Table of Contents

Advertisement

Quick Links

Advertisement

Chapters

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for ETAS ES411.1

- Page 1 ETAS ES411.1 A/D Module User Guide...

- Page 2 The data in this document may not be altered or amended without special noti- fication from ETAS GmbH. ETAS GmbH undertakes no further obligation in relation to this document. The software described in it can only be used if the customer is in possession of a general license agreement or single license.

-

Page 3: Table Of Contents

Features of the ES411.1 ........ - Page 4 Troubleshooting ES411.1 Problems ........

- Page 5 Measurement Probes and Cables ......... 96 ES411.1 - User Guide...

- Page 6 ES411.1 ........

-

Page 7: About This Document

Presentation of Instructions The target to be achieved is defined in the heading. The necessary steps for his are in a step-by-step guide: Target definition 1. Step 1 2. Step 2 3. Step 3 > Result ES411.1 - User Guide... -

Page 8: Typographical Conventions

ETAS About this Document Typographical Conventions Hardware Bold Menu commands, buttons, labels of the product Italic Emphasis on content and newly introduced terms Presentation of Supporting Information NOTE Contains additional supporting information. ES411.1 - User Guide... -

Page 9: About This Manual

(see chapter 10.1 on page 102). Additional cables and adapters can be obtained separately from ETAS. A list of available accessories and their order designation is located in chapter “Acces- sories” on page 102 of this manual or in the ETAS product catalog. -

Page 10: Basic Safety Notices

• “Intended Use” on page 10 General Safety Information Please observe the Product Safety Notices ("ETAS Safety Notice") and the fol- lowing safety notices to avoid health issues or damage to the device. NOTE Carefully read the documentation (Product Safety Advice and this User's Guide) that belongs to the product prior to the startup. - Page 11 • Route the power cable in such a way that it is protected against abrasion, damages, deformation and kinking. Do not place any objects on the power cable! ES411.1 - User Guide...

- Page 12 • Adhere to the maximum permissible cable lengths! • Do not use any damaged cables! Cables may be repaired only by ETAS! CAUTION Never apply force to insert a plug into a socket. Ensure that there is no contamination in and on the connection, that the plug fits the socket, and that you correctly aligned the plugs with the connection.

- Page 13 • the temperature resistance of the modules (for example, do not install modules on the motor, turbocharger, exhaust manifold or their environ- ments). CAUTION During the installation of the modules, observe the permissible temperature range of the cable ties being used! ES411.1 - User Guide...

- Page 14 Maintenance The product is maintenance-free. Repair If a repair of an ETAS hardware product should become necessary, send the product to ETAS. Cleaning the module housing • Use a dry or lightly moistened, soft, lint-free cloth for cleaning the module housing.

-

Page 15: Es400 Product Family

Fig. 4-1 Central and Decentral Sensor Cabling With the ES400 modules, ETAS provides a decentral solution which consider- ably simplifies the test setup of the sensors. The basic idea of this concept is to install the modules of the ES400 family as close as possible to the sensors, to concatenate the modules with each other and to connect just the first module of this chain with the laptop in the vehicle. -

Page 16: Features Of The Es400 Line

• The A/D Modules of the ES400 family use a XCP-based protocol which is compatible to the existing ETAS Ethernet topology. The concept fulfills the following requirements: – high bandwidth to be able to realize lots of channels with high resolu-... -

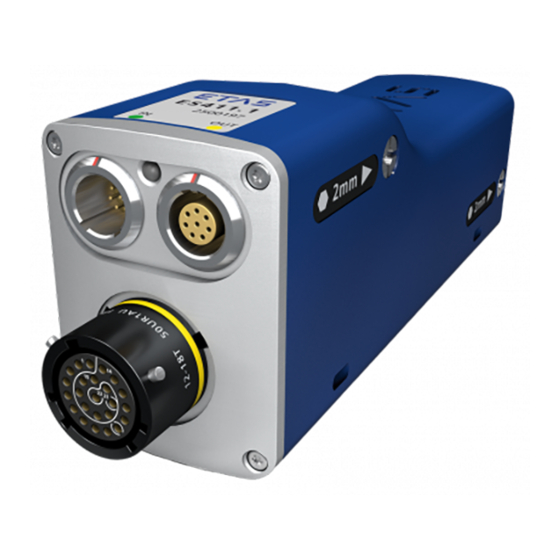

Page 17: Housing

Data” on page 69. Housing A sturdy metal housing is used for the ES411.1; it has ports on the front of the device so it can fit into tight spaces. The ES411.1 is specifically designed to be installed in engine compartment, but also in the passenger cell. -

