Summary of Contents for PLANEPRINT RISE

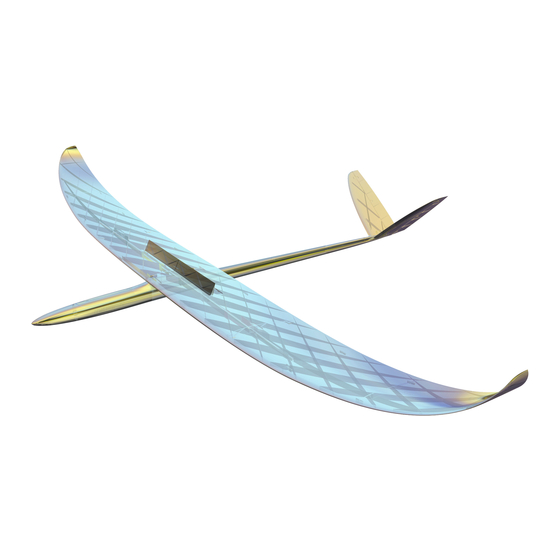

- Page 1 RISE Glider version Motor/Spoiler upgrade Kit You can fi nd the STL data NOTE: Slicing only at www.planeprint.com works with CURA!

- Page 2 Here we show you how to make adjustments from a standard CURA profile. For this model we need only 4, easy to create profiles. It is important to follow the instructions from PLANEPRINT.com to slice the part correctly. However, it can be useful to perfect your 3D printing by making some additional settings depending on the printer and filament used.

- Page 3 Please note the additional settings for the individual parts! Interconnects_profi le1_rise.stl MATERIAL PLA, Weight: ~ 1 g ADDITIONAL SETTINGS None required Parts_profi le1_rise.stl MATERIAL PLA, ~ 4 g ADDITIONAL SETTINGS None required There are several versions to choose from: RISE PRINTING & ASSEMBLING MANUAL © PLANEPRINT...

- Page 4 Please note the additional settings for the individual parts! Servomount_xxx_profi le1_rise.stl MATERIAL PLA, ~ 3 g ADDITIONAL SETTINGS None required Snap lock_profi le1_rise.stl MATERIAL PLA, ~ 4 g ADDITIONAL SETTINGS • Wall Line Count: 6 RISE PRINTING & ASSEMBLING MANUAL © PLANEPRINT...

- Page 5 PROFILE P2_HOLLOWBODY normal PLA The following parts must be sliced with the PROFILE P2_HOLLOWBODY. Please note the additional settings for the individual parts! Wingmount_profi le2_rise.stl MATERIAL PLA, ~ 4 g ADDITIONAL SETTINGS None required RISE PRINTING & ASSEMBLING MANUAL © PLANEPRINT...

- Page 6 The optimal weight and suffi cient strength is achieved with 60 % fl ow. Increase the temperature until the wall thickness is 0.4 to 0.5 mm. (We print at 250° and 60% fl ow). RISE PRINTING & ASSEMBLING MANUAL © PLANEPRINT...

- Page 7 The optimal weight and suffi cient strength is achieved with 60 % fl ow. Increase the temperature until the wall thickness is 0.4 to 0.5 mm. (We print at 250° and 60% fl ow). RISE PRINTING & ASSEMBLING MANUAL © PLANEPRINT...

- Page 8 The optimal weight and suffi cient strength is achieved with 60 % fl ow. Increase the temperature until the wall thickness is 0.4 to 0.5 mm. (We print at 250° and 60% fl ow). RISE PRINTING & ASSEMBLING MANUAL © PLANEPRINT...

- Page 9 The optimal weight and suffi cient strength is achieved with 60 % fl ow. Increase the temperature until the wall thickness is 0.4 to 0.5 mm. (We print at 250° and 60% fl ow). RISE PRINTING & ASSEMBLING MANUAL © PLANEPRINT...

- Page 10 The optimal weight and suffi cient strength is achieved with 60 % fl ow. Increase the temperature until the wall thickness is 0.4 to 0.5 mm. (We print at 250° and 60% fl ow). RISE PRINTING & ASSEMBLING MANUAL © PLANEPRINT...

- Page 11 The optimal weight and suffi cient strength is achieved with 60 % fl ow. Increase the temperature until the wall thickness is 0.4 to 0.5 mm. (We print at 250° and 60% fl ow). RISE PRINTING & ASSEMBLING MANUAL © PLANEPRINT...

