Advertisement

Advertisement

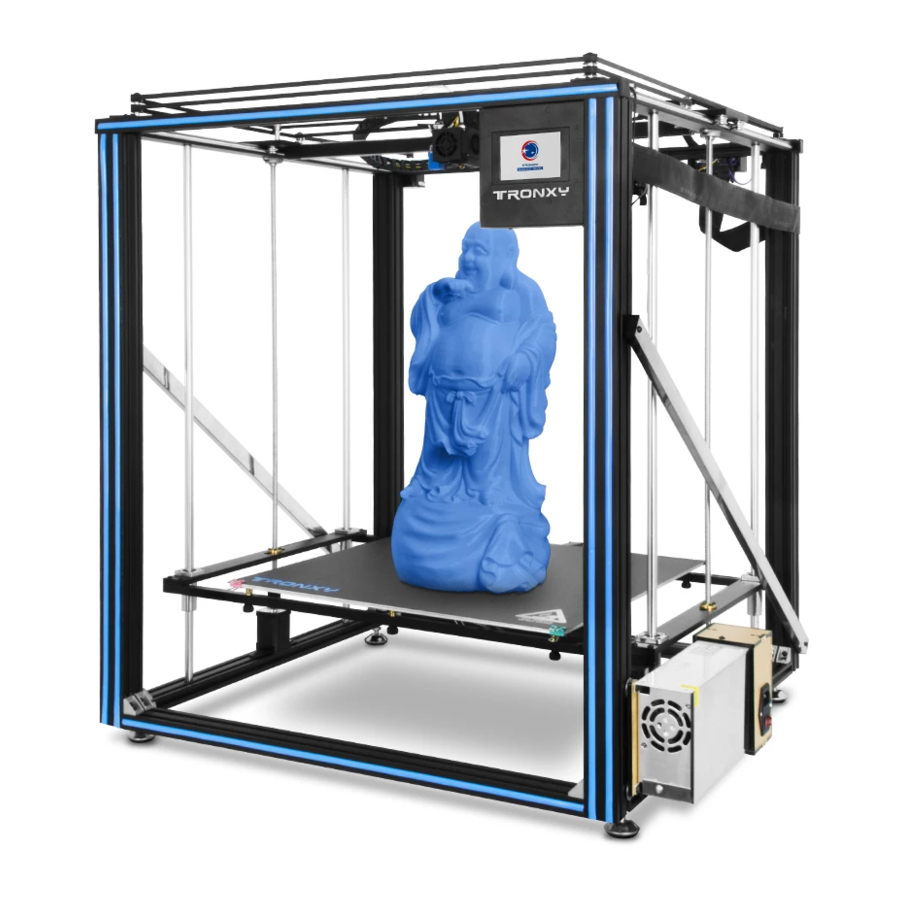

Summary of Contents for TRONXY X5SA-500-PRO

- Page 2 Thank you for choosing TRONXY products! We will serve you whole heartedly! Please read the instruction carefully Please visit tronxy.com for more information TEL:+86-755-89968500 Relevant information is stored in SD card,please check...

- Page 3 عب : البيعsupport@tronxy.com د 판매 후 서비스 : support@tronxy.com Servicio postventa: support@tronxy.com Serviço pós-venda: support@tronxy.com After- sale service:support@tronxy.com アフターサービス:support@tronxy.com Service nach dem Verkauf: support@tronxy.com Послепродажное обслуживание: support@tronxy.com X5SA-500Pro Install Aftersale contact Facebook QR Code video QR Code QR Code...

- Page 4 Pay attention Please read this instruction carefully and follow the safety instruction. When the 3D printer is working, it will produce high temperature.Do not touch working parts or extruder directly.After printing, the working part may still be in the high temperature state.Please wait patiently for the working parts and the print model to cool down before removing the model from the print platform.

