Summary of Contents for turck QR24

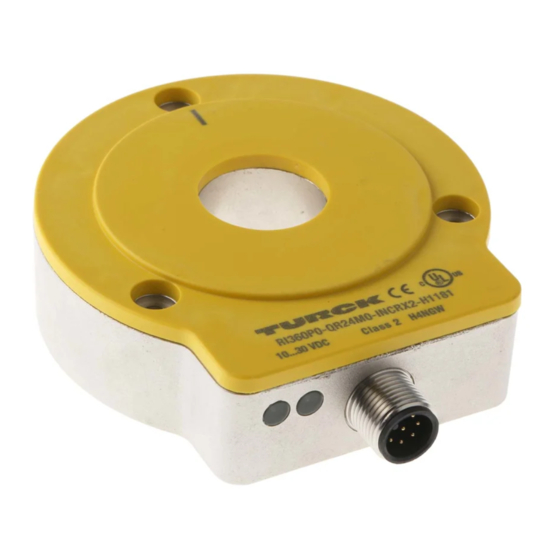

- Page 1 Your Global Automation Partner Your Global Automation Partner Encoder QR24 with an Incremental Interface Instructions for Use...

- Page 2 Hans Turck GmbH & Co. KG | T +49 208 4952-0 | F +49 208 4952-264 | more@turck.com | www.turck.com...

-

Page 3: Table Of Contents

Output function 4.4.2 Burst output Encoder – components and accessories 4.5.1 Encoder – sensor QR24 4.5.2 Encoder – positioning element QR24 4.5.3 Encoder – reducing sleeves QR24 4.5.4 Encoder – protecting rings and mounting kits 4.5.5 Encoder – Sensor EQR24 4.5.6... - Page 4 Set via manual bridging (short-circuit) Set via PACTware (FDT/DTM) Eliminate Interference Maintenance Repairs 12.1 Returning devices Decommissioning Disposal Technical Data 15.1 Default settings Hans Turck GmbH & Co. KG | T +49 208 4952-0 | F +49 208 4952-264 | more@turck.com | www.turck.com...

-

Page 5: About These Instructions

ACTION RESULT ➥ This symbol identifies relevant results of actions and action sequences. Additional documents You will find supplementary documents online at www.turck.com: ■ Data sheet Feedback on these instructions We are committed to always keeping these instructions as informative and as clear as possible. -

Page 6: Notes On The Product

Sensor, mounting element and the positioning element of the encoder are available both as single components and in the complete set. Hans Turck GmbH & Co. KG | T +49 208 4952-0 | F +49 208 4952-264 | more@turck.com | www.turck.com... -

Page 7: Scope Of Delivery

These devices are designed for use in industrial areas. When used in other areas, the devices can cause electromagnetic interference. The encoders of the Ri360…-QR24 … INCR series with incremental output are used to measure speeds and angular movements. To do this, the devices absorb mechanical rotary movements and convert them into electrical pulse sequences. -

Page 8: Obvious Misuse

ø 20 ø 3.2 ø 52 ø 42 Fig. 3: Encoder – sensor (rear) Fig. 4: Encoder – positioning element P1 Hans Turck GmbH & Co. KG | T +49 208 4952-0 | F +49 208 4952-264 | more@turck.com | www.turck.com... -

Page 9: Display Elements

Z-track is also available. The QR24 is an absolute encoder that calculates the pulses of a clock cycle and emits these pulses according to the clock cycle within 800 µs. The cycle duration is therefore not inversely proportional to the speed of rotation. -

Page 10: Encoder - Components And Accessories

Positioning element with reducing sleeve for connection ø 12 on shafts with a diameter of 12 mm ø 3.2 ø 52 ø 42 Hans Turck GmbH & Co. KG | T +49 208 4952-0 | F +49 208 4952-264 | more@turck.com | www.turck.com... - Page 11 Dimension drawing Type Description P4-Ri-QR24 Positioning element with reducing sleeve for connection ø 10 on shafts with a diameter of 10 mm ø 3.2 ø 52 ø 42 P5-Ri-QR24 Positioning element with reducing sleeve for connection ø 6 on shafts with a diameter of 6 mm ø...