Page 18: Ports

Front 4.4.1 “Sensor” Port The front of the ES411.1 features a 22-pin Souriau port to which four sensors can be connected using a adapter cable. An individual sensor power supply port is available for each sensor. The use of a “cable tail” or “whip” solution with just one connector makes it possible to change the modules quickly within complex test setups. -

Page 19: Led

Functional State Display State yellow-red flashing Warning 0,5 s yellow reduced / Overload on a sensor supply 0,5 s red reduced voltage channel red illuminated Error during self-test fully bright red illuminated Internal error semi bright ES411.1 - User Guide... -

Page 20: Hardware Description

Features of the ES411.1 Fig. 5-1 ES411.1 Housing The ES411.1 A/D Module with Sensor Supply is a member of the family of ES400-Modules. The ES411.1 can acquire analog voltages at four input chan- nels. There is a sensor supply for every channel. -

Page 21: Block Diagram

ETAS Hardware Description Block Diagram The ES411.1 is a module with four identical sensor channels, two shared Ether- net interfaces and a power supply. póåÅÜêçåçìë=p~ãéäáåÖ Channel 4 Channel 1 +/-0,1 V +/-1 V 16-Bit A/D Digital Filter Converter +/-10 V... -

Page 22: Sensor Channels

In the application program (e.g. INCA MDA), the signal must be delayed to compensate for the group delay. A special feature of the ES411.1 is the compensation of the group delay within the module. The group delays of the analog anti-aliasing filter and the configu- rable digital filter are taken into consideration in this process. - Page 23 8.10.5 on page 79. Digital Filter Configuration Recommendations The -3 dB cutoff frequency of the digital filter system of the ES411.1 can be configured in the application program. To avoid aliasing effects, be sure to observe recommendations for the configu- ration of the filter depending on the selected INCA sampling rate.

-

Page 24: Galvanically Isolation

ETAS Hardware Description Fig. 5-5 ES411.1 Filter B: f = 200 Hz (with compensation of the group C,FIR delay) Fig. 5-4 and Fig. 5-5 show the relevant signal trace - in the upper part of the figure without a filter, in the lower part of the figures with a filter and without or with group delay compensation respectively. -

Page 25: Fig. 5-6 Maximum Input And Common-Mode Voltages

) = 60 V CMxy CMyz 10 V + 5 V + 10 V + 15 V + max (U ) = 60 V CMyz max (U ) = 60 V - 40 V = 20 V CMyz ES411.1 - User Guide... -

Page 26: Sensor Supply

Hardware Description 5.3.4 Sensor Supply Every sensor that can be switched to the ES411.1 has an individual sensor sup- ply voltage which can be set separately. The cable connected to the sensor port of the ES411.1 transfers both the sen- sor supply voltage and the sensor output voltage for the sensor. -

Page 27: Data Transfer

Message Format “XCP on UDP” (Schematic) Using the UDP/IP standard for data transfer makes it possible to connect the modules directly to a PC, a router or a switch. In XCP communication, the PC has the master function. ES411.1 - User Guide... -

Page 28: Realization

The communication protocol used by the ES400 family makes it possible for third-party suppliers to use the communication protocol for their own, non- ETAS applications once the modules have been configured with the „ES4xx Configuration Tool from ES4xx_DRV_SW“ . 5.4.2... - Page 29 IEEE1588 (Precision Time Protocol). The modules add the time stamp to the Ethernet data package for every measure date. The combination of time stamp synchronization, full duplex and time slice pro- cedure results in a very high reference data rate of the modules. ES411.1 - User Guide...

