Mandik SEDM Manual

Smoke extraction damper - multi

Hide thumbs

Also See for SEDM:

- Maintenance and service manual (79 pages) ,

- Technical documentation manual (60 pages) ,

- Manual (59 pages)

Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Mandik SEDM

-

Page 2: Table Of Contents

TPM 087/12 These technical specifications state a row of manufactured sizes and models of smoke extraction dampers - multi (further only dampers) SEDM. It is valid for production, designing, ordering, delivery, maintenance and operation. I. CONTENT II. GENERAL INFORMATION 1. Description......................... -

Page 3: General Information

• External Casing leakage class C, Internal leakage min. class 2 acc. to EN 1751 • Cycling test in class C 10000 acc. to EN 15650 • ES Certificate of conformity No. 1391-CPD-0098/2012 • Declaration of Perfomance No. CDM/SEDM/001/13 • Hygienic assessment of fire dampers - Report No. 1.6/13/16/2 Tab. 1.2.1. Classification of Dampers... -

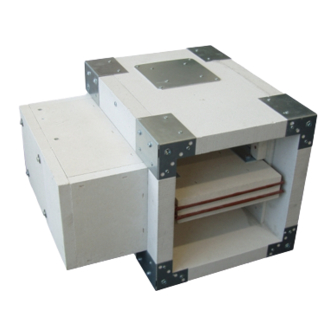

Page 4: Design

Design with actuating mechanism 2.1. Design .44 and .54 SEDM is equipped by actuating mechanism Belimo BLE24(BE24-12) for 24V supply or BLE230(BE230-12) for 230V supply. SEDM with big dimensions is equipped by actuating mechanism Schischek InMax 50.75-S (dual supply 24V or 230V). - Page 5 TPM 087/12 Tab. 2.1.1. Actuating mechanism BELIMO BLE 24(-ST), BLE 230 Actuating mechanism BELIMO BLE 24(-ST) BLE230 AC 230 V 50/60Hz Nominal voltage AC 24V 50/60Hz DC 24 V Power consumption - motoring 7,5 W < 1 W - holding <...

- Page 6 TPM 087/12 Tab. 2.1.2. Actuating mechanism BELIMO BE 24-12(-ST), BE 230-12 Actuating mechanism BELIMO BE 24-12 (-ST) BE230-12 AC 230 V 50/60Hz Nominal voltage AC 24V 50/60Hz DC 24 V Power consumption - motoring 12 W 0,5 W - holding 0,5 W 15 VA (Imax 7.9 A @ 5 ms) Dimensioning...

- Page 7 TPM 087/12 Tab. 2.1.3. Actuating mechanism SCHISCHEK InMax 50.75-S InMax 50.75-S Actuating mechanism SCHISCHEK Nominal voltage 24-240 VAC/DC 50/60Hz Power consumption - motoring 10 W - heating 16 W (start at -20°C) Protection class Degree of protection IP 66 Running time for 95° <...

- Page 8 TPM 087/12 The 2-wire conductor must be connected to screw terminals 6 and 7. It is recommended that a fire alarm signal cable suitable for the application be used for the 2-wire conductor. It is essential to ensure the correct polarity. More information in catalogue Belimo.

- Page 9 TPM 087/12 3. Communication and control devises BKSE24-6 indicates operating status and fault signals for the smoke extraction dampers. The 3.1. auxiliary contacts that are incorporated also allow functions to be signaled or passed on to higherlevel control systems. The signals from the BKNE230-24 unit are received by the BKSE24-6 unit and evaluated individually.

-

Page 10: Dimensions, Weights

TPM 087/12 4. Dimestions, weights Dimensions 4.1. Fig. 11 Smoke extraction dampers - multi without flanges * Dimensions with actuating mechanism InMax 50.75 Position: Damper body Damper blade Inspection hole Actuating mechanism covering Fig. 12 Smoke extraction dampers - multi with flanges A FLANGE DETAIL - connection dimensions External dimensions of flance A(B) + 60 is not same as external dimensions of damper... - Page 11 TPM 087/12 Weights and effective area 4.2. Tab. 4.2.1. Weights and effective area Without With Weight [kg] Effective flanges flanges Size Actuating mechanism area S type Without With [m ] flanges flanges 41,4 38,3 0,0077 BELIMO BLE (15 N.m) 180 x 180 42,8 39,6 0,0099...

