Table of Contents

Advertisement

OPERATOR'S MANUAL

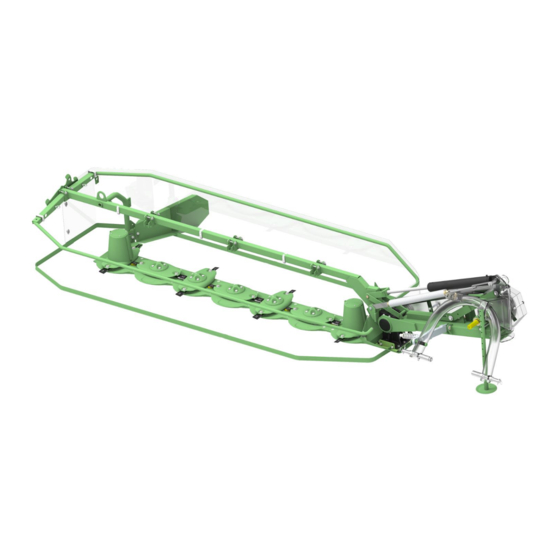

LIGHTWEIGHT, REAR DISC MOWER

The original operator's manual

SAMBA 160

SAMBA 200

SAMBA 240

SAMBA 280

SAMBA 320

ENGLISH

SaMASZ Sp. z o.o.

tel. (+48) (85) 664 70 31

ul. Trawiasta 1

fax (+48) (85) 664 70 41

16-060 Zabłudów

e-mail: samasz@samasz.pl

Polska

www.samasz.pl

Serial no.

IN0670USA004

06.07.2020

EDITION NO. 4

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for SaMASZ SAMBA 160

- Page 1 SaMASZ Sp. z o.o. tel. (+48) (85) 664 70 31 ul. Trawiasta 1 fax (+48) (85) 664 70 41 16-060 Zabłudów e-mail: samasz@samasz.pl Polska www.samasz.pl OPERATOR’S MANUAL LIGHTWEIGHT, REAR DISC MOWER SAMBA 160 SAMBA 200 SAMBA 240 SAMBA 280 SAMBA 320 IN0670USA004 The original operator’s manual...

- Page 2 Well-proven design with thousands of machines in regular use in many countries and quality materials ensure high durability and reliability of SaMASZ mowers. We congratulate you on the purchase of your new SaMASZ mower and wish you much pleasure and the very best work results through the years to come.

-

Page 3: Table Of Contents

OPERATOR’S MANUAL REAR DISC MOWERS SAMBA Table of contents page 1. IDENTIFYING THE MACHINE ................... 5 2. INTRODUCTION ......................5 3. PROPER AND INTENDED USE ..................5 3.1. Technical data ..........................7 3.2. Design and operating principle ......................7 3.3. Standard equipment and spare parts ....................8 4. - Page 4 SAMBA REAR DISC MOWER OPERATOR’S MANUAL 10. WARRANTY CARD ....................... 41 11. WARRANTY TERMS ..................... 41 11.1. Warranty claim procedures ......................41 11.2. Warranty repairs record ........................43...

-

Page 5: Identifying The Machine

OPERATOR’S MANUAL REAR DISC MOWERS SAMBA 1. IDENTIFYING THE MACHINE Data plate is permanently mounted to the mower's main frame in place shown below in Fig. 1. Fig. 1. Data plate placement Data plate includes: name and adress of the manufacturer, model year, ❑... - Page 6 SAMBA REAR DISC MOWER OPERATOR’S MANUAL WARNING! Use of the mower for purposes other than mentioned herein is forbidden. Different use than the above mentioned shall be considered as improper and may lead to revoking of the warranty. The mower should be operated, maintained and repaired only by personnel who are familiarized with its detailed specifications and safety rules and procedures.

-

Page 7: Technical Data

OPERATOR’S MANUAL REAR DISC MOWERS SAMBA 3.1. Technical data Tab. 2. Technical data Mower type: SAMBA 160 SAMBA 200 SAMBA 240 SAMBA 280 SAMBA 320 Working width [ft.in.] 5' 3" 6' 7" 7' 10" 9' 2" 10' 6" Number of knives [pcs]... -

Page 8: Standard Equipment And Spare Parts

Optional extra equipment should be ordered separately. Tab. 3. Recommended PTO shaft Power Length Momentum Mower Clutch Manufacturer mm / ft. in. SAMBA 160 SAMBA 200 660-900 / Right-hand SAMBA 240 7G3N066CE007096MA BONDIOLI& PAVESI 2'2" - 2'11" overrunning SAMBA 280... -