-

Page 30: Examples

5.4.3 Examples Example 1 Fig. 5-9 on page 30 shows an example of an application with three concatenated ES400 modules with the same acquisition rates. The transfer scheme for this configuration is shown in Fig. 5-10 on page 30. jlarib=N jlarib=O jlarib=P `çåíêçä=î~êá~ÄäÉë... -

Page 31: Fig. 5-11 Time-Multiplex Data Transfer Between An Es400 Module Chain And A Pc

Example 2 Fig. 5-11 on page 31 shows an example in which three modules with different acquisition rates are linked to each other. The transfer scheme for this configuration is shown in Fig. 5-12 on page 31. jlarib=N jlarib=O jlarib=P `çåíêçä=î~êá~ÄäÉë... -

Page 32: Power Supply

ES400 modules with supply voltages between 5 V and 50 V DC over the entire temperature range. With the power supply management of the ES411.1, you can use an automatic power-saving feature (“Standby”) as well as a “Wake Up” function via the Ether- net interface. - Page 33 ETAS Example 1: For module chains which are equipped exclusively with ES410.1 or ES441.1, ETAS recommends the use of Y boost cables if the length of the module chain is longer than 10 modules. Example 2: For module chains which are equipped exclusively with ES411.1 or ES413.1 or ES421.1, ETAS recommends the use of Y boost cables if the length of the mod-...

- Page 34 With a minimum voltage of 9 V, no additional feeding is necessary with a Y cable if the module chain consists of the following modules: • five ES420.1 or ES421.1 and • two ES415.1 (with sensor feeding) and • one ES441.1 NOTE All examples apply at 85 °C ambient temperature. ES411.1 - User Guide...

-

Page 35: Es411.1 - Documentconfiguration

ETAS ES411.1 - DocumentConfiguration The configuration of the ES411.1 is performed entirely via the GUI within INCA. The configuration of the individual channels is saved either in INCA or in the individual ES400 modules. In the first case, you can prepare settings for spe- cific measure tasks, e.g. -

Page 36: Getting Started

CAUTION Potential equalization in the vehicle over the shield of the Ethernet connecting cables of modules may occur! Mount the modules only to components with the same electrical potential or insulate the modules from the components. ES411.1 - User Guide... -

Page 37: Guarantee Of Features As Defined By Ip67

(cascading). The two inte- grated assembly elements also make it possible to screw the modules directly onto other components (parts of the vehicle body, units). ES411.1 - User Guide... -

Page 38: Fig. 6-3 Accessing The Integrated Assembly Elements

– on DIN rails with ES4xx angle brackets (right) – on other components • Attaching ES400 modules with cable fasteners: – on DIN rails with ES4xx angle brackets (left) – on DIN rails with ES4xx angle brackets (right) – on other components ES411.1 - User Guide... -

Page 39: Connecting Several Es400 Modules Mechanically

2. Position the modules so that their fronts are in a line. 3. Hold the two modules together firmly on their outer sides. Connecting the Modules To connect several ES400 modules, you require a 2 mm Allen key (minimum length 20 mm). ES411.1 - User Guide... -

Page 40: Fig. 6-6 Connected Es400 Modules

To connect the ES400 module to other modules, you require a 2 mm Allen key (minimum length 20 mm). To connect to other modules: 1. Assemble other modules in accordance with the procedure described in the section 6.2.2 on page ES411.1 - User Guide... -

Page 41: Attaching Es400 Modules To Other Components Using The Integrated As

Preparing the Component To cut the thread in the component: 1. Cut two M3 threads into the selected component. The threads should be cut 8 mm deep. NOTE Use the drilling template (see Fig. 6-13 on page 51). ES411.1 - User Guide... - Page 42 You can only successively screw additional modules, but not module blocks, onto the right-hand side of this module. To connect the ES400 module to other modules, you require a 2 mm Allen key (minimum length 20 mm). ES411.1 - User Guide...

-

Page 43: Attaching Es400 Modules On Din Rails With The Integrated Assembly Ele

1. Connect the module with the ES4xx angle bracket (left). 2. Connect the module with additional modules (as required). 3. Connect the ES4xx angle bracket with the DIN rail. Fig. 6-9 Fastening to an ES4xx Angle Bracket (left) using the Integrated Assembly Elements ES411.1 - User Guide... - Page 44 5. Insert the hex key in the other hexagon head of the module. 6. Screw the parts together by turning the hex key clockwise to the stop within the module. NOTE Screw the two parts together without canting the threads! Both parts are now completely connected mechanically. ES411.1 - User Guide...