- Page 12 TPM 087/12 Without With Weight [kg] Effective flanges flanges Size Actuating mechanism area S type Without With [m ] flanges flanges 60,1 55,5 0,0450 BELIMO BLE (15 N.m) 225 x 400 63,6 58,9 0,0527 BELIMO BLE (15 N.m) 225 x 450 67,2 62,1 0,0605...

- Page 13 TPM 087/12 Without With Weight [kg] Effective flanges flanges Size Actuating mechanism area S type Without With [m ] flanges flanges 80,2 74,2 0,1134 BELIMO BLE (15 N.m) 280 x 650 83,9 77,6 0,1239 BELIMO BLE (15 N.m) 280 x 700 84,6 78,3 0,1260...

- Page 14 TPM 087/12 Without With Weight [kg] Effective flanges flanges Size Actuating mechanism area S type Without With [m ] flanges flanges 50,2 46,3 0,0200 BELIMO BLE (15 N.m) 355 x 180 51,7 47,7 0,0257 BELIMO BLE (15 N.m) 355 x 200 53,6 49,5 0,0328...

- Page 15 TPM 087/12 Without With Weight [kg] Effective flanges flanges Size Actuating mechanism area S type Without With [m ] flanges flanges 71,8 66,3 0,0931 BELIMO BLE (15 N.m) 450 x 355 75,5 69,9 0,1102 BELIMO BLE (15 N.m) 450 x 400 79,7 73,8 0,1292...

- Page 16 TPM 087/12 Without With Weight [kg] Effective flanges flanges Size Actuating mechanism area S type Without With [m ] flanges flanges 100,1 93,1 0,2496 BELIMO BLE (15 N.m) 550 x 630 101,9 94,8 0,2592 BELIMO BLE (15 N.m) 550 x 650 106,3 98,8 0,2832...

- Page 17 TPM 087/12 Without With Weight [kg] Effective flanges flanges Size Actuating mechanism area S type Without With [m ] flanges flanges 139,4 130,1 0,4717 BELIMO BE (40 N.m) 600 x 1000 65,9 60,6 0,0392 BELIMO BLE (15 N.m) 630 x 180 67,6 62,4 0,0504...

- Page 18 TPM 087/12 Without With Weight [kg] Effective flanges flanges Size Actuating mechanism area S type Without With [m ] flanges flanges 61,6 78,6 BELIMO BLE (15 N.m) 700 x 315 80,6 64,5 82,2 BELIMO BLE (15 N.m) 700 x 355 84,8 67,8 86,4...

- Page 19 TPM 087/12 Without With Weight [kg] Effective flanges flanges Size Actuating mechanism area S type Without With [m ] flanges flanges 110,6 0,3332 BELIMO BLE (15 N.m) 750 x 600 113,5 105,7 0,3536 BELIMO BLE (15 N.m) 750 x 630 115,4 107,5 0,3672...

- Page 20 TPM 087/12 Without With Weight [kg] Effective flanges flanges Size Actuating mechanism area S type Without With [m ] flanges flanges 156,2 146,3 0,6557 BELIMO BE (40 N.m) 900 x 900 166,8 156,4 0,7387 BELIMO BE (40 N.m) 900 x 1000 83,5 78,1 0,0651...

- Page 21 TPM 087/12 Without With Weight [kg] Effective flanges flanges Size Actuating mechanism area S type Without With [m ] flanges flanges 106,2 0,2242 BELIMO BLE (15 N.m) 1250 x 300 114,8 0,2419 BELIMO BLE (15 N.m) 1250 x 315 119,9 112,9 0,2891 BELIMO BE (40 N.m)

- Page 22 TPM 087/12 Without With Weight [kg] Effective flanges flanges Size Actuating mechanism area S type Without With [m ] flanges flanges 151,9 162,7 0,6435 BELIMO BE (40 N.m) 1500 x 560 157,2 168,2 0,7007 BELIMO BE (40 N.m) 1500 x 600 161,2 172,4 0,7436...

