Table of Contents

Advertisement

Advertisement

Table of Contents

Summary of Contents for corob EVO1ST

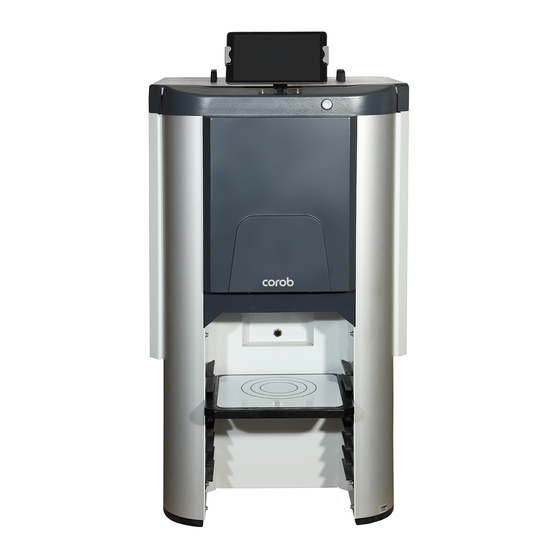

- Page 1 EVO1ST Automatic Dispenser User’s manual V1.0 - R2 (09/2019) 4043862...

- Page 2 COROB is a registered trademark and/or commercial trademark used on an exclusive basis by COROB S.p.A. and its affiliated companies (hereinafter “COROB”). A failure of a trademark to appear hereunder does not mean that COROB does not use the trademark in question nor does it constitute a waiver by COROB of any related intellectual property rights.

- Page 3 At the end of the working day • Refill the canisters. • Update the canister filling levels in the management software. • Shut down the computer. Do not shut off the machine. It is recommended to carefully read the user’s manual. EVO1ST...

-

Page 4: Table Of Contents

7.5 Cleaning the nozzle center (humidifier cap)........................32 7.6 Cleaning and moistening the sponge (humidifier cap)......................33 7.7 Refilling the humidifier bottle.............................. 36 TECHNICAL SPECIFICATIONS 8.1 Technical data..................................36 8.2 Dimensions..................................37 8.3 Declaration of conformity..............................37 8.4 Warranty....................................37 EVO1ST... -

Page 5: General Information

He or she must work only in safety conditions and is allowed to carry out routine maintenance operations. MAINTENANCE TECHNICIAN/INSTALLATION TECHNICIAN Specialist prepared and trained in a technical field (mechanical and electrical) and assigned by the manufacturer to work on the machine to perform machine installation, adjustments, repair breakdowns or carry out maintenance. - 5 - EVO1ST... -

Page 6: Features

If the machine is supplied with the option COROB Connect, it will be possible to drive it through the use of an Android or Windows Tablet device, with its corresponding dispensing software. The connection between the device where the dispensing software is installed and the machine is automatic. -

Page 7: Description Of Units

The rotating cap opens thanks to the push applied to the opening bar while the can is being positioned. The cap closes when the can is removed. When the cap is open, the system confirms the can presence to begin dispensing. - 7 - EVO1ST... - Page 8 Bung Hole Locator (B.H.L.) This is a system that emits laser beams that allow the positioning of pre-punched cans, so that the hole is in line with the center of the dispensing nozzles. EVO1ST - 8 -...

-

Page 9: Usable Cans

2.5 Identifying information The machine has an identification plate (chapter 3.4) indicating: 1. Manufacturer’s name. 2. Marking. 3. Machine model. 4. Month and year of manufacture. 5. Serial number. 6. Electrical specifications. Do not remove or tamper with the identification plate in any way. - 9 - EVO1ST... -

Page 10: Safety

• To prevent any risk of electrical shock or injuries, use the machine indoors only. It is prohibited to use the machine outdoors where it could be subjected to rain or high humidity. • Always unplug the power supply cable from the socket outlet before carrying out any maintenance operations. EVO1ST - 10 -... -

Page 11: Warnings On The Use Of Colorants

5. In case of accidental product leaks or spills, thoroughly ventilate the area and proceed as indicated in this manual and in the instructions provided with the product itself. 6. Do not dispose of colorant in the sewage system. Follow local regulations when disposing of waste. - 11 - EVO1ST... -

