Summary of Contents for turck QR24

- Page 1 Your Global Automation Partner Contactless QR24 Encoders with CANOPEN Interface Manual...

- Page 2 Turck Inc. | 3000 Campus Drive, Minneapolis, MN 55441 | T +1 800 544 7769 | F +1 763 553 0708 | www.turck.com...

-

Page 3: Table Of Contents

Contents 1 About this manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 1.1 Target groups . -

Page 4: About This Manual

We aim to keep this manual as informative and clear as possible. Please send any suggestions to tusa.marketing@turck.com if you feel there is information missing or if you have ideas on how to improve the layout. Turck Inc. | 3000 Campus Drive, Minneapolis, MN 55441 | T +1 800 544 7769 | F +1 763 553 0708 | www.turck.com... -

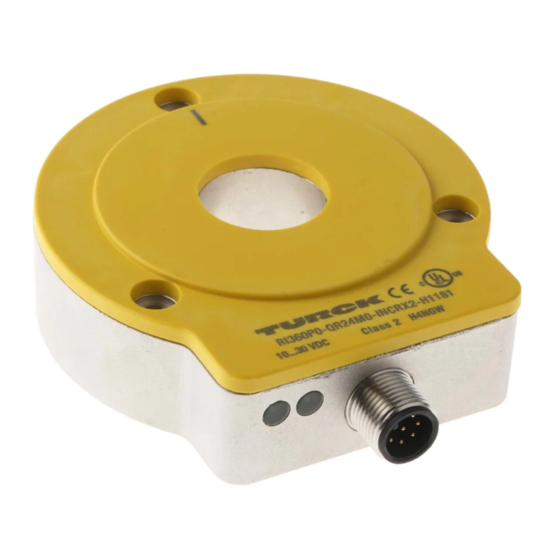

Page 5: Notes On The Product

2. Notes on the product 2 .1 Product identification (type key) Ri 360 P1 – QR24 M0 – CN X4 – 2 H1 1 5 0 Ri 360 P1 Operating principle – QR24 M1 Housing style – CN X4 Electrical version –... -

Page 6: Scope Of Delivery

This will apply to the electrical device and to the user information/operating manual, as well as any other documentation provided by Hans Turck GmbH & Co. KG. Turck Inc. | 3000 Campus Drive, Minneapolis, MN 55441 | T +1 800 544 7769 | F +1 763 553 0708 | www.turck.com... -

Page 7: Explanation Of Symbols

3 .4 Explanation of symbols The following symbols are used in this manual: WARNING: Warning denotes a possibly hazardous situation with medium risk which could result in fatality or severe injury if not prevented. Notes: In connection with WARNING, you will find tips, recommendations, and important information. These notes will simplify your work, contain information about specific steps to be taken, and help prevent additional work due to incorrect procedures. -

Page 8: Functional Principle

The device is working with reduced accuracy. Green No data signal The device is not functioning Error LED (ERR) Turck Inc. | 3000 Campus Drive, Minneapolis, MN 55441 | T +1 800 544 7769 | F +1 763 553 0708 | www.turck.com... -

Page 9: Connection Assignments

Colour/Status Status Description No error The device is functioning correctly Red flashing LSS status The device is in LSS operation (intermittently flashing RUN LED) Two short red flashes Guard event occurrence A guard event (NMT slave or master) or heartbeat event has occurred Three short flashes SYNC error The SYNC message was not received within the preconfigured cycle time... -

Page 10: Assembly

Mount the encoder depending on and protected unit. application requirement. Turck Inc. | 3000 Campus Drive, Minneapolis, MN 55441 | T +1 800 544 7769 | F +1 763 553 0708 | www.turck.com... -

Page 11: Configuration

6 Configuration The wear-resistant encoder with CANopen interface is ideally suited for use in mobile machinery and industrial applications. Short latencies and cyclic, event-controlled communication are only two of the many advantages of the CANopen protocol, which is often used in this area of application. A particular highlight is the software-controlled, bus-activated terminating resistor. 6 .1 Objects 1000h –... - Page 12 Contains the manufacturer’s software version number. 100Ah Manufacturer software version Vis string Data content: e.g. “SW-1.0.0.1” in ASCII code Turck Inc. | 3000 Campus Drive, Minneapolis, MN 55441 | T +1 800 544 7769 | F +1 763 553 0708 | www.turck.com...

- Page 13 6 .1 .8 Object 1010h: Store parameters Writing the command “save” initiates the storing of the parameters to the non-volatile memory (EEPROM). 1010h ARRAY Store parameters Unsigned 32 The following commands are stored with this command: 1005h, 1014h, 1800h (sub-index 1 and 3), 1802h (sub-index 1), 2000h, 2001h, 2005h, 6000h, 6001h, 6002h, 6003h, 6200h.

- Page 14 An emergency message with code 8200h is generated if a faulty NMT command (CAN message ID = 0) is received. Turck Inc. | 3000 Campus Drive, Minneapolis, MN 55441 | T +1 800 544 7769 | F +1 763 553 0708 | www.turck.com...

