Summary of Contents for corob Flex 900

- Page 1 COROB™ FLEX 900 Automatic Dispenser User’s Manual 207153 - ENGLISH PRELIMINARY VERSION (05/2014)

- Page 2 COROB™ is a registered trademark and/or commercial trademark used on an exclusive basis by COROB S.p.A. and its affiliated companies (hereinafter “COROB”). A failure of a trademark to appear hereunder does not mean that COROB does not use the trademark in question nor does it constitute a waiver by COROB of any related intellectual property rights.

- Page 3 At the end of the working day • Refill the canisters. • Update the canister filling levels in the management software. • Shut down the computer. Do not shut off the machine. It is recommended to carefully read the user’s manual. COROB™ FLEX 900...

- Page 4 COROB™ FLEX 900...

-

Page 5: Table Of Contents

Automatic timed processes ..................... 28 Refilling the canisters ..................... 29 Troubleshooting ......................31 ORDINARY MAINTENANCE ....................33 General warnings ......................33 Maintenance table ......................33 Products to be used ....................... 33 External cleaning ......................34 Cleaning the nozzle center ....................34 COROB™ FLEX 900... - Page 6 CONTENTS Cleaning and moistening the humidifier cap sponge ............36 TECHNICAL SPECIFICATIONS ....................39 Technical data ....................... 39 Dimensions ........................40 Declaration of conformity ....................40 Reference standards ...................... 41 Warranty ........................41 COROB™ FLEX 900...

-

Page 7: General Information

The machine has an identification plate (chapter 2.4), indicating: 1. Manufacturer’s name. 2. CE and WEEE marking. 3. Machine model. 4. Year of manufacture. 5. Serial number. 6. Electrical specifications. Do not remove or tamper with the identification plate in any way. COROB™ FLEX 900... -

Page 8: Intended And Improper Use

He or she must work only in safety conditions and is allowed to carry out routine maintenance operations. Specialist prepared and trained in a technical field (mechanical and electrical) and MAINTENANCE assigned to work on the machine to perform adjustments, repair breakdowns or carry TECHNICIAN out maintenance. COROB™ FLEX 900... -

Page 9: Safety

• Do not use multisockets to connect other equipment to the same socket that powers the machine. • Periodically check the condition of the power supply cable; if it is damaged, replace it with a new cable supplied by the manufacturer. COROB™ FLEX 900... -

Page 10: Warnings On The Use Of Colorants

5. In case of accidental product leaks or spills, thoroughly ventilate the area and proceed as indicated in this manual and in the instructions provided with the product itself. 6. Do not dispose of colorant in the sewage system. Follow local regulations when disposing of waste. COROB™ FLEX 900... -

Page 11: Residual Risks

Canister top up must be carried out opening one canister at the time. chapter 6.5 If during this operation, some colorant should spill out of the canister, immediately disconnect the machine from the mains before cleaning. COROB™ FLEX 900... -

Page 12: Position Of Labels

3. Label “Laser danger” (only with Laser BHL) 4. Label “Electrical danger” Do not remove or make illegible the safety or instruction labels. Replace any label which has become illegible or is missing, by requesting it to the manufacturer. COROB™ FLEX 900... -

Page 13: Features

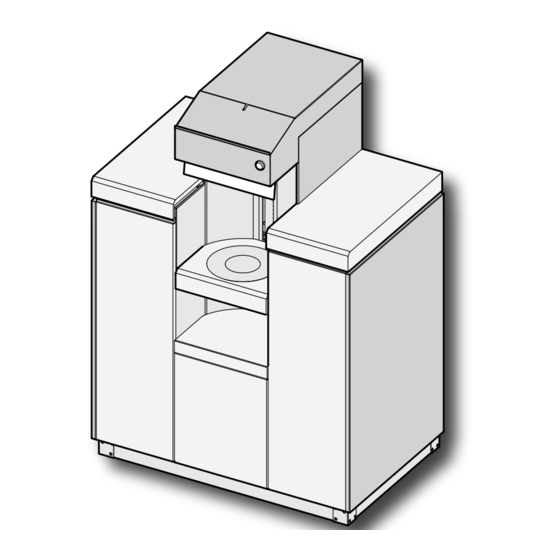

FEATURES Description of the machine The COROB™ FLEX 900 automatic dispenser is a device to automatically dispense fluid colorant products into containers (metal or plastic canisters, cans or bins) of the size indicated in this manual, pre-filled with base, to produce finished products such as paints, dyes, enamels, and inks of the desired hue, chosen by means of the machine management software. -