-

Page 45: Attaching Es400 Modules To Other Components With Screws

Here, you connect the ES400 module to the component using two additional M3 screws which are screwed into the drill holes of the component. The inte- grated assembly elements of the module are not used. Fig. 6-10 Attaching to Other Components Using Additional Screws ES411.1 - User Guide... - Page 46 4. Screw the screw from the right-hand side of the component into the module. NOTE Screw the two parts together without getting them off- thread! Both parts are now connected mechanically on one side. 5. Insert the other screw into the other hole in the component. ES411.1 - User Guide...

-

Page 47: Attaching Es400 Modules On Din Rails Using Screws

1. Connect the module with additional modules (as required). 2. Connect the module with the ES4xx angle bracket (right). 3. Connect the ES4xx angle bracket with the DIN rail. Fig. 6-11 Fastening on DIN Rails with Additional Screws ES411.1 - User Guide... - Page 48 ES4xx angle bracket. NOTE Screw the two parts together without canting the threads! Both parts are now mechanically connected on one side. 5. Insert the other screw through the other bore of the ES4xx angle bracket (right). ES411.1 - User Guide...

- Page 49 DIN rail. 3. Engage the ES4xx angle bracket in the DIN rail by pressing on the ES4xx angle bracket or the module. The module connected with the ES4xx angle bracket is fas- tened to the DIN rail. ES411.1 - User Guide...

-

Page 50: Attaching Es400 Modules To Other Components Using Cable Fasteners

DIN rail. 3. Engage the ES4xx angle bracket in the DIN rail by pressing on the ES4xx angle bracket or the module. The module connected with the ES4xx angle bracket is fas- tened to the DIN rail. ES411.1 - User Guide... -

Page 51: Drilling Template

ETAS Getting Started Drilling Template Fig. 6-13 Drilling Template ES411.1 - User Guide... -

Page 52: Applications

ES411.1 with additional ETAS Modules for MC Applications The ETAS Daisy Chain concept enables a simple network architecture since only the ES411.1 or the first module of the module chain is connected with the PC or with the "ETH" port of the ES59x.1. -

Page 53: Es411.1 With Additional Etas Modules (Rapid Prototyping Application)

Vehicle, Test Bench, Motor , ... Fig. 6-15 ES411.1 with ES910.3 and additional ETAS Modules for Rapid Prototyping Applications The concept of the ES4xx/ES63x/ES93x product family to install the modules as close as possible to the sensors, the chain the modules with each other, and to connect only the first module of this chain with the ES910.3 or the RTPRO-... -

Page 54: Wiring Examples

ES595 ES411 ES413 ES420 ES430 ES410 ES415 ES421 ES432 ES441 Fig. 6-16 ES400 Modules with add. ETAS Modules (Measurement & Calibration) Cable in Function Order name Fig. 6-16 Power supply cable CBP120, CBP1205 Host connection cable CBE100 Power supply and Ethernet cable Daisy Chain... -

Page 55: Es400 Modules With Additional Etas Modules And Drive Recorder

Tempera- Frequency, Exhaust Voltage ture Counter Results, Pressure Times Fig. 6-17 ES400 Modules with additional ETAS Modules and Drive Recorder (Measurement and Calibration) Cable in Function Order name Fig. 6-17 ES520-, ES59x-, ES6xx-, ES1120- or ES1135- CBE130, CBE140 Ethernet cable... -

Page 56: Es400 Modules With Es910.3 (Rapid Prototyping)

Power supply and Ethernet cable Daisy Chain CBEP430, modules CBEP4305 ETK connection cable CBM150 5, 6 CAN/LIN/FLX connection cable (CAN/LIN/ CBCFI100 FLX combined) at ES910.3, at ES921.1 CAN connection cable (CAN only), at ES910.3, CBAC130, at ES921.1 CBAC140, CBAC150, CBCX130 ES411.1 - User Guide... -

Page 57: Es400 Modules With Es910.3 And Drive Recorder (Rapid Prototyping)

Cable in Function Order name Fig. 6-19 Ethernet adapter cable (100 Mbit/s) CBAE330 (con- nected to cable Ethernet connection cable(1 Gbit/s) CBE230 (con- nected to cable Power supply and Ethernet cable Daisy Chain CBEP430, modules CBEP4305 ES411.1 - User Guide... -