- Page 15 (4 entries) Sub-index 1h: delivers the Turck vendor ID (0000009Ch) Sub-Index 2h: delivers the product code (e.g. Turck QR24 CANopen) Sub-Index 3h: delivers the SW revision number (e.g. 1.0.0.1), see table “3-Point notation” Example: Version 1.0.0.1 = 10...

- Page 16 0 = sensor changes to pre-operational mode 1 = sensor does not change mode 2 = sensor changes to stopped mode Turck Inc. | 3000 Campus Drive, Minneapolis, MN 55441 | T +1 800 544 7769 | F +1 763 553 0708 | www.turck.com...

- Page 17 6 .1 .15 Object 1800h: PDO1- Parameter (asynchronous) PDO1: Metering value output “Position” in set time cycles The object contains the parameter for the process data object PDO1. Via this service, the process data of the encoder is output asynchronously, triggered by the internal cycle timer (prerequisite: the cycle timer was set via object 6200h). 1800h RECORD PDO1 parameter...

- Page 18 2 ms 50 kBit/s 0,39 3 ms 20 kBit/s 0,15 7 ms 10 kBit/s 0,07 15 ms Turck Inc. | 3000 Campus Drive, Minneapolis, MN 55441 | T +1 800 544 7769 | F +1 763 553 0708 | www.turck.com...

- Page 19 6 .1 .17 Object 1802h: PDO3 parameters (asynchronous) PDO3: Metering value output “Position” at value change The object contains the parameters for the process data object PDO3. Via this service, the process data of the encoder is output in transmission type “Manufacturer, asynchronous” when triggered by a change in the process value. 1802h RECORD PDO3 parameters...

- Page 20 2 ms 50 kBit/s 0,39 3 ms 20 kBit/s 0,15 7 ms 10 kBit/s 0,07 15 ms Turck Inc. | 3000 Campus Drive, Minneapolis, MN 55441 | T +1 800 544 7769 | F +1 763 553 0708 | www.turck.com...

- Page 21 6 .1 .19 Overview transmission types A value between 1...240 means that the PDO is sent synchronously or cyclic. The transmission type number means the number of SYNC impulses required to send the PDOs. Transmission type 252 and 253 mean that the PDO is only sent on request via RTR. Type 254 means that the event is triggered application-dependently, while number 255 is device profile-dependent.

-

Page 22: Variables Pdo Mapping

No entry, as 64 bits assigned Mapping object 4 No entry, as 64 bits assigned 1A00h,0x04 1A01h,0x04 Turck Inc. | 3000 Campus Drive, Minneapolis, MN 55441 | T +1 800 544 7769 | F +1 763 553 0708 | www.turck.com... - Page 23 Sample entry in the mapping table: The mapped PDO consists of 3 application object entries with varying lengths: Application object 2 occupies byte 1 (08h) in the transmission PDO. Application object 3 with a length of 16 bit (10h = 2 byte) follows, and then comes application object 1 with 1 byte length.

- Page 24 PDO4 mapping parameter PDO MAPPING (21h) Data content: Sub-index 0h: Number of supported sub-indices. Read only Value range: 1...4 Turck Inc. | 3000 Campus Drive, Minneapolis, MN 55441 | T +1 800 544 7769 | F +1 763 553 0708 | www.turck.com...

- Page 25 6 .2 .5 Example: Create mapping for PDO3 (speed) Up to four application objects (position, speed, ...) can be transmitted in one PDO. The max. data length is 64 bit. Example: A ) Configure the communication parameters via object 1802h The communication parameters of the encoder are configured via object 1802h (communication parameter).

- Page 26 0x1800ff, sub-index 1, COB ID, set bit 31 to “0” (unlock PDO) Data: 0xC000 019B -> 0x4000 019B (example) Turck Inc. | 3000 Campus Drive, Minneapolis, MN 55441 | T +1 800 544 7769 | F +1 763 553 0708 | www.turck.com...

-

Page 27: Objects 2000H - 2Fffh (Manufacturer Specifications)

6 .3 Objects 2000h – 2FFFh (manufacturer specifications) 6 .3 .1 Object 2100h: Baud rate The Baud rate without LSS service is set via this object. 2100h Baud rate Unsigned16 NOTE A password is necessary to change the object. Service pass code object 0x2900, 0x01 (Unsigned32). The password is 12345 (dec) resp. - Page 28 It will take several seconds for the current metering value to level out if the values selected for the filter constant are very high (higher than 50). Turck Inc. | 3000 Campus Drive, Minneapolis, MN 55441 | T +1 800 544 7769 | F +1 763 553 0708 | www.turck.com...

-

Page 29: Objects 6000H - 6Fffh (Default Device Parameters)

6 .3 .7 Object 2110h: Customer memory The start-up mode of the encoder is specified via this object. 2110h Customer memory Unsigned32 0x2110, 0x01…0x04 Customer memory range - Four number values can be stored here in the range unsigned 32. - The stored data is informal and have no impact on the function of the encoder. - Page 30 Output: One revolution is divided into 10 × 0…360 Example 2: Setting: 6001h: MUR= 3600 6002h: TMR= 3600 Output: One revolution is divided into 0…3600 Turck Inc. | 3000 Campus Drive, Minneapolis, MN 55441 | T +1 800 544 7769 | F +1 763 553 0708 | www.turck.com...