Page 12: Residual Risks

3.2 - 4 used may cause poisoning and/or Equipment be provided by the colorant manufacturer. sensitization during canister refilling - 6 - 7 as specified operations, machine cleaning and Keep the room suitably ventilated. in MSDS. disposal. EVO1ST - 12 -... -

Page 13: Position Of Labels

Desconectar el cable de alimentación antes de efectuar cualquier operación de mantenimiento. Débrancher le câble d’alimentation avant d’effectuer toute opération d’entretien. COROB India Pvt. Ltd. - Mumbai c/o Daman Factory: Plot No. 10-13&13A, Daman Industrial Estate, Somnath Road - Daman - India... -

Page 14: Requirements Of The Installation Site

No type of parts must be leant against or stocked close to the machine. Avoid naked flames or material that may create sparks and cause a fire. It is forbidden to smoke in the machine nearby area. EVO1ST - 14 -... -

Page 15: Shipping And Handling

3. Remove machine wrapping. Take out any accessories and/or material supplied with the machine. DANGER Should the machine appear damaged during shipping, do not attempt to start it and contact the authorized technical service or dealer. - 15 - EVO1ST... - Page 16 6. Insert the shelf on the machine. 130 kg / 287 lb To repack the machine, follow the unpacking instructions in reverse order. We recommend reusing the original packing any time the machine must be moved or shipped. - 16 - EVO1ST...

-

Page 17: Standard Material Supplied

For the colorants remaining in the canisters, for the machine components most soiled with colorant and if any products have been used on the machine that require special disposal procedures, follow local regulations when disposing of waste. - 17 - EVO1ST... -

Page 18: Start-Up

The temporary adapter shall be used only until a properly grounded outlet (A) is installed by a qualified electrician. The green colored rigid ear, lug, or similar part extending from the adapter must be connected to a permanent ground EVO1ST - 18 -... - Page 19 0 - 2 2 - 3 3 - 4 4 - 5 5 - 6 6 - 8 8 - 10 10 - 12 12 - 14 14 - 16 16 - 18 18 - 20 - 19 - EVO1ST...

-

Page 20: Management Computer

The dispenser is managed by the computer. The manufacturer can also supply a wide range of software applications to manage all of the machine’s functions. If the machine is supplied with the option COROB Connect, it will be possible to drive it through the use of an Android or Windows Tablet device, with its corresponding dispensing software. -

Page 21: Use Of The Off-Line Button

Pressing the off-line button while a formula is being dispensed will cause dispensing to be interrupted. The interrupted formula recovery function, i.e. the ability to resume dispensing the quantity necessary to complete the formula, is enabled only if the dispensing program supports this function. - 21 - EVO1ST... -

Page 22: Electrical Connection And Start-Up

5.7 Electrical connection and start-up If the computer and monitor do not come on, make sure the power cables have been properly connected to the power sockets, and that the corresponding switches have been turned on. When the software is launched it offers the operator a series of procedure requests that have the purpose to get the machine ready for use. These procedures are strictly related to the type of management software used. EVO1ST - 22 -... -

Page 23: Shut-Down

Should it be essential to shut down the machine, avoid keeping it off for extended periods of time. When the machine is not being used, if necessary shut off only the computer. Very little power is used by the machine itself when inactive or during a stirring cycle. - 23 - EVO1ST... -

Page 24: Using The Dispenser

1. Insert the manually adjustable shelf in the slots provided, based on the size of the can to be used. DANGER Do not load on the shelf cans weighing more than 35 kg (77 lb). Do not climb onto the shelf and/or sit on it. Do not use the shelf as a ladder. - 24 - EVO1ST... -

Page 25: Dispensing

When the dispensing command is entered, the automatic cap opens to expose the nozzles and the machine begins to dispense the products included in the formula in the set amounts; the cap will automatically close when dispensing is finished. The dispensing system depends on the machine version. - 25 - EVO1ST... -

Page 26: Automatic Timed Stirring

(refer to the CorobTECH user’s manual), based on the nature of the products used on the machine. We recommend to keep the canisters closed with their corresponding lids; do not insert hands in the canister even when no colorant is present When an automatic process is in progress, the machine can still be used; the process will be suspended and restarted after a few seconds that the machine is inactive. - 26 - EVO1ST... -

Page 27: Refilling The Canisters

6.5 Refilling the canisters 5 cm 2 in - 27 - EVO1ST... - Page 28 After topping up the colorant, it is advisable to carry out the stirring process using the functions provided in the management software, to eliminate any air that may be emulsified and incorporated into the colorant. - 28 - EVO1ST...