Page 58: Es400 Modules With Etas Rtpro-Pc (Rapid Prototyping)

ETAS 6.5.5 ES400 Modules with ETAS RTPRO-PC (Rapid Prototyping) Ether net USB2 Power Supply Daisy Chain Modules ES581.4 ES411 ES413 ES420 ES430 ES410 ES415 ES421 ES432 ES441 Fig. 6-20 ES400 Modules with ETAS RTPRO-PC (Rapid Prototyping) Cable in Function Order name Fig. -

Page 59: Wiring

An overview is contained in the chapter “Cables and Accessories” on page 83. 6.6.1 “Sensor” Port You can use different cables to connect the sensors to the ES411.1: • CBAV411.1 sensor cable You can adapt the open connection of the CBAV411.1 sensor cable your- self to suit the specific connector system of your test set-up. -

Page 60: Fig. 6-21 Es411.1 With Es4Xx_Bridge

“OUT” port of the ES411.1 of the last module of the chain towards the PC. 3. Connect the combined Ethernet and power supply cable to the “IN” port of the ES411.1 of the next module towards the end of the chain. 4. Connect the supply voltage connector of the combined Ether- net and power supply cable to the desired power supply. -

Page 61: Troubleshooting Problems

LED Displays Please observe the LEDs which provide information on the functions of the interface and the ES411.1 (see the chapter “LED” on page 19) to be able to judge the operational state of the ES411.1 as well as troubleshooting mea- sures. - Page 62 Are you using WLAN in your WLAN is not permissible within this data transfer. test setup? ETAS network. Wire your test setup (ETAS modules and their connection to the PC) with ETAS cables only. Are you using the correct Check whether you are using a PCMCIA type of network card in your network card in your laptop.

-

Page 63: Problems And Solutions

Windows 7, 8.1 and 10 systems. Network security policies, however, may request the APIPA mechanism to be disabled. In this case, you cannot use a network adapter which is configured for DHCP to access ETAS hardware. The ETAS Network Manager displays a warning message. -

Page 64: Search For Ethernet Hardware Fails

Whenever you switch from a DHCP company LAN to the ETAS hardware net- work, it takes at least 60 seconds until ETAS hardware can be found. This is caused by the operating system’s switching from the DHCP protocol to APIPA, which is being used by the ETAS hardware. - Page 65 Select the Energy Management tab. ii. Deactivate the Computer can switch off device to save energy option. 7. Select the Extended tab. 8. If the property Autosense is included, deactivate it. 9. Click OK to apply the settings. ES411.1 - User Guide...

-

Page 66: Personal Firewall Blocks Communication

Ethernet hardware at all, although the configuration parameters are correct. Some actions in ETAS products can lead to problems if the firewall is not prop- erly parameterized, e.g. when opening the experiment environment in ASCET or for the hardware search by INCA or HSP. - Page 67 ETAS • Incoming IP unicasts via UDP originating from any IP address in the net- work configured for the ETAS application, originating ports 17099 to 18020, destination ports 17099 to 18020 • Outgoing TCP/IP connections to the network configured for the ETAS...

- Page 68 *.ini files are modified during the work. The ETAS software must be installed by an administrator in any case. It is rec- ommended that the administrator ensures that the ETAS product or the pro- cesses are added to the list of selected exceptions of the Windows Firewall after the installation.

-

Page 69: Technical Data

F 00K 123 456 Ordering number of the product, see chapter 10.1 on page 102 Operating voltage range (DC), Power consumption Labeling for WEEE, see chapter 8.6 on page 73 Marking for CE conformity (Chapter 8.3 on page 72) ES411.1 - User Guide... -

Page 70: Standards And Norms

Shocks per direction and axis: 10, Units under test: active ISO 16750-3, Sec. 4.3 Drop test Number of drops: 2, Height: 1 m, Surface: concrete, steel Units under test: passive ISO 16750-4, Sec. 5.2 Phased temperature test ES411.1 - User Guide... -

