Subscribe to Our Youtube Channel

Summary of Contents for turck RI360P0 IOLX2 3GD Series

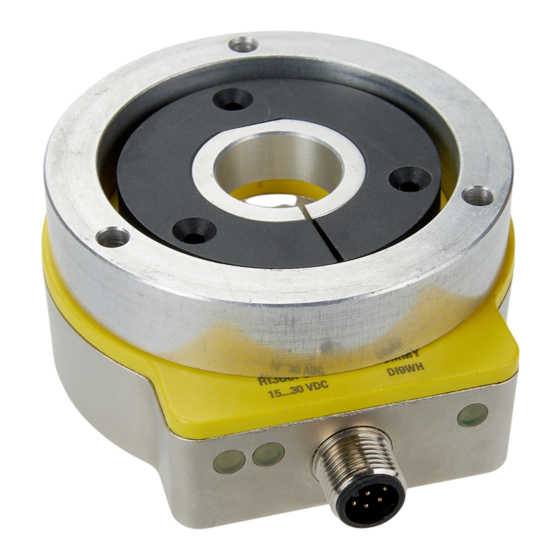

- Page 1 Your Global Automation Partner RI360P0-…-IOLX2-…/3GD Encoders with IO-Link Interface Instructions for Use...

-

Page 2: Table Of Contents

LED display........................ 28 Setting .............................. 29 Setting via IO-Link ...................... 29 9.1.1 IO-Link parameters ........................ 29 9.1.2 IO-Link process data........................ 29 V01.00 | 2023/01 | 2 Hans Turck GmbH & Co. KG | T +49 208 4952-0 | more@turck.com | www.turck.com... - Page 3 14 Technical data........................... 33 15 Appendix ............................ 34 15.1 Approvals and markings ..................... 34 16 Turck subsidiaries — contact information.................. 35 V01.00 | 2023/01 | 3 Hans Turck GmbH & Co. KG | T +49 208 4952-0 | more@turck.com | www.turck.com...

-

Page 4: About These Instructions

If you have any suggestions for improving the design or if some information is missing in the document, please send your suggestions to techdoc@turck.com. V01.00 | 2023/01 | 4 Hans Turck GmbH & Co. KG | T +49 208 4952-0 | more@turck.com | www.turck.com... -

Page 5: Notes On The Product

Encoder – Sensor Mounting aid MT-QR24 Quick Start Guide Turck service Turck supports you with your projects, from initial analysis to the commissioning of your applic- ation. The Turck product database under www.turck.com contains software tools for program- ming, configuration or commissioning, data sheets and CAD files in numerous export formats. -

Page 6: For Your Safety

The product is designed according to state-of-the-art technology. However, residual risks still exist. Observe the following warnings and safety notices to prevent damage to persons and property. Turck accepts no liability for damage caused by failure to observe these warning and safety notices. -

Page 7: Product Description

Encoder — positioning element P1 4.1.1 Indication elements The devices are provided with a green Power supply LED and a yellow Status LED. V01.00 | 2023/01 | 7 Hans Turck GmbH & Co. KG | T +49 208 4952-0 | more@turck.com | www.turck.com... -

Page 8: Properties And Features

IO-Link: Device access protection Rotation direction Zero setting Multiturn reset Reset settings V01.00 | 2023/01 | 8 Hans Turck GmbH & Co. KG | T +49 208 4952-0 | more@turck.com | www.turck.com... -

Page 9: Encoders - Components And Accessories

Positioning element with aluminum reducing bushing to connect to Ø 20 mm shafts ø 20 ø 3.2 ø 52 ø 42 V01.00 | 2023/01 | 9 Hans Turck GmbH & Co. KG | T +49 208 4952-0 | more@turck.com | www.turck.com... - Page 10 Positioning element with aluminum reducing bushing to connect to Ø 6 mm shafts ø 6 ø 3.2 ø 52 ø 42 V01.00 | 2023/01 | 10 Hans Turck GmbH & Co. KG | T +49 208 4952-0 | more@turck.com | www.turck.com...

- Page 11 Positioning element with aluminum reducing bushing to connect to Ø 1/2" shafts ø 1/2“ ø 3.2 ø 52 ø 42 V01.00 | 2023/01 | 11 Hans Turck GmbH & Co. KG | T +49 208 4952-0 | more@turck.com | www.turck.com...

