Table of Contents

Advertisement

Quick Links

Thank you for purchasing this product.

Read this instruction manual before using the product to make sure that you use it correctly.

This product is designed to be installed into the housing (sold separately) for use. Make sure to install this product into the housing for use.

This device is an opposed type photoelectric beam sensor that consists of

a photo transmitter that transmits infrared light, and a photo receiver

for the transmitted light, as shown in the illustration on the right.

The infrared light transmitted from the transmitter expands in a cone

shape, while the light beams enter the receiver.

The straight line that connects the transmitter with the receiver is the

detection line.

This model is designed to prevent a crawling intrusion to coverage area

by means of OR-gated detection in addition to AND-gated detection.

In order to ensure that the detection line has sufficient margin of

sensitivity, adjust the direction of the light beams before placing the

system into operation. Providing sufficient margin of sensitivity reduces

the occurrence of malfunction caused by dense fog, heavy rain, frost,

snow, and other such weather conditions.

(1) ANTI-CRAWL DETECTION

Upper and lower beam individually detects the objects and

issues a signal only by blocking each beam.

(2) AT . HF SEPARATE OUTPUT

AT

AT output : OR-gated by upper and lower beam.

&

HF output : AND-gated.

HF

(3) SYNCHRONIZED HIGH POWER BEAM

1

By synchronizing the timing of transmitting and receiving

2

3

beam, the stacking system will be more reliable.

4

(4) DOUBLE MODULATION

Double modulated beams are designed to distinguish the true

beam signal from accidental or deliberate interference from

sunlight, car headlights and other artificial light sources.

This increases the reliability in the outdoor security system.

(5) QUAD HIGH POWER BEAM

The beam power is 100 times of the minimum requirement.

The beam distance is 10 times of the described specification.

This high power beam also realizes the reliability against

the harsh conditions like fog, snow, heavy rain.

(6) ECOLOGY

RoHS adapted - Environment friendly. Free from Lead,

Mercury, Cadmium, Hexavalent chromium, Polybrominated

biphenyl, Polybrominated diphenyl ether.

PHOTOELECTRIC BEAM SENSOR

PXB-100ATC-KH: 330ft (100m)

Instruction Manual

Main Features

Transmitter

(7) LOW CURRENT CONSUMPTION

30% less than current models. The low current

consumption reduces cabling costs.

(8) DUAL RING SIGHT

Enables better and clear view for easy beam

alignment.

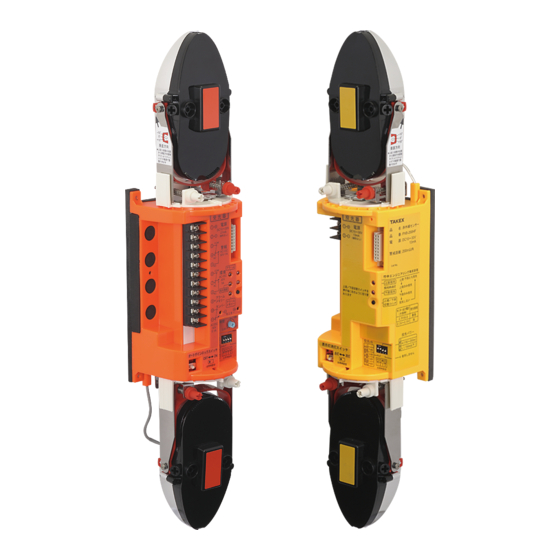

(9) TARGET COLOR

The vivid color of the internal structure can be

recognized easily from the far end in the beam

alignment procedure.

The color differs between a transmitter and a

receiver which helps easy installation and

checking.

(10) INCREASED RANGE

ADJUSTMENT ALLOWANCE

Vertically ±20°compared with previous version.

It may adapt to the slope installation flexibly

(11) WIRELESS ALIGNMENT CHECKER

Enables easy and accurate beam alignment.

(Sold separately)

(12) LIGHTNING PROTECTION

Minimizes the damage caused by induced

lightning through wiring.

1

Detection line

Coverage of light beams

Receiver

Advertisement

Table of Contents

Summary of Contents for Takex PXB-100ATC-KH

- Page 1 PHOTOELECTRIC BEAM SENSOR PXB-100ATC-KH: 330ft (100m) Instruction Manual Thank you for purchasing this product. Read this instruction manual before using the product to make sure that you use it correctly. This product is designed to be installed into the housing (sold separately) for use. Make sure to install this product into the housing for use.

