Chapters

Table of Contents

Summary of Contents for Festo Sorting Station Inline

- Page 1 8129436 Sorting Station Inline Stations Betriebsanleitung Operating instructions Instrucciones de utilización Notice d'utilisation Festo Didactic 8129444 en/de/es/fr 01/2020...

- Page 2 01/2020 Authors: Dimitrios Tsakas, Mustafa Ersoy Layout: Festo Didactic © Festo Didactic SE, Rechbergstraße 3, 73770 Denkendorf, Germany, 2020 +49 711 3467-0 www.festo-didactic.com +49 711 34754-88500 did@festo.com Reproduction, distribution and utilisation of this document, as well as the communication of its contents to others without explicit authorisation, is prohibited.

- Page 3 Lesbarkeit und dem besseren Verständnis der Formulierungen. VORSICHT Diese Betriebsanleitung muss dem Anwender ständig zur Verfügung stehen. Vor Inbetriebnahme muss die Betriebsanleitung gelesen werden. Die Sicherheitshinweise müssen beachtet werden. Bei Missachten kann es zu schweren Personen- oder Sachschäden kommen. © Festo Didactic 8129444...

- Page 4 Les instructions de service doivent être constamment à la disposition de l'utilisateur. Les instructions de service doivent avoir été lues avant la mise en service. Se conformer aux consignes de sécurité. Le non-respect peut entraîner de graves dommages corporels ou matériels. © Festo Didactic 8129444...

-

Page 5: Table Of Contents

Transport, unpacking, scope of delivery ______________________________________________ 22 Transport ________________________________________________________________________ 22 Unpacking _______________________________________________________________________ 22 Scope of delivery _________________________________________________________________ 22 Configuration ____________________________________________________________________ 23 The Sorting Station Inline ___________________________________________________________ 23 The detection module ______________________________________________________________ 24 The slide module__________________________________________________________________ 24 The conveyor module ______________________________________________________________ 25 Function ________________________________________________________________________ 26... - Page 6 Sorting Station Inline Sequence description _____________________________________________________________ 26 11.1 Start-up prerequisite ______________________________________________________________ 26 11.2 Initial settings ____________________________________________________________________ 26 11.3 Sequence _______________________________________________________________________ 26 Commissioning ___________________________________________________________________ 28 12.1 General information on using MPS Stations ____________________________________________ 28 12.2 Technical equipment of the workstation _______________________________________________ 28 12.3...

-

Page 7: General Prerequisites For Operating The Devices

Sorting Station Inline 1 General prerequisites for operating the devices General requirements for safe operation of the devices: • National regulations for operating electrical systems and equipment must be observed in commercial and industrial facilities. • The laboratory or classroom must be overseen by a supervisor. -

Page 8: Safety Instructions And Pictograms

Sorting Station Inline 2 Safety instructions and pictograms 2.1 Safety instructions DANGER ... indicates an imminently hazardous situation that will result in fatal or severe personal injury if not avoided. WARNING … indicates a potentially hazardous situation that may result in fatal or severe personal injury if not avoided. -

Page 9: Pictograms

Sorting Station Inline 2.2 Pictograms Hazard warning Warning of dangerous electric voltage Information and/or references to other documentation © Festo Didactic 8129444... -

Page 10: Intended Use

Nevertheless, incorrect use can lead to risk of severe or fatal injury for the user and third parties, and damage to the components. The learning system from Festo Didactic has been developed and produced exclusively for basic and further training in the field of automation technology. The training company and/or trainers must ensure that all trainees observe the safety precautions described in these operating instructions. -

Page 11: For Your Safety

Knowledge of the basic safety instructions and safety regulations is a fundamental prerequisite for safe handling and trouble-free operation of Festo Didactic components and systems. These operating instructions include the most important instructions for safe use of the components and systems. -

Page 12: Obligations Of The Operating Company

Sorting Station Inline 4.2 Obligations of the operating company The operating company undertakes to allow only those persons to work with the components and systems who: • Are familiar with the basic regulations regarding work safety and accident prevention and have been instructed in the use of the components and systems. -

Page 13: Work Instructions And Safety Precautions

Sorting Station Inline 5 Work instructions and safety precautions 5.1 General information CAUTION • Trainees should work with the components and systems only under the supervision of an instructor. • Observe the specifications included in the datasheets for the individual components, and in particular all safety information! •... -

Page 14: Electrics

Sorting Station Inline 5.3 Electrics DANGER • Risk of death in case of an interrupted grounding conductor! – The grounding conductor (yellow-green) must not be interrupted, neither inside nor outside of the device. – The insulation of the grounding conductor must never be damaged or removed. - Page 15 Sorting Station Inline CAUTION • Use safety extra-low voltages only: max. 24 V DC. • The power supply unit must be operated only with a power supply with a grounding conductor. • Establishing and interrupting electrical connections – Electrical connections may be established only in the absence of voltage.

-

Page 16: Pneumatics

Sorting Station Inline 5.4 Pneumatics WARNING • Depressurize the system! – Switch off the compressed air supply before working on the circuit. – Check the system with pressure gauges to make sure that the entire circuit is fully depressurized. –... - Page 17 Sorting Station Inline CAUTION • Pneumatic circuit setup – Connect the components with plastic tubing with an outside diameter of 4 or 6 mm. – Push the tubing as far as it will go into the push-in connector. • Pneumatic circuit dismantling –...