Page 71: Environmental Conditions

Works on the module housing may be executed only by qualified technical personnel. 8.1.4 Maintenance the Product Do not open or change the module! Works on the module housing may be exe- cuted only by qualified technical personnel. Send defect modules to ETAS. ES411.1 - User Guide... -

Page 72: Cleaning The Product

People's Republic of China with a China RoHS label attached to the product or its packaging. CE conformity With the CE mark attached to the product or its packaging, ETAS confirms that the product corresponds to the product-specific, applicable directives of the European Union. -

Page 73: Product Return And Recycling

The user is obligated to separate the waste equipment and to provide it to the WEEE return system for reuse. The WEEE Directive applies to all ETAS devices, but not to external cables or batteries. Additional information about the recycling program of ETAS GmbH is available from the ETAS sales and service locations (see chapter 11 on page 107). -

Page 74: Hardware

“Link down Power saving” • "Allow the computer to turn off this device to save power". 8.9.2 Software To configure the ES411.1 and for control and data acquisition, you need soft- ware in the following versions: • INCA V6.0 and higher •... -

Page 75: Electrical Data

INCA V5.4.1 and higher • ES4xx Configuration Tool V1.0.4 from ES4xx_DRV_SW (stand-alone operation). NOTE Operating the ES411.1 with older versions of software is not possible. 8.10 Electrical Data This chapter contains information on the following topics: • “Host Interface” on page 75 •... -

Page 76: Power Supply

Outputs (plus) short-circuit proof against ground and up to 26 V over- voltage. Ground connected to operating volt- age ground and protected by a fuse. Diagnostics Short-circuit detection per channel; overload conditions reduce the output voltage ES411.1 - User Guide... -

Page 77: Sensor Inputs

Input-to-ground of voltage supply or housing: 60 V DC / 30 V AC Maximum Input voltage Input-to-input: (wet environment) 35 V DC / 16 V AC Input-to-ground of voltage supply or housing: 35 V DC / 16 V AC ES411.1 - User Guide... - Page 78 Input impedance Measurement ranges ±0.1 V, ±1V: > 10 M || < 300 pF Measurement ranges ±10 V, ±60 V: > 2 M || < 400 pF Module not powered: > 2 M || < 400 pF ES411.1 - User Guide...

-

Page 79: Signal Processing

0.4 Hz 0.2 Hz 5 Hz 200 ms 2 Hz 0.8 Hz 0.4 Hz 0.2 Hz 2 Hz 500 ms 0.8 Hz 0.4 Hz 0.2 Hz 1 Hz 0.4 Hz 0.2 Hz 0.5 Hz 0.2 Hz ES411.1 - User Guide... -

Page 80: Pin Assignment

““IN” Connector” on page 80 • ““OUT” Connector” on page 81 • ““Sensor” Connector” on page 82 NOTE All connectors are shown with a view of the front of the ES411.1. All shields are at case potential. 8.11.1 “IN” Connector Fig. 8-2 “IN” Connector... -

Page 81: Out" Connector

Operating voltage UBatt Operating voltage Ground Ground Received data, plus Send data, minus Received data, minus Ground Ground Send data, plus The following socket is mounted on "OUT" connector: LEMO 1B 8-pin A-coding (connection identified in yellow) ES411.1 - User Guide... -

Page 82: Sensor" Connector

Sensor channel 1, input - CH1 TEDS- Sensor channel 1, TEDS- CH2 TEDS- Sensor channel 2, TEDS- CH3 TEDS- Sensor channel 3, TEDS- CH4 TEDS- Sensor channel 4, TEDS- TEDS- Cable, TEDS- *): connected with operating voltage ground ES411.1 - User Guide... -

Page 83: Cables And Accessories

“Measurement Probes and Cables” on page 96 • “Protective Caps” on page 100 • “Angle Brackets” on page 101 NOTE Only use ETAS cables at the interfaces of the module. Adhere to the maxi- mum cable lengths! ES411.1 - User Guide... -

Page 84: Combined Ethernet And Power Supply Cable

Connect the power cable only with a suitable vehicle battery or with a suitable lab power supply! The connection to power outlets is not allowed! To prevent an inadvertent insertion in power outlets, ETAS recommends to equip the combined ethernet and power supply cables with safety banana plugs in areas with power outlets. -