Page 14: Description Of Units

Bung Hole Locator (B.H.L.) This is a system that emits laser beams that allow the positioning of pre-punched cans, so that the hole is in line with the center of the dispensing nozzles. COROB™ FLEX 900... - Page 15 The Sliding Autocap is an automatically activated cap, whose movement is managed by the application program, which opens it automatically before dispensing and closes it automatically immediately afterwards. A photocell prevents dispensing from taking place when no can is resting on the shelf. COROB™ FLEX 900...

-

Page 16: Standard And Optional Configurations

* Hole diameter for pre-punched cans = flow diameter + 15 mm. Usable cans Humidifier cap > sliding cap sliding autocap Panels > sheet metal sheet metal 505 mm 490 mm 490 mm 475 mm 75 mm 60 mm 35 mm 20 mm 230 mm 340 mm COROB™ FLEX 900... -

Page 17: Shipping, Handling And Unpacking

(air exchange) and no type of parts must be leant against or stocked close to the machine. If the machine is installed near a wall, keep it at least 10 cm away to allow the upper covers to be opened and prevent the cables from being crushed. COROB™ FLEX 900... -

Page 18: Unpacking And Placement

6. Remove all screws and nuts that fix the rear bracket to the machine and to the pallet. 7. Operating from the front side, with one person at each corner, tilt the machine frontally until the rear bracket is free and can be removed by a third person. 8. Now remove the front bracket. COROB™ FLEX 900... - Page 19 Grasp then the machine on the sides, then slide it slowly to the ground along the cover. 11. Lower the feet (chapter 4.3.1) to support and level the machine properly, and make sure that the wheels are not resting. COROB™ FLEX 900...

-

Page 20: Adjusting The Support Feet

16 - SHIPPING, HANDLING AND UNPACKING 4.3.1 Adjusting the support feet To open machine panels 1 x 17 mm To adjust machine feet Figure 5 Figure 6 COROB™ FLEX 900... -

Page 21: Standard Material Supplied

Use appropriate equipment to move the packed machine. If stored, the machine must be kept in a protected, dry environment, not subjected to harsh weather, to avoid damaging the electrical components. WARNING Do not stack items on the packing. COROB™ FLEX 900... - Page 22 18 - START-UP COROB™ FLEX 900...

-

Page 23: Start-Up

Do not attempt to power the machine from a source having specifications other than those listed on the identification plate. The machine is isolated from the power supply line when the power plug is disconnected; it must therefore be installed near an easily accessible mains socket outlet. COROB™ FLEX 900... -

Page 24: Control Devices And Connections

For the connection to the management computer. 5. USB serial port. To interrupt machine functions, without shutting it off; it also 6. Off-line button with ON lamp. enables to open and close the Autocap (if present) to allow cleaning the nozzles. COROB™ FLEX 900... -

Page 25: Electrical Connection And Start-Up

START-UP - 21 Electrical connection and start-up Figure 9 When the software is launched it offers the operator a series of procedure requests, including initialization (chapter 5.5). COROB™ FLEX 900... -

Page 26: Machine Conditions

Pressing the off-line button while a formula is being dispensed will cause dispensing to be interrupted. Once the machine has been restored to normal operation, IT WILL NOT BE POSSIBLE to continue dispensing the formula previously interrupted. COROB™ FLEX 900... -

Page 27: Shut-Down

Should it be essential to shut down the machine, avoid keeping it off for extended periods of time. When the machine is not being used, shut off only the computer. Very little power is used by the machine itself when inactive or during a stirring cycle. Shut off the machine as follows: Figure 10 COROB™ FLEX 900... - Page 28 24 - USING THE DISPENSER COROB™ FLEX 900...