-

Page 23: Placement And Assembly

TPM 087/12 For damper without flanges (Fig. 14) the open damper blade overlaps the damper body from 4.3. dimension B = 250 by the value “c” or “a” and “c”. These values are specified in the Tab. 4.2.1. For damper without flanges (Fig. 15) the open damper blade overlaps the damper body from dimension B = 355 by the value “f”... - Page 24 Fig. 17 Example of installation in solid wall construction of fire compartment - vertical blade axis position. Cover of actuating mechanism has to be removable after installation Position: 1 Damper SEDM 2 Solid wall construction 3 Mineral stone wool, density 140 kg/m 4 Fire protection mastic, thickness 1 mm...

- Page 25 TPM 087/12 Fig. 18 Example of installation in solid wall construction of fire compartment - horizontal blade axis position. Position: 1 Damper SEDM 2 Solid wall construction 3 Mineral stone wool, density 140 kg/m 4 Fire protection mastic, thickness 1 mm...

- Page 26 Fig. 21 Example of installation in gypsum wall construction of fire compartment. Cover of actuating mechanism has to be removable after installation Position: 1 Damper SEDM 2 Gypsum wall construction 3 Mineral stone wool, density 140 kg/m 4 Fire protection mastic, thickness 1 mm...

- Page 27 Installation on solid wall or ceiling construction of fire compartment 5.4.3. Fig. 22 Example of installation on solid wall construction of fire compartment. - vertical blade axis position. Position: 1 Damper SEDM 2 Solid wall construction 3 Ceramic paper* 4 Hinges * Ceramic paper is placed between damper and solid wall construction Fig.

- Page 28 TPM 087/12 Fig. 24 Example of installation on solid ceiling construction of fire compartment - suspension. Position: Damper SEDM Solid ceiling construction Ceramic paper* Hinges Holder L Cement lime plate * Ceramic paper is placed between damper and solid wall construction Fig.

- Page 29 TPM 087/12 Installation in smoke exhaust duct. 5.4.3. Fig. 26 Example of installation in vertical smoke exhaust duct. Position: Damper SEDM Duct Hinges Holder L...

- Page 30 TPM 087/12 Fig. 27 Example of installation in horizontal smoke exhaust duct. Position: Damper SEDM Duct Hinges Holder L...

- Page 31 TPM 087/12 6. Damper suspension and connection to the duct Dampers can be suspended by using of threaded rods and fixing rails. Threaded rods has to be 6.1. designed depend on damper weight. Damper suspension has to be solve separately. Back-to-back smoke exhaust duct has to be 6.2.

- Page 32 TPM 087/12 Examples of hinges fixing 6.5. Fig. 29 Examples of hinges fixing Position: 1 Threaded rod 6 Bolt 2 Nut 7 L - holder 3 C - washer 8 Screw 4 Fixing rail 9 Cantilever arm 41x41x2 10 Mounting angle 5 Washer Connection to the exhaust duct to be made according to recommendation of exhaust duct supplier.

-

Page 33: Technical Data

TPM 087/12 III. TECHNICAL DATA 7. Pressure loss Pressure loss calculation 7.1. [Pa] presure loss [m.s ] air flow speed in nominal damper section [kg.m ] air density coefficient of local pressure loss for the nominal damper section (see Tab. 8.1.1.) Determination of pressure loss by using diagram = 1,2 kg.m 7.2. -

Page 34: Coefficient Of Local Pressure Loss

TPM 087/12 8. Coefficient of local pressure loss Coefficient of local pressure loss (-) 8.1. Tab. 8.1.1. Coefficient of local pressure loss 3,1433 2,5092 2,0162 1,6711 1,4773 1,3192 1,1951 1,0336 0,9095 0,8126 0,7429 2,9529 2,3545 1,9584 1,5657 1,3991 1,2512 1,1186 0,9673 0,8500 0,7582... - Page 35 TPM 087/12 9. Noise data Level of acoustic output corrected with filter A 9.1. Tab. 9.1.1. Level of acoustic output corrected with filter A Air velocity 4 m/s Level of acoustic output [dB] 180 200 225 250 280 300 315 355 400 450 500 550 560 600 630 650 700 710 750 800 900 1000 180 56 49 48 46 200 52 48 45 44 225 50 47 45 40...