- Page 29 Here below you will find a reference diagram to perform canister filling. - 29 - EVO1ST...

-

Page 30: Troubleshooting

The Autocap is open and the Close the Autocap and bring the machine to the fast and the machine refuses machine is in the off-line 2 on-line condition by using the off-line button the commands. condition. (chapter 5.6). - 30 - EVO1ST... -

Page 31: Ordinary Maintenance

Should growths form in the cap, in the sponges or in the humidifier water bottle, it is advisable to use the following fluids: • Propylene glycol solution, 50% by volume, in water; • AgCl solution in water; • Bleach (dilution 1%). - 31 - EVO1ST... -

Page 32: External Cleaning

3. Accurately clean the nozzles using a sharp tool; remove any dried colorant residue delicately, to avoid damaging the ends of the circuits. 4. Connect power supply and switch on the machine (chapter 5.7). 5. Close the Autocap with the off-line button (on-line) (chapter 5.6). 6. Carry out purge. EVO1ST - 32 -... -

Page 33: Cleaning And Moistening The Sponge (Humidifier Cap)

If it is very dirty, remove the sponge from the cap and wash it thoroughly. If the sponge is severely damaged, replace it. 6. Open the cap with your hand and reinstall the sponge holding cup. 7. Connect power supply and switch on the machine (chapter 5.7). - 33 - EVO1ST... - Page 34 If the sponge is severely damaged, replace it. 5. Screw back the sponge holding lid. 6. Connect power supply and switch on the machine (chapter 5.7). 7. Close the Autocap with the off-line button (on-line) (chapter 5.6). EVO1ST - 34 -...

- Page 35 - 35 - EVO1ST...

-

Page 36: Refilling The Humidifier Bottle

3. Unscrew the bottle cap and add water (0.5 liters / 1 Pint maximum), paying attention NOT TO EXCEED THE MAXIMUM LEVEL. To reduce the risk of lime encrustations due to hard water, it is recommended to use distilled water. 4. Re-place the cap and firmly tighten. 5. Re-place the upper cover, connect power supply and switch on the machine (chapter 5.7) EVO1ST - 36 -... -

Page 37: Technical Specifications

All-purpose (POM acetalic resin) Type of valves Membrane valve: Viton (water) - FFKM (universal/solvent) Machine 130 kg (287 lb) Packed machine 175 kg (386 lb) (a) Excluding connected auxiliary devices (machine without optional auxiliary sockets). The power information is purely indicative, and depends strictly on the machine configuration. The machine serial number label indicates the exact power data, referred to the specific machine configuration. (b) Value measured in laboratory and documented by the corresponding test report available at the manufacturer’s. Operating conditions: machine normal working cycle, under simulated load conditions. (c) The environment working conditions are strictly related to the type of colorants used (ask for information from the paint manufacturer). The data shown are valid for the machine only. (d) Hole diameter for pre-punched cans = flow diameter + 15 mm (0.59”). (e) Data refer to the machine with empty canisters. - 37 - EVO1ST... -

Page 38: Dimensions

• Failure to observe the instructions and maintenance rules set forth in the manual. • Making or having changes and/or repairs made on the machine by personnel outside the service organization authorized by the manufacturer and/or made using non-original spare parts. - 38 - EVO1ST... - Page 39 Mandatario e persona autorizzata a costituire il fascicolo tecnico: Authorised representative and person authorised to compile the technical file: COROB S.p.A. - Via Agricoltura, 103 - 41038 San Felice s/P (MO) - Italy Il fabbricante dichiara sotto la propria esclusiva responsabilità...

- Page 40 BG - Производителят, който е лицето упълномощено за изготвяне на техническата документация, декларира на собствена изключителна отговорност, че машината, за която се отнася тази декларация, е в съответствие със съществените изисквания, предвидени от следните Директиви: Директива 2006/42/EО - Машини - Директива 2014/30/ЕС относно Електромагнитна съвместимост - Директива RoHS2 2011/65/ЕС - WEEE 2012/19/EC - 2014/53/EU - EN 61000-6-2:2005 - EN 61000-6-3:2007+A1:2011.

Need help?

Do you have a question about the EVO1ST and is the answer not in the manual?

Questions and answers