Advertisement

Quick Links

Step 1. Assemble base frame

Assemble parts specifications and quantity:

Aluminium profile 1 20*20*530mm

Aluminium profile 2 20*20*460mm

4pcs

T nut M4 4pcs

1.Lock the aluminium profile 1 2pcs, Aluminium profile 2 2pcs, aluminium 3 4pcs

together by 8pcs screw PM5*25, same as the illustration.

Note: Before locking the screws, make sure the aluminum profile are aligned and vertical

2.Assemble the pad, spacer, screw PM4*9, T nut M4 with the aluminium profile 1

together,distance from the end around 20mm, same as the illustration

Aluminium profile 3 20*40*530mm

2pcs

4pcs

3.Lock the aluminium profile 1 2pcs with 4pcs screw PM5*25

Note: Do not tighten too much, enable they can be adjusted in further step.

Aluminium profile 1

Aluminium profile 2

Aluminium profile 3

Aluminium profile 1

Screw PM5*25

screw PM4*9

Pad 4pcs

12pcs

4pcs

Spacer M4

4pcs

Aluminium profile 1

Advertisement

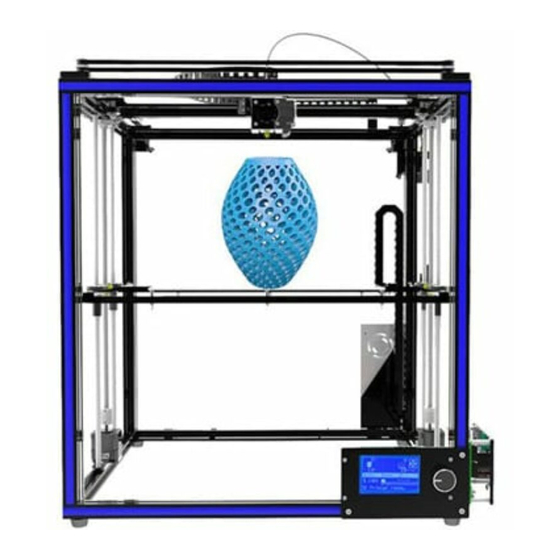

Summary of Contents for TRONXY X5S

- Page 1 Step 1. Assemble base frame Assemble parts specifications and quantity: Aluminium profile 1 20*20*530mm Aluminium profile 2 20*20*460mm Aluminium profile 3 20*40*530mm Screw PM5*25 screw PM4*9 Spacer M4 Pad 4pcs 4pcs 2pcs 4pcs 12pcs 4pcs 4pcs T nut M4 4pcs 3.Lock the aluminium profile 1 2pcs with 4pcs screw PM5*25 1.Lock the aluminium profile 1 2pcs, Aluminium profile 2 2pcs, aluminium 3 4pcs together by 8pcs screw PM5*25, same as the illustration.

- Page 2 Step 2:Assemble slider plate Assemble parts specifications and quantity: Screws Alu. profile 2 PM4*9mm M4 T nut Aluminium Frame Slider plate (Left) 1pcs Slider plate (Right) 1pcs PM5*25mm 20*20*460mm screws 4pcs 4pcs 2pcs 4pcs 4.Put the aluminum 2 components into the end of the aluminum 1, Respectively insert 2pcs PM4*9mm screws to Left and Right slider frame 3 of the bottom frame, then secured by 4pcs screw PM5*25, as plate , lock with M4 T nut , as same as the illustration.

- Page 3 Step 3:Assemble printing head Assemble parts specifications and quantity: Printing head Alu. Profile 4 M4 T-Nut M3 Nut Towline holder PM3*10MM PM3*8MM PM4*9mm Aluminium frame component 20*20* 484mm 2pcs 4pcs 1pcs 2pcs 2pcs 2pcs (with Towline) 1pcs 1pcs 1, Place the towline to the printing heat , secure with 2pcs PM3*8mm screws and M3 Nut Slider plate(Right) Slider plate(Left)

- Page 4 Step 4:Assemble XY axis motor and wheel Assemble parts specifications and quantity: Motor 2pcs(With M4 T-Nut Screws Pulley component Pulley component X Motor base Y Motor base Screws PM3*10 Framework Synchronous 10pcs (Right) 1pcs (Left) 1pcs plate 1pcs plate 1pcs PM4*12 10pcs 8pcs wheel)

- Page 5 Step 5:Assemble belt Assemble parts specifications and quantity: Main frame 1pc Belt 2pcs Tie 4pcs 1.Pass through the belt as same as the illustration ,let the rack is 2.Pass through the belt as same as the illustration,let the rack is wrapped with a motor gear, determine direction of the belt, tighten it wrapped with a motor gear, determine direction of the belt, tighten the to the metal slot of the printing head component with a tie.