- Page 36 TPM 087/12 Tab. 9.1.2. Level of acoustic output corrected with filter A Air velocity 5 m/s Level of acoustic output [dB] 180 200 225 250 280 300 315 355 400 450 500 550 560 600 630 650 700 710 750 800 900 1000 180 >55 55 53 52 200 >55 55 52 49 225 >55 54 50 48...

- Page 37 TPM 087/12 Tab. 9.1.3. Level of acoustic output corrected with filter A Air velocity 6 m/s Level of acoustic output [dB] 180 200 225 250 280 300 315 355 400 450 500 550 560 600 630 650 700 710 750 800 900 1000 180 ˃55 ˃55 ˃55 ˃55 55 200 ˃55 ˃55 ˃55 55 225 ˃55 ˃55 ˃55 54...

- Page 38 TPM 087/12 Tab. 9.1.4. Level of acoustic output corrected with filter A Air velocity 7 m/s Level of acoustic output [dB] 180 200 225 250 280 300 315 355 400 450 500 550 560 600 630 650 700 710 750 800 900 1000 180 ˃61 ˃61 ˃61 ˃61 61 200 ˃61 ˃61 ˃61 ˃61 59 225 ˃61 ˃61 ˃61 60...

- Page 39 TPM 087/12 Tab. 9.1.5. Level of acoustic output corrected with filter A Air velocity 8 m/s Level of acoustic output [dB] 180 200 225 250 280 300 315 355 400 450 500 550 560 600 630 650 700 710 750 800 900 1000 180 ˃63 ˃63 ˃63 ˃63 ˃63 ˃63 ˃63 63 200 ˃63 ˃63 ˃63 ˃63 ˃63 62 225 ˃63 ˃63 ˃63 ˃63 ˃63 61...

- Page 40 TPM 087/12 Tab. 9.1.6. Level of acoustic output corrected with filter A Air velocity 9 m/s Level of acoustic output [dB] 180 200 225 250 280 300 315 355 400 450 500 550 560 600 630 650 700 710 750 800 900 1000 180 ˃65 ˃65 ˃65 ˃65 ˃65 ˃65 ˃65 ˃65 ˃65 65 200 ˃65 ˃65 ˃65 ˃65 ˃65 ˃65 ˃65 65 225 ˃65 ˃65 ˃65 ˃65 ˃65 ˃65 65...

-

Page 41: Material, Finishing

TPM 087/12 IV. MATERIAL, FINISHING 10. Material Damper casings and blades are made of fire resistant asbestos free boards made of mineral fibres. 10.1. Fasteners are galvanized. 10.2. V. INSPECTION, TESTING 11. Inspection, testing The appliance is constructed and preset by the manufacturer, its operation is dependent on 11.1. -

Page 42: Entry Into Service And Revisions

TPM 087/12 14. Entry into service and revisions Before entering the dampers into operation after assembly and after sequential revisions, checks 14.1. and functionality tests of all designs including operation of the electrical components must be successfully provided and finished. After entering into operation, these revisions must be done according to requirement set by national regulations. -

Page 43: Product Data

VIII. PRODUCT DATA 16. Nameplate Nameplate is placed on the damper casing 16.1. Fig. 32 Nameplate MANDÍK, a.s., Dobříšská 550, 267 24 Hostomice, Czech Republic SMOKE EXTRACTION DAMPER - MULTI SEDM DIMENSION: DESIGN: WEIGHT (kg): SERIAL NUMBER: acc.certificate 1391-CPD-0098/2012/O CLASSIFICATION:... -

Page 44: Ordering Key

TPM 087/12 IX. ORDERING INFORMATION 18. Ordering key SEDM 180x355 .44/P TPM 087/12 technical specifications - without flanges P - with flanges design according tab. 18.1.1. size type Tab. 18.1.1. Dampers design Additional Dampers design digit with actuating mechanism BLE230(BE230-12), InMax 50.75-S...

Need help?

Do you have a question about the SEDM and is the answer not in the manual?

Questions and answers