-

Page 12: Encoder - Qr24 Reducing Bushings For Pe1-Qr24 Positioning Elements

ø 28 ø 24 RA2-QR24 Aluminum reducing bushing to connect to Ø 14 mm shafts ø 14 ø 28 ø 24 V01.00 | 2023/01 | 12 Hans Turck GmbH & Co. KG | T +49 208 4952-0 | more@turck.com | www.turck.com... - Page 13 ø 28 ø 24 RA6-QR24 Aluminum reducing bushing to connect to Ø 3/8" shafts ø 3/8“ ø 28 ø 24 V01.00 | 2023/01 | 13 Hans Turck GmbH & Co. KG | T +49 208 4952-0 | more@turck.com | www.turck.com...

- Page 14 ø 28 ø 24 RA10-QR24 Aluminum reducing bushing to connect to Ø 5/8" shafts ø 5/8“ ø 28 ø 24 V01.00 | 2023/01 | 14 Hans Turck GmbH & Co. KG | T +49 208 4952-0 | more@turck.com | www.turck.com...

- Page 15 ø 28 ø 24 RA12-QR24 Aluminum reducing bushing to connect to Ø 18 mm shafts ø 18 ø 28 ø 24 V01.00 | 2023/01 | 15 Hans Turck GmbH & Co. KG | T +49 208 4952-0 | more@turck.com | www.turck.com...

-

Page 16: Encoders - Protecting Rings And Mounting Sets For Qr24 Device Types

+ SP2-QR24 aluminum ø 74 shield plate: Ø 74 mm, ø 22 with Ø 22 mm hole for shaft ø 65 feedthrough V01.00 | 2023/01 | 16 Hans Turck GmbH & Co. KG | T +49 208 4952-0 | more@turck.com | www.turck.com... - Page 17 Ø 52 mm for mounting the positioning element on large rotatable machine parts 120° ø 3.2 ø 52 ø 42 V01.00 | 2023/01 | 17 Hans Turck GmbH & Co. KG | T +49 208 4952-0 | more@turck.com | www.turck.com...

-

Page 18: Encoders - General Accessories

M12 x 1 ø 15 length: 2 m, jacket material: PVC, black; cULus approval; 11.5 other cable lengths and qualities available, www.turck.com V01.00 | 2023/01 | 18 Hans Turck GmbH & Co. KG | T +49 208 4952-0 | more@turck.com | www.turck.com... -

Page 19: Installing

The positioning element must be located in the middle of the measuring range of the sensor before the power supply is applied. V01.00 | 2023/01 | 19 Hans Turck GmbH & Co. KG | T +49 208 4952-0 | more@turck.com | www.turck.com... -

Page 20: Front Mounting - Shaft Diameters Up To 20 Mm

4. Fasten clamp fitting of the positioning element with hexagon spanner. 2.5 mm 0.6…0.8 Nm fig. 6: Fastening the positioning element V01.00 | 2023/01 | 20 Hans Turck GmbH & Co. KG | T +49 208 4952-0 | more@turck.com | www.turck.com... - Page 21 Zero point default value „ Fasten the encoder with three screws in order to produce a closed and protected unit. V01.00 | 2023/01 | 21 Hans Turck GmbH & Co. KG | T +49 208 4952-0 | more@turck.com | www.turck.com...

-

Page 22: Rear Mounting - Shaft Diameters Up To 20 Mm

1. Option 2: Push the encoder with the rear to the shaft onto the shaft and fasten with three screws in the encoder. M4 × 0.5 1.4…1.5 Nm fig. 10: Fastening screws in the encoder V01.00 | 2023/01 | 22 Hans Turck GmbH & Co. KG | T +49 208 4952-0 | more@turck.com | www.turck.com... - Page 23 5. Remove mounting aid. 0° fig. 12: Removing the mounting aid fig. 13: Zero point default value „ Optional: Use protecting ring and shield plate. V01.00 | 2023/01 | 23 Hans Turck GmbH & Co. KG | T +49 208 4952-0 | more@turck.com | www.turck.com...