-

Page 12: Encoder - Reducing Sleeves Qr24

ø 24 RA7-QR24 Reducing sleeve for connection on shafts with a diameter of 1/4“ ø 1/4“ ø 28 ø 24 Hans Turck GmbH & Co. KG | T +49 208 4952-0 | F +49 208 4952-264 | more@turck.com | www.turck.com... -

Page 13: Encoder - Protecting Rings And Mounting Kits

ø 4.5 ø 74 ø 57 14.3 ø 65 SP1-QR24 Aluminum screening plate SP1-QR24: diameter 74 mm For front-panel mounting of the sensor on shafts with a 120° diameter of up to 20 mm ø 4.5 ø 74 ø 65... -

Page 14: Encoder - Sensor Eqr24

Stainless steel reducing sleeve for connection on shafts with a diameter of 20 mm ø 20 ø 28 ø 24 Hans Turck GmbH & Co. KG | T +49 208 4952-0 | F +49 208 4952-264 | more@turck.com | www.turck.com... -

Page 15: Encoder - General Accessories

Connection cable, M12 female, straight, 8-pin, stainless M12 x 1 steel coupling nut, cable length 5 m, sheath material: PVC, ø 15 black; cULus approval; other cable lengths and qualities 45,4 available, see www.turck.com TX2-Q20L60 Teach-adapter for parameterization M12 x 1 ø 4.5 USB-2-IOL-0002... -

Page 16: Installing

0°: yellow arrow on the position sensor points to black marks on the sensor, see figure "zero point default value"). Secure the rotary encoder with three screws to form a closed and protected unit. ➤ Hans Turck GmbH & Co. KG | T +49 208 4952-0 | F +49 208 4952-264 | more@turck.com | www.turck.com... -

Page 17: Rear Installation - Shaft Diameter Up To 20 Mm

Install on a larger rotating machine Fig. 10: Zero point default value parts 1. If it does not yet exist: Fit the blind plug RA8-QR24 in the positioning element. 2. Secure the clamping fitting of the positioning element with an Allen key. 3. Optional: Abschirmplatte SP3-QR24 einsetzen. -

Page 18: Connection

8000 6000 4000 2000 1000 2000 3000 4000 5000 Auflösung [ppr] Fig. 11: Maximum usable speed depending on the resolution Hans Turck GmbH & Co. KG | T +49 208 4952-0 | F +49 208 4952-264 | more@turck.com | www.turck.com... -

Page 19: Led Display

PACTware) Burst trigger output The position measured by QR24 rotary encoder as an absolute value is output once as an incremental pulse sequence. This corresponds to the number of pulses of the angular distance to the zero point (single-turn) in the set effective direction and resolution. -

Page 20: Set Via The Easy-Teach Function

If the power LED and the status LED flash alternately, the device has successfully been reset to ➥ the factory setting. Hans Turck GmbH & Co. KG | T +49 208 4952-0 | F +49 208 4952-264 | more@turck.com | www.turck.com... -

Page 21: Set Via Manual Bridging (Short-Circuit)

Set the pulses per revolution in the preset mode (360…2048 pulses per revolution) NOTE The setting is only available for RI…-QR24-INCR… devices. Remove the position sensor (yellow status LED flashes). ➤ Press and hold the button on the adapter for 2 seconds against GND. - Page 22 Status LED flashes 2 × 4096 2 × Status LED flashes 3 × 5000 3 × Status LED flashes 4 × Hans Turck GmbH & Co. KG | T +49 208 4952-0 | F +49 208 4952-264 | more@turck.com | www.turck.com...

-

Page 23: Set Via Pactware (Fdt/Dtm)

Set via PACTware (FDT/DTM) NOTE Only the RI…-QR24…-INCR… devices can be set via FDT/IODD. The devices can use a PC with an FDT frame application (e.g. PACTware). All the necessary Turck software components can be downloaded via the Turck software manager: ■... -

Page 24: Eliminate Interference

If necessary, undo the connection of the device to the mounting aid. ➤ Disposal The device must be properly disposed of, not in general household waste. Hans Turck GmbH & Co. KG | T +49 208 4952-0 | F +49 208 4952-264 | more@turck.com | www.turck.com... -

Page 25: Technical Data

Technical Data Measuring function – information Angular range 0…360° Max. rotational speed 10,000 rpm Determined with standardized construction, with a steel shaft diameter 20 mm, L = 50 mm and reducer ring diameter 20 m Resolution, incremental 1…5000 pulses per revolution Effective mode CW/CCW (factory setting: CW) Z-track (zero point setting) -

Page 26: Default Settings

Z-track (zero point setting) Factory setting: 0° (yellow arrow on the position sensor points to the black mark on the sensor) Hans Turck GmbH & Co. KG | T +49 208 4952-0 | F +49 208 4952-264 | more@turck.com | www.turck.com... - Page 27 2016/08...

- Page 28 Over 30 subsidiaries and over 60 representations worldwide! D102198 | 2016/08 *D102198* www.turck.com...

Need help?

Do you have a question about the QR24 and is the answer not in the manual?

Questions and answers