-

Page 18: Safety Sockets

The component might not include all of the safety sockets shown above. Further safety sockets may be included in the circuit setup due to using different components. The specified protection classes and safe use will be achieved if laboratory safety cables supplied by Festo Didactic are used. - Page 19 Sorting Station Inline The protective grounding terminal is designed as PE+ contact. This connection provides a low-impedance, safe protective grounding conductor connection. The mechanically incompatible connection prevents a connection error with a 4 mm laboratory safety cable. The operator bears the responsibility for any removal of this adapter. The adapter can be unscrewed with a 1.5 mm socket head screw.

-

Page 20: Technical Data

Sorting Station Inline 7 Technical data 7.1 General data Parameter Value Operating pressure 600 kPa (6 bar) Operating voltage 24 V DC, 4 A 5 V DC, 3 A (Raspberry Pi) Digital inputs/outputs Max. 24 V DC Inputs: Max. 2 A per output Outputs: Max. -

Page 21: Pin Allocation Table

0 V power supply for inputs • Cable jumpers are connected from emergency off to bit 1.5 on all preferred PLC versions. • You can find electric circuit diagrams for the Sorting Station Inline at the "Festo Didactic Info Portal". (www.ip.festo-didactic.com) © Festo Didactic 8129444... -

Page 22: Transport, Unpacking, Scope Of Delivery

Transport the crate only with a suitable pallet jack or forklift. Secure the crate against tipping over and falling. – Immediately notify the freight forwarder and Festo Didactic of any transport damage. 8.2 Unpacking Carefully remove the filling material from the crate when unpacking the station. When unpacking the station, make sure none of the station assemblies are damaged. -

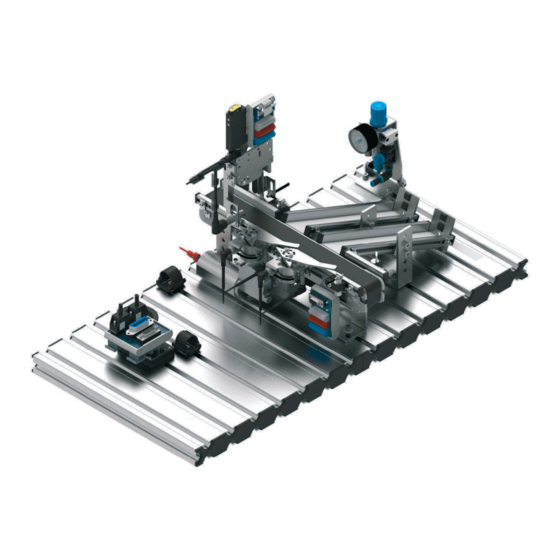

Page 23: Configuration

Sorting Station Inline 9 Configuration 9.1 The Sorting Station Inline According to VDI 2860, sorting is a sub-concept of the “change quantity” handling function. The conveyor is equipped with branches for sorting the workpieces. Various deflectors are set, depending on the workpiece. -

Page 24: The Detection Module

Sorting Station Inline 9.2 The detection module The detection module is capable of verifying the presence of red, black, transparent and metallic workpieces. The detection module detects the material or the color of the workpieces by means of three proximity sensors with digital output. -

Page 25: The Conveyor Module

Sorting Station Inline 9.4 The conveyor module The conveyor module can be mounted on a profile plate, a profile foot or a slotted mounting plate. The conveyor module is suitable for transporting, buffering and separating workpieces with a diameter of 40 mm (e. g. workpiece set “Cylinder bodies”... -

Page 26: Function

Sorting Station Inline 10 Function The Sorting Station Inline sorts workpieces on two slides or forwards the workpiece to the next application. Workpieces placed onto the beginning of the conveyor belt are detected by a fork light barrier. The workpieces are stopped briefly in order to determine their characteristics. The sensors in the detection module ascertain the workpieces’... - Page 27 Sorting Station Inline Red workpiece detected, deposited on slide 1 4. Advance deflector 1 5. Workpiece ejected 6. Retract deflector 1 7. Conveyor motor off Metallic workpiece detected, deposited on slide 2 4. Advance deflector 2 5. Workpiece ejected 6. Retract deflector 2 •...

-

Page 28: Commissioning

Sorting Station Inline 12 Commissioning 12.1 General information on using MPS Stations The stations of the MPS are generally delivered • Fully assembled • Individually adjusted and ready for use • Pre-commissioned • Tested When stations are combined, the mechanical setup, as well as sensor positions and settings, may have to be changed. -

Page 29: Mounting The Profile Plate And The Control Console

Sorting Station Inline 12.3 Mounting the profile plate and the control console Profile plate T-head nut, M6-32 (4x) Carriage Serrated washer, J6.4 (4x) Washer, B-6.4 (4x) Socket head screw, M6 x 10 (4x) Self-tapping screw, 3.5 x 9 (2x) Control console 12.4 Cable connections... -

Page 30: Power Supply

Sorting Station Inline 12.5 Power supply • The stations are supplied with electrical power from a power supply with 24 V DC voltage (max. 4 A). • The entire station is supplied with electrical power from the rack PLC. 12.6 Loading PLC programs Proceed as described in the user’s manuals for the programming software used in order to load the PLC... -