-

Page 5: Table Of Contents

Catalogue 1. Machine parameter ………………………………………1 2. Introduction to machine structure …………………2 3. Packing list ……………………………………………………3 4. Installation instructions …………………………………4 5. Interface operation and printing …………………17 6. Slice software ………………………………………………20 7. Fault cause analysis ………………………………………23... -

Page 6: Machine Parameter

1. Machine parameter Print parameters Print principle: FDM (Fused deposition molding) 500 × 500 × 600 (mm3) Print size: Print accuracy: 0.1-0.4 mm X/Y0.00625mm , Z 0.0125mm Positioning accuracy: Nozzle quantity: Nozzle size: 0.4 mm Print speed: 20~100mm/s (suggest 60mm/s) Moving speed: 100mm/s Filament:... -

Page 7: Introduction To Machine Structure

2. Introduction to machine structure ⑧ ⑦ ⑨ ⑥ ⑩ ⑤ ⑪ ④ ⑫ ③ ⑬ ② ⑭ ① ⑮ ⑱ ⑲ ㉑ ⑰ ⑳ ⑯ 1.Power Supply 4.Y axis switch 2.Stainless steel pipe 3.Heatbed 6.Y-right guide rail 5.Y- right skateboard 7.Xmotor 8.Ymotor 9. -

Page 8: Packing List

3. Packing list 2040aluminum 040aluminum profile 2020aluminum OSG External double OSG External double profile 780mm 4PCS profile axis guide rail axis guide rail 630mm 2PCS Stainless steel pole -X axis 650mm 1PCS 740mm 2PCS -Y axis 670mm 2PCS 660mm 2PCS 2PCS polished rod beams/footlock... -

Page 9: Installation Instructions

4. Installation instructions Step 1:base frame assembly Assembly material specification and quantity : aluminum1 aluminum2 aluminum3 Corner code 40*40*780 4PCS 40*20*660 2PCS 40*20*630 2PCS 20PCS screws M4*8 gasket M4 boat nuts M4 screws M5*45 40PCS 40PCS 40PCS 8PCS M6 threaded hole M6 threaded hole 2-aluminum1 2-aluminum1... - Page 10 Step 2: Sliding plate assembly Assembly material specification and quantity : base frame aluminum4 screwsM6*25 L skateboard 1PCS R skateboard 1PCS Y left guide 1PCS Y right guide 1PCS 1pcs 20*20*740 2PCS 16PCS The screw M6*25 is slightly locked on the Y-axis guide rail to facilitate subsequent adjustment.

- Page 11 Step 3: Sliding plate assembly Assembly material specification and quantity : Print head parts drag chain plate screws X axis guide rail parts basic frame 1pcs 20*18*650 1PCS 1pcs 1pcs M4*20 6PCS As shown in the figure, the pulley on the print head runs through the X axis guide rail and the slide block moves smoothly without any clearance print head...

- Page 12 Step 4:XY axis motors and wheels assembly Assembly material specification and quantity : basic frame parts right wheel parts left wheel parts X motor Y motor 1pcs 1pcs 1pcs 1pcs 1pcs 1. Lock and fix the assembled parts in the position as shown in the figure Assembly tips for M4 ship nut: first align the M4 nut with the aluminum...

- Page 13 Step 5:Belts assembly Assembly material specification and quantity : basic frame Belt Ties 1pcs 2pcs X motor Belt tying diagram Y motor Location of Print Head Band Left and right wheels 1.As shown in the figure, after adjusting the distance between the motor gear and the belt, lock the 2 rice screws on the gear.

- Page 14 Step 6:Linear bearing assembly Assembly material specification and quantity : copper linear screws M3*8 beams Linear bearing screws M4*12 bearing 8pcs 2pcs 4pcs 16pcs 2pcs 16-M4*12 8-M3*8...

- Page 15 Step 7:Z axis parts assembly Assembly material specification and quantity : basic frame Z axis motor parts foot lock parts bearing base parts polish rod 1pcs 2pcs 2pcs 2pcs Φ8*760 4PCS lead screwT8*665 screws M4*30 screws M4*8 screws M4*16 2PCS 8PCS 4PCS 4PCS...

