Table of Contents

Advertisement

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for MKS 248A

- Page 1 Artisan Technology Group is your source for quality new and certified-used/pre-owned equipment SERVICE CENTER REPAIRS WE BUY USED EQUIPMENT • FAST SHIPPING AND DELIVERY Experienced engineers and technicians on staff Sell your excess, underutilized, and idle used equipment at our full-service, in-house repair center We also offer credit for buy-backs and trade-ins •...

- Page 2 107428-P1 Rev L, 8/06 MKS Type 248A/B/C Control Valve...

- Page 3 All rights reserved. No part of this work may be reproduced or transmitted in any form or by any means, electronic or mechanical, including photocopying and recording, or by any information storage or retrieval system, except as may be expressly permitted in writing by MKS Instruments, Inc.

-

Page 4: Table Of Contents

Table of Contents Table of Contents Safety Procedures and Precautions....................1 Chapter One: General Information .....................5 Introduction........................5 How This Manual is Organized..................6 Customer Support ......................6 Chapter Two: Installation ......................7 How To Unpack the Type 248 Unit ................7 Unpacking Checklist..................7 Interface Cables ......................8 Generic Shielded Cable Description ..............8 Setup ..........................10 Dimensions ......................10... - Page 5 Table of Contents Index ............................27...

- Page 6 List of Figures and Tables List of Figures and Tables Figures Figure 1: Preferred Method To Connect a Shielded Cable ............9 Figure 2: Alternate Method To Connect a Shielded Cable ............9 Figure 3: Dimensions of a Type 248 Control Valve..............10 Figure 4: Typical Valve Assembly .....................Error! Bookmark n Tables Table 1: Type 248 Valve Components ..................

- Page 7 List of Figures and Tables...

-

Page 8: Safety Procedures And Precautions

DO NOT SUBSTITUTE PARTS OR MODIFY INSTRUMENT Do not install substitute parts or perform any unauthorized modification to the instrument. Return the instrument to an MKS Calibration and Service Center for service and repair to ensure that all safety features are maintained. - Page 9 Safety Procedures and Precautions PURGE THE INSTRUMENT After installing the unit, or before its removal from a system, be sure to purge the unit completely with a clean dry gas to eliminate all traces of the previously used flow material. USE PROPER PROCEDURES WHEN PURGING This instrument must be purged under a ventilation hood, and gloves must be worn to protect personnel.

- Page 10 Safety Procedures and Precautions Definitions of WARNING, CAUTION, and NOTE messages used throughout the manual. Warning The WARNING sign denotes a hazard. It calls attention to a procedure, practice, condition, or the like, which, if not correctly performed or adhered to, could result in injury to personnel.

- Page 11 Safety Procedures and Precautions This page intentionally left blank.

-

Page 12: Chapter One: General Information

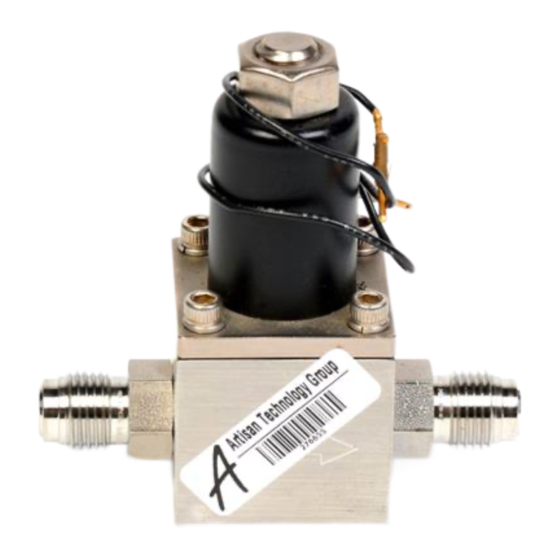

The MKS Type 248 Control Valve is a modified solenoid valve that, when supplied with a controlling current, is able to modulate the flow of gas. When used with a MKS controller and appropriate flow sensor, the 248 valve modulates gas flow such that pressure or flow is maintained accurately and with precision. -

Page 13: How This Manual Is Organized

Calibration and Service Center before shipping. The RMA Number expedites handling and ensures proper servicing of your instrument. Please refer to the inside of the back cover of this manual for a list of MKS Calibration and Service Centers. Warning All returns to MKS Instruments must be free of harmful, corrosive, radioactive, or toxic materials. -

Page 14: Chapter Two: Installation

Chapter Two: Installation How To Unpack the Type 248 Unit MKS has carefully packed the Type 248 unit so that it will reach you in perfect operating order. Upon receiving the unit, however, you should check for defects, cracks, broken connectors, etc., to be certain that damage has not occurred during shipment. -

Page 15: Interface Cables

Generic Shielded Cable Description MKS offers a full line of cables for all MKS equipment. Should you choose to manufacture your own cables, follow the guidelines listed below: 1. The cable must have a braided shield, covering all wires. Neither aluminum foil nor spiral shielding will be as effective;... -

Page 16: Figure 1: Preferred Method To Connect A Shielded Cable

Chapter Two: Installation Interface Cables Example 1: Preferred Method To Connect Cable (shown on a transducer) Metal Cable Clamp Screw Transducer Split Lock Washer Overall Insulation External Tooth Lock Washer (if present) Bare Metal Cable Clamp Transducer Housing Making Firm Contact To Braid Braid Here Is Desirable Optional Plastic or Metal Cable (but not usually necessary) -