Page 31: Accessories

Sorting Station Inline 13 Accessories • MPS carriage 700 x 350 With height adjustment, order no. 8033590 Without height adjustment, order no. 8033248 • Control console, SysLink, order no. 8127608 Control console, SysLink, emergency stop, signal light panel, order no. 8127610 •... -

Page 32: Maintenance And Cleaning

Sorting Station Inline 14 Maintenance and cleaning Festo Didactic systems and components are to a great extent maintenance free. The following components should be cleaned at regular intervals with a soft, lint-free cloth or brush: • The lenses on the optical sensors, the fiber optics and the reflectors •... - Page 33 Transport/Auspacken/Lieferumfang _________________________________________________ 50 Transport ________________________________________________________________________ 50 Auspacken _______________________________________________________________________ 50 Lieferumfang _____________________________________________________________________ 50 Aufbau __________________________________________________________________________ 51 Die Station Sortieren Inline _________________________________________________________ 51 Das Modul Erkennen_______________________________________________________________ 52 Das Modul Rutsche ________________________________________________________________ 52 Das Modul Band __________________________________________________________________ 53 Funktion ________________________________________________________________________ 54 © Festo Didactic 8129444...

- Page 34 Montage von Profilplatte und Bedienpult ______________________________________________ 57 12.4 Kabelverbindungen________________________________________________________________ 57 12.5 Spannungsversorgung _____________________________________________________________ 58 12.6 SPS Programme laden _____________________________________________________________ 58 12.7 Ablauf starten ____________________________________________________________________ 58 Zubehör _________________________________________________________________________ 59 Wartung und Reinigung ____________________________________________________________ 60 Weitere Informationen und Aktualisierungen __________________________________________ 60 Entsorgung ______________________________________________________________________ 60 © Festo Didactic 8129444...

-

Page 35: Allgemeine Voraussetzungen Zum Betreiben Der Geräte

Es dürfen keine Geräte mit Schäden oder Mängeln verwendet werden. – Schadhafte Geräte sind zu sperren und aus dem Labor- oder Unterrichtsraum zu entnehmen. – Beschädigte Verbindungsleitungen, Druckluftschläuche und Hydraulikschläuche stellen ein Sicherheitsrisiko dar und müssen aus dem Labor- oder Unterrichtsraum entfernt werden. © Festo Didactic 8129444... -

Page 36: Sicherheitshinweise Und Piktogramme

… weist auf eine möglicherweise gefährliche Situation hin, die zu mittleren und leichten Körperverletzungen oder zu schwerem Sachschaden führen kann, wenn sie nicht vermieden wird. HINWEIS … weist auf eine möglicherweise gefährliche Situation hin, die zu Sachschaden oder Funktionsverlust führen kann, wenn sie nicht vermieden wird. © Festo Didactic 8129444... -

Page 37: Piktogramme

Station Sortieren Inline 2.2 Piktogramme Warnung vor einer Gefahrenstelle Warnung vor gefährlicher elektrischer Spannung Informationen und/oder Verweise auf andere Dokumentationen © Festo Didactic 8129444... -

Page 38: Bestimmungsgemäße Verwendung

Regeln gebaut. Dennoch können bei unsachgemäßer Verwendung Gefahren für Leib und Leben des Benutzers oder Dritter und Beeinträchtigungen der Komponenten entstehen. Das Lernsystem von Festo Didactic ist ausschließlich für die Aus- und Weiterbildung im Bereich Automatisierung und Technik entwickelt und hergestellt. Das Ausbildungsunternehmen und/oder die Ausbildenden hat/haben dafür Sorge zu tragen, dass die Auszubildenden die Sicherheitsvorkehrungen, die... -

Page 39: Für Ihre Sicherheit

4 Für Ihre Sicherheit 4.1 Wichtige Hinweise Grundvoraussetzung für den sicherheitsgerechten Umgang und den störungsfreien Betrieb der Komponenten und Systeme von Festo Didactic ist die Kenntnis der grundlegenden Sicherheitshinweise und der Sicherheitsvorschriften. Diese Betriebsanleitung enthält die wichtigsten Hinweise, um die Komponenten und Systeme sicherheitsgerecht zu betreiben. -

Page 40: Verpflichtung Des Betreibers

Alle Personen, die mit Arbeiten an den Komponenten und Systemen beauftragt sind, verpflichten sich, vor Arbeitsbeginn: • das Sicherheitskapitel und die Warnhinweise in dieser Betriebsanleitung zu lesen, • die grundlegenden Vorschriften über Arbeitssicherheit und Unfallverhütung zu beachten. © Festo Didactic 8129444... -

Page 41: Arbeits- Und Sicherheitshinweise

Montieren Sie alle Komponenten fest auf die Profilplatte. • Stellen Sie sicher, dass Grenztaster nicht frontal betätigt werden. • Stellen Sie alle Komponenten so auf, dass das Betätigen von Schaltern und Trenneinrichtungen nicht erschwert wird. • Beachten Sie Angaben zur Platzierung der Komponenten. © Festo Didactic 8129444... -

Page 42: Elektrik

Beachten Sie, dass elektrische Energie in einzelnen Komponenten gespeichert sein kann. Informationen hierzu finden Sie in den Datenblättern und Betriebsanleitungen der Komponenten. – Warnung! Kondensatoren im Gerät können noch geladen sein, selbst wenn das Gerät von allen Spannungsquellen getrennt wurde. © Festo Didactic 8129444... - Page 43 – sichtbarer Beschädigung, – defekter Funktion, – unsachgemäßer Lagerung oder – unsachgemäßem Transport ist kein gefahrloser Betrieb des Geräts mehr möglich. – Schalten Sie sofort die Spannung ab. • Schützen Sie das Gerät vor unbeabsichtigtem Wiedereinschalten. © Festo Didactic 8129444...