Page 85: Cbep410.1 Cable

(MINI flat automotive fuse, quick-response, 3 A, 58 V). Robust, waterproof and dust-proof (IP67). Temperature rated for: -40 °C to +125 °C / -40 °F to +257 °F Product Length Order number CBEP4105.1-3 F 00K 110 026 ES411.1 - User Guide... -

Page 86: Cbep415.1 Cable

(MINI flat automotive fuse, quick-response, 3 A, 58 V). Robust, waterproof and dust-proof (IP67). Temperature rated for: -40 °C to +125 °C / -40 °F to +257 °F Product Length Order number CBEP4155.1-5 F 00K 110 027 ES411.1 - User Guide... -

Page 87: Cbep420.1 Cable

(MINI flat automotive fuse, quick-response, 3 A, 58 V). Robust, waterproof and dust-proof (IP67). Temperature rated for: -40 °C to +125 °C/ -40 °F to +257 °F Product Length Order number CBEP4205.1-3 F 00K 110 041 ES411.1 - User Guide... -

Page 88: Cbep425.1 Cable

(MINI flat automotive fuse, quick-response, 3 A, 58 V). Robust, waterproof and dust-proof (IP67). Temperature rated for: -40 °C to +125 °C / -40 °F to +257 °F Product Length Order number CBEP4255.1-3 F 00K 110 029 ES411.1 - User Guide... -

Page 89: Cbep430.1 Cable

(MINI flat automotive fuse, quick-response, 3 A, 58 V). Robust, waterproof and dust-proof (IP67). Temperature rated for: -40 °C to +125 °C / -40 °F to +257 °F Product Length Order number CBEP4305.1-0m5 0.5 m F 00K 110 030 ES411.1 - User Guide... -

Page 90: Ethernet Cable

(MINI flat automotive fuse, quick-response, 3 A, 58 V). Robust, waterproof and dust-proof (IP67). Temperature rated for: -40 °C to +125 °C / -40 °F to +257 °F Product Length Order number CBE401.1-0m5 0.5 m F 00K 106 128 ES411.1 - User Guide... -

Page 91: Cbe430.1 Cable

Can also be used to connect ES4xx via PC, ES600 or ES1135 alter- natively while keeping cable installation through bulkhead. Robust, waterproof and dust-proof (IP67). Temperature rated for: -40 °C to +125 °C / -40 °F to +257 °F Product Length Order number CBEX400.1-3 F 00K 105 294 ES411.1 - User Guide... -

Page 92: Es4Xx_Bridge

ETAS 9.2.6 ES4xx_BRIDGE Fig. 9-16 ES4xx Bridge Ethernet bridge connecting blocked ES400 modules. Facilitates very compact measurement setups. IP67 compliant. Product Order number ES4xx_BRIDGE F 00K 105 684 ES411.1 - User Guide... -

Page 93: Cable For The Connection "Sensor

Temperature rated for: -40 °C to +125 °C Product Length Order number CBAV400.1-0m3 0.3 m F 00K 104 916 ES411.1 - User Guide... -

Page 94: Cbav411.1 Cable

You can customize the open connection of sensor cable CBAV411.1 and adapt it to the specific plug connector system of your measuring setup. Temperature rated for: -40 °C to +125 °C Product Length Order number CBAV411.1-2 F 00K 104 918 ES411.1 - User Guide... -

Page 95: Cbav417.1 Cable

Measurement channel [n], sensor supply GND *) *): connected with operating voltage Ground Notes about the Application Temperature rated for: -40 °C bis +125 °C Product Length Order number CBAV417.1-0m3 0.3 m F 00K 111 855 ES411.1 - User Guide... -

Page 96: Measurement Probes And Cables

CBN401.1 Isolating Measurement Probe The CBN401.1 Isolating Measurement Probe for use with the ES411.1/ ES411.1 module offers four input channels for voltages up to +/-10 V DC, a sep- arate signal conditioning for each channel with voltage reduction and isolation (max. -

Page 97: Cbn41X.1 Current Probe

The CBN41x.1 Current Probe consists of four identical active current measur- ing channels that are integrated in a splitter cable and designed for the com- bined use with the ES411.1 / ES411.1 A/D module. Application area: Measuring high currents Temperature rated for: -40 to +85°C... -