Page 9: Safety Precautions

To be mounted on the tractor side mounted from the mower side Fig. 3. Shaft lubrication instructions. Shaft connection PTO shafts of other brands with equivalent technical parameters may be used on the SaMASZ permission. 4. SAFETY PRECAUTIONS The following precautions are for your safety. They must be read carefully and followed by every person who operates or maintains the machine. - Page 10 Start mowing only when the tractor's spline shaft reaches its nominal value of 540 rpm (for: SAMBA ❑ 160, 200, 240, 280) or 1000 rpm (for: SAMBA 320). DO NOT exceed value of 600 rpm (for: SAMBA 160, 200, 240, 280) or 1050 rpm (for: SAMBA 320 ❑ for spline shaft.

-

Page 11: Qualifications Of Operator

OPERATOR’S MANUAL REAR DISC MOWERS SAMBA 9. Never leave tractor’s engine running without supervision. Before you leave the tractor, turn off the engine and remove the key from tractor’s ignition. 10. DO NOT operate the mower when driving the tractor backwards. Permissible inclination of the mower on a slope when working and during transport is 8°. -

Page 12: Conditions Of Mounting Mower On Tractor

SAMBA REAR DISC MOWER OPERATOR’S MANUAL Operator must be in proper physical condition to be able to operate the machine. ❑ Operator must not be under the influence of alcohol, drugs and medicines, which all have ❑ influence on vehicle driving and machine operation. Operator should be familiarized with this manual and follow its provisions. - Page 13 OPERATOR’S MANUAL REAR DISC MOWERS SAMBA Transport should be done by qualified and specifically trained personnel, ❑ Grab the mower by any lifting devices only in places indicated by hook sign (Fig. 4), ❑ For mower lifting, use only lifting devices with hoisting capacity larger than mower’s weight shown ❑...

-

Page 14: Working Parts

REAR DISC MOWER OPERATOR’S MANUAL Fig. 5. Location of center of gravity for SAMBA mowers Tab. 4. Location of center of gravity Mower type Dimension [ft. in] SAMBA 160 SAMBA 200 SAMBA 240 SAMBA 280 SAMBA 320 1' 8" 1' 8"... -

Page 15: Residual Risk

❑ 4.8. Residual risk Despite the fact that SaMASZ, the manufacturer of the mower, has taken great care in the design and manufacturing of the mower, certain risks during mower operation and maintenance are unavoidable. A major source of risk that could result in serious injury or death can occur during the performance of these operations. - Page 16 SAMBA REAR DISC MOWER OPERATOR’S MANUAL 1. Danger of machine entanglement This risk occurs when (1) changing position of a mower, (2) operating near rotating parts, and (3) working without safety guards. During operation, maintenance and adjustment, always wear protective gloves, shoes and clothes without loose parts, belts and so on.

-

Page 17: Safety Decals And Their Meaning

OPERATOR’S MANUAL REAR DISC MOWERS SAMBA When the risk of exposure to noise cannot be avoided or eliminated by any protective means or organization of work, the employer (farmer) must: 1) provide the operator with individual means of noise protection if the noise level in work place exceeds 80 dB. - Page 18 SAMBA REAR DISC MOWER OPERATOR’S MANUAL N-28 (For: SAMBA 320) N-14 N-15 N-29 (For: SAMBA 160, 200, 240, 280) N-32 N-23 N-40 Watch out! Catching point when (For: SAMBA 240, SAMBA 280, SAMBA 320) Power lines relocating mower N-48 N-49...

- Page 19 OPERATOR’S MANUAL REAR DISC MOWERS SAMBA N-65 (For: SAMBA 160, SAMBA 200) N-63 N-162 N-109 N-117 N-155 N-167 N-168 Avoid contact with liquid Do not get onto guardrails Do not touch machine parts coming out under pressure or protective guards...

-

Page 20: Operation

SAMBA REAR DISC MOWER OPERATOR’S MANUAL N-14; N-15; N-63; N-162 N-52; N-100 N-101; N-102 N-40 N-01; N-02; N-03; N-04; N-05; N-06 N-07; N-103; N-104 N-23; N-48; N-49; N-50; N-117 N-167; N-168; N-224 N-28/ N-29 N-155 N-49 N-40 N-109 N-32/ N-65 Fig. - Page 21 OPERATOR’S MANUAL REAR DISC MOWERS SAMBA WARNING: Proper securing of the pins must be inspected regularly before using the mower. Fig. 7. Proper pin locking during the mower mounting After the mower has been attached, adjust (on the flat ground) the mower’s position by means of ❑...