- Page 31 Example 3 skip in the source code: Setting: 6001h: MUR= 3600 6002h: TMR= 3000 Output: One revolution is divided into 0…3000 and 0…600 NOTE The max. physical resolution is a factory setting in object 6501h (read only). In object 6000h bit 2: Set scaling function to enable (1). 6 .4 .4 Object 6003h: Preset value The position value of the encoder is configured to this preset value.

- Page 32 Value range: 0…FFFFh (65535dec) provides the cycle time in milliseconds. Default value: 100dec NOTE No measuring value output occurs if cycle time = 0. Turck Inc. | 3000 Campus Drive, Minneapolis, MN 55441 | T +1 800 544 7769 | F +1 763 553 0708 | www.turck.com...

- Page 33 6 .4 .9 Object 6400h: Work area state register This object contains the current status of the encoder position in relation to the programmed limits. Depending on position of the two endpoints, flags are set or reset. Where the measuring values are within the work area, bits 0...7 will have the value 0 .

- Page 34 6 .4 .11 Object 6500h: Operating status read only This is where the basic settings can be read from object 6000h. 6500h Operating status Unsigned16 Turck Inc. | 3000 Campus Drive, Minneapolis, MN 55441 | T +1 800 544 7769 | F +1 763 553 0708 | www.turck.com...

- Page 35 6 .4 .12 Object 6501h: Single-turn resolution (read only) This is where the basic settings can be read from object 6000h. Resolution value (max. phys. resolution) is stored in the encoder, and can only be read. 6501h Single-turn resolution Unsigned32 Resolution value: RI360P0-QR24M0-CNX4-2H1150: 327680...

- Page 36 1= Warning message "Overspeed" is supported. Bit 7…14: free Bit 15: 1= Warning message "RLC coupling weak" is supported. Turck Inc. | 3000 Campus Drive, Minneapolis, MN 55441 | T +1 800 544 7769 | F +1 763 553 0708 | www.turck.com...

- Page 37 6 .4 .18 Object 6507h: Profile and software version (read only) The first 16 bit contain the version number of the encoder profile applied. The second 16 bit contain the number of the software version implemented in the encoder. 6507h Profile and software version Unsigned32 Software version...

-

Page 38: Lss Services Ds 305 V2.0

• Serial number (numerical number) • LSS master CAN ID 2021 • LSS slave CAN ID 2020 Turck Inc. | 3000 Campus Drive, Minneapolis, MN 55441 | T +1 800 544 7769 | F +1 763 553 0708 | www.turck.com... -

Page 39: Network Management

6 .6 Network management The encoder supports the simplified network management (minimum boot-up) defined in the profile for minimum capability devices. The following status diagram in accordance with DS 301 shows the various node states and relevant network commands (controlled by the network master via NMT services): Initialization Initialization: This is the initial state of the device after connection to the power supply following a reset or power-up. -

Page 40: Accessories (Assembly Accessories And Position Elements)

ø 28 ø 24 SP3-QR24 Shield plate Ø 52 mm, aluminium 120° ø 3.2 ø 52 ø 42 Turck Inc. | 3000 Campus Drive, Minneapolis, MN 55441 | T +1 800 544 7769 | F +1 763 553 0708 | www.turck.com... - Page 41 The positioning elements are connected to the moving parts of the machine, but are themselves capable of free movement (with- out any mechanical connection to the sensor) across the active surface of the sensor. Dimension drawing Type Description P1-Ri-QR24 Positioning element for connection on shafts with Ø 20 mm ø 20 ø 3.2 ø 52 ø...

-

Page 42: Technical Information

LED red, flashing red Miscellaneous Included in the scope of delivery Assembly aid MT-QR24 VZ 3 screw plug Turck Inc. | 3000 Campus Drive, Minneapolis, MN 55441 | T +1 800 544 7769 | F +1 763 553 0708 | www.turck.com... -

Page 43: Service

Please note that we can only accept the return of devices accompanied by a decontamination declaration, should it become necessary to return a device. The declaration form is available for download at http://www.turck.de/static/media/downloads/ Dekontamination_de.pdf, must be filled out completely, and must be attached to the exterior of the packaging in a transport-safe and weather-proof sleeve. - Page 44 Turck Inc. | 3000 Campus Drive, Minneapolis, MN 55441 | T +1 800 544 7769 | F +1 763 553 0708 | www.turck.com...

- Page 45 For Application Assistance or for the location of your nearest Turck distributor, call: 1-800-544-7769 Specifications in this manual are subject to change with out notice. Turck also reserves the right to make modifications and makes no guarantee of the accuracy of the information contained herein.

- Page 46 28 subsidiaries and over 60 representations worldwide! Printed in USA ©2015 by Turck Inc. All rights reserved. No part of the www.turck.com MA1019 A 04/17 publication may be reproduced without written permission.

Need help?

Do you have a question about the QR24 and is the answer not in the manual?

Questions and answers