-

Page 44: Pneumatik

Schalten Sie die Druckluft erst ein, wenn Sie alle Schlauchverbindungen hergestellt und gesichert haben. • Entkuppeln Sie keine Schläuche unter Druck. – Versuchen Sie nicht, Schläuche oder Steckverbindungen mit den Fingern oder der Hand zu verschließen. © Festo Didactic 8129444... - Page 45 Reduzieren Sie den Lärm durch den Einsatz von Schalldämpfern oder tragen Sie einen Gehörschutz, falls der Lärm sich nicht vermeiden lässt. – Alle Abluftanschlüsse der Komponenten der Gerätesätze sind mit Schalldämpfern versehen. Entfernen Sie diese Schalldämpfer nicht. © Festo Didactic 8129444...

-

Page 46: Sicherheitssteckbuchsen

Die Komponente enthält möglicherweise nicht alle der oben dargestellten Sicherheitssteckbuchsen. Im Schaltungsaufbau können durch die Verwendung verschiedener Komponenten weitere Sicherheitssteckbuchsen enthalten sein. Die angegebenen Schutzklassen und die Sicherheit werden bei Verwendung von Festo Didactic Sicherheits- Laborleitungen erreicht. © Festo Didactic 8129444... - Page 47 In Verantwortung des Betreibers kann dieser Adapter entfernt werden. Mit einem 1,5 mm Inbusschlüssel kann der Adapter gelöst werden. Die Arretierung befindet sich in der Bohrung des Adapters. Die Schraube wird rechtsdrehend gelöst. WARNUNG Gefahr durch Stromschlag! Schadhafte Sicherheits-Laborleitungen sind sofort zu sperren und aus dem Prüfbereich zu entfernen! © Festo Didactic 8129444...

-

Page 48: Technische Daten

Pneumatischer Anschluss Kunststoffschlauch mit 6 mm Außendurchmesser Druckluftverbrauch bei 600 kPa (Dauerzyklus) 3 l/min Maße 350 mm x 700 mm x 353 mm (ohne Wagen) 350 mm x 700 mm x 1104 mm (inkl. Wagen) Änderungen vorbehalten © Festo Didactic 8129444... -

Page 49: Kontaktbelegungstabelle

GND B 23+24 weiß-blau 0V Versorgung der Eingänge • Bei allen Vorzugsvarianten SPS sind Kabelbrücken von NOT-AUS auf Bit 1.5 gesteckt. • Elektrische Schaltpläne der Station Sortieren Inline finden Sie auf dem „Festo Didactic Info Portal“. (www.ip.festo-didactic.com) © Festo Didactic 8129444... -

Page 50: Transport/Auspacken/Lieferumfang

Transportieren Sie die Transportbox ausschließlich mit geeigneten Hubwagen oder Gabelstaplern. Sichern Sie die Transportbox gegen Umfallen und Herunterfallen. – Melden Sie Transportschäden unverzüglich dem Spediteur und Festo Didactic. 8.2 Auspacken Entfernen Sie beim Auspacken der Station vorsichtig das Füllmaterial aus der Transportbox. Achten sie darauf, dass beim Auspacken der Station keine Aufbauten der Station beschädigt werden. -

Page 51: Aufbau

Die Werkstücke müssen einzeln laufen, damit die Schaltvorgänge der Weichen nicht behindert werden. In der Station Sortieren werden Werkstücke nach Material und Farbe sortiert. Die Aufgabe der Station Sortieren ist es • Werkstücke nach Beschaffenheit sortieren • Werkstücke an die Folgestation durchschleusen © Festo Didactic 8129444... -

Page 52: Das Modul Erkennen

5 Werkstücke auf die Rutsche. In der Station Sortieren wird das Modul Rutsche zweimal verwendet. Vom Modul Band ankommende Werkstücke werden auf dem Modul Rutsche gelagert. Eine über einen Spiegel umgelenkte Lichtschranke überwacht den Füllstand der Rutschen. © Festo Didactic 8129444... -

Page 53: Das Modul Band

Sensor (Induktiver Näherungsschalter) für Komponente Weiche 1 für Signal Weiche 1 ausgefahren • Sensor (Induktiver Näherungsschalter) für Komponente Weiche 2 für Signal Weiche 2 ausgefahren • Beide Komponenten Weiche anstatt mit Vereinzeler mit „Auswerfer“ bestückt • Umlenkspielgel für Werkstück an Bandende und Rutsche voll © Festo Didactic 8129444... -

Page 54: Funktion

2. Bandmotor ein 3. Farb-/Materialidentifikation Schwarzes Werkstück erkannt, Ablage am Bandende 4. Werkstück wird zum Bandende transportiert 5. Werkstück am Bandende 6. Werkstück wird weitergeleitet, wenn Folgestation frei (I6 am Bedienfeld) oder Werkstück wird manuell entfernt © Festo Didactic 8129444... - Page 55 • Der Ablauf kann durch Drücken des NOT-HALT Tasters jederzeit, oder durch Drücken des STOP Tasters nach dem Zyklus unterbrochen werden. • Bei einer Kombination mehrerer Stationen gilt: Richten der einzelnen Stationen erfolgt entgegen dem Materialfluss. © Festo Didactic 8129444...