-

Page 22: Connecting The Articulated Telescopic Shaft (Ats)

SAMBA REAR DISC MOWER OPERATOR’S MANUAL NOTICE: Before dismounting the mower from the tractor put safety pin (1) into hole (3) in the cutter bar to protect the hitch from falling. After the mower has been mounted put the pin in bushing (2) (Fig. 9a) on central beam. a) 1 –... -

Page 23: Preparing Mower For Transport

OPERATOR’S MANUAL REAR DISC MOWERS SAMBA WARNING! Handle all parts with utmost care. Never place your hands or fingers between one part and the other. Wear safety clothes such as gloves, protective footwear and goggles. The operation of shortening must be carried out with the utmost care as the PTO shaft will have to be replaced if the telescopic shafts are shortened to an excessive extent. -

Page 24: Preparing Mower For Transport On Public Roads

SAMBA REAR DISC MOWER OPERATOR’S MANUAL lift the cutter bar vertically with hydraulic cylinder and lock the locking pawl (Z) (Fig. 9b), ❑ protect the cutter bar from falling by disconnecting shut-off valve (Z) (Fig. 12b) found on mower's ❑ cylinder, dismount PTO shaft from tractor, ❑... -

Page 25: Moving The Mower From Transport To Working Position

OPERATOR’S MANUAL REAR DISC MOWERS SAMBA plate for marking slow moving vehicles (being standard tractor equipment), which should be ❑ removed from the tractor and placed at the holder located at the belt gear’s guard. NOTICE: Marking slow moving vehicles can be ordered at the mower's manufacturer. 5.5. -

Page 26: Operating Positions Of The Mower

Fig. 14. Operating positions of the mower 5.6. Preparing mower for operation NOTICE: Before sale SaMASZ protects the cylinders with special grease against weather which may cause premature wear. Before operating the mower, remove the excess grease from the cylinders. -

Page 27: Operation

After the grass is mowed, it stands up, which makes an impression of inaccurate mowing. 5.7.2. Essential information concerning mowing Optimum work parameters Keep the constant PTO rpm: 470 ÷ 540 rpm (for: SAMBA 160, 200, 240, 280) or 950 ÷ 1000 rpm ❑ (for: SAMBA 320). -

Page 28: Design And Operation Of Safety Breakaway Device

SAMBA REAR DISC MOWER OPERATOR’S MANUAL Always check to make sure that the ground speed suits the conditions or work and that it does not ❑ create a potential source of danger. Do not take sharp turns anytime and do not operate in reverse. ❑... -

Page 29: Driving With Mower Over Windrows When Taking Turns

OPERATOR’S MANUAL REAR DISC MOWERS SAMBA objects in the grass (stones, branches, piles of soil). In order to avoid clogging and jams, operating speed should be adjusted to the mentioned conditions. WARNING! Removing clogs and jams while the machine is in operation can lead to the accident! In case of machine blockage caused by wrapped material, set the machine on a flat surface, remove excess material using sharp tool. -

Page 30: Mounting And Adjustments

SAMBA REAR DISC MOWER OPERATOR’S MANUAL 6. MOUNTING AND ADJUSTMENTS 6.1. Mounting and timing of the knives Mount the knives as shown in Fig. 18 and Fig. 23. Mount the knives so that cutting edges are directed towards the ground, so that a knife lifts the grass after cutting. Fig. -

Page 31: Controlling Condition Of Knives And Holder Pins

OPERATOR’S MANUAL REAR DISC MOWERS SAMBA 6.2. Controlling condition of knives and holder pins WARNING! Condition of knives and holders should be checked each time before commencing any operation. Damaged or worn elements pose danger of throwing and are as well health and life threatening. WARNING! When operating pay attention whether there are no excessive vibrations of the mower which may indicate that the disc(s) operate with 1 cutting knife attached... - Page 32 SAMBA REAR DISC MOWER OPERATOR’S MANUAL Fig. 20. Rear guard lifted up for replacement of cutting knives Fig. 21. Quick replacement of cutting knives 130 Nm Fig. 22. Knife mounting torqueing NOTICE: Before you change the knife check disc turns (Fig. 23). NOTICE: Due to high discs rpm speed, change knife holders in sets of the same weight.