Page 98: Cbn42X.1 Sensor Cable

The CBN42x.1 Sensor Cable Providing Bipolar Sensor Supply consists of four identical active current measuring channels that are integrated in a splitter cable and designed for the combined use with the ES411.1 / ES411.1 A/D mod- ule. Application area: potential-free measuring of high currents with current trans- formers from LEM (series HTR) or comparable current transformers and with other sensors with bipolar supply voltage. -

Page 99: Cbn430.1 Temperature Sensor Connection Cable

The CBN430.1 Temperature Sensor Connection Cable consists of four identi- cal active current measuring channels that are integrated in a splitter cable and designed for the combined use with the ES411.1 / ES411.1 A/D module. Application area: precise measuring of temperatures with platinum tempera- ture sensors Temperature rated for: -40 to +85°C... -

Page 100: Protective Caps

ETAS Protective Caps The connections "IN" and "OUT" of the ES411.1 can be protected with different protective caps according to the operating conditions. 9.5.1 Protective Caps supplied The "IN" and "OUT" ports of the ES4xx are covered with simple dust and trans- port caps on delivery. -

Page 101: Angle Brackets

Angle Bracket for mounting ES4xx modules to a DIN rail 35 x 7.5 (EN 60715 TH35). Stainless steel V2A. For mounting on right side of an ES4xx module. Product Order number Angle bracket right F 00K 107 176 ES411.1 - User Guide... -

Page 102: Ordering Information

Package“, ES4xx Safety Advice, China-RoHS-leaflet_Compact_green_cn, Calibration-Certification 10.2 Accessories 10.2.1 Cables NOTE If you require customized cables, please contact your ETAS contact partner or sales.de@etas.com. 10.2.1.1 Cables for the connectors "IN" and "OUT" Ethernet cable Order name Short name Order number Ethernet Chain Connection Cable, Lemo CBE400.2-3... - Page 103 F 00K 110 030 Supply Cable, Lemo 1B FGL - Lemo 1B FGA - Safety Banana (8fc-8mc-2mc), 0m5 Ethernet Bridge Order name Short name Order number Bridge to connect two assembled ES4xx ES4xx_BRIDGE F 00K 105 684 Modules ES411.1 - User Guide...

- Page 104 F 00K 107 566 cable providing bipolar sensor supply volt- age, 4 Channel, Souriau 4xMolex 51191- 004, 2m CBN430.1 PT100 Sensor Connection CBN430.1-2m F 00K 107 725 Cable, 4 Channels, Souriau 8ST12-35 4xOpen Wire, 2 m ES411.1 - User Guide...

-

Page 105: Protective Caps

F 00K 107 175 ES4xx Angle Bracket right ES4xx_AB_R F 00K 107 176 10.2.4 Calibration NOTICE ETAS recommends a calibration interval of 12 months. 10.2.4.1 Factory calibration Factory calibration service • Verification of measurement accuracy • Issue a standard-compliant calibration certificate... - Page 106 Issue of internationally recognized, ISO/IEC 17025 compliant calibration certificates for "pre-adjustment" and "post-adjustment" Order name Short name Order number DAkkS adjustment service for ES411 DAkkS_A_ES411 F-00K-111-775 1. Accreditation by Deutsche Akkreditierungsstelle (DAkkS) 2. Supervision of the calibration certificate by DAkkS ES411.1 - User Guide...

-

Page 107: Contact Information

Germany Internet: www.etas.com ETAS Subsidiaries and Technical Support For details of your local sales office as well as your local technical support team and product hotlines, take a look at the ETAS website: ETAS subsidiaries Internet: www.etas.com/en/contact.php ETAS technical support Internet: www.etas.com/en/hotlines.php... -

Page 108: Figures

ES411.1 Housing ........ - Page 109 ES411.1 with ES4xx_BRIDGE ........

- Page 110 Angle Bracket Right ..........101 ES411.1 - User Guide...

-

Page 111: Index

Measurement error ....78 Data Mechanical data ....72 ES411.1 - User Guide... - Page 112 Synchronization of the timebases ..29 Synchronization, clock generator ..29 System requirements ....73 ES411.1 - User Guide...

Need help?

Do you have a question about the ES411.1 and is the answer not in the manual?

Questions and answers