- Page 12 The optimal weight and suffi cient strength is achieved with 60 % fl ow. Increase the temperature until the wall thickness is 0.4 to 0.5 mm. (We print at 250° and 60% fl ow). RISE PRINTING & ASSEMBLING MANUAL © PLANEPRINT...

- Page 13 The optimal weight and suffi cient strength is achieved with 60 % fl ow. Increase the temperature until the wall thickness is 0.4 to 0.5 mm. (We print at 250° and 60% fl ow). RISE PRINTING & ASSEMBLING MANUAL © PLANEPRINT...

- Page 14 The optimal weight and suffi cient strength is achieved with 60 % fl ow. Increase the temperature until the wall thickness is 0.4 to 0.5 mm. (We print at 250° and 60% fl ow). RISE PRINTING & ASSEMBLING MANUAL © PLANEPRINT...

- Page 15 The following parts must be sliced with the PROFILE P4_FLEX. Please note the additional settings for the individual parts! N_Hinges_profi le4_rise.stl MATERIAL TPU ~ A95, Weight: ~ 1 g ADDITIONAL SETTINGS None required RISE PRINTING & ASSEMBLING MANUAL © PLANEPRINT...

- Page 16 ADDITIONAL SETTINGS None required INFO If your motor has other hole spacing than 16 mm use the fi le Motormount undrilled_profi le1.stl Spoiler mount_profi le1_rise.stl MATERIAL PLA, ~ 2 g ADDITIONAL SETTINGS None required RISE PRINTING & ASSEMBLING MANUAL © PLANEPRINT...

- Page 17 60 % fl ow. Increase the temperature until the wall thickness is 0.4 to 0.5 mm. (We print at 250° and 60% fl ow). *Display in Cura. The actual weight is then 60% of this. RISE PRINTING & ASSEMBLING MANUAL © PLANEPRINT...

- Page 18 60 % fl ow. Increase the temperature until the wall thickness is 0.4 to 0.5 mm. (We print at 250° and 60% fl ow). *Display in Cura. The actual weight is then 60% of this. RISE PRINTING & ASSEMBLING MANUAL © PLANEPRINT...

- Page 19 • Steel wire Ø1mm, short piece for the servo linkages • Rod connection, 2 pieces Carbon tube Rod connection Socket Head Screw with nut Tools • Cutter knife • small Philips screwdriver • needle-nose pliers RISE PRINTING & ASSEMBLING MANUAL © PLANEPRINT...

- Page 20 3S Lipo, about 600-1000 MaH SERVOS Hitec HS-5055MG or (or similar in the same size), 2 or 3 pieces Maximum dimensions: Maximum dimensions: max. 23 mm max. 13 mm Ø max. 22 mm 16 mm RISE PRINTING & ASSEMBLING MANUAL © PLANEPRINT...

-

Page 22: Assembling Manual

IMPORTANT The carbon tube must NOT be glued! Wing2-right LW_profi le3_rise.stl Wing1-right LW_profi le3_rise.stl medium l. Carbon rods Ø1,2*30mm medium l. Carbon tube Ø6*1000mm Wing1-left LW_profi le3_rise.stl medium l. Wing2-left LW_profi le3_rise.stl RISE PRINTING & ASSEMBLING MANUAL © PLANEPRINT... - Page 23 Insert the parts into the slots provided as far as they will go and check that they engage exactly when the wing parts are assembled before gluing. Snap lock_profi le1_rise.stl Wing3 LW_profi le3_rise.stl Wing2 LW_profi le3_rise.stl RISE PRINTING & ASSEMBLING MANUAL © PLANEPRINT...

-

Page 24: Fuselage Assembly

CA glue. The three long rods must reach all the way to the end! Carbon rod Ø1,2*55mm Fuselage6 LW_profi le3_rise.stl thin Carbon rods Ø1,2*1000mm RISE RISE PRINTING & ASSEMBLING MANUAL PRINTING & ASSEMBLING MANUAL © PLANEPRINT © PLANEPRINT... - Page 25 Fuselage6 LW_profi le3_rise.stl Fuselage6 LW_profi le3_rise.stl Fuselage5 LW_profi le3_rise.stl Fuselage4 LW_profi le3_rise.stl Repeat with the fuselage parts 4 and 3 ... Fuselage3 LW_profi le3_rise.stl RISE PRINTING & ASSEMBLING MANUAL © PLANEPRINT...