-

Page 56: Inbetriebnahme

SPS Board mit 16 digitalen Ein- und Ausgängen • ein Netzgerät 24 V DC, 4 A, ≤ 100 W Ausgangsleistung, SELV/PELC Energiebegrenztes Netzgerät (LPS) • eine Druckluftversorgung mit 600 kPa (6 bar) • einen PC mit installierter SPS Programmiersoftware • zwei E/A-Kabel (SysLink) © Festo Didactic 8129444... -

Page 57: Montage Von Profilplatte Und Bedienpult

Buchse B durch ein SysLink Kabel mit der SysLink Buchse des Bedienpults. SPS Board – Netzgerät Stecken Sie die 4 mm Sicherheitsstecker in die Buchsen des Netzgerätes. PC – SPS Verbinden Sie Ihren PC durch ein Programmierkabel mit der SPS. © Festo Didactic 8129444... -

Page 58: Spannungsversorgung

9. Die Station startet den Ablauf. • Der Ablauf kann durch Drücken des NOT-HALT Tasters oder durch Drücken des STOP Tasters jederzeit unterbrochen werden. • Bei einer Kombination mehrerer Stationen gilt: Richten der einzelnen Stationen erfolgt entgegen dem Materialfluss. © Festo Didactic 8129444... -

Page 59: Zubehör

E/A-Datenkabel mit SysLink-Steckern nach IEEE 488, 2,5 m Bestell-Nr. 34031 • Simulationsbox, digital Bestell-Nr. 170643 • Werkstücksatz „Grundkörper“ Bestell-Nr. 167021 • Werkstücksatz „Montierbarer Zylinder“ Bestell-Nr. 162239 • Werkstücksatz „Gehäuse“ Bestell-Nr. 534619 • Erdungsset für MPS Bestell-Nr. 8088988 © Festo Didactic 8129444... -

Page 60: Wartung Und Reinigung

Station Sortieren Inline 14 Wartung und Reinigung Die Komponenten und Systeme von Festo Didactic sind weitestgehend wartungsfrei. In regelmäßigen Abständen sollten: • die Linsen der optischen Sensoren, der Faseroptiken sowie Reflektoren • die aktive Fläche der Näherungsschalter • die gesamte Komponente bzw. das System mit einem weichen, fuselfreien Tuch oder Pinsel gereinigt werden. - Page 61 Desembalaje _____________________________________________________________________ 78 Suministro _______________________________________________________________________ 78 Estructura _______________________________________________________________________ 79 Estación de clasificación en línea ____________________________________________________ 79 El módulo de detección ____________________________________________________________ 80 Módulo plano inclinado ____________________________________________________________ 80 Módulo cinta de transporte _________________________________________________________ 81 Función _________________________________________________________________________ 82 © Festo Didactic 8129444...

- Page 62 Conexiones mediante cables ________________________________________________________ 85 12.5 Alimentación eléctrica _____________________________________________________________ 86 12.6 Cargar programas PLC _____________________________________________________________ 86 12.7 Inicio del proceso _________________________________________________________________ 86 Accesorios _______________________________________________________________________ 87 Mantenimiento y limpieza __________________________________________________________ 88 Informaciones complementarias y actualizaciones _____________________________________ 88 Eliminación ______________________________________________________________________ 88 © Festo Didactic 8129444...

-

Page 63: Condiciones Generales Para El Uso De Los Equipos

Los equipos defectuosos deberán inhabilitarse y retirarse del laboratorio o aula donde se impartan las clases. – Los cables de conexión, los tubos flexibles de aire comprimido y los tubos flexibles hidráulicos dañados representan un peligro y deben retirarse del laboratorio o del aula. © Festo Didactic 8129444... -

Page 64: Instrucciones De Seguridad Y Pictogramas

INDICACIÓN ...indica que existe un posible peligro, que puede causar daños materiales o una pérdida de las funciones si no se adoptan las medidas necesarias para evitarlo. © Festo Didactic 8129444... -

Page 65: Pictogramas

Estación de clasificación en línea 2.2 Pictogramas Advertencia de un peligro general Advertencia de tensión eléctrica peligrosa Información y/o referencias a otros documentos © Festo Didactic 8129444... -

Page 66: Uso Previsto

El sistema para la enseñanza de Festo Didactic ha sido concebido exclusivamente para la formación y el perfeccionamiento profesional en materia de sistemas y técnicas de automatización industrial. La empresa... -

Page 67: Indicaciones De Seguridad

4 Indicaciones de seguridad 4.1 Observaciones importantes Para un uso seguro y sin fallas de los componentes y sistemas de Festo Didactic, es indispensable conocer las indicaciones básicas de seguridad y las instrucciones de seguridad correspondientes. Estas instrucciones de utilización contienen las indicaciones más importantes para un uso correcto y seguro de los componentes y sistemas. -

Page 68: Obligaciones Asumidas Por El Operador

Todas las personas que trabajan con los componentes y sistemas se comprometen, antes de utilizar el equipo, a lo siguiente: • leer el capítulo relativo a la seguridad y las advertencias de seguridad incluidas en estas instrucciones, • respetar las disposiciones básicas de seguridad laboral y de prevención de accidentes. © Festo Didactic 8129444... -