-

Page 2: Table Of Contents

— TABLE OF CONTENTS — PRODUCT COMPONENTS WIRING METHOD POSITION AND RATING OF TERMINALS ......PARTS DESCRIPTION ............ ACCESSORIES ..............WIRING DISTANCE ............. NAMES OF OPERATION SECTION ........ WIRING DISTRIBUTION DIAGRAM (WIRING DIAGRAM) OPERATING PRECAUTIONS OPTICAL AXIS ADJUSTMENT EXAMPLE OF INCORRECT INSTALLATION .... -

Page 3: Names Of Operation Section

NAMES OF OPERATION SECTION [Transmitter] Transmission LED (Upper/lower) Upper/lower changeover switch Transmitter LED “9 EXPLANATION OF FUNCTIONS (9-2 UPPER/LOWER CHANGEOVER FUNCTION)” switch (Factory set : ON) “9 EXPLANATION OF FUNCTIONS (9-3 LED LIGHT TURN-OFF FUNCTION)” 1 2 3 4 5 6 7 8 6,7,8. -

Page 4: Operating Precautions

EXAMPLE OF INCORRECT INSTALLATION erroneous detection or detection failure. Installation in locations Installation in location where Installation in areas where Using PXB-100ATC-KH shaded by trees etc. strong light such as sunlight or objects that move with the together with other... -

Page 5: Before Use

In order to use these sensors correctly, thoroughly read this instruction manual and select the mounting position and BEFORE USE protection distance. As the infrared light leaves the transmitter, it expands into conic shape light beams. PROTECTION DISTANCE AND The optical axis is in the center of the light beams. Arrange the reflector so that the RANGE OF LIGHT BEAM COVERAGE device on the opposite side is in the center of the light beams. -

Page 6: Term Description

TERM DESCRIPTION This manual uses the following terms for explanation. Refer to the terms and their meanings. Channel (CH) : Frequency channel of the infrared beam signal. (There are four channels from 1CH to 4CH) : A signal emitted from the synchronized output of the master, which is the reference signal to Synchronized signal determine the timing for transmitting and receiving the infrared beams. - Page 7 2 level stackings 1st beam setting (Same as single stacking) Set the transmitter and receiver to the same channel Set the transmitter and receiver to the same syncronized timing Set the transmitter as a master Connect the synchronized units by wire 2nd beam setting Set the transmitter and receiver to the same channel as 1st beam Set the transmitter and receiver to the different syncronized timing from 1st beam...

- Page 8 Triple level stacking Fourth level stacking (Maximum : Four spans) Avoid setting the neighboring number of channel Avoid setting the neighboring number of channel in the same direction. (Like 1CH and 2 CH) in the same direction. (Like 1CH and 2 CH) In the 3rd and 4th beam, set the same channel and different synchronized timing.

-

Page 9: Installation Method

INSTALLATION METHOD INSTALLATION INTO HOUSING Read the instruction manual for your housing carefully, and install the product into the housing correctly. Wiring is required based on the sensor installation. Refer to "6 WIRING METHOD" for wiring and connection. Refer to "9 EXPLANATION OF FUNCTIONS" for switching channels and transmitting beam power. Housing (Frame) Panhead screw... -

Page 10: Beam Power Selection

BEAM POWER SELECTION * Only installed on the transmitter * Select the suitable power according to the installation site (Detection Distance) 300ft (90m)=H Factory set : H 300ft (90m) 200ft (60m)=L 250ft (75m) or less 250ft (75m) - 330ft (100m) 200ft (60m) ALARM OUTPUT SWITCH * Only installed on the receiver... -

Page 11: Wiring Method

WIRING METHOD POSITION AND RATING OF TERMINALS <Transmitter> <Receiver> Power input 12 to 30V DC Power input 12 to 30V DC (non-polarity) (non-polarity) Current consumption : 27mA Current consumption : 48mA Synchronized output 30V(AC/DC) . 0.25A (Resistance load) Alarm output (polarity) (AT output) *1 Dry contact N.C./N.O.switchable... - Page 12 WIRING DISTRIBUTION DIAGRAM (WIRING DIAGRAM) Note : Connect all transmitters and receivers of the same group by synchronized wiring. Select one transmitter as a master, all the others are as slave. One master may have maximum 7 slaves. Single level protection, AT output, Environmental output Transmitter Receiver master...