- Page 26 After that, you can glue fuselage 1 and 2. After gluing one fuselage part, it is suffi cient thin Fuselage2 LW_profi le3_rise.stl to let some thin CA glue fl ow into the carbon rod. medium l. Fuselage1 LW_profi le3_rise.stl RISE PRINTING & ASSEMBLING MANUAL © PLANEPRINT...

- Page 27 The motor mount must be glued very well, also make sure that the carbon rods reach all the way to the front! medium l. RISE PRINTING & ASSEMBLING MANUAL © PLANEPRINT...

-

Page 28: Stabilizer Assembly

CA glue on the hinge. Wait again for the glue to run in, and then spray the activator on it. Do not use too much glue, the fl ap must move easily! RISE PRINTING & ASSEMBLING MANUAL © PLANEPRINT... - Page 29 To attach it, fi rst insert the front end into the fuselage, push the canopy slightly forward and then insert it into the fuselage at the back. The carbon rod should not be glued. Canopy LW_profi le3_rise.stl STEP 2 STEP 1 RISE PRINTING & ASSEMBLING MANUAL © PLANEPRINT...

-

Page 30: Servo Mounting

(shrink it beforehand on a piece of steel wire and then cut short pieces) and a drop of medium CA glue. Mount the adjustable rod connections to the servos. RISE PRINTING & ASSEMBLING MANUAL © PLANEPRINT... -

Page 31: Spoiler Assembly

Remove support First remove support: Wing1 spoiler-right LW_profi le3_rise.stl Wing1 spoiler-left LW_profi le3_rise.stl Remove support See Wings assembly instructions on page 22. medium l. Spoiler mount_profi le1_rise.stl RISE RISE PRINTING & ASSEMBLING MANUAL PRINTING & ASSEMBLING MANUAL © PLANEPRINT © PLANEPRINT... - Page 32 In the parts Wing2 are short bowden for the swivel integrated. Carbon rod Ø1,2*404mm Wing1 spoiler-left LW_profi le3_rise.stl Wing1 spoiler-right LW_profi le3_rise.stl See Wings assembly instructions on page 22. Wing2-right LW_profi le3_rise.stl RISE PRINTING & ASSEMBLING MANUAL © PLANEPRINT...

- Page 33 Bend a steel wire Ø1mm as shown. The distance between the axes should be exactly 42mm. Steel wire Ø1mm medium l. maximum 10 to 11mm Mount the servo as shown: Wing1 spoiler-left LW_profi le3_rise.stl Wing1 spoiler-right LW_profi le3_rise.stl RISE PRINTING & ASSEMBLING MANUAL © PLANEPRINT...

- Page 34 The launch hook is only recommended for experienced pilots, because the wings made of LW-PLA are very soft and must only be loaded very gently! The rear hook should be positioned about 5mm in front of the CG. medium l. RISE PRINTING & ASSEMBLING MANUAL © PLANEPRINT...

-

Page 35: Control Direction Test

ELEVATOR RUDDER SPOILER 0 % SPOILER 100 % Motor version We recommend that you put the engine on a switch and the spoiler on the gas stick. RISE PRINTING & ASSEMBLING MANUAL © PLANEPRINT... -

Page 36: Center Of Gravity (Cg)

The CG of 76 mm is the setting we tested with the best flight characteristics. If you are not yet an expert pilot, your CG should be a few millimeters further forward, not further back! RISE PRINTING & ASSEMBLING MANUAL... -

Page 37: Technical Specifications

It is a good idea to be conservative with the flight timer until you gain experience with your airplane. TECHNICAL SPECIFICATIONS WINGSPAN 2000 mm/78.7 inches LENGHT 1198 mm/47 inches FLIGHT WEIGHT Glider version 650 grams Motor version 680 grams (with 3S/640MaH-Battery) RISE PRINTING & ASSEMBLING MANUAL © PLANEPRINT... -

Page 38: Age Recommendation

Filaments, printing supplies, hardware or mitter or model. consumables that can not be used after faulty 3D printing will not be replaced by PLANEPRINT.com in any way. Always keep the model in view and under control. Use only fully charged batteries.

Need help?

Do you have a question about the RISE and is the answer not in the manual?

Questions and answers