Page 69: Indicaciones De Seguridad Y Utilización

Asegúrese de que los interruptores de final de carrera no puedan accionarse frontalmente. • Efectúe el montaje de todos los componentes de tal manera que pueda acceder fácilmente a los interruptores y los seccionadores. • Respete las indicaciones sobre el posicionamiento de los componentes. © Festo Didactic 8129444... -

Page 70: Sistema Eléctrico

ATENCIÓN • Utilice únicamente tensiones protectoras de bajo voltaje, de máximo 24 V CC. • La unidad de alimentación eléctrica solo se debe utilizar con alimentación de red que disponga de conductor de protección. © Festo Didactic 8129444... - Page 71 – daño visible, – funcionamiento defectuoso, – almacenamiento incorrecto o – transporte inadecuado ya no es posible el funcionamiento seguro del equipo. – Desconecte inmediatamente la tensión. • Evite que el equipo pueda volverse a conectar. © Festo Didactic 8129444...

-

Page 72: Neumática

• No desacople tubos flexibles mientras el sistema esté bajo presión. – No intente obturar los tubos flexibles o los conectores enchufables ni con los dedos ni con la mano. © Festo Didactic 8129444... - Page 73 Reduzca el nivel de ruido utilizando silenciadores o tapones para los oídos si no fuese posible evitar los ruidos. – Todas las conexiones del aire de escape de los componentes de los conjuntos de equipos deberán estar provistas de silenciadores. No retire estos silenciadores. © Festo Didactic 8129444...

-

Page 74: Conectores De Seguridad

A menos que se indique lo contrario en las especificaciones técnicas, en los componentes del sistema de aprendizaje de automatización y tecnología de Festo Didactic son válidos los siguientes códigos de colores para las conexiones de alimentación y de transmisión de señales. - Page 75 Allen de 1,5 mm. El bloqueo se encuentra en el orificio del adaptador. El tornillo se afloja girándolo en el sentido horario. ADVERTENCIA Peligro de descarga eléctrica Los cables de seguridad defectuosos deberán inhabilitarse de inmediato y retirarse de la zona de trabajo. © Festo Didactic 8129444...

-

Page 76: Especificaciones Técnicas

Consumo de aire comprimido con 600 kPa (ciclo continuo) 3 l/min Dimensiones 350 mm x 700 mm x 353 mm (sin carro) 350 mm x 700 mm x 1104 mm (carro incl.) Reservado el derecho de modificación © Festo Didactic 8129444... -

Page 77: Tabla De Ocupación De Contactos

En todas las variantes de PLC, los cables que puentean la parada de emergencia están conectados al bit 1.5. • Los esquemas del circuito eléctrico de la estación de clasificación en línea se encuentran en el portal de información de Festo Didactic. (www.ip.festo-didactic.com) © Festo Didactic 8129444... -

Page 78: Transporte/Desembalaje/Dotación Del Suministro

La caja deberá transportarse únicamente utilizando una carretilla de horquilla elevadora apropiada. Asegure la caja de transporte contra caídas y vuelcos. – Comunique de inmediato cualquier daño ocurrido durante el transporte al transportista y a Festo Didactic. 8.2 Desembalaje Para sacar la estación de su caja de transporte, deberá retirarse primero cuidadosamente el material de relleno. -

Page 79: Estructura

En la estación de clasificación, las piezas a manipular se clasifican según material y color. La función de la estación de clasificación consiste en • clasificar piezas a manipular, diferenciándolas por sus características. • Desvío de las piezas a la siguiente estación © Festo Didactic 8129444... -

Page 80: El Módulo De Detección

Las piezas a manipular que provienen de la cinta transportadora se almacenan en el módulo de plano inclinado. Una barrera de luz desviada con espejos controla el nivel de llenado en los planos inclinados. © Festo Didactic 8129444... -

Page 81: Módulo Cinta De Transporte

• Los dos desvíos están provistos de un elemento de expulsión, en vez de incluir una unidad separadora de piezas. • Espejo reflector para la pieza al final de la cinta y el plano inclinado completo © Festo Didactic 8129444... -

Page 82: Función

4. La pieza se transporta hasta el final de la cinta 5. Pieza en el final de la cinta 6. La pieza avanza si la siguiente estación está libre (I6 en el panel de control) o esta se retira manualmente © Festo Didactic 8129444... - Page 83 STOP después del ciclo. • Tratándose de una combinación de varias estaciones, se aplica lo siguiente: La alineación de cada una de las estaciones se realiza en sentido contrario al flujo del material. © Festo Didactic 8129444...