- Page 13 Control panel 2 level protection. 1st pair is PXB-100HF-KH, 2nd pair is PXB-100ATC-KH Slave 1) In case PXB-100HF-KH and PXB-100ATC-KH is connected, channel setting cannot be neighbouring or the same number. 2) Synchronized wiring cannot be connected to PXB-100HF. PXB-100HF-KH...

-

Page 14: Optical Axis Adjustment

By aligning the optical axis correctly, a protection line with a sufficient OPTICAL AXIS ADJUSTMENT margin of sensitivity can be created, reducing the occurrence of malfunction. Always adjust on both upper and lower sections Transmitter Receiver Transmitter LED switch (Factory set : ON) Auto-gain lock switch (Factory set : OFF) Receiver... -

Page 15: Optical Axis Adjustment Using The Alignment Mechanism

Names of the Operation Section Note:This section describes the name and function of each part used during optical axis adjustment. <Transmitter> <Transmitter> To show which beam operates. Transmission LED: When synchronization is unstable, LED blinks alternatively. Upper/lower changeover switch Transmitter Each time the switch is pressed, the optical unit that transmits the light switches. - Page 16 Look through the view finder from a distance, and readjust so that the sensor of the opposite device is visible at the center of the ring using the horizontal and vertical angle fine adjustment screws. Vertical angle adjustment Horizontal angle fine adjustment Turn on the power to the transmitter and receiver, check that the LEDs of both the transmitter and receiver are on.

- Page 17 To improve accuracy of optical axis Perform the procedure of “Optical Axis Adjustment Using the Sound Check”, “Optical Axis Fine Adjustment Using the Monitor Output Voltage”, or “Optical Axis Fine Adjustment Using the Alignment Wireless Checker”. Optical Axis Fine Adjustment Using the Sound Check The sound check function indicates the light reception level by using high and low pitch tones.

- Page 18 Accurate adjustments of the optical axis can be achieved by Optical Axis fine Adjustment Using the Monitor Output Voltage checking the light reception level value using the voltage of the monitor output. <<Caution>> First, check only the transmission on the upper level and reception on the upper level, and then check only the transmission on the lower level and reception on the lower level.

-

Page 19: Operation Check

OPERATION CHECK Be sure to perform an operation check after the optical axis adjustment. Transmitter Set Transmitter LED switch of the transmitter to [OFF] and mount the cover (housing). When Transmitter LED switch is set to [OFF], the LED light turns off, but the upper and lower beams are transmitted. -

Page 20: 9 Explanation Of Functions

This section describes the detailed information of the functions that EXPLANATION OF FUNCTIONS appear in this instruction manual. Set each function according to the description below. AUTO GAIN LOCK FUNCTION * Only installed on the receiver Provided the units are used within the maximum rated protection distance, this function is used to automatically set the optimum margin of sensitivity for the receiver in any protection distance <<Caution>>... -

Page 21: External Environment Diagnostic Function

PROGRAMMABLE AGC(AUTO GAIN CONTROL) FUNCTION * Only installed on the receiver When the beam power decreases in harsh environment by dense fog, heavy rain. This is a function to increase the receiving sensitivity temporarily and to stabilize operation. The receiver adjusts this function to start or to stop automatically depending on beam power from transmitter. -

Page 22: Function

(If the device does not operate properly) TROUBLESHOOTING Check the device by referring to the table below. If you cannot restore the device to a normal condition after the check, contact the place of purchase or TAKEX. Status Cause Remedy... -

Page 23: 12 External Dimensions

EXTERNAL DIMENSIONS Unit: inch (mm) 3.31"(84 mm) 3.31"(84 mm) 2.83"(72 mm) 4-Ø0.12" Panhead screws (4-Ø3 mm) 2.91"(74 mm) Reference installation drawing Transmitter Receiver ■Options : Alignment wireless checker : ER-02... - Page 24 Limited Warranty : TAKEX products are warranted to be free from defects in material and workmanship for 12 months from original date of shipment. Our warranty does not cover damage or failure caused by natural disasters, abuse, misuse, abnormal usage, faulty installation, improper maintenance or any repairs other than those provided by TAKEX.

Need help?

Do you have a question about the PXB-100ATC-KH and is the answer not in the manual?

Questions and answers