- Page 6 Step 6:Assemble bearings and Z-axis motor Assemble parts specifications and quantity: Z fixed plate 2pcs Flange bearing 4pcs Copper Nut 2pcs Screws PM3*8 24pcs Z motor component 2pcs Screws PM4*9 8pcs Bearing seat 2pcs Elastic gasket 4pcs M4 T Nut 8pcs 1.Assemble 1pc Z fixed plate , 2pcs bearing seat, 1pc screw 3.Assemble 1pc Z motor component,2pcs screw PM4*9mm, 2pcs nut,12pcs screw PM3*8 together, as the illustration, total need to...

- Page 7 Step 7:Assemble Z axis component Assemble parts specifications and quantity: Bearing seat Base frame component Z carriage Sliding rod Lead screw Screw PM4*20 Z motor component 2pcs component 1pcs 2pcs Φ8*528 4pcs T8*453 2pcs 8pcs 2pcs 1.Insert the solid end of the Sliding rod to the hole on Z axis motor holder, insert the barrel of the motor holder into the hole,do not let the pole stand out,same as the illustration.Then, put the Z fixed plate component with the pole Φ8*528 together.

- Page 8 Step 8:Assemble feeding motor Assemble parts specifications and quantity: Main framework Feeding motor component 1pcs 1.Place the feeding motor component with 2pcs screw PM4*12 and T nut M4 ,same as the illustration Feeding motor component...

- Page 9 Step 9:Assemble printer plateform Assemble parts specifications and quantity: Heatbed (with towline) M3 Wing PM4*9 screw Main framework Metal bar 2pcs Spring 6pcs 330x330mm 1pcs nut 6pcs 2pcs M3 Nut PM4*12 M4 T nut Towline PM3*10 Towline base KM3*30 screw 6pcs 10pcs screw 8pcs 2pcs...

- Page 10 Step 10:Assemble electronic board Assemble parts specifications and quantity: Plastic pillar 1 Plastic pillar2 Main frame 1pcs Fan Cover 1pcs board holder 1pcs electronic board 1pcs Φ7*Φ3*4 4pcs Φ7*Φ4*11 8pcs Screw PM4*9 3pcs Nut M3 8pcs Screw PM3*45 4pcs T nut M4 3pcs 1.Put the scew PM3*45 through the fan cover, plastic 3.Fix the electronic board component in the groove of aluminum pillar2,electronic board,Plastic pillar 1,board holder the lock them by...

- Page 11 Step 11:Assemble LCD Assemble parts specifications and quantity: T nut M4 Screw Plastic pillar 3 Main frame 1pcs LCD 1pcs LCD holder 1pcs Knob 1pcs 3pcs PM4*9 3pcs Φ8*Φ5*8.5 4pcs M3 Nut 4pcs PM3*20 screws 4pcs 3. Fix the LCD component in the groove of the aluminum 1.Put the screw PM3 * 20 through the LCD holder,Plastic profile by T nuts,then lock the screw PM4*9, same as the pillar 3, PCB board of the display, then lock them by M3 nut...

- Page 12 Step 12:Assemble power supply Assemble parts specifications and quantity: Main frame 1pcs Power supply 30A 1pcs 2.Fix the power supply component in the groove of aluminum 1, Take the power supply , select the correct voltage by using profile by 3pcs screw PM4*9 and T nut, same as illustration screwdriver, same as illustration.

- Page 13 Step 13:Assemble feeding holder Assemble parts specifications and quantity: Feeding holder Main framework T nut M4 2pcs Screw PM4*12 2pcs Nut M8 2pcs Hexagon Screw M8*110 1pcs Plate 1pcs 3.Fix feeding holder component in the groove of aluminum profile by 1.Assemble 1pc Feeding holder plate with 1pc Hexagon 2pcs screw PM4*12,same as the sillustration (Put the material tray Screw,2pcs nut M8 together, same as the illustration...

- Page 14 Step 14:Assemble Decorative strip and Feeding tube Assemble parts specifications and quantity: Main framework Aluminium profile seal Feeding tube 1pcs Print board 1pcs Binder Clip 4pcs 1.Put the feeding tube into the hole of the Air cock,insert feeding 2.Align the end seal with the end aluminum profile,then press the seal tube,press the outer plastic ring of Air cock,loosen the plastic into the groove of the aluminum profile,same as illustration.

- Page 15 Step 15:Assemble limit switch Assemble parts specifications and quantity: PM3*35 M4 T Nut Limit switch (with wires) PM4*9 M3 Wing Nut Switch holder Screw PA2*10 Main framework screws 2pcs 1pcs 4pcs 2pcs screws 2pcs 1pcs 1pcs 1, Assemble the limit switchs to the holder by using 2pcs PA2*10 Screws , secure them .

- Page 16 Step 16:Connecting wire Assemble parts specifications and quantity: Main framework Power wires 2pcs USB cable 1pcs LCD cable 2pcs Motor wires 4P*5pcs Winding Pipe 1pcs Power plug 1pcs Y-Motor X Endstop X-Motor Extruder 4010 Fan 2 4010 Fan 1 Heat Extr.motor Y Endstop Z-motor 2...

Need help?

Do you have a question about the X5S and is the answer not in the manual?

Questions and answers