-

Page 84: Puesta A Punto

24 V CC, 4 A, ≤ 100 W potencia de salida, PELV/PELC fuente de alimentación de energía limitada (LPS) • una alimentación de aire comprimido con 600 kPa (6 bar) • un PC con software de programación PLC instalado • dos cables E/S (SysLink) © Festo Didactic 8129444... -

Page 85: Montaje De La Placa Perfilada Y Del Panel De Mando

SysLink. Placa PLC – Fuente de alimentación Conecte las clavijas de seguridad de 4 mm en los conectores de la fuente de alimentación. PC – PLC Conecte el PC al PLC con un cable de programación. © Festo Didactic 8129444... -

Page 86: Alimentación Eléctrica

PARADA DE EMERGENCIA o el pulsador de STOP. • Tratándose de una combinación de varias estaciones, se aplica lo siguiente: La alineación de cada una de las estaciones se realiza en sentido contrario al flujo del material. © Festo Didactic 8129444... -

Page 87: Accesorios

Juego de piezas "Cuerpos de cilindros" n.º de art. 167021 • Juego de piezas "Cilindro para montar" n.º de art. 162239 • Juego de piezas "Cuerpos" n.º de art. 534619 • Kit de toma de tierra para MPS n.º de art. 8088988 © Festo Didactic 8129444... -

Page 88: Mantenimiento Y Limpieza

Estación de clasificación en línea 14 Mantenimiento y limpieza Los componentes y sistemas de Festo Didactic casi no requieren trabajos de mantenimiento. Sin embargo, deberán ejecutarse regularmente los trabajos que se indican a continuación: • Limpiar las lentes de los sensores ópticos, las fibras ópticas y los reflectores, •... - Page 89 Transport/Déballage/Fourniture ___________________________________________________ 106 Transport _______________________________________________________________________ 106 Déballage ______________________________________________________________________ 106 Fourniture ______________________________________________________________________ 106 Conception _____________________________________________________________________ 107 Station de tri Inline _______________________________________________________________ 107 Module de détection ______________________________________________________________ 108 Module Goulotte _________________________________________________________________ 108 Module Convoyeur _______________________________________________________________ 109 Fonction _______________________________________________________________________ 110 © Festo Didactic 8129444...

- Page 90 Alimentation électrique ___________________________________________________________ 114 12.6 Chargement des programmes API ___________________________________________________ 114 12.7 Démarrage du cycle ______________________________________________________________ 114 Accessoires _____________________________________________________________________ 115 Maintenance et nettoyage_________________________________________________________ 116 Informations complémentaires et mises à jour ________________________________________ 116 Mise au rebut ___________________________________________________________________ 116 © Festo Didactic 8129444...

-

Page 91: Exigences Générales Pour L'utilisation Des Appareils

être retirés de la salle de classe ou de TP. – Les câbles de liaison, tuyaux d'air comprimé et tuyaux hydrauliques endommagés présentent un risque pour la sécurité et doivent être retirés de la salle de classe ou de TP. © Festo Didactic 8129444... -

Page 92: Consignes De Sécurité Et Pictogrammes

à modérées ou des dommages matériels graves si elle n'est pas évitée. REMARQUE … signale une situation potentiellement dangereuse qui peut causer des dommages matériels ou une perte de fonction si elle n'est pas évitée. © Festo Didactic 8129444... -

Page 93: Pictogrammes

Station de tri Inline 2.2 Pictogrammes Avertissement concernant une zone dangereuse Avertissement : tension électrique dangereuse Informations et/ou renvois vers d'autres documentations © Festo Didactic 8129444... -

Page 94: Utilisation Prévue

Le système didactique de Festo Didactic est exclusivement destiné à la formation initiale et continue dans le domaine de l’automatisation et de la technique. Il incombe à l’établissement de formation et/ou aux formateurs de faire respecter par les étudiants les consignes de sécurité... -

Page 95: Pour Votre Sécurité

4.1 Notes importantes La condition de base de l’utilisation en toute sécurité et du parfait fonctionnement des composants et des systèmes de Festo Didactic est une bonne connaissance des directives et consignes fondamentales de sécurité. La présente notice d'utilisation contient les informations essentielles pour utiliser les composants et systèmes en toute sécurité. -

Page 96: Engagement De L'exploitant

Avant toute opération sur les composants et systèmes, le personnel s’engage à : • lire le chapitre sur la sécurité et les avertissements de la présente notice, • respecter les prescriptions principales de sécurité au travail et de prévention des accidents. © Festo Didactic 8129444... -

Page 97: Consignes De Travail Et Précautions De Sécurité

Veillez à ce que les capteurs de fin de course ne soient jamais actionnés de face. • Installez les appareils de manière à ne pas entraver l'actionnement des commutateurs et dispositifs de sectionnement. • Notez les indications concernant l'implantation des composants. © Festo Didactic 8129444... -

Page 98: Electrique

Vous trouverez des informations à ce sujet dans les fiches techniques et notices d'utilisation des composants. – Avertissement ! Des condensateurs intégrés à l'appareil peuvent encore être chargés même après coupure de toutes les sources de tension. © Festo Didactic 8129444... - Page 99 – dysfonctionnement, – stockage impropre ou de – transport non conforme l'utilisation sans danger de l'appareil n'est plus possible. – Coupez immédiatement la tension. • Empêchez toute remise en marche involontaire de l'appareil. © Festo Didactic 8129444...

-

Page 100: Pneumatique

N'appliquez l'air comprimé qu'après avoir branché et fixé tous les raccords de tuyaux. • Ne débranchez pas de tuyaux sous pression. – N'essayez pas d'obturer un tuyau ou un connecteur avec les doigts ou la main. © Festo Didactic 8129444... - Page 101 Le bruit produit par l'échappement d'air comprimé peut impacter l'audition. Réduisez le bruit en utilisant des silencieux ou portez un casque anti-bruit si le bruit est inévitable. – Equipez tous les raccords d'échappement des ensembles d'équipement de silencieux. Ne retirez pas ces silencieux. © Festo Didactic 8129444...