-

Page 24: Mounting On Large Rotatable Machine Part

Fastening the clamp fitting of the positioning element 3. Use the SP3-QR24 shield plate. 0.6…0.8 Nm fig. 15: Inserting the shield plate V01.00 | 2023/01 | 24 Hans Turck GmbH & Co. KG | T +49 208 4952-0 | more@turck.com | www.turck.com... - Page 25 (factory setting for 0°: yellow arrow on the positioning element pointing to the black mark on the sensor, see figure “Zero point default value”.) 0° fig. 17: Zero point default value V01.00 | 2023/01 | 25 Hans Turck GmbH & Co. KG | T +49 208 4952-0 | more@turck.com | www.turck.com...

-

Page 26: Connection

1 BN n. c. 4 BK – fig. 18: M12 male connector — pin assignment fig. 19: M12 male connector — wiring diagram V01.00 | 2023/01 | 26 Hans Turck GmbH & Co. KG | T +49 208 4952-0 | more@turck.com | www.turck.com... -

Page 27: Commissioning

IO-Link master. Setting IO-Link mode „ Set the cycle time on the IO-Link master. The device is operational. V01.00 | 2023/01 | 27 Hans Turck GmbH & Co. KG | T +49 208 4952-0 | more@turck.com | www.turck.com... -

Page 28: Operation

Positioning element is within the measuring range, reduced signal quality (e.g. gap too large). Yellow flashing Positioning element is not within the measuring range. V01.00 | 2023/01 | 28 Hans Turck GmbH & Co. KG | T +49 208 4952-0 | more@turck.com | www.turck.com... -

Page 29: Setting

9.1.2 IO-Link process data Process data (bit) 3…15 16…31 Resonance No resonance Multiturn fault Multiturn counter Position coupling weak coupling V01.00 | 2023/01 | 29 Hans Turck GmbH & Co. KG | T +49 208 4952-0 | more@turck.com | www.turck.com... -

Page 30: Troubleshooting

If there are no faults, there is a device malfunction. In this case, decommission the device and replace it with a new device of the same type. V01.00 | 2023/01 | 30 Hans Turck GmbH & Co. KG | T +49 208 4952-0 | more@turck.com | www.turck.com... -

Page 31: Maintenance

Ensure that the plug connections and cables are always in good condition. The devices are maintenance-free, clean dry if required. V01.00 | 2023/01 | 31 Hans Turck GmbH & Co. KG | T +49 208 4952-0 | more@turck.com | www.turck.com... -

Page 32: Decommissioning

If present: undo the connection between the device and the mounting aid. Disposal The devices must be disposed of correctly and must not be included in general household garbage. V01.00 | 2023/01 | 32 Hans Turck GmbH & Co. KG | T +49 208 4952-0 | more@turck.com | www.turck.com... -

Page 33: Technical Data

MTTF 138 years acc. to SN 29500 (Ed. 99) 40 °C Operating voltage indication LED green Status display LED yellow V01.00 | 2023/01 | 33 Hans Turck GmbH & Co. KG | T +49 208 4952-0 | more@turck.com | www.turck.com... -

Page 34: Appendix

ÉII 3 D Ex tc IIIC T100°C Dc Ex ec IIA T4 Gc 编码器 Ex tc IIIC T100°C Dc Ambient temperature T : -25…+85 °C V01.00 | 2023/01 | 34 Hans Turck GmbH & Co. KG | T +49 208 4952-0 | more@turck.com | www.turck.com... -

Page 35: Turck Subsidiaries - Contact Information

Baner-Balewadi Link Rd., 411045 Pune - Maharashtra www.turck.co.in Italy TURCK BANNER S.R.L. Via San Domenico 5, IT-20008 Bareggio (MI) www.turckbanner.it V01.00 | 2023/01 | 35 Hans Turck GmbH & Co. KG | T +49 208 4952-0 | more@turck.com | www.turck.com... - Page 36 Inönü mah. Kayisdagi c., Yesil Konak Evleri No: 178, A Blok D:4, 34755 Kadiköy/ Istanbul www.turck.com.tr Turck Inc. 3000 Campus Drive, USA-MN 55441 Minneapolis www.turck.us V01.00 | 2023/01 | 36 Hans Turck GmbH & Co. KG | T +49 208 4952-0 | more@turck.com | www.turck.com...

- Page 37 Over 30 subsidiaries and 60 representations worldwide! 100046869 | 2023/01 100046869 www.turck.com...

Need help?

Do you have a question about the RI360P0 IOLX2 3GD Series and is the answer not in the manual?

Questions and answers