- Page 16 Step 8:Controller box assembly Assembly material specification and quantity : basic frame Power Supply controller box 1PCS 1PCS 1PCS Install the main control box on the right Install the power supply in the (facing the machine) profile (including a lower right corner of the front of photoelectric switch), and the other the printer photoelectric switch is fixed on the left...

- Page 17 Step 9:Print plate assembly Assembly material specification and quantity : basic frame heat bed parts beams plastic nuts M3 screws M4*12 1pcs 1pcs 2pcs 6pcs 8pcs Double limit spring nuts M3 screws KM3*30 plate 2pcs 6pcs 6pcs 6pcs beams Double limit plate 8-M4*12...

- Page 18 Step 10:Feeding motor assembly Assembly material specification and quantity : filament run out basic frame Titan extruder screw RM4*8 boat nuts M4 detection parts 1pcs 1pcs 2pcs 2pcs 1pcs screw RM4*6 2pcs Assemble Titan extruder to filament runout detection parts RM4*8 2-RM4*6 2-boat nuts...

- Page 19 Step 11:Switch and filament bracket assembly Assembly material specification and quantity : screw RM4*6 boat nuts M4 printer Y switch parts bracket part screw 1PCS 1PCS 1PCS PM5*10 4PCS 2PCS Note: the feed tube of the print head is not inserted at the bottom, which may lead to blockage.

- Page 20 Step 12:Black sticker and seal assembly Assembly material specification and quantity : Stainless printer end cap clips steel pole seal 4PCS 4PCS 1PCS 2PCS Fix stainless steel rod to both sides of printer boat nuts M4 boat nuts M4 4-clips 4-end cap seal...

- Page 21 Step 13:Wiring X-motor heatbed heating Y-motor Y axis switch heat bed Power cord Z2 motor Y motor E motor X motor controller Z1motor filament run out detection heat bed Z2 motor E motor Z1 motor Y-axis Adapter switch line plate filament break detection Y axis switch...

-

Page 22: Interface Operation And Printing

Interface operation and printing... - Page 23 Print test: ,start print。 Click →“Testing file”→ If the first layer is not sticky, the nozzle is on the high side and the platform can be raised appropriately; If the nozzle has a small amount of thread, the nozzle is on the low side and the platform can be appropriately lowered.

- Page 24 Precautions: Before each zeroing or automatic leveling, the Z axis must be lowered to the position below the photoelectric sensor switch, as shown in the figure below Double limit Photoelectric plate sensor switch The board is in the switch sensing area Auto leveling:...

-

Page 25: Slice Software

6.Slice software 1. Installation Find out slice software in SD card“TronxyInstall.exe ”double click, Then follow these steps to complete the installation. - Page 26 2. How to use slice software ① 、Type setting: follow the steps below to complete the setting. ① ② ③ ④ ⑤ ⑥...

- Page 27 ② 、Parameter setting:(The following figure gives the reference value, according to their own needs can be modified) Some parameters are set for reference: Layer thickness : 0.1-0.3mm : PLA - 200 ℃ ABS - 240 ℃ Print temp ABS - 80 ℃ Heatbed temp :...

-

Page 28: Fault Cause Analysis

7.Fault cause analysis 1. Machine cannot start ? 1)Check the power line and other wires connect correct or not. 2)Check whether the supply voltage matches the local standard. 3)Check whether the screen or power supply is damaged and replace in time. 4)Check the wires if damage or breakage. - Page 29 1)Heating the hot bed to 50-70 ℃, and after cooling to try again, or use the shovel. 2) It is recommended to buy TRONXY magnetic stickers. 6. Can't heat it up? 1)Check the heating rod and thermistor for poor contact or damage.

- Page 30 9. Model dislocation and fault 1)Nozzle feeding not smoothly, please clean the nozzle or replace the nozzle 2)Check that if the printing speed is too fast 3)The quality of filaments is poor, please replace with new filaments 10. Abnormal sound and vibration of filaments feeding motor 1)Please check whether the nozzle is blocked 2)The nozzle feeding is not smooth, please clean the nozzle...

Need help?

Do you have a question about the X5SA-500-PRO and is the answer not in the manual?

Questions and answers