-

Page 29: Using The Dispenser

• Carry out system Initialization and Purge. Running the machine The operator is guided in running the machine by the COROB™ management software, which displays the instructions to be carried out and the actions performed by the machine. Steps... -

Page 30: Adjusting The Can Shelf Height

Autocap Place the can on the shelf to push the cap opening bar Place the can on the shelf, making sure that photocell inward and thus cause it to open. (A) is obscured. Figure 12 COROB™ FLEX 900... -

Page 31: Use Of The Can Centering Device

1. After having correctly loaded the can on the shelf (chapter 6.3.2), the laser beams will switch on. 2. Position the can in such a way that the hole on the lid is in the center of the laser beams. Figure 14 COROB™ FLEX 900... -

Page 32: Dispensing

When an automatic timed process is in progress, the machine can still be used; the process will be suspended and restarted after a few seconds that the machine is inactive. COROB™ FLEX 900... -

Page 33: Refilling The Canisters

Colorant spills cause the circuit pumping unit to be blocked. 5. Close the canister with its corresponding lid. 6. Repeat the above steps to fill other canisters. 7. Close the upper covers and restore the machine by pressing for an instant the off-line button (chapter 5.6). COROB™ FLEX 900... - Page 34 Here below you will find a reference diagram to perform canister filling. MAX 2.3 l 2.4 qt 1.8 l 1.9 qt 1 qt Figure 16 COROB™ FLEX 900...

-

Page 35: Troubleshooting

The ON lamp blinks fast and The Autocap is open and the to the on-line condition by using the the machine refuses the machine is in the off-line 2 off-line button or by sending a Reset commands. condition. command (chapter 5.6). COROB™ FLEX 900... - Page 36 32 - ORDINARY MAINTENANCE COROB™ FLEX 900...

-

Page 37: Ordinary Maintenance

Should growths form in the cap or in the sponges, it is advisable to use the following fluids: • Propylene glycol solution, 50% by volume, in water; • AgCl solution in water; • Bleach (dilution 1%). COROB™ FLEX 900... -

Page 38: External Cleaning

4. Connect power supply and switch on the machine (chapter 5.3). 5. Close the Autocap bringing the machine to the on-line condition, by means of the off-line button (chapter 5.6). COROB™ FLEX 900... -

Page 39: Corob™ Flex

ORDINARY MAINTENANCE - 35 Figure 18 COROB™ FLEX 900... -

Page 40: Cleaning And Moistening The Humidifier Cap Sponge

4. Screw back the sponge holding lid. 5. Connect power supply and switch on the machine (chapter 5.3). 6. Close the Autocap bringing the machine to the on-line condition, by means of the off-line button (chapter 5.6). COROB™ FLEX 900... - Page 41 ORDINARY MAINTENANCE - 37 Figure 19 COROB™ FLEX 900...

- Page 42 38 - TECHNICAL SPECIFICATIONS COROB™ FLEX 900...

-

Page 43: Technical Specifications

** The environment working conditions are strictly related to the type of colorants used (ask for information from the paint manufacturer). The data shown are valid for the machine only. *** Values highly affected by the nature of the colorants and their rheological properties. **** Data refer to the machine with empty canisters. COROB™ FLEX 900... -

Page 44: Dimensions

40 - TECHNICAL SPECIFICATIONS Dimensions VL 950 mm - 37.4” VP 966 mm - 38” 334 mm 13” 350 mm 13.8” 166 mm 6.5” Declaration of conformity See Declaration of conformity attached. COROB™ FLEX 900... -

Page 45: Reference Standards

TECHNICAL SPECIFICATIONS - 41 Reference standards COROB S.p.A. designs, manufactures, and subjects its machines to tests to ensure compliance with safety and electromagnetic compatibility regulations. Any changes not authorized by COROB S.p.A. may jeopardize this compliance. The manufacturer certifies, under its own responsibility, that the machine to which this statement refers to, complies with the essential requirements foreseen by the regulations: •... - Page 46 42 - TECHNICAL SPECIFICATIONS COROB™ FLEX 900...

Need help?

Do you have a question about the Flex 900 and is the answer not in the manual?

Questions and answers