-

Page 33: Adjusting Cutting Height

OPERATOR’S MANUAL REAR DISC MOWERS SAMBA SAMBA 160 SAMBA 200 SAMBA 240 Disc with the forming drum Disc without the forming drum SAMBA 280 SAMBA 320 Fig. 23. Direction of disc rears for mower 6.4. Adjusting cutting height To get the required mowing height, change length of upper link for suspension assembly (S) (Fig. 8). -

Page 34: Operating Service

SAMBA REAR DISC MOWER OPERATOR’S MANUAL L= 3.15" – SAMBA 160 L= 3.15" – SAMBA 200 L= 11" – SAMBA 240 L= 10.2" – SAMBA 280 L= 10.4" – SAMBA 320 Fig. 24. Ground pressure setting 6.6. Operating service 6.6.1. Checking the tension of V-belts on belt gear Tensioning of V-belts for belt gear is controlled by means of tensioner index (Fig. -

Page 35: After-Season Maintenance And Storing

OPERATOR’S MANUAL REAR DISC MOWERS SAMBA WARNING: When performing maintenance or adjustment works underneath the mower, use adequate locks for lifted parts of the machine preventing their falling and risk of crushing. 6.6.3. After-season maintenance and storing At the end of mowing season the following shall be performed: Lower the mower’s cutter bar onto the ground, ❑... -

Page 36: Lubricating

SAMBA REAR DISC MOWER OPERATOR’S MANUAL Remove any traces of rust and paint the area affected, ❑ Check the oil level in the angle drives and the cutter bar (Section 7). If leaks are found, remove them ❑ immediately and refill the oil. If water in oil is found, immediately change the oil as it could cause corrosion of internal mechanisms such as gear wheels, bearings, or shafts, and thus breakdowns, Periodically inspect the mower and lubricate moving parts in order to protect them against ❑... -

Page 37: Cutter Bar

Tab. 6. Amount of oil to be filled in cutter bar Oil capacity Mower type Oil type Replacement frequency gallon SAMBA 160 0.32 SAE 90 EP SAMBA 200 0.40 (ISO VG 320) After first 50 h of operation, then after next 500 h SAMBA 240 0.48... -

Page 38: Defects And Their Repair

SAMBA REAR DISC MOWER OPERATOR’S MANUAL Tab. 7. Oil to be filled in gear volume Mower Oil type Replacement frequency type gallon lqd] After first 50 h of operation, All types 0.185 80W90 then after next 500 h (or at least once a year) Fig. - Page 39 OPERATOR’S MANUAL REAR DISC MOWERS SAMBA Defect type Cause Recommendations Wash mower thoroughly. Check that nothing Belt’s slipping Mower is clogged with grass or foreign body is wound on the disc modules (e.g. strings) Lack of wheels axial Damaged bearings on PTO shaft Replace bearings with new ones symmetry Wash cutterbar thoroughly.

-

Page 40: Disassembly And Withdrawal From Use

SAMBA REAR DISC MOWER OPERATOR’S MANUAL 9. DISASSEMBLY AND WITHDRAWAL FROM USE 9.1. Repair WARNING! Before repair and disassembly the mower should be disconnected from the tractor. WARNING! It is forbidden to make any repairs under farming machine, or its individual components, which is lifted and unprotected against a free fall. - Page 41 2. Warranty period is for two years from the date of sale to the purchaser, stated above. 3. Any repair which is subject to warranty should be carried out by an authorized SaMASZ dealer. Upon completion of the repair, the dealer must submit a warranty claim within 14 days.

- Page 42 SaMASZ, e) negligent maintenance, f) use of non-genuine spare or replacement parts that are not specifically designed for the model...

- Page 43 OPERATOR’S MANUAL REAR DISC MOWERS SAMBA 11.2. Warranty repairs record Repairs scope and spare parts replaced: Date, stamp and signature of repair shop. Date, stamp and signature of repair shop. Date, stamp and signature of repair shop.

- Page 44 SAMBA REAR DISC MOWER OPERATOR’S MANUAL APPENDIX. Defining the total weight, axis load, tyre load capacity and minimum load CAUTION: When mounting the machine on a tractor using front and/or rear 3-point linkage, a maximum value of permissible load cannot be exceeded – tractor's front axis load must be 20% of the tractor's overall weight.

- Page 45 OPERATOR’S MANUAL REAR DISC MOWERS SAMBA 10. Calculating minimum weight of front balast M – machine mounted at tractor's rear: P min. �� × ( �� + �� ) − �� × �� + 0,2 × �� × �� �� ��...

- Page 46 SAMBA REAR DISC MOWER OPERATOR’S MANUAL SaMASZ Sp. z o.o. tel. (+48) (85) 664 70 31 ul. Trawiasta 1 fax (+48) (85) 664 70 41 16-060 Zabłudów e-mail: samasz@samasz.pl Polska www.samasz.pl...

Need help?

Do you have a question about the SAMBA 160 and is the answer not in the manual?

Questions and answers