-

Page 102: Douilles De Sécurité

La structure de montage peut comprendre d'autres douilles de sécurité du fait de l'utilisation de différents composants. Les classes de protection et de sécurité indiquées sont vérifiées en cas d'utilisation des équipements de laboratoire de sécurité de Festo Didactic. © Festo Didactic 8129444... - Page 103 Le verrou se trouve dans le trou de l'adaptateur. Desserrez la vis en tournant vers la droite. AVERTISSEMENT Danger d’électrocution ! Les câbles endommagés doivent être immédiatement interdits d'utilisation et retirés de la zone de contrôle ! © Festo Didactic 8129444...

-

Page 104: Caractéristiques Techniques

Tuyau plastique de 6 mm de diamètre extérieur Consommation d'air comprimé sous 600 kPa (cycle permanent) 3 l/min Dimensions 350 mm x 700 mm x 353 mm (sans chariot) 350 mm x 700 mm x 1104 mm (avec chariot) Sous réserve de modifications © Festo Didactic 8129444... -

Page 105: Brochage

Sur toutes les variantes préférentielles d'API, des cavaliers sont enfichés entre COUPURE D’URGENCE et le bit 1.5. • Les schémas de circuit de la Station de tri Inline sont disponibles sur le portail «°Festo Didactic Info Portal°». (www.ip.festo- didactic.com) © Festo Didactic 8129444... -

Page 106: Transport/Déballage/Fourniture

Veillez à ce que la caisse de transport ne puisse pas se renverser ni tomber. – Signalez sans délai au transporteur et à Festo Didactic tout dommage dû au transport. 8.2 Déballage Lorsque vous déballez la station, retirez avec précaution le matériau de calage de la caisse de transport. -

Page 107: Conception

Sur la Station de tri, les pièces à usiner sont triées en fonction de leur matière et de leur couleur. Les tâches de la Station de tri consistent à : • Trier les pièces à usiner en fonction de leur nature • Evacuer les pièces à usiner vers la station en aval © Festo Didactic 8129444... -

Page 108: Module De Détection

La Station de tri utilise par deux fois le module Goulotte. Le module Goulotte stocke les pièces à usiner arrivant du module Convoyeur. Une barrière lumineuse déviée par un miroir surveille le niveau de remplissage des goulottes. © Festo Didactic 8129444... -

Page 109: Module Convoyeur

(capteur inductif) sur le composant aiguillage 2 pour le signal aiguillage 2 sorti • les deux composants aiguillage équipés non pas d'un séparateur mais d'un « éjecteur » • miroir de déviation pour Pièce à usiner en fin de convoyeur/Goulotte pleine © Festo Didactic 8129444... -

Page 110: Fonction

5. Pièce à usiner en fin de convoyeur 6. La pièce à usiner est acheminée lorsque la station en aval est libre (I6 sur le panneau de commande) ou lorsque la pièce à usiner est supprimée manuellement © Festo Didactic 8129444... - Page 111 Le cycle peut être interrompu à tout moment par actionnement du bouton d'ARRÊT D’URGENCE ou à la fin du cycle par actionnement du bouton STOP. • Si plusieurs stations sont combinées, la mise en référence des différentes stations s'opère en sens inverse du flux matière. © Festo Didactic 8129444...

-

Page 112: Mise En Service

24 V DC 4 A, puissance de sortie ≤ 100 W, TBTS/TBTP, bloc d'alimentation à énergie limitée (LPS), • une alimentation pneumatique de 600 kPa (6 bar), • un PC sur lequel est installé un logiciel de programmation d’API et • deux câbles I/O (SysLink). © Festo Didactic 8129444... -

Page 113: Montage De La Plaque Profilée Et Du Pupitre De Commande

Carte d'API – Bloc d'alimentation Branchez les fiches mâles de sécurité de 4 mm dans les connecteurs femelle du bloc d'alimentation. PC – API Raccordez votre PC à la commande API avec un câble de programmation. © Festo Didactic 8129444... -

Page 114: Alimentation Électrique

Le cycle peut être interrompu à tout moment par l'actionnement du bouton d'ARRÊT D’URGENCE ou du bouton STOP. • Si plusieurs stations sont combinées, la mise en référence des différentes stations s'opère en sens inverse du flux matière. © Festo Didactic 8129444... -

Page 115: Accessoires

Jeu de pièces à usiner « Corps », référence 167021 • Jeu de pièces « Vérin à assembler », référence 162239 • Jeu de pièces « Boîtiers », référence 534619 • Kit de mise à la terre pour MPS, référence 8088988 © Festo Didactic 8129444... -

Page 116: Maintenance Et Nettoyage

Station de tri Inline 14 Maintenance et nettoyage Les composants et systèmes de Festo Didactic ne nécessitent pratiquement aucun entretien. Il convient toutefois, à intervalles réguliers, de nettoyer : • les lentilles des capteurs optiques, les fibres optiques ainsi que les réflecteurs, •... - Page 120 Festo Didactic SE Rechbergstraße 3 73770 Denkendorf Germany +49 711 3467-0 www.festo-didactic.com +49 711 34754-88500 did@festo.com...

Need help?

Do you have a question about the Sorting Station Inline and is the answer not in the manual?

Questions and answers