Page 17: Setup

Setup Chapter Two: Installation Setup Dimensions Note All dimensions are listed in inches with millimeters referenced in parentheses. Table 1 (in.) (mm) (in.) (mm) 4 VCR 3.37 85.6 3.38 85.9 4 VCO 3.05 77.5 1/4" Swagelok 2.76 70.1 Figure 3: Dimensions of a Type 248 Control Valve... -

Page 18: Mounting Instructions

Chapter Two: Installation Setup Mounting Instructions The valve may be installed in any position, although base vertically down is recommended. Although ¼” O.D. tubing connections are generally adequate to support the weight of the valve, two 10-24 mounting holes permit base mounting. A 0.62” minimum clearance hole in a mounting plate should be provided to allow the valve orifice to be adjusted or replaced without disconnecting the valve. - Page 19 Setup Chapter Two: Installation This page intentionally left blank.

-

Page 20: Chapter Three: Operation

Chapter Three: Operation General Information Chapter Three: Operation General Information The 248 valve (<10,000 sccm) may be operated with 150 psig maximum inlet pressure, however, the nominal flow rating is established at 1 atmosphere differential across the valve, increasing the inlet pressure up to the maximum allowed. - Page 21 General Information Chapter Three: Operation This page intentionally left blank.

-

Page 22: Chapter Four: Maintenance

Chapter Four: Maintenance General Information Chapter Four: Maintenance General Information Periodically check for wear on the cables and inspect the valve for visible signs of damage. Orifice Adjustment and Replacement All 248 valve seals are 100% leak checked at the factory prior to shipment. With no power applied, the valve should have no measurable leakage or flow when the valve is positioned vertically, base down, and 1 atmosphere differential pressure is applied. - Page 23 Orifice Adjustment and Replacement Chapter Four: Maintenance Note The drawing above is provided for reference purposes only. Disassembly of the valve will void its warranty. For maintenance, please contact MKS Instruments, Inc. and obtain an RMA (Return Materials Authorization). .

-

Page 24: Table 1: Type 248 Valve Components

O-Ring, Viton, Size 3-902 Table 1: Type 248 Valve Components Note Table 1 above is provided for reference purposes only. Disassembly of the valve will void its warranty. For maintenance, please contact MKS Instruments, Inc. and obtain an RMA (Return Materials Authorization. -

Page 25: Disassembly, Inspection, And Cleaning

Note The guide below is provided for reference purposes only. Disassembly of the valve will void its warranty. For maintenance, please contact MKS Instruments, Inc. and obtain an RMA (Return Materials Authorization. Disassemble the 248 valve as follows with the valve held vertically, base down. Refer to Figure Error! Bookmark not defined., page Error! Bookmark not defined., as needed. -

Page 26: Assembly

Chapter Four: Maintenance Assembly Assembly Reassemble the 248 valve as follows. Refer to Figure Error! Bookmark not defined., page Error! Bookmark not defined., as needed. 1. Screw the Orifice Assembly into the Body until it is just flush with the base. 2. - Page 27 Assembly Chapter Four: Maintenance This page intentionally left blank.

-

Page 28: Chapter Five: Repair

MKS Instruments immediately. If it is necessary to return the unit to MKS, obtain an RMA number (Return Material Authorization Number) from a MKS Service Center before shipping. Please refer to the inside back cover of this manual for a list of MKS Calibration and Service Centers. - Page 29 General Information Chapter Five: Repair This page intentionally left blank.

-

Page 30: Appendix A: Product Specifications

Appendix A: Product Specifications General Information Appendix A: Product Specifications Specifications CE Mark Compliance (248A Valve only) EMC Directive 89/336/EEC Compatible MKS Controllers Types 250, 1250, and 260 External Leak Integrity < 1 x 10 scc/sec He Material exposed to gas (process wetted) - Page 31 General Information Specifications This page intentionally left blank.

-

Page 32: Appendix B: Model Code Explanation

Appendix B: Model Code Explanation Model Code Appendix B: Model Code Explanation Model Code The options of your valve are identified in the model code when you order the unit. The model code is identified as follows: ##### - XXXXX Y Z where: ##### XXXXX... - Page 33 Model Code Appendix B: Model Code Explanation Fittings (Y) Three types of fittings are available, designated by a single letter code. Ordering Code Swagelok ¼” tube, standard Cajon 4-VCR male, optional Cajon 4-VCO male, optional Seals (Z) Four types of seals are available, designated by a single letter code. Ordering Code Viton, standard Neoprene, optional...

- Page 34 Index Index CE Mark, 7, 11 Safety procedures and precautions, 1 Setup Customer support, 6 dimensions, 10 mounting instructions, 11 Dimensions, 10 Specifications, 23 Fittings, 26 valve, description of, 5 Interface cables CE Mark, 8 shielded cables, 8 Maintenance cleaning, 18 disassembly, 18 inspection, 18 orifice, 15...

- Page 35 Artisan Technology Group is your source for quality new and certified-used/pre-owned equipment SERVICE CENTER REPAIRS WE BUY USED EQUIPMENT • FAST SHIPPING AND DELIVERY Experienced engineers and technicians on staff Sell your excess, underutilized, and idle used equipment at our full-service, in-house repair center We also offer credit for buy-backs and trade-ins •...

Need help?

Do you have a question about the 248A and is the answer not in the manual?

Questions and answers