOSAL Take the machine out of Strip the machine from the support stand tube and 2.3.1 lay it down. operation Disconnecting the machine from the compressed air Machine disposal 2.3.3 supply (only machines with installed applicator): It is advisable to remove reusable machine... - Page 43 Avery Dennison Deutschland GmbH Ohmstraße 3 85386 Eching Germany | Tyskland | Alemania | Saksa | Allemagne | Germania | Duitsland | Alemanha | Герма ́ ния +49-8165-925-0 http://www.monarch.averydennison.com...

Need help?

Do you have a question about the ALS 204 and is the answer not